15

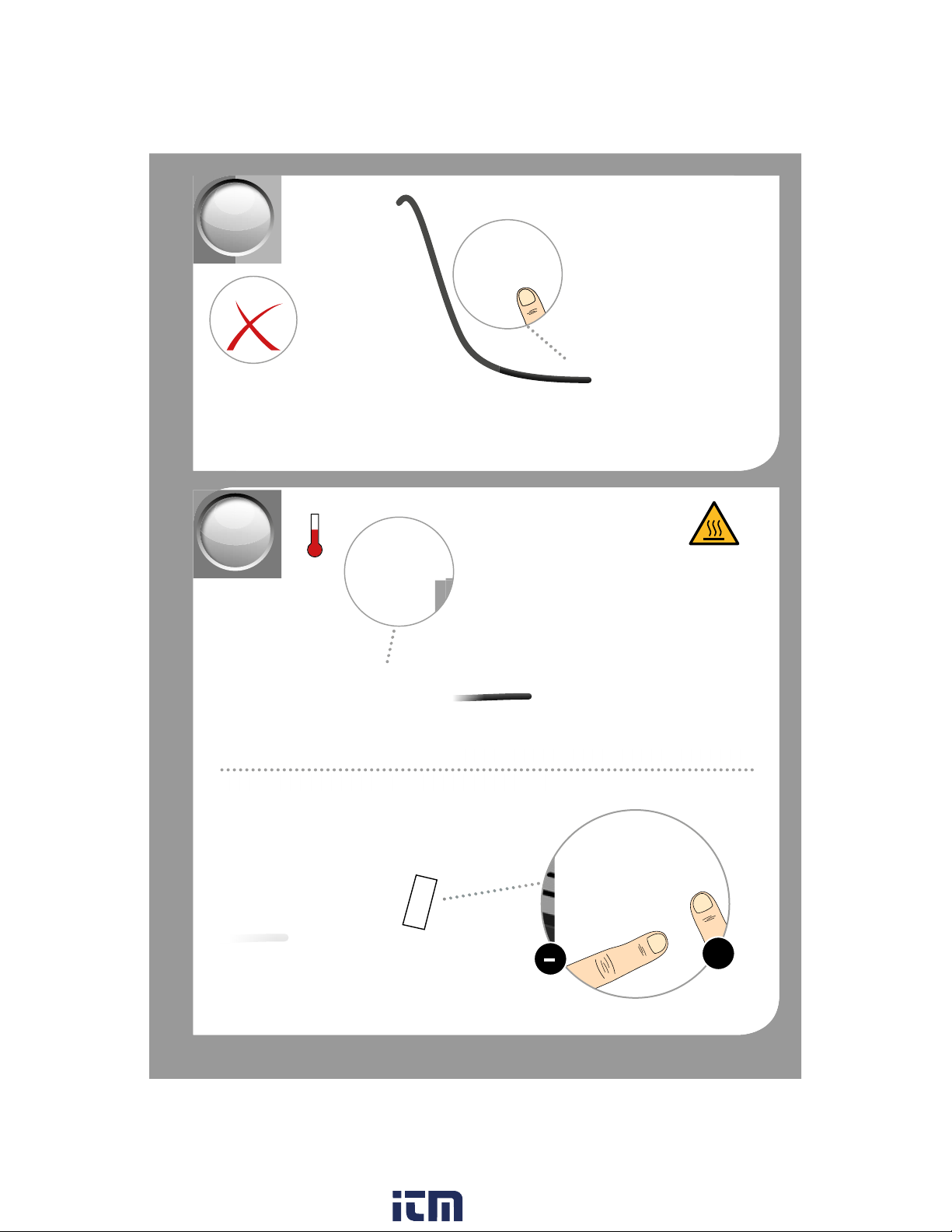

WARNING Fire hazard

Covering the soldering iron or the safety holder poses

a re hazard. Always keep objects well away from the

soldering iron and safety holder.

• Alwayskeepobjectswellawayfromthesolderingiron

andsafetyholder.

• Keepallcombustibleobjects,liquidsorgaseswellaway

from the hot soldering tool.

Store your soldering tool in a safe place. When not in

use,unitsandtoolsshouldbestoredinadry,highorlocked

area out of the reach of children. Make sure that unused

soldering tools are free of voltage and de-pressurised.

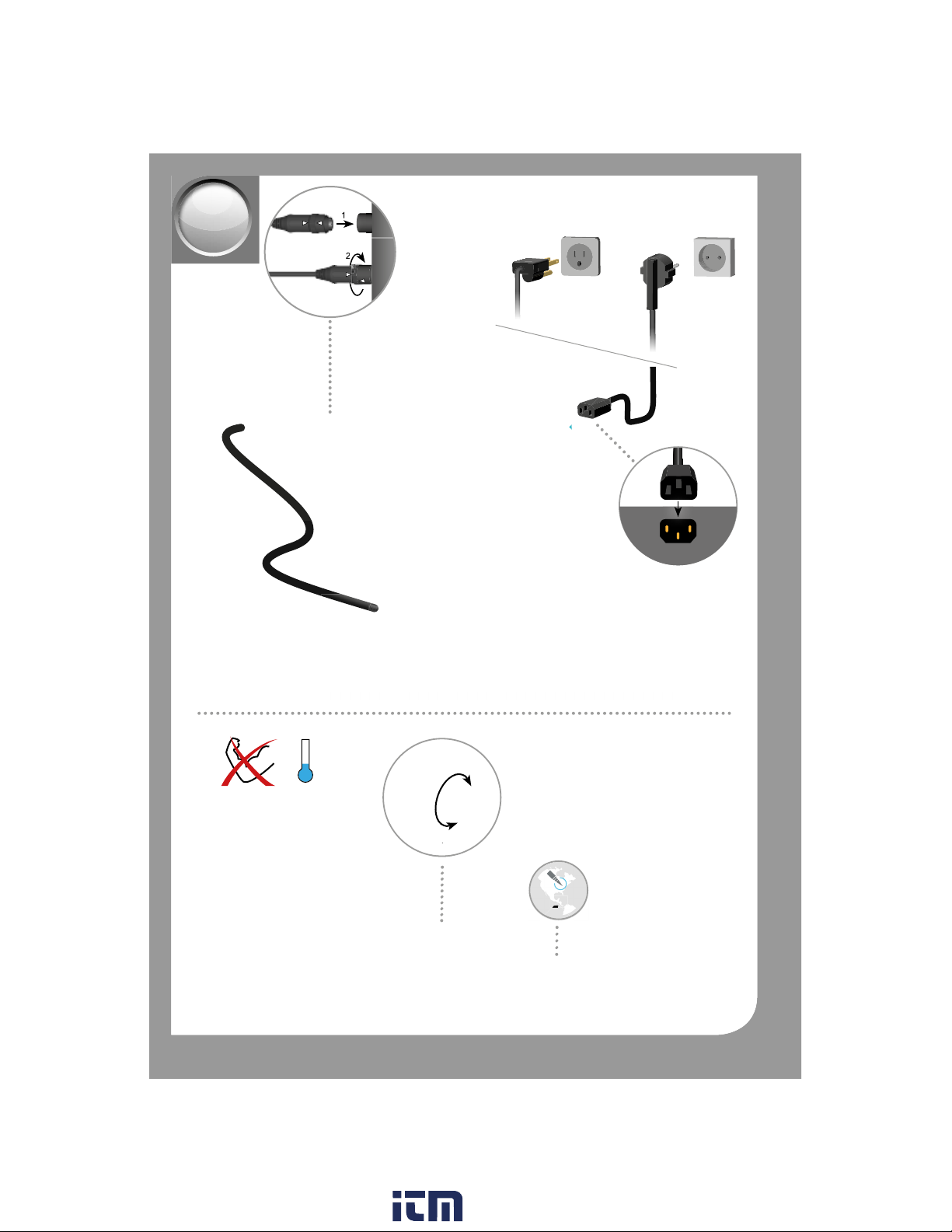

The power cable must only be plugged into the power

socket or adapter approved for this purpose. Checkto

seeifthemainsvoltagematchestheratingsonthe

nameplate.Makesurethemachineisswitchedobefore

pluggingin.

Do not use the cable for purposes other than those for

which it is intended.Nevercarrytheunitbythecable.Do

not use the cable to pull the plug out of the socket. Protect

the cable against heat, oil and sharp edges..

Be alert. Payattentiontowhatyouaredoing.Besmart

whenusingtheunit.Donotusethesolderingtoolifyouare

havingdifcultyconcentrating.

Avoid abnormal posture. Arrangeyourworkstationinan

ergonomicallycorrectway.Avoidbadposturewhenusingthe

unit, as this can lead to postural problems.

The soldering tool must be operated only in perfect

technical working order.Safetydevicesmustnotbe

deactivated.

Faults and defects must be repaired immediately.

Beforeusingtheunit/tool,safetydevicesmustbecarefully

checkedtomakesurethattheyarefunctioningproperlyand

in the manner intended. Check that moving parts are func-

tioningproperlyandarenotsticking,andwhetherpartsare

damaged.Allpartsmustbecorrectlyttedandmustsatisfy

alltherequirementsnecessarytoguaranteetroublefree

operation of the unit.

Use the correct tool. Useonlyaccessoriesorauxiliary

devices which are included in the list of accessories or

approvedforusebythemanufacturer.UseWELLERacces-

soriesorauxiliarydevicesonoriginalWELLERequipment

only.Theuseofothertoolsandotheraccessoriescancause

injury.

Secure the tool.Useclampingxturestoholdthe

workpiece.

Use a solder fume extraction unit. If appliances for

connecting solder fume extraction units are available, ensure

thattheyareconnectedandusedproperly.

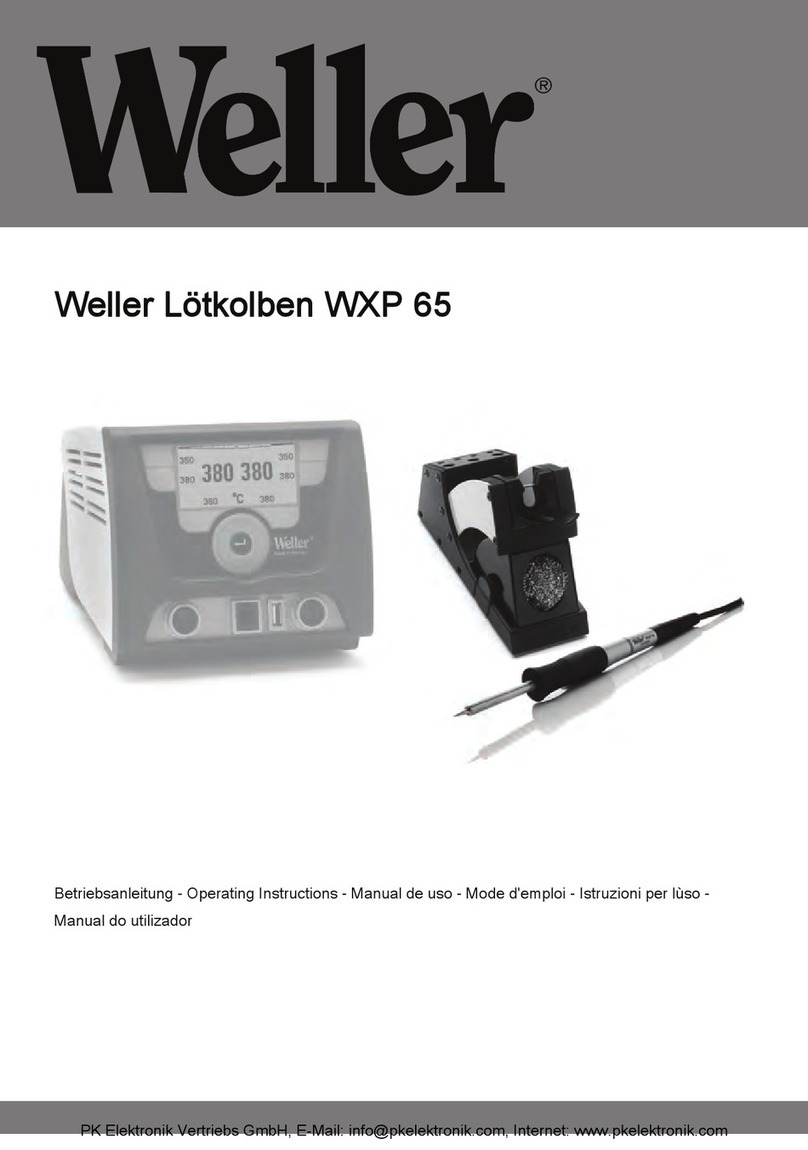

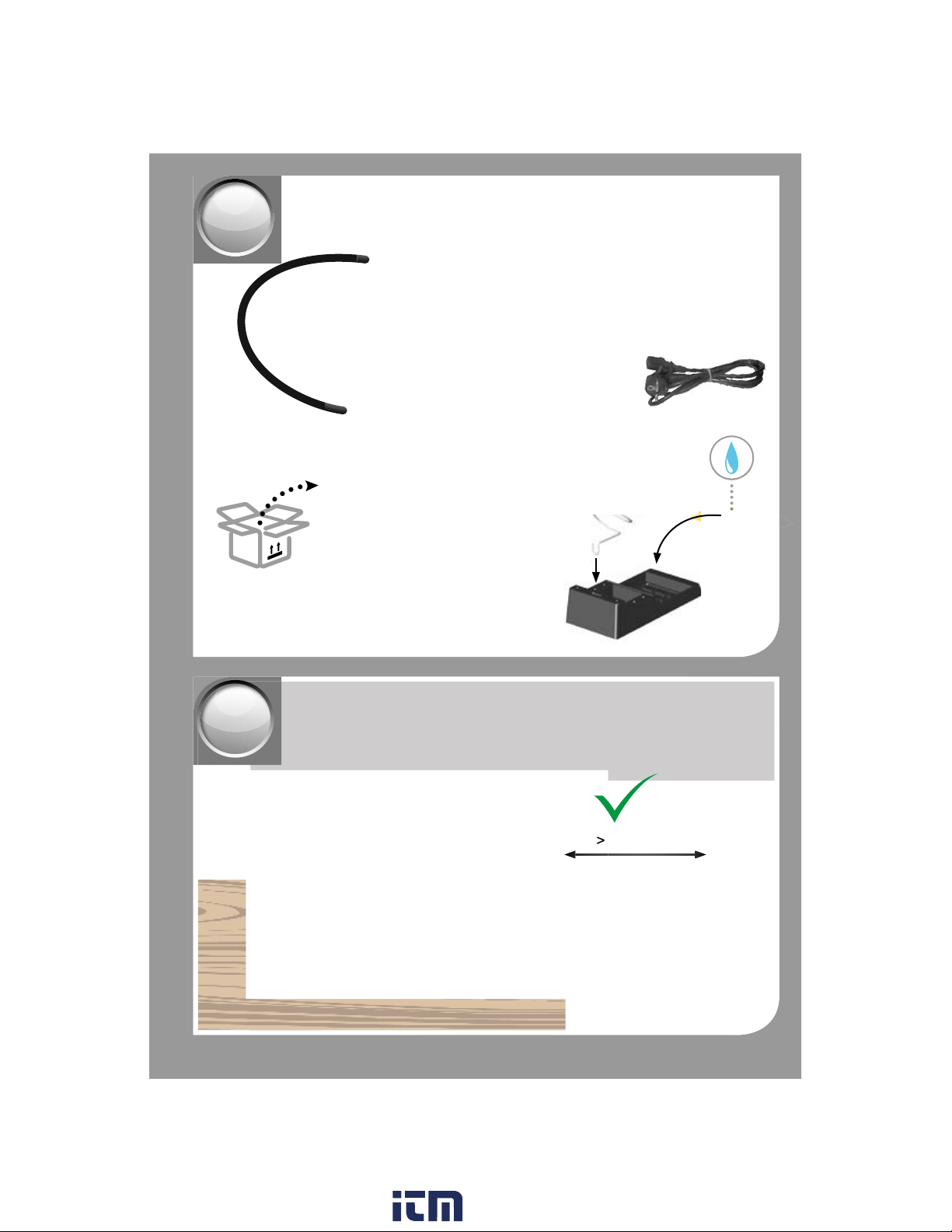

Soldering

Please be sure to read and follow the operating

instructions for your Weller Supply Unit.

Use only original Weller soldering

tips!

Handling the soldering tips

• Coattheselectiveandtinnablesolderingtipwithsolder

whenheatingitupforthersttime.Thisremovesoxide

coatingswhichhaveformedduringstorageandimpurities

fromthesolderingtip.

• Makesurethatthesolderingtipiswellcoatedwithsolder

duringbreaksbetweensolderingworkandpriortostorage

ofthedevice.

• Donotuseaggressiveuxingagents.

• Alwaysmakesurethatthesolderingtipsaretted

properly.

• Selectaslowaworkingtemperatureaspossible.

• Selectthelargestpossiblesolderingtipshapeforthe

application.Ruleofthumb:thesolderingtipshouldbe

roughlyaslargeasthesolderingpad.

• Coatthesolderingtipwellwithsoldertoensurethatthere

isecientheattransferbetweenthesolderingtipandthe

solderingarea.

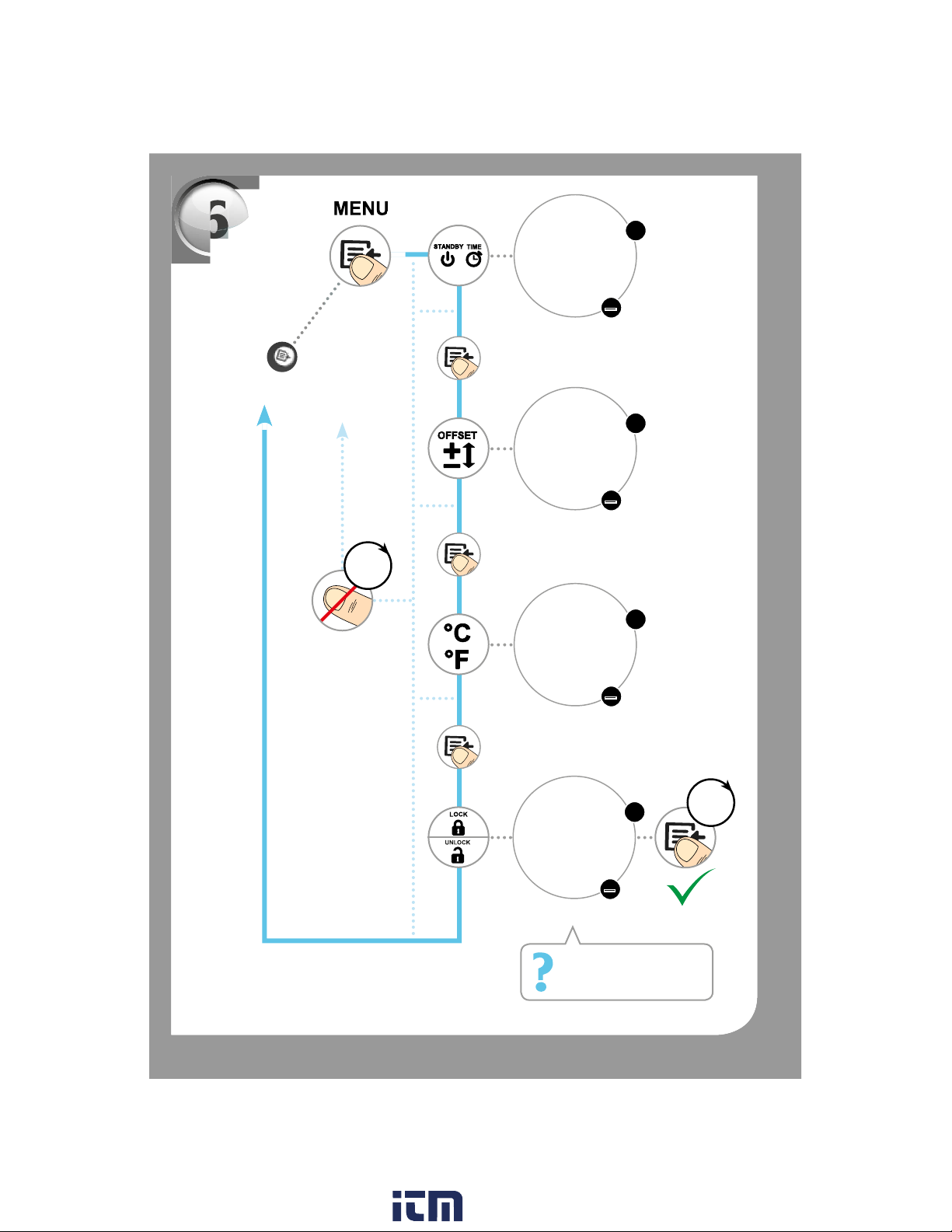

• Priortoextendedbreaksbetweensolderingwork,switch

othesolderingsystemorusetheWellerfunctionto

reducethetemperaturewhenthesolderingequipmentis

notinuse.

• Coatthetipwithsolderpriortostorageifyoudonot

intendtousethesolderingironforanextendedperiodof

time.

• Applysolderdirectlytothesolderingarea,nottothe

solderingtip.

• Donotapplymechanicalforcetothesolderingtip.

Specied Conditions Of Use

SupplyunitforWELLERsolderingtools.Usethesoldering

stationonlyforthepurposeofsoldering,asspeciedinthe

OperatingInstructions.

Usethesolderingironexclusivelyforthepurposeindicated

in the Operating Instructions of soldering and desoldering

undertheconditionsspeciedhere.

ThesolderingironmayonlyusedincombinationwithWeller

SupplyUnits.

Thisdevicemayonlybeusedatroomtemperatureand

indoors. Protect against moisture and direct sunlight.

GB

ENGLISH

www. .com information@itm.com1.800.561.8187