primer first. Otherwise chemical interaction and decomposition could occur.

If you want to protect your VARIPROP with Antifouling,

use only Antifouling which needs a

shaft plus the prop anode. We recommend the replacement of the anode once a

year.

The propeller must be protected from electrolytic corrosion by fitting the usual zinc anodes on the

The propeller body must always be completely filled with a high viscosity grease.

We recommend

feathering blades. This is normal and not a problem or a defect

of your

VARIPROP.

When going from ahead to astern or the opposite,

you can hear the turning-noise of the

substantially lengthen the service life of your propeller

gears.

rpm’s (max.1200rpm)

between gears to allow smooth reversing of rotation without binding.

This will

When going from ahead to astern or the opposite, it is necessary to idle down and shift at low

to the gears, shortening their life.

WARNING:

It is important to follow the instructions below carefully so as to avoid excessive load and shock

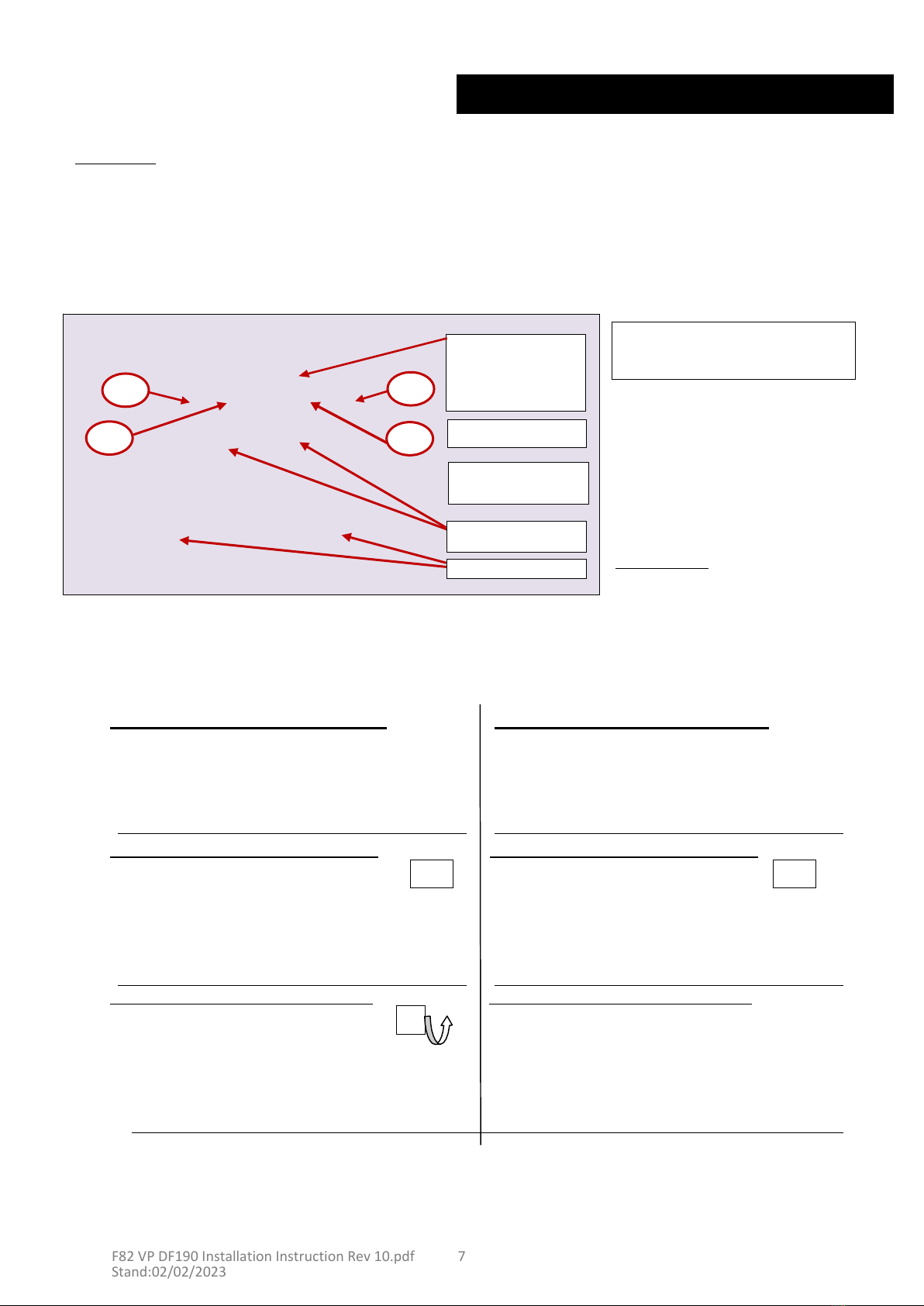

Check the clutch discs of the transmission. They could be worn

out.

way detrimental.

in the owners manual of your transmission.

A larger amount of lever travel is in

no

lever,

between the neutral position and end positions for forward and reverse can be found

not too short.

The amount of lever travel,

as measured at the pivot point of the actuating

Check shifting movement of the transmission lever.

Make sure that the

shifting travel is

Check low idle of the engine. It should be 800 to 900 rpm in

idle.

points below:

TROUBLE SHOOTING:

If the propeller does not work in forward or reverse go systematically through the

stays in sailing

position.

VARIPROP XLS range,

we highly recommend to fit a shaft lock to ensure the propeller feathers and

work,

you

most

likely

need

to

fit

a

shaft

lock.

For

large

yachts,

equipped

with

a

propeller

from

our

usually

enough

to

feather

the

propeller

instantly

into

sailing

position.

If

this

procedure

does

not

This procedure generates higher oil pressure and prevents shaft rotation. This small-scale friction is

sailing

position

without

a

shaft

lock

as

you

turn

off

the

engine

with

forward

gear

still

clutched

in.

Please

note

that

98%

of

our

delivered

VARIPROP

propellers

for

hydrolic

gear

boxes

feather

into

will not feather. You can actually use this feature to drive a shaft generator.

DO NOT stop

the engine while it turns in reverse. In this case the blades will stay in the reverse position and

Once the prop is feathered, it is better to shift the transmission to neutral.

In that case start the engine again and repeat the steps above.

If the propeller is not feathered in the sailposition the shaft will freewheel like with a fixed propeller.

stop spinning the shaft to feather the blades in the

sailposition.

Stop the engine while still engaged in forward. The remaining oil pressure of the transmission will

Power at 3 to 4 knots in

forward.

VARIPROP sailposition with hydraulic transmission:

the shaft.

Now engage in Neutral

again.

Stop the engine, turn it off

and engage the transmission in reverse to stop the freewheeling of

Power at 3 to 4 knots in

forward.

VARIPROP sailposition with mechanical gear-box:

THE BEST WAY TO FEATHER THE PROPELLER IN THE SAILPOSITION IS:

into gear the blades will engage in either forward or reverse.

The VARIPROP feathers automatically when the shaft rotation is stopped. After engine start-up and shifting

synthetic

grease

typ

TW.2

GEL

or

mineral

multi-purpose

grease

EP/SAL

(see

servicing

page

9)

F82 VP DF190 Installation Instruction Rev 10.pdf

Stand:02/02/2023