REV 1 EZCT-2000B USER’S MANUAL

ii

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION.................................................................................................................... 2

1.1 General Description and Features ................................................................................... 2

1.2 Furnished Test Accessories.............................................................................................. 4

1.3 Technical Specifications ................................................................................................... 5

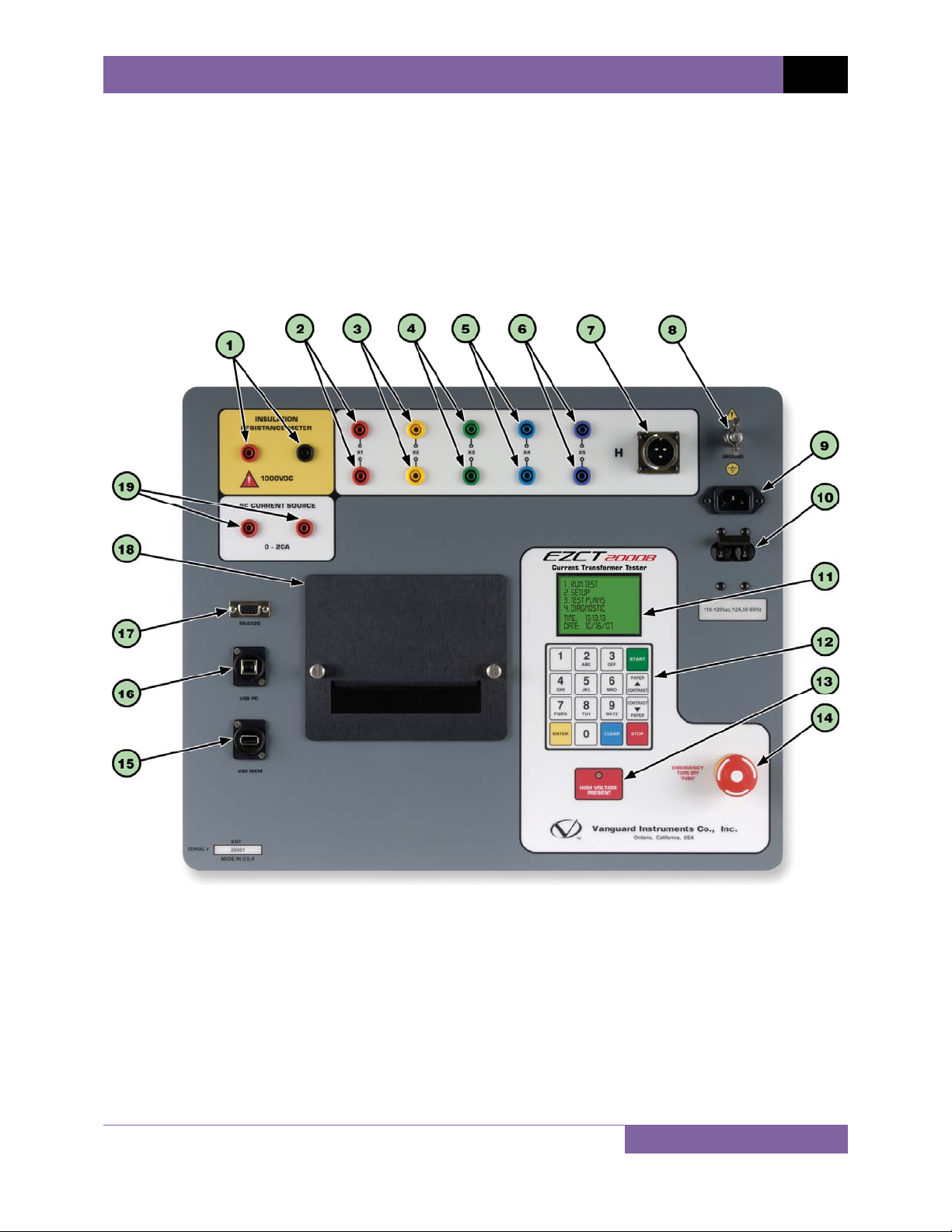

1.4 EZCT-2000B Controls and Indicators ............................................................................... 6

2.0 PRE-TEST SETUP ................................................................................................................... 8

2.1 Operating Voltages .......................................................................................................... 8

2.2 LCD Screen Contrast Control............................................................................................ 8

2.3 Printer Paper Control....................................................................................................... 8

2.4 Printer Paper.................................................................................................................... 8

3.0 OPERATING PROCEDURES ................................................................................................. 10

3.1 EZCT-2000B Cable Connections ..................................................................................... 10

3.2 EZCT-2000B X Input Voltage Warning ........................................................................... 15

3.3 Performing Tests............................................................................................................ 16

3.3.1. Entering Test Record Header Information ............................................................. 16

3.3.2. Performing Resistance, Excitation, and Ratio Tests ............................................... 19

3.3.3. Performing a CT Burden Test ................................................................................. 30

3.3.4. Performing an Insulation Resistance Test.............................................................. 35

3.3.5. Performing a Current Source Test.......................................................................... 40

3.4 Working With Test Records ........................................................................................... 42

3.4.1. Restoring and Printing a Test Record From Flash EEPROM ................................... 42

3.4.2. Restoring and Printing a Test Record From a USB Flash Drive .............................. 46

3.4.3. Printing a Restored Test Record............................................................................. 48

3.4.4. Printing a Directory of Test Records Stored in the EZCT-2000B’s Memory........... 50

3.4.5. Printing a Directory of Test Records Stored in a USB Flash Drive.......................... 53

3.4.6. Copying Test Records to a USB Flash Drive............................................................ 55

3.4.7. Erasing Test Records From the Flash EEPROM ...................................................... 58

3.4.8. Erasing Test Records From a USB Flash Drive ........................................................ 61

3.5 Working With Test Plans................................................................................................ 64

3.5.1. Extracting the Test Plan From a Test Record ......................................................... 64

3.5.2. Printing a Directory of Test Plans Stored in the EZCT-2000B’s Memory ............... 66

3.5.3. Printing a Directory of Test Plans Stored in a USB Flash Drive .............................. 68

3.5.4. Printing a Test Plan................................................................................................. 70

3.5.5. Erasing Test Plans From the Flash EEPROM........................................................... 72

3.5.6. Erasing Test Plans From a USB Flash Drive............................................................. 75

3.5.7. Loading a Test Plan from the EZCT-2000B’s Flash EEPROM .................................. 78

3.5.8. Loading a Test Plan from a USB Flash Drive ........................................................... 80

3.5.9. Running a Test Using a Loaded Test Plan............................................................... 82

3.5.10. Unloading a Test Plan from the Working Memory ................................................ 87

4.0 CHANGING SETUP PARAMETERS ....................................................................................... 88

4.1 Setting the Knee Point Marker ...................................................................................... 88