Valtir.com 2 Revision F August 2022

Table of Contents

Customer Service Contacts .......................................................................................................... 3

Important Introductory Notes ........................................................................................................ 3

Safety Symbols ............................................................................................................................. 4

Safety Rules for Assembly............................................................................................................ 4

Limitations and Warnings.............................................................................................................. 5

System Overview .......................................................................................................................... 6

Inspect Shipping...................................................................................................................... 6

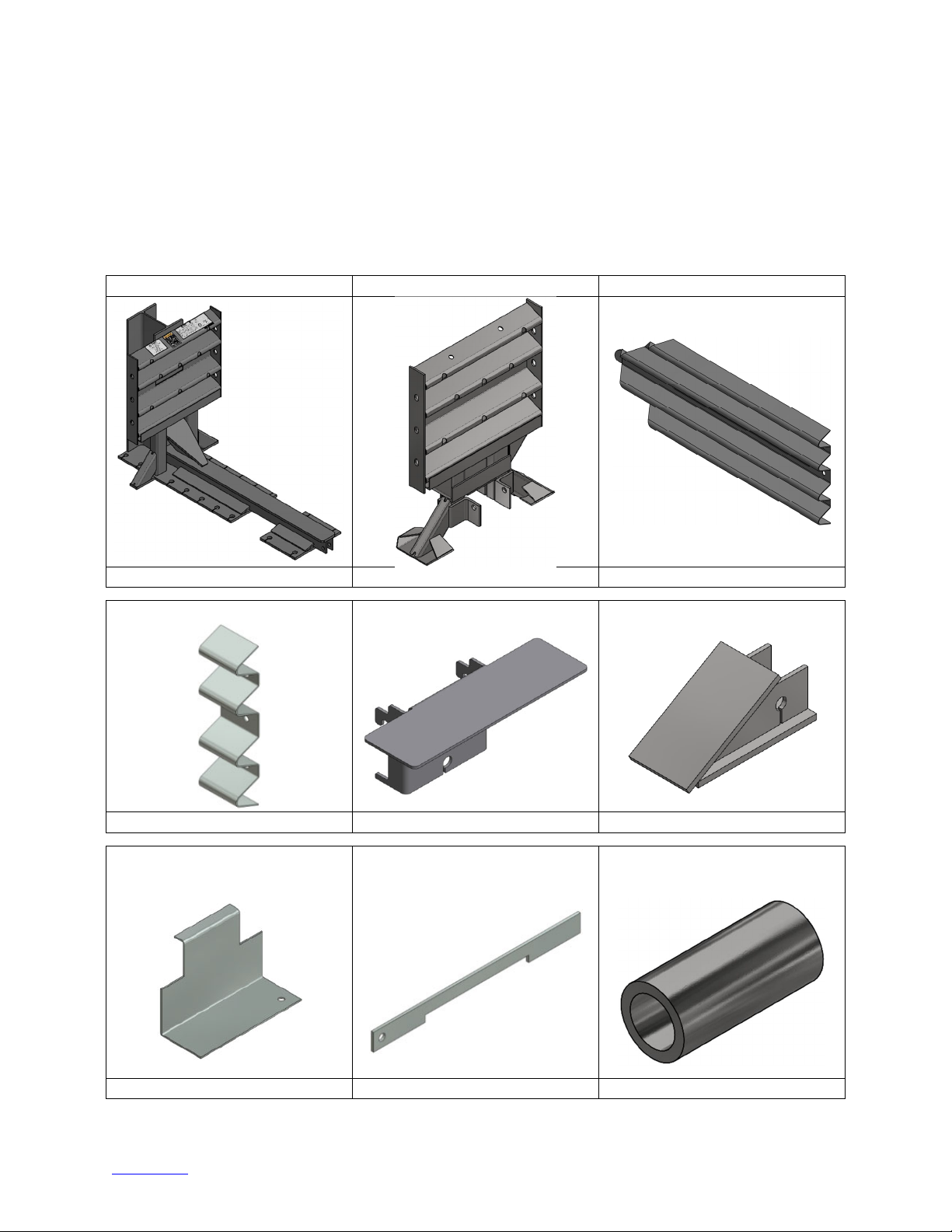

System Components............................................................................................................... 7

Determine Transition Type......................................................Error! Bookmark not defined.

Recommended Tools.................................................................................................................. 12

Site Preparation/Foundation ....................................................................................................... 14

Foundation/Anchoring........................................................................................................... 15

Valtir Approved Adhesive Anchoring System .............................................................................16

Vertical Anchors.................................................................................................................... 16

Anchor Assembly Cautions ................................................................................................... 17

Horizontal Anchors................................................................................................................ 18

System Assembly ....................................................................................................................... 21

QuadGuard®M10 24” Final Inspection Checklist........................................................................ 34

Maintenance and Repair............................................................................................................. 35

Inspection Frequency............................................................................................................ 35

Visual Drive-By Inspection ....................................................................................................35

Walk-Up Inspection Checklist ...............................................................................................35

Post-Impact Instructions........................................................................................................ 36

Parts Ordering Procedure & Drawings........................................................................................ 38

Parts List(s) & Quantities ...................................................................................................... 38

QuadGuard®M10 w/ Tension Strut BackupQGMTSCVR-U............................................. 40

TS Concrete Pad618686 ................................................................................................... 41

TS Concrete Pad 8” w/Rebar618686 ................................................................................ 42

TS Concrete Pad 8” wo/Rebar618686 .............................................................................. 43

Tension Strut Backup 627448 ........................................................................................... 44

Monorail Assembly625637 ................................................................................................ 45

Diaphragm Assembly625650 ........................................................................................... 46

Shim Kit627518............................................................................................................... 47

Fender Panel Assembly608236 ........................................................................................ 48

Nose Assembly626814..................................................................................................... 49

31” W-Beam Guardrail TransitionQGMTSCVR-TWLR...................................................... 50

Thrie-Beam Guardrail TransitionQGMTSCVR-TTLR ....................................................... 51

Safety Shape Barrier TransitionQGMTSCVR-T4 ............................................................. 52

Single Slope TransitionQGMTSCVR-T6 ........................................................................... 53

Vertical Barrier TransitionQGMTSCVR-ES ...................................................................... 54

Vertical Barrier Transition, ExtendedQGMTSCVR-SPE................................................... 55