3001002 Rev. T Page 7

Section 3 Principles of operation

The Precision Flow®

warms and humidifies breathing gas for delivery by nasal cannula at flows

from 1 to 40 lpm. The unit incorporates an electronic blender and flow sensors that allow the

oxygen percentage and total gas flow to be set independently.

The Precision Flow®

consists of two parts:

Main unit

•The main unit which contains all the electrical and electronic components including the

electronic blender and flow controllers, and remote sensors to monitor the disposable water

path. The main unit has no water pathways and the gas pathway contains only dry gas at room

temperature, and consequently does not need internal cleaning or disinfection.

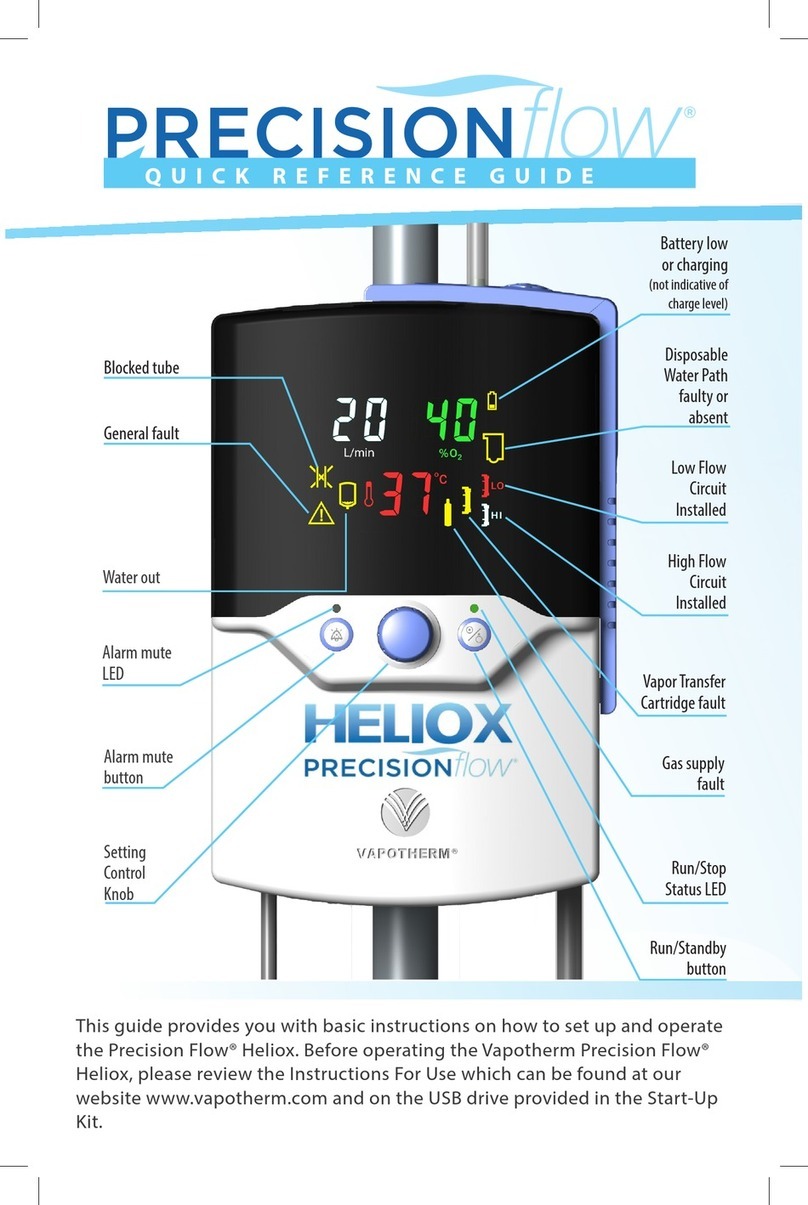

• The flow of oxygen and air are measured by mass flow sensors. The operating software

calculates the required flow of each needed to reach the target flow and oxygen percentage

set by the operator. The system controls gas flows accordingly by adjusting proportional

solenoid valves on the gas lines. An oxygen sensor monitors the gas mixture and signals any

discrepancy between target and measured percentage. The oxygen sensor is automatically

calibrated with oxygen at power-up and every 24 hours.

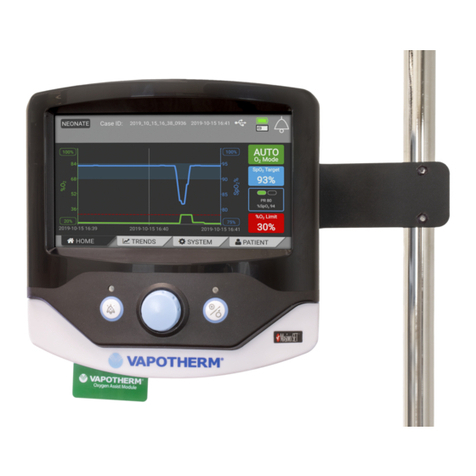

• Firmware running in the main unit uses sensors to monitor gas pressure, water temperature, and

to detect air leaks into the disposable patient circuit (bubble detector). Alarms are displayed if any

parameters are outside the normal range. Other indicators show low charge in the backup battery, and

the type of cartridge installed. See Appendix for a description of the firmware states and transitions.

• After a two hour charging period, an internal battery backup will maintain the set flow and

oxygen blend for at least 15 minutes without AC power. The battery is not operator replaceable.

WARNING: The back-up battery is designed for temporary use only, when AC power to the unit

has been interrupted. After the battery is fully discharged the device will not operate and patient

gas flow will cease. There are no alarms or display indicators after the battery has discharged.

The battery is not intended for patient transport.

Disposable patient circuit

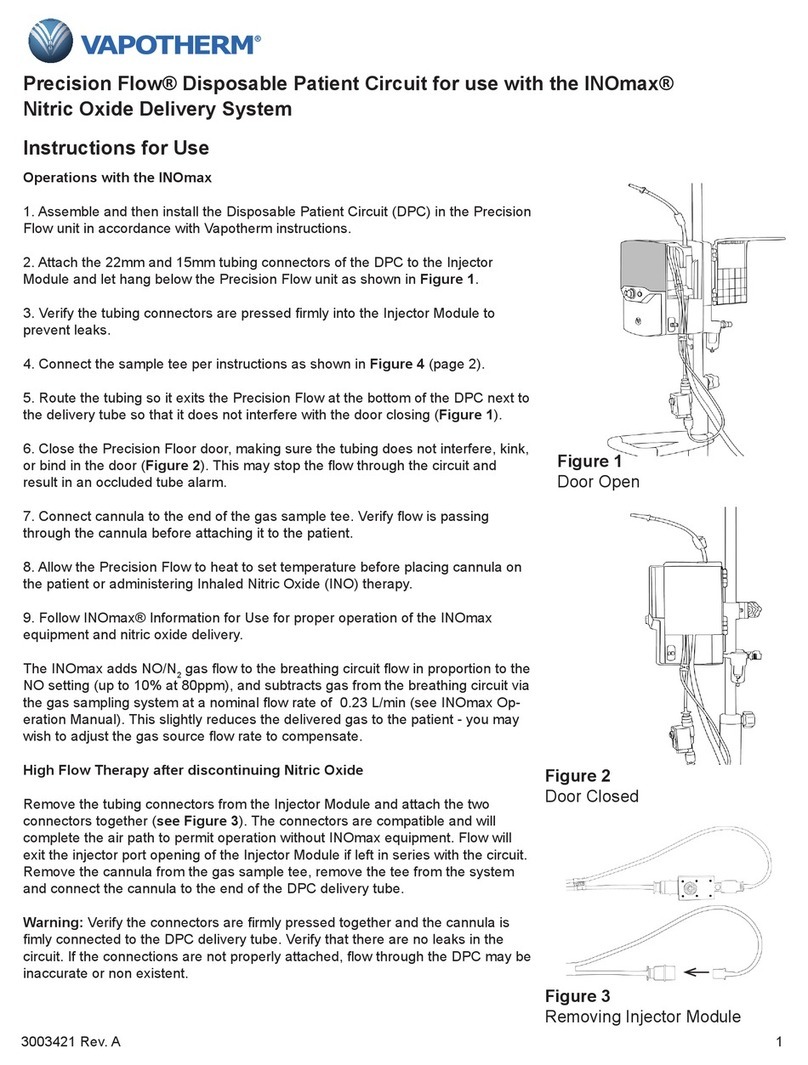

• The disposable patient circuit (DPC) is comprised of the disposable water path (DWP), vapor

transfer cartridge (VTC) and delivery tube. Conditions in the circulating water and gas streams

are sensed remotely via the interface between the main unit and the disposable water path.

• Vapor transfer cartridge. In the cartridge, blended gas passes through the lumens of hundreds

of parallel hollow fibers made of a specially developed polymer. Warm water circulates around

the fibers and diffuses as vapor through the fiber material into the gas stream flowing through

each fiber. Unlike most humidifiers, there is no direct contact between the water and gas

streams. The gas stream leaves the cartridge saturated with vapor at the set temperature.

Note:Use only approved cartridges from Vapotherm Inc.

• Patient delivery tube.The warmed humidified gas passes through the center of a triple-lumen

heated delivery tube. The center lumen is surrounded by two outer lumens circulating warmed

water to maintain the temperature of the inner lumen and to minimize rain-out. A proprietary

short nasal cannula is connected to the end of the delivery tube and passes the humidified

breathing gas to the patient’s nares. It is normal for non-DEHP PVC tubing to appear slightly

cloudy, or yellow, especially during longer use or when operated at higher temperatures.

• Disposable water path. The disposable water path houses a water reservoir, pump,connections

for the vapor transfer cartridge and delivery tube, and sensor interfaces to the main unit.

Water is pumped past a heater plate through the outer lumens of the delivery tube. Returning

water passes through the outer jacket of the specially designed vapor transfer cartridge where

some water is lost as vapor to the gas stream. There is no direct contact between water and gas

flows. The water then returns to the pump reservoir. Heater power automatically maintains the

set temperature. Water flows into the circuit from the sterile water supply to replace evaporative

losses in the vapor transfer cartridge. Air is purged to atmosphere from the circulation via a

hydrophobic filter membrane.

See Section 5 for a description of the modes of operation.