2

Contents

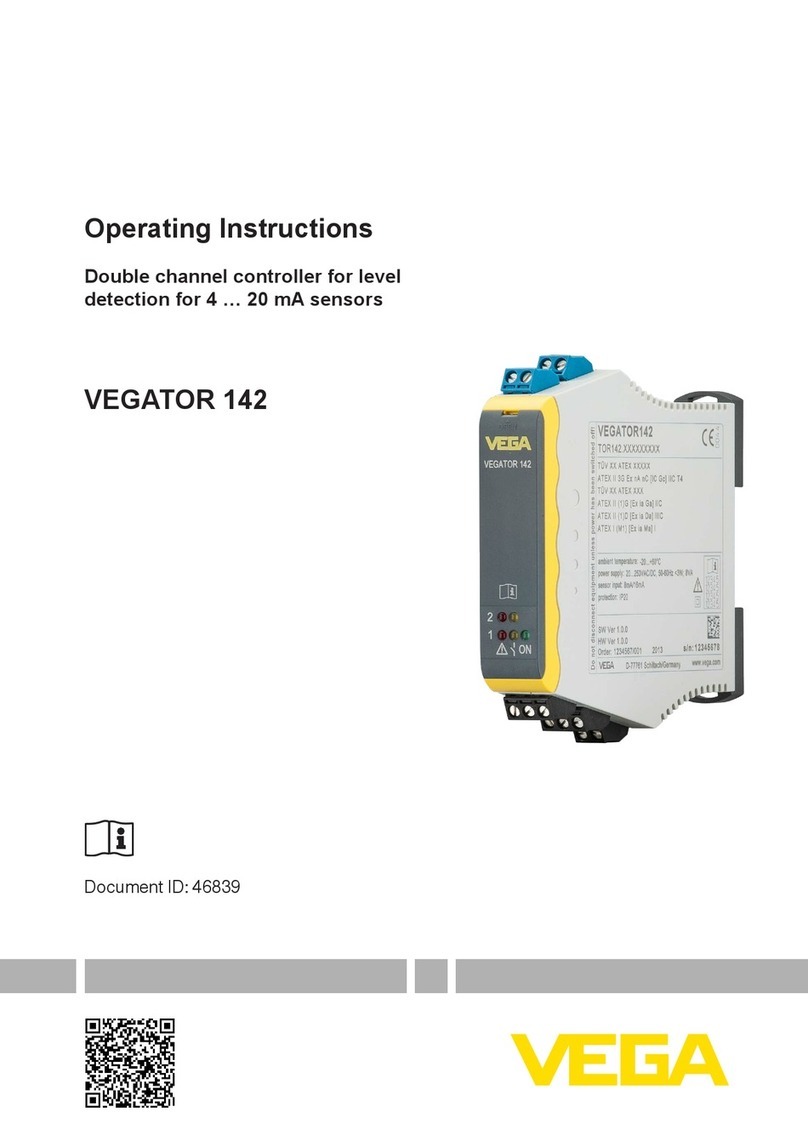

VEGATOR 111 •

46105-EN-210714

Contents

1 About this document ............................................................................................................... 4

1.1 Function ........................................................................................................................... 4

1.2 Target group ..................................................................................................................... 4

1.3 Symbols used................................................................................................................... 4

2 For your safety ......................................................................................................................... 5

2.1 Authorised personnel ....................................................................................................... 5

2.2 Appropriate use................................................................................................................ 5

2.3 Warning about incorrect use............................................................................................. 5

2.4 General safety instructions............................................................................................... 5

2.5 Installation and operation in the USA and Canada ........................................................... 5

2.6 Safety instructions for Ex areas ........................................................................................ 6

3 Product description ................................................................................................................. 7

3.1 Conguration.................................................................................................................... 7

3.2 Principle of operation........................................................................................................ 7

3.3 Adjustment ....................................................................................................................... 8

3.4 Packaging, transport and storage..................................................................................... 8

4 Mounting................................................................................................................................... 9

4.1 General instructions ......................................................................................................... 9

5 Connecting to power supply................................................................................................. 10

5.1 Preparing the connection ............................................................................................... 10

5.2 Connection procedure.................................................................................................... 11

5.3 Wiring plan ..................................................................................................................... 11

6 Setup ....................................................................................................................................... 13

6.1 Adjustment system......................................................................................................... 13

6.2 Adjustment elements...................................................................................................... 13

6.3 Function table "Point level" ............................................................................................. 16

7 Diagnostics and servicing .................................................................................................... 17

7.1 Maintenance .................................................................................................................. 17

7.2 Rectify faults................................................................................................................... 17

7.3 Diagnosis, fault messages ............................................................................................. 17

7.4 How to proceed if a repair is necessary.......................................................................... 18

8 Dismount................................................................................................................................. 20

8.1 Dismounting steps.......................................................................................................... 20

8.2 Disposal ......................................................................................................................... 20

9 Certicatesandapprovals.................................................................................................... 21

9.1 Approvals for Ex areas ................................................................................................... 21

9.2 EU conformity................................................................................................................. 21

9.3 SIL conformity (optional) ................................................................................................ 21

9.4 Environment management system ................................................................................. 21

10 Supplement ............................................................................................................................ 22

10.1 Technical data ................................................................................................................ 22

10.2 Dimensions .................................................................................................................... 24

10.3 Industrial property rights................................................................................................. 25

10.4 Trademark ...................................................................................................................... 25