Operating Instruction Manual Page 15

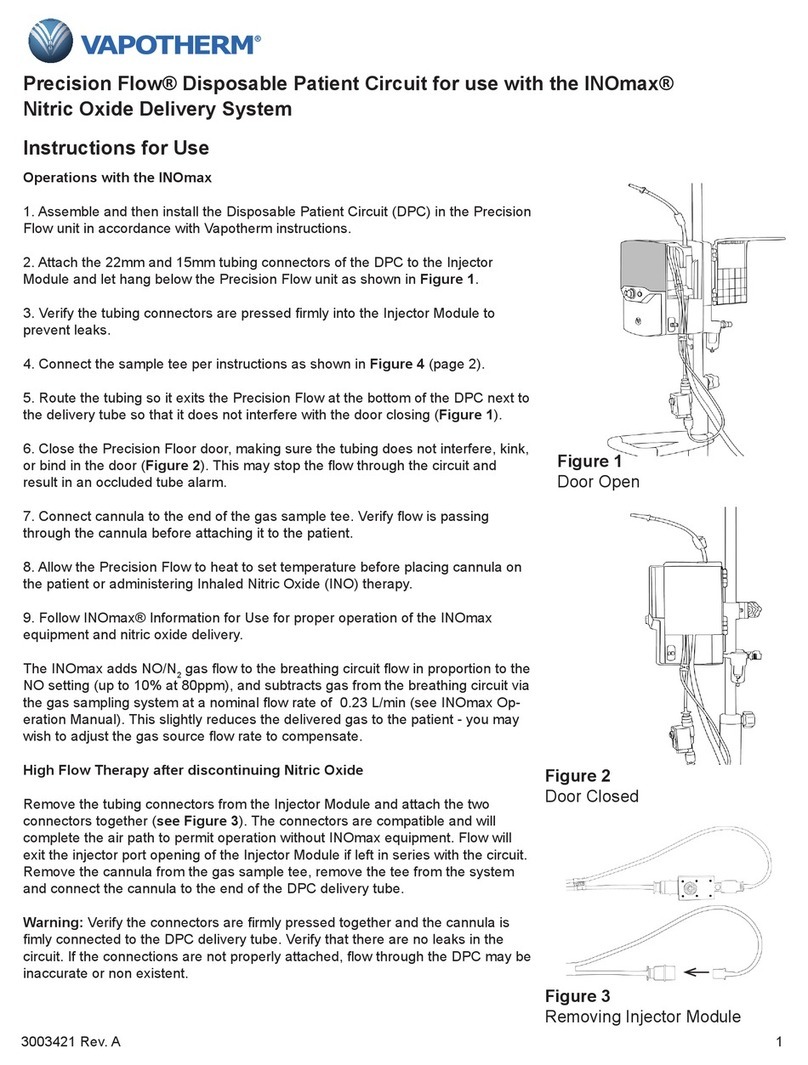

Fig. 1

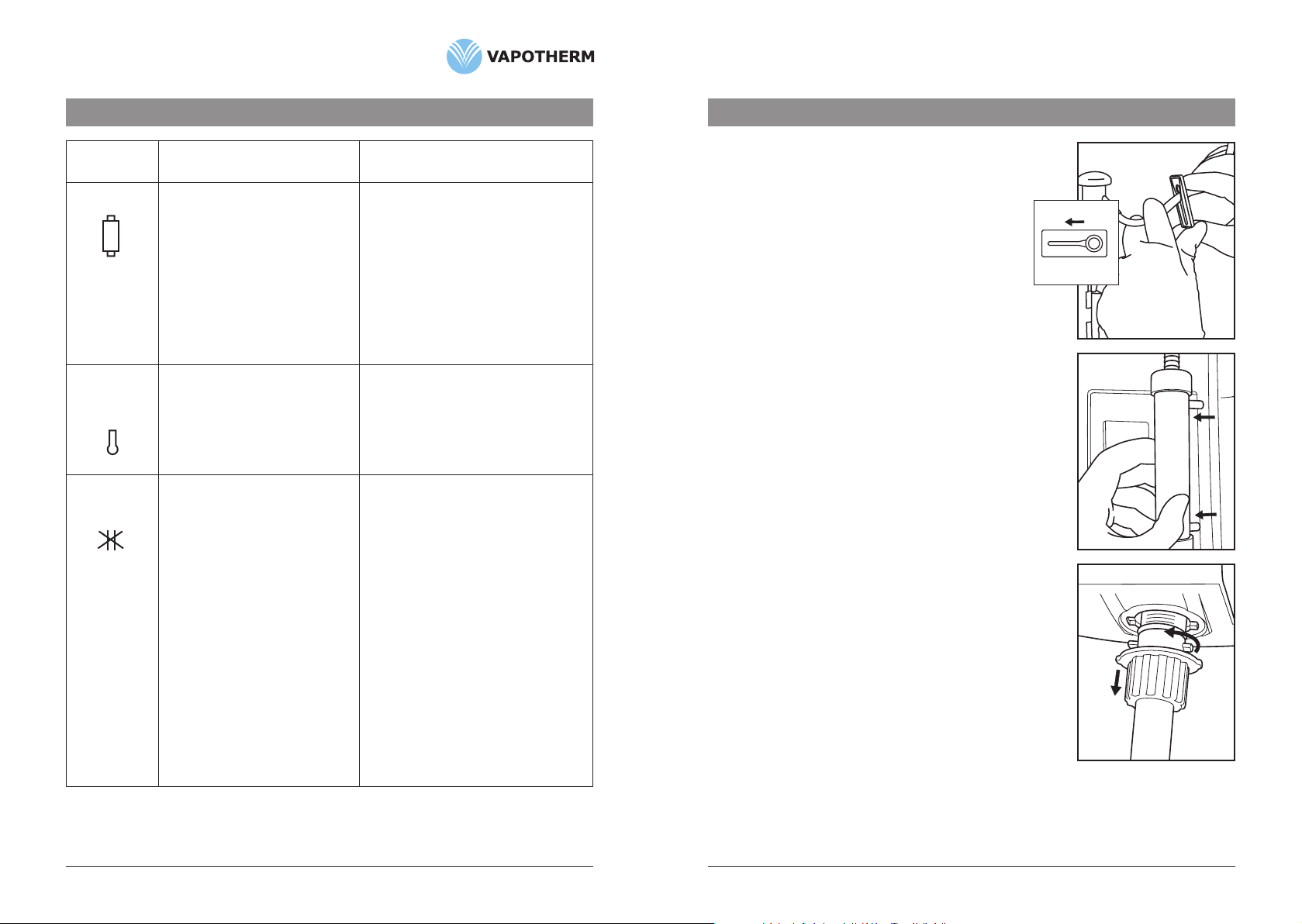

Fig. 3

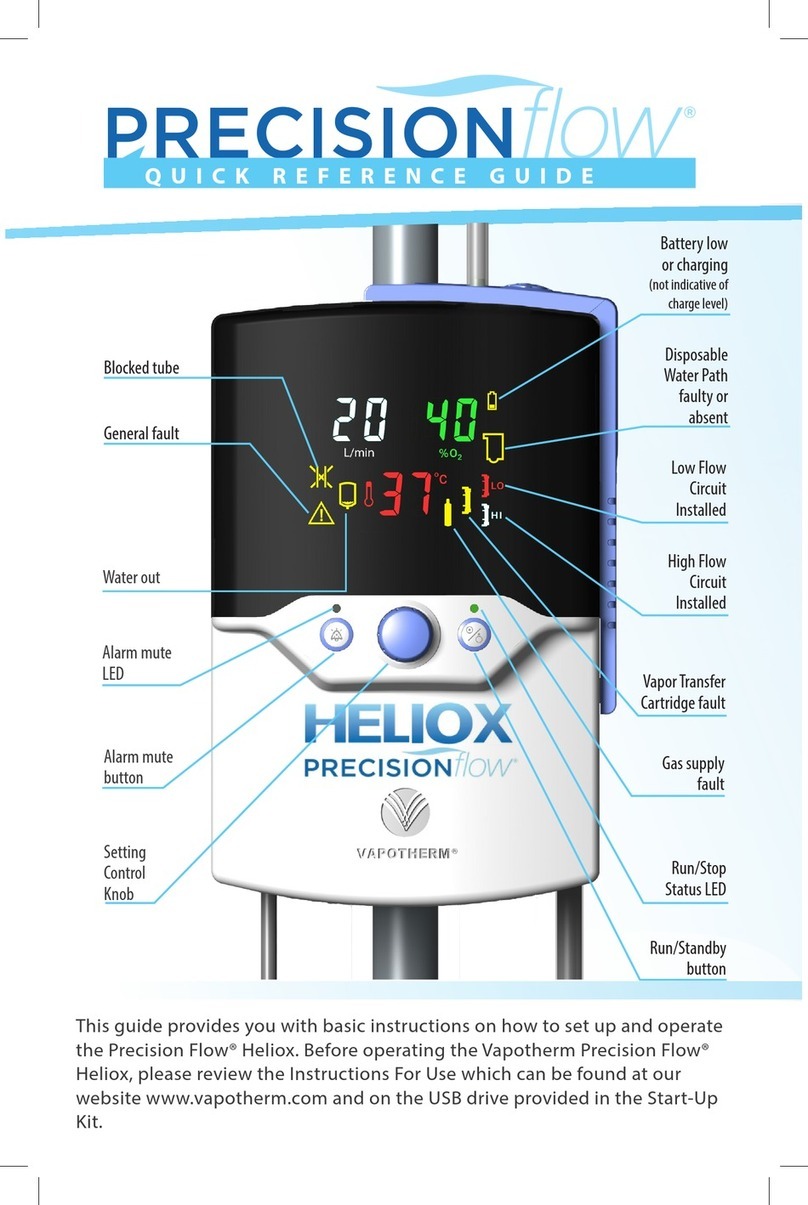

Section 6Alarms,TroubleShootingandComponentChange-Outs

6.3 Component Change Outs

WARNINGS:

The vapor transfer cartridge, patient delivery tube, and VSS-1

spike set are all single use only and should be discarded after

removal from the Vapotherm 2000i.

The Patient Delivery Tube, VSS-1 and Vapor Transfer Cartridge

should not be changed or replaced in the patient care area.

The system must be disinfected any time the Vapor Transfer

Cartridge, VSS-1 or Patient Delivery Tube are removed.

NOTE: The cannula and sterile water source can be replaced without

disinfecting the system. As with all respiratory equipment, proper

hand washing techniques should be followed before contacting

or replacing any patient interfaces.

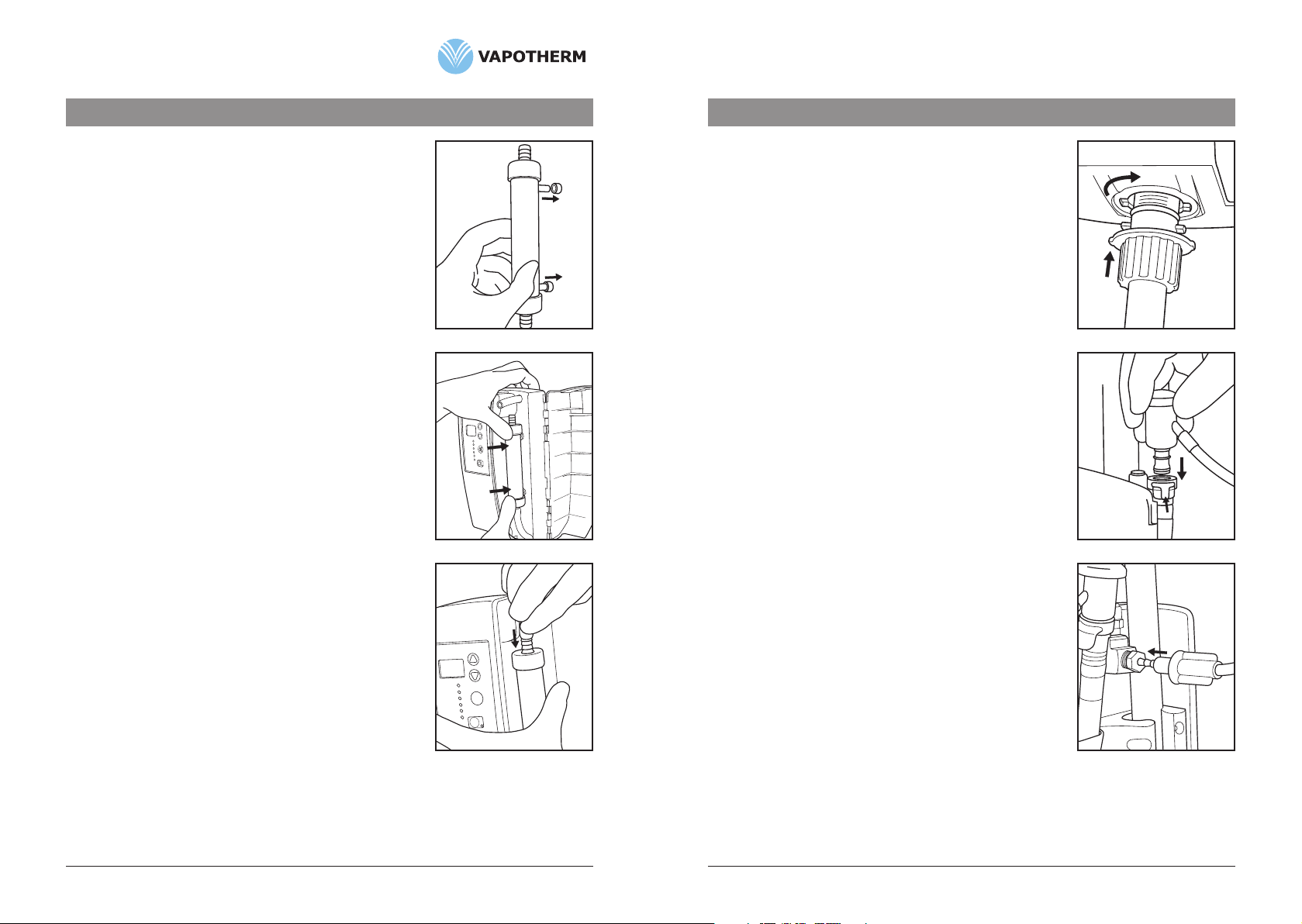

6.3.1 Replacing Vapor Transfer Cartridge

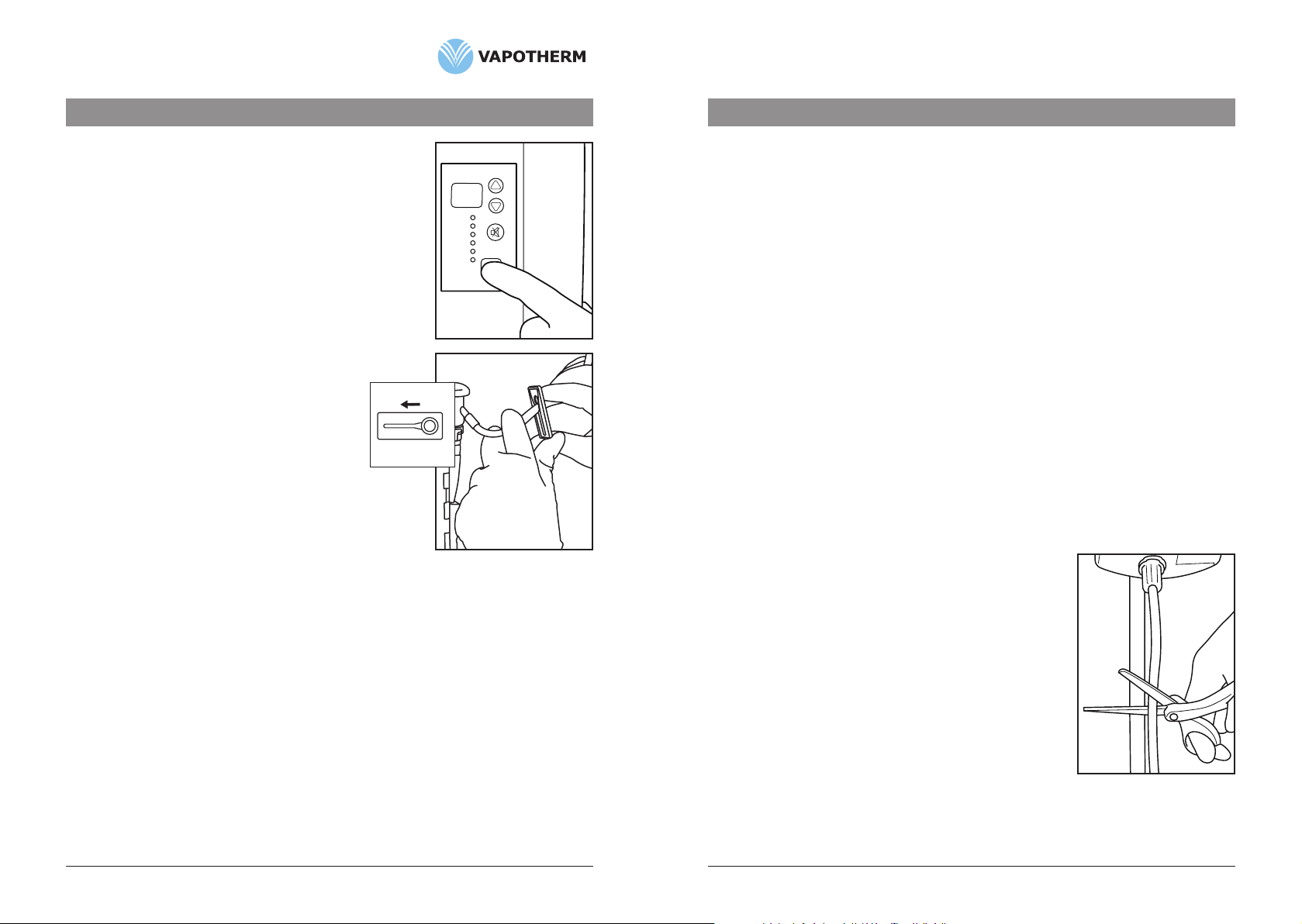

1. Poweroffunit.Disconnectgasflow.

2. ClosecliponVSS-1.(Fig. 1)

3. Openhingedcover.

4. Disconnectairtubesfromcartridgeendsbypressingtubingaway

fromcartridge.

5. Removecartridgebypullingstraightoutwards.(Fig. 2)

6. ProceedtoSection8.0anddisinfecttheVapotherm®2000idevice

beforereturningthedevicetoservice.

7. Forset-uppleaserefertoSection4.3ofthemanual.

CAUTION: Do not grip cartridge tubing with sharp instruments.

6.3.2 Replacing the Patient Delivery Tube

1. Powerunitoff.Disconnectgasflow.

2. Toremovetube,pushbaseoftubeupwards,rotate1/4turn

counterclockwiseandpulldownward.(Fig. 3)

3. ProceedtoSection8.0anddisinfecttheVapotherm®2000idevice

beforereturningthedevicetoservice.

4. Forset-uppleaserefertoSection4.4ofthemanual.

6.3.3 Replacing the VSS-1 Spike Set

1. Poweroffunit.Disconnectgasflow.

2. ClampVSS-1andremoveVSS-1SpikeSetfromthewaterinlet

portonthebackoftheVapotherm2000ibyreleasingthe

quickconnectonthewaterinletport.

3. ProceedtoSection8.0anddisinfecttheVapotherm®2000idevice

beforereturningthedevicetoservice.

4. Forset-uppleaserefertoSection4.5ofthemanual.

Fig. 2

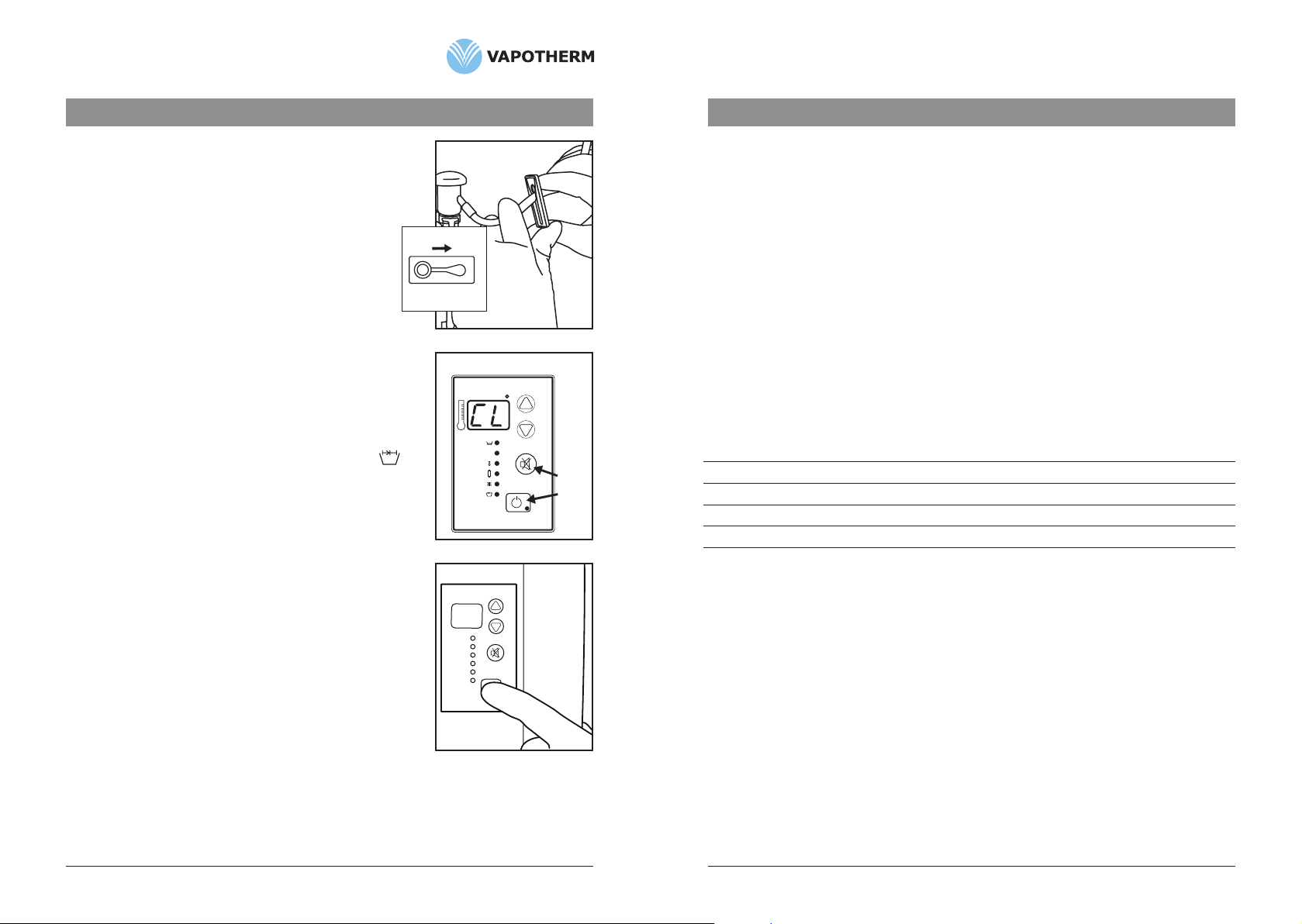

Alarm Cause Action

indication

Operating Instruction Manual Page 14

If further assistance is needed please call your clinical product specialist or local distributor representative.

IftheCartridgeAlarmiscontinuous

and air bubbles are rising into the

VSS-1bubbletraporifaflowor

waterisvisibleinthetubebelow

the cartridge, then the cartridge

hasfailed.

If cartridge alarm is intermittent

and there are no bubbles in the

VSS-1bubbletrapornoobvious

water flow below the cartridge there

maybecondensationinthesystem.

Firstdisconnectthepatientfromtheunit,

shut down unit, drain unit, disinfect unit,

replacecartridge,VSS-1anddeliverytube,

andfollowsetupinstructions.

Occasional brief alarms due to

condensationarenotacauseforconcern.

Trybrieflypinchingandreleasingtube

undercartridgetodislodgethedropsand/

ordecreasesettemperature.

Cartridge

MalfunctionofTemperature

ControlSystem.

Shutdownsystemandreturnforservice.

NOTE: A momentary High Temperature

alarm may occur when the unit has

been switched off and on again. If the

temperature then stabilizes, no action

is needed.

High

Temperature

Alarm

Highwaterorairpressuredueto

high resistance in water circulation

or air outlet: or malfunctioning

pressuresensor.

Blockedtubealarmduetohigh

WATERpressurewillcausea

continuous or intermittent tone

andalarmlight.Theflowof

breathing gas continues, but is

nolongerheated.

Blockedtubealarmduetohigh

GASpressurewillcausea5second

alarmtone.Iftheobstruction

persists the system will continue

toalarmin5secepisodes.Water

circulation continues but the heater

shutsoff.

Checkthatdeliverytubeiscorrectly

positioned, rotated clockwise, and pulled

intolockedposition.Checkthatwateris

circulatingwithindeliverytube.Ifalarm

persistsreplacedeliverytubeand/or

cartridge.Disinfectunitpriortoreplacing

components.

Findandcorrectthecauseofobstruction.

Themostcommoncauseisakinkinthe

nasalcannualorintheprong.Attempting

toruntheVapotherm2000iatveryhigh

flow through a patient interface not

approvedbyVapothermmayalsoraisethe

internal pressure sufficiently to trigger a

BlockedTubeAlarm.

Blocked Tube

Alarm

Section 6Alarms,TroubleShootingandComponentChange-Outs