Vega VEGAFLEX 81 User manual

Other Vega Measuring Instrument manuals

Vega

Vega VEGACAP 65 User manual

Vega

Vega VEGAPULS 66 User manual

Vega

Vega VEGAPULS 66 User manual

Vega

Vega VEGAPULS PS6x.UD series Installation instructions

Vega

Vega VEGACAL 62 User manual

Vega

Vega VEGACAP 35 User manual

Vega

Vega WEIGHTRAC 31 User manual

Vega

Vega VEGAMET 625 User manual

Vega

Vega VEGAPULS 62 User manual

Vega

Vega VEGABAR 82 User manual

Vega

Vega VEGAVIB 62 Installation instructions

Vega

Vega VEGAPULS 56K User manual

Vega

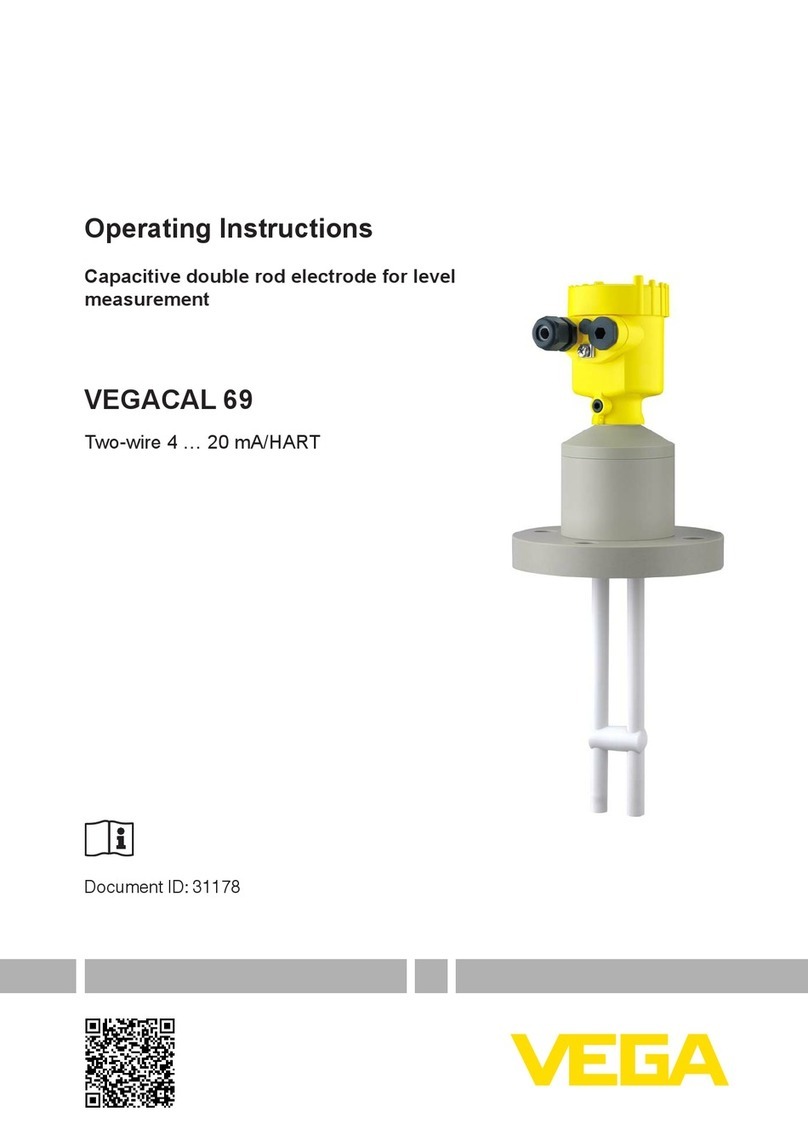

Vega VEGACAL 69 User manual

Vega

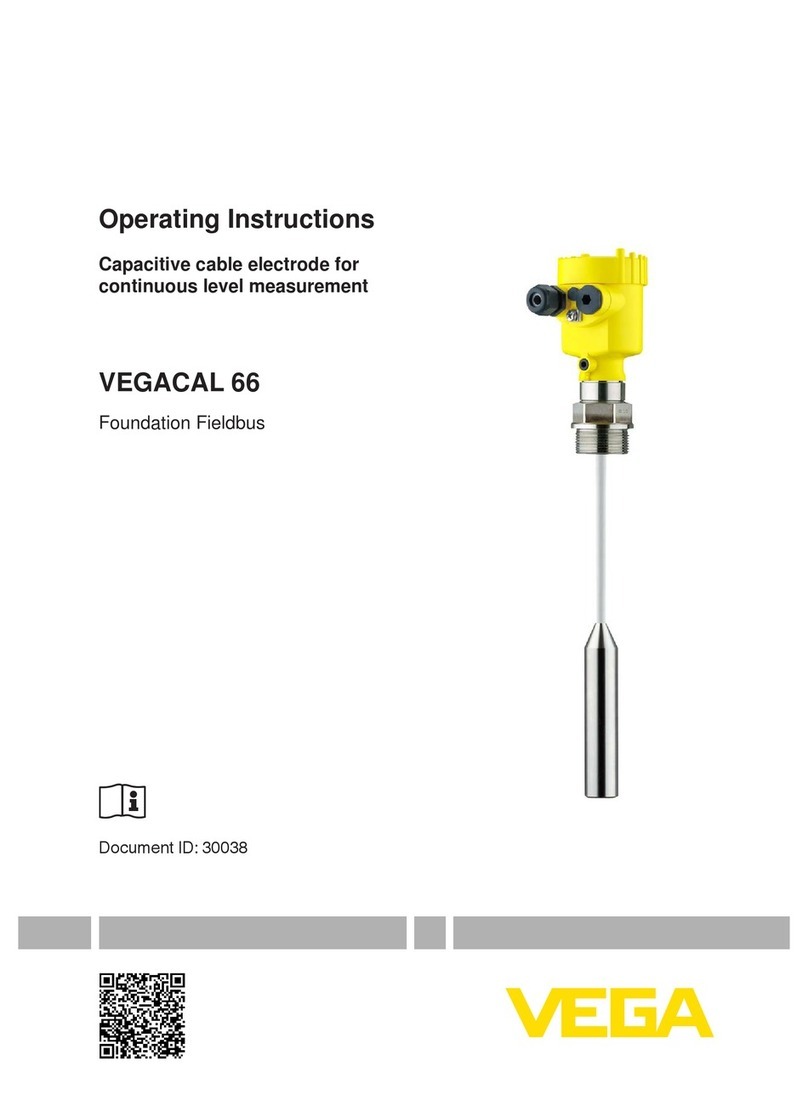

Vega VEGACAL 66 User manual

Vega

Vega VEGABAR 17 User manual

Vega

Vega PULS SR 68 User manual

Vega

Vega VEGAPULS 69 User manual

Vega

Vega VEGAPULS 65 User manual

Vega

Vega VEGAPULS 31 User manual

Vega

Vega VEGAMIP R61 User manual