REV 1.0 SGT-200 USER’S MANUAL

ii

TABLE OF CONTENTS

CONVENTIONS USED IN THIS DOCUMENT ..................................................................................... 1

1.0 INTRODUCTION .................................................................................................................... 2

1.1 General Description and Features ................................................................................... 2

1.2 SGT-200 Technical Specifications .................................................................................... 4

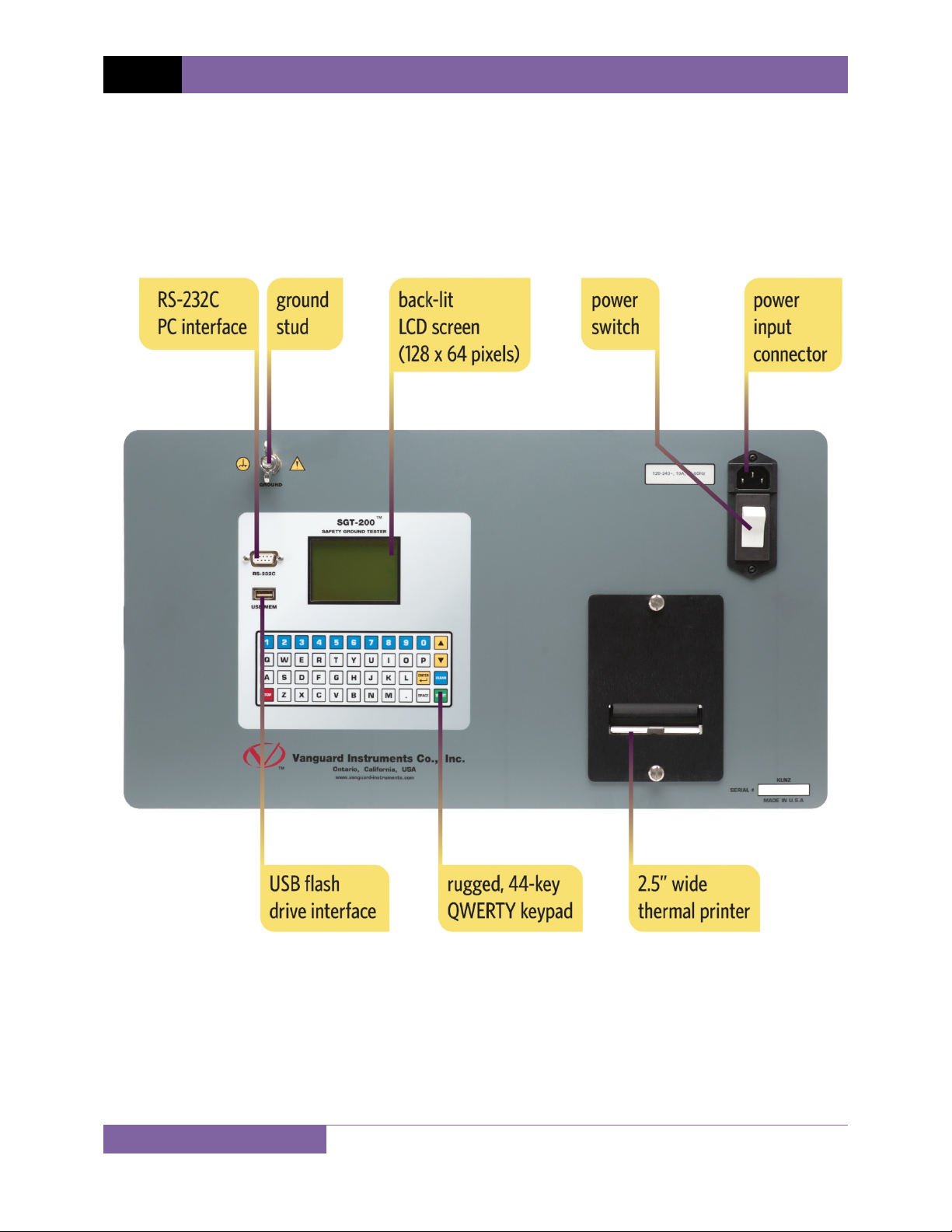

1.3 SGT-200 Controls and Indicators ..................................................................................... 5

2.0 PRE-TEST SETUP ................................................................................................................... 6

2.1 Operating Voltages .......................................................................................................... 6

2.2 LCD Screen Contrast Control ............................................................................................ 6

3.0 OPERATING PROCEDURES ................................................................................................... 7

3.1 Lid Removal ...................................................................................................................... 7

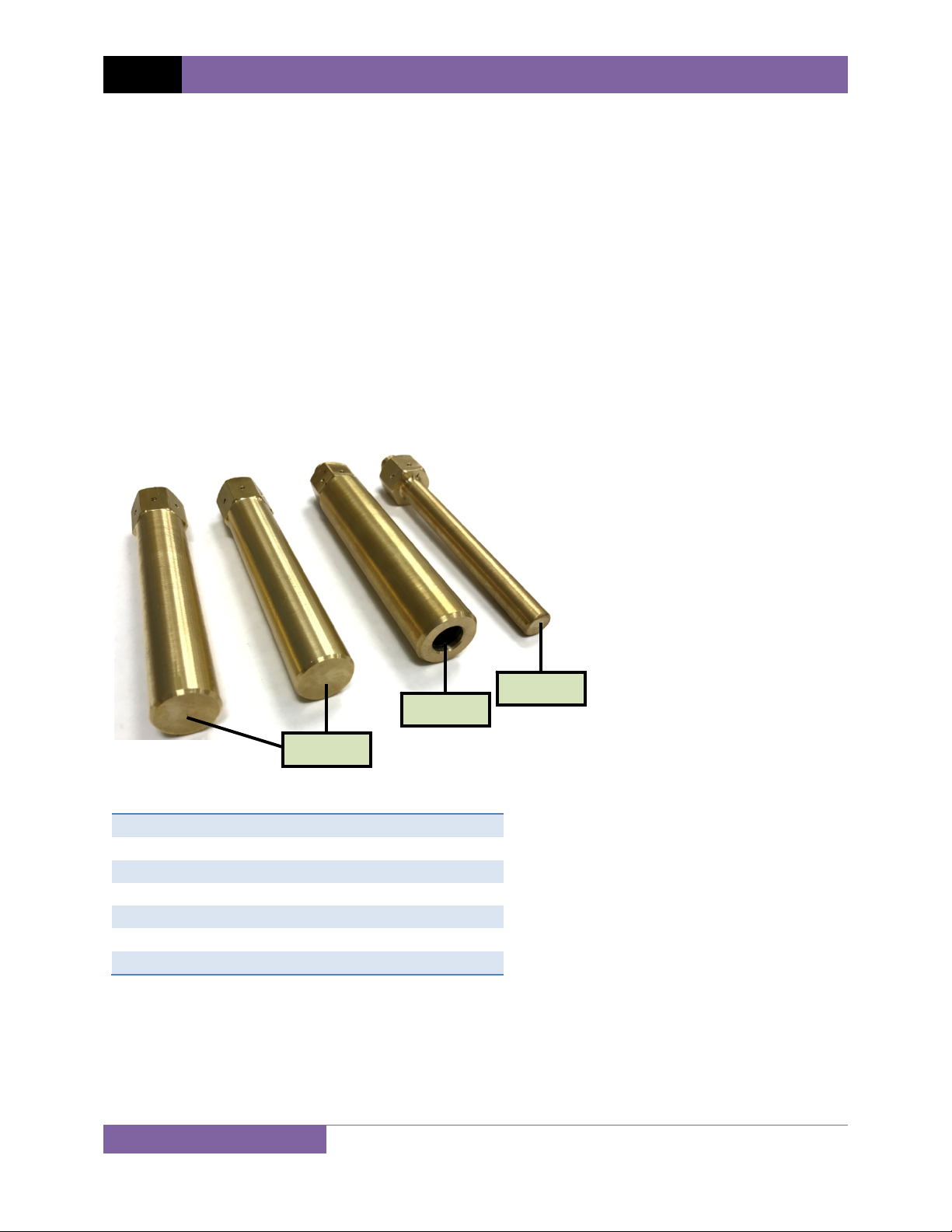

3.2 Cable Connection Post and Sense Wire Installation ........................................................ 9

3.4 Setting the Interface Language ...................................................................................... 12

3.5 Setting the Option to Print the Calibration Expiration Date .......................................... 13

3.6 Setting the Units of Measure ......................................................................................... 15

3.7 Testing Procedures ........................................................................................................ 17

3.7.1. Entering Test Record Header Information ............................................................. 17

3.7.2. Performing a Test ................................................................................................... 20

3.8 Working With Test Records ........................................................................................... 26

3.8.1. Viewing the Contents of the Working Memory ..................................................... 26

3.8.2. Saving Test Results to a Test Record ...................................................................... 28

3.8.3. Restoring a Test Record From Flash EEPROM ........................................................ 30

3.8.4. Restoring a Test Record From a USB Flash Drive ................................................... 34

3.8.5. Copying Test Records to a USB Flash Drive ............................................................ 36

3.8.6. Printing the Test Record Directory ......................................................................... 39

3.8.7. Erasing Test Records from the Unit's Flash EEPROM ............................................. 42

3.8.8. Erasing Test Records from a USB Flash Drive ......................................................... 47

4.0 Getting the Latest Firmware, Software, and Manuals....................................................... 50

LIST OF FIGURES

Figure 1. SGT-200 Controls and Indicators ..................................................................................... 5

Figure 2. Sample Test Report Printout with Calibration Expiration Date ..................................... 14

Figure 3. Sample SGT-200 Test Results Printout .......................................................................... 25

Figure 4. Sample Thumb Drive Directory Printout ....................................................................... 41

Figure 5. Sample Internal Test Record Directory Printout............................................................ 41