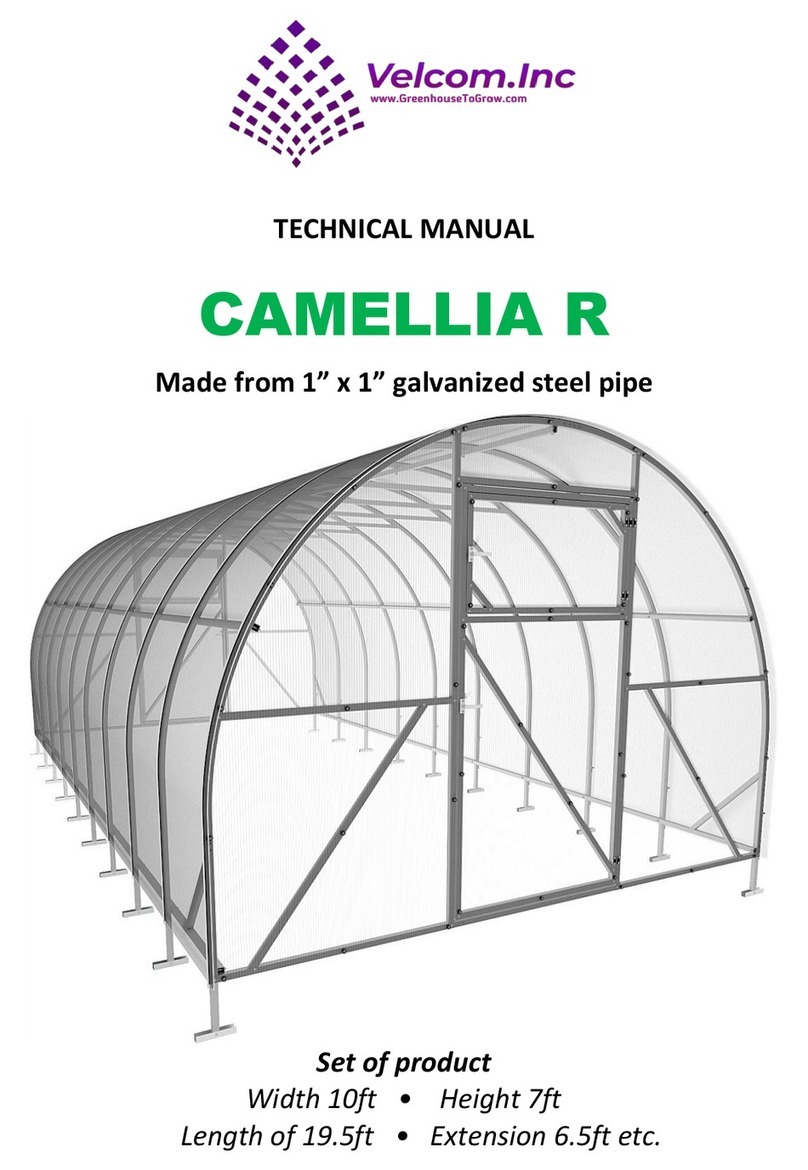

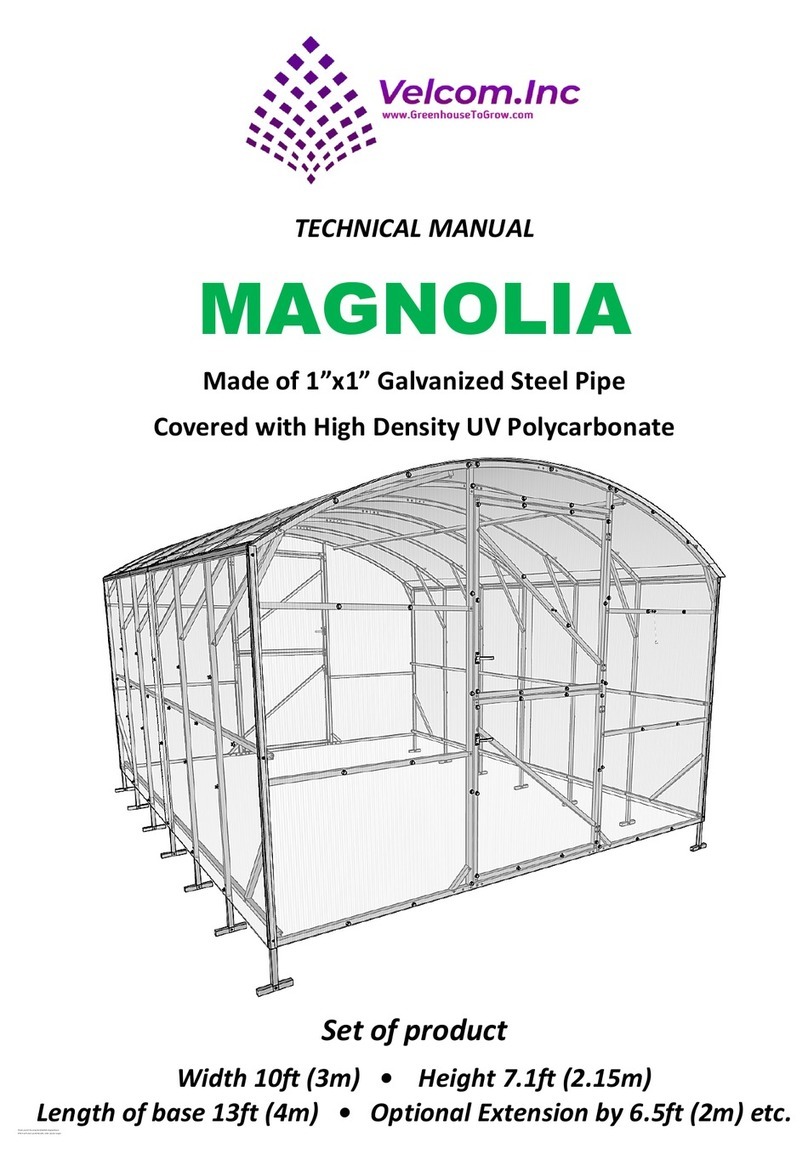

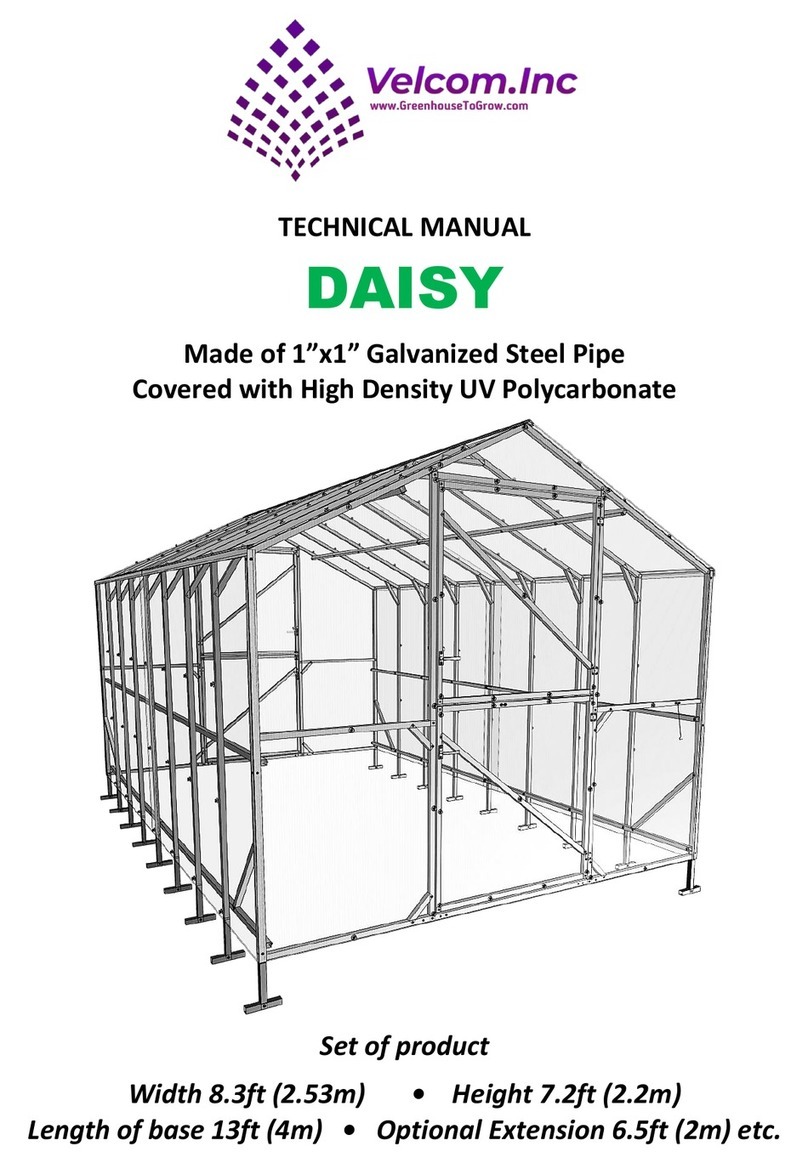

TECHNICAL CERTIFICATE of GREENHOUSE “CAMELLIA”

DISCRIPTION

The greenhouse “CAMELLIA” is designed to create the climate, which is productive to grow

horticultural crops on the garden plots.

The length of the greenhouse is 13’L (4m) width is 10’ (3m) and height is 7’ (2.10m) with ability

to extend length by 6.5’ (2m) up to 32.5’ (10m) the surface of the protected soil is 130 ft2.

The frame of the greenhouse is made of square galvanized pipe 1”x1” and it is assembled with

the studs, screws, nuts.

The kit includes everything you need to assemble the frame and fasten the covering. The

foundation of the greenhouse is not obligatory to install but recommended. The greenhouse is

fixed on the ground by digging in to the ground special frame endings.

For fixing cellular polycarbonate to the greenhouse roof, galvanized steel strapping tape is

used.

The greenhouse covering is completed on buyer’s request. To cover the greenhouse you need

a greenhouse frame is designed for covering with cellular polycarbonate 4 mm thick with a High

Density of at least 0.7 kg / m2. The greenhouse has two doors, one on each end and two vents.

Assembly instructions and operating rules

The greenhouse should be assembled and installed on the ground according the instruction.

The buyer should control the assembly quality if it is made by third person.

Self-tapping screws of mount structure should be tightened to contact the flat head of the

screw with the covering surface and hold it to the frame, but do not allow the extra rundown of

the screws.

Avoid installing the greenhouse closely to the buildings and trees. The melting snow or ice is a

potential hazard. The recommended distance is minimum 7ft.

The greenhouse is designed to endure the wind of less than 50mph.

There is no need to skin the greenhouse during the winter time for the greater parts of the

regions of Canada and USA. If the greenhouse in not looked after during winter, the customer

should determine the possible snow load or to skin the covering.

The limit snow load for the frame takes place when the weight of the snow blanket is

240 kg/m2 (120Lb/ft2) of horizontal ground surface. This limit snow load requires characteristic

snow load of the North snow region (according the classification of construction rules and

regulations “Loads and actions”).

For assembly, you will need: a 10mm wrench, a screwdriver with a PH2 attachment,

a sharp knife, a carpenter square, a level, a 7-10 m tape measure*, a ladder and

protective gloves.*Metric measuring tape needed! Cm/mm