Quick Guide _______________________________________________________________________________ PDT101

© Vaisala 2020. All rights reserved. ___________________________________________________________________ 2

SETUP

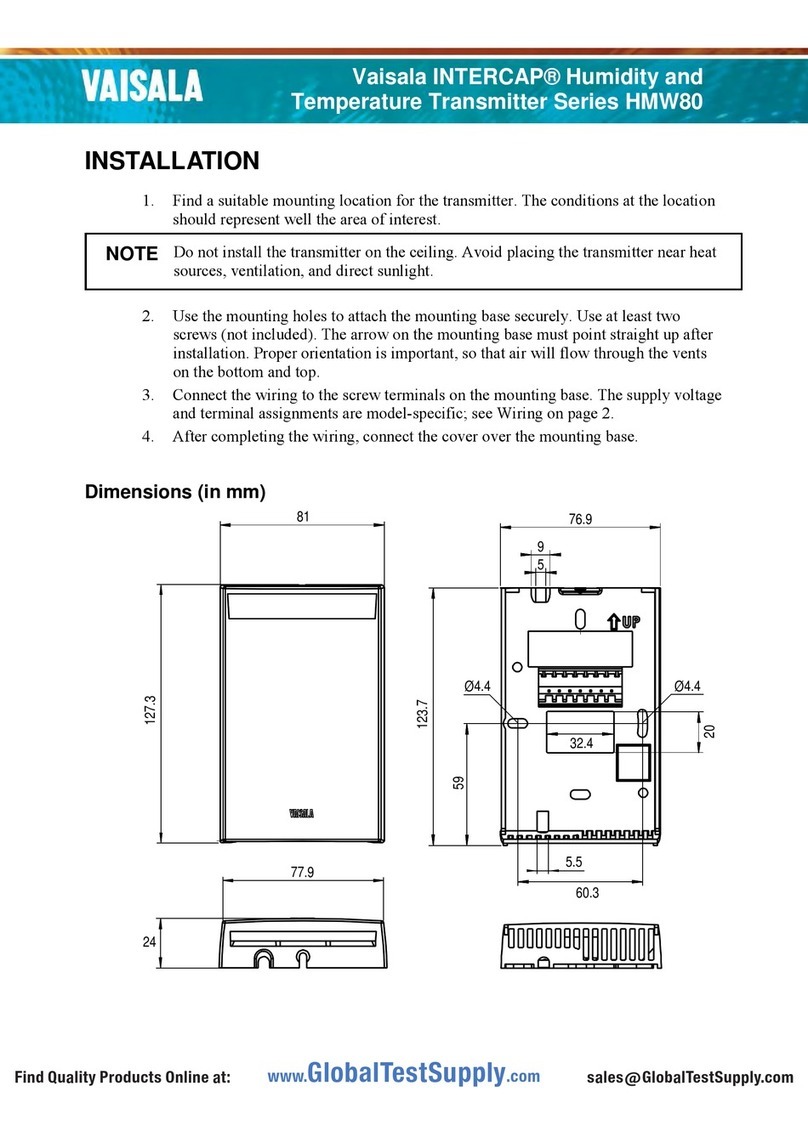

Transmitters are calibrated in a vertical position at the factory. Mounting in a

horizontal position may cause a zero shift of as much as +/-1 % of span. To

check for zero shift, see section Calibration below.

ELECTRICAL WIRING

1. Remove the terminal block on the front of the transmitter.

2. Follow the terminal block label markings on the PDT101 to identify the

terminals, and connect the wires.

3. Firmly reinstall the terminal block plug to its mating connector.

Current Output Wiring (Black Terminal Block)

The left, negative (-), and right, positive (+) terminals are used, ignore the

center terminal which is not used. Connect the power supply positive lead to

the PDT101 positive terminal, connect the negative power supply lead to the

negative terminal of the BCS 4...20 mA input. Last, connect the (-) negative

terminal on the PDT101 to the (+) positive BCS input.

Use of a shielded cable, with the shield grounded, is required. Do not connect

the shield to the transmitter.

Figure 3 Current Output Wiring

Loop Resistance (Ω)

Supply

Voltage (V)

Vmin = 12V+ [.022A*(R L)]

*includes a 10% safety factor

RL = RS + RW

RL = Loop Resistance (ohms)

RS = Sense Resistance (ohms)

RW = Wire Resistance (ohms)

Loop Supply Voltage (Vdc)

OPERATING

REGION

Figure 4 Load Limitations

Voltage Output Wiring (Green Terminal Block)

The left terminal is the common (supply and output negative), the right

terminal is the Vin (supply positive). The middle terminal is the Vout (output

signal).

Use of a shielded cable, with the shield grounded, is required. Do not connect

the shield to the transmitter. Maximum cable length for voltage output wiring

is 30 m (98.4 ft).

+

–

Output signal

Common (V-) V

out Vin (V+, Supply)

Power Supply

Figure 5 Voltage Output Wiring

The PDT101 voltage output model is supplied as standard with 0...5 VDC

output. You can convert the unit to 0...10 VDC output by moving a jumper

inside the transmitter. Access the jumper by simultaneously pushing both

housing tabs away from the housing. Change jumper (orange or red) to the left

as shown below, and carefully reattach the housing cover. When finished,

mark the checkbox on front label indicating that the unit now provides a 0...10

VDC output.

Figure 6 Voltage Output Jumper

CALIBRATION

1. Pneumatically connect the transmitter’s pressure ports to each other.

The barbed pressure connections accept 1/4” O.D. 1/8” I.D. tubing.

2. Measure the analog output of the transmitter to establish the zero offset

reading in the as-installed position.

3. If the reading is not at the middle of the output range (for example, 12 mA

for 4 … 20 mA output), the zero point of the transmitter has shifted. To

remove the zero shift, adjust the transmitter as described below.

ADJUSTMENT

Note: You need a high accuracy pressure standard and high quality electrical

meter to adjust the PDT101.

1. Connect the pressure standard to the ports of the PDT101.

2. Bring the pressure to 0 % of the transmitter’s span (-60 Pa or -0.25 in H2O,

depending on model).

3. Adjust the zero potentiometer (on the front, left side of the transmitter) so

that the analog output value is at the low end of its range. Use a 3/32” or

2.5 mm slotted or Phillips screwdriver to turn the potentiometer.

4. Now bring the pressure to 100 % of the transmitter’s span (+60 Pa or

+0.25 in H2O, depending on model).

5. Adjust the span potentiometer (on the front, right side of the transmitter) so

that the analog output value is at the high end of its range.

REMOVAL FROM DIN RAIL

1. Unplug the wiring terminal block from the transmitter.

2. Insert a small slotted screwdriver into the black plastic clip extending

slightly below the transmitter case.

3. Raise the screwdriver handle up thereby forcing the spring clip down.

WARRANTY

For warranty information, visit our Internet pages at:

www.vaisala.com/warranty.

DISPOSAL

Dispose of the unit according to local regulations. Do not dispose of with

regular household waste. Recycle all applicable material.