lElectronics with increased sensitivity type PS60FFS.-

The scope of delivery encompasses:

lRadar sensor

lDocumentation

-this operating instructions manual

-Test certificate measuring accuracy,depending on the

instrument VEGAPULS 62 (optional)

-Operating instructions manual 27835 "Indicating and adjust-

ment module PLICSCOM"(optional)

-Supplementary instructions "GSM/GPRS radio module"(op-

tional)

-Supplementary instructions manual "Heating for indicating and

adjustment module"(optional)

-Supplementary instructions manual "Plug connector for con-

tinuously measuring sensors"(optional)

-Ex-specific"Safety instructions"(with Ex versions)

-if necessary,further certificates

3.2Principle of operation

The instrument is suitable for applications in liquids in storage tanks

and process vessels under difficult process conditions.Application

possibilities are in the chemical industry,in environmental and

recycling technology as well as in the petrochemical industry.

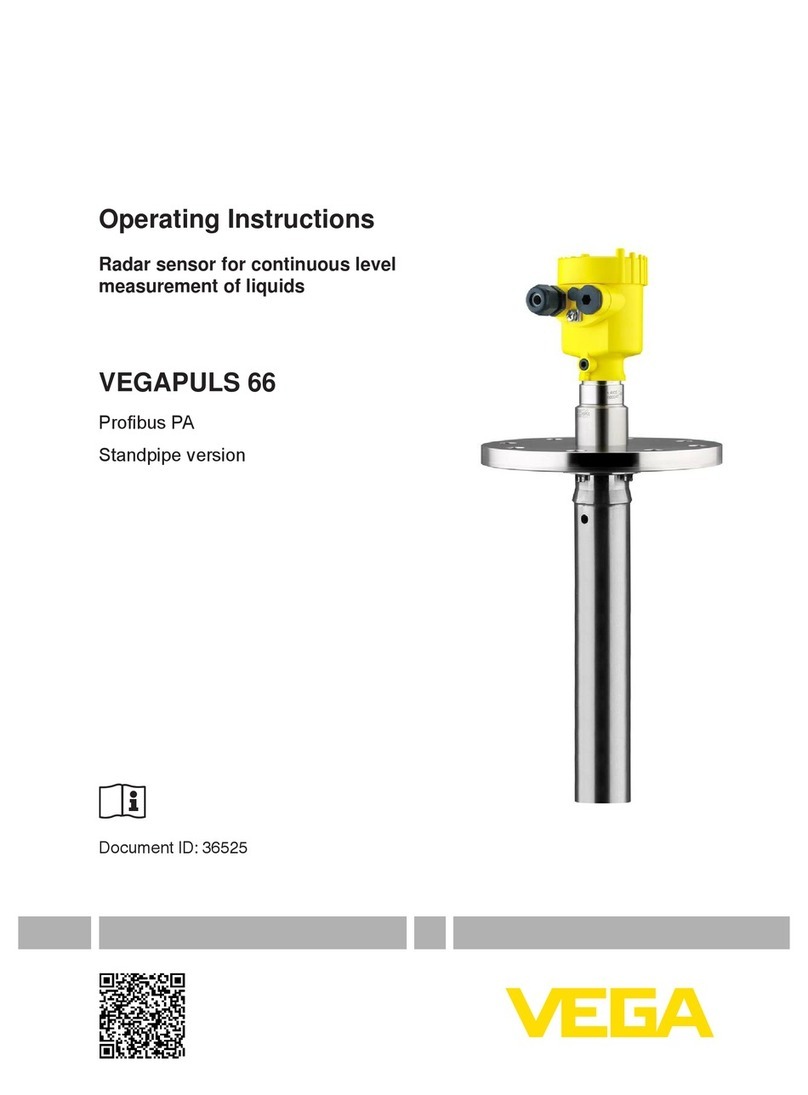

The version with horn antenna ø40 mm (1.575 in)is particularly

suitable for small tanks and process vessels for measurement of

virtually all products.

The version with horn antenna ø48 …95 mm (1.89 …3.74 in)is

particularly suitable for storage tanks and process vessels,for

measurement of products such as solvents,hydrocarbons and fuels

under most difficult process conditions.

The version with parabolic antenna is particularly suitable for

measurement of products with low ε

r

value at great measuring

distances.

The standard electronics enables the use of instruments in products

with an ε

r

-Wert ≥1.8.The electronics version with increased sensitivity

enables the use of the instrument also in applications with very poor

reflective properties or products with an ε

r

value ≥1.5.The values that

can be actually reached depend on the measurement conditions,the

antenna system or the standpipe or bypass tube.

The antenna of the radar sensor emits short radar pulses with a

duration of approx.1ns.These pulses are reflected by the product

and received by the antenna as echoes.The running time of the radar

pulses from emission to reception is proportional to the distance and

hence to the level.The determined level is converted into an

appropriate output signal and outputted as measured value.

Scope of delivery

Application area

Functional principle

8VEGAPULS 62 •Foundation Fieldbus

3Product description

36506-EN-110127