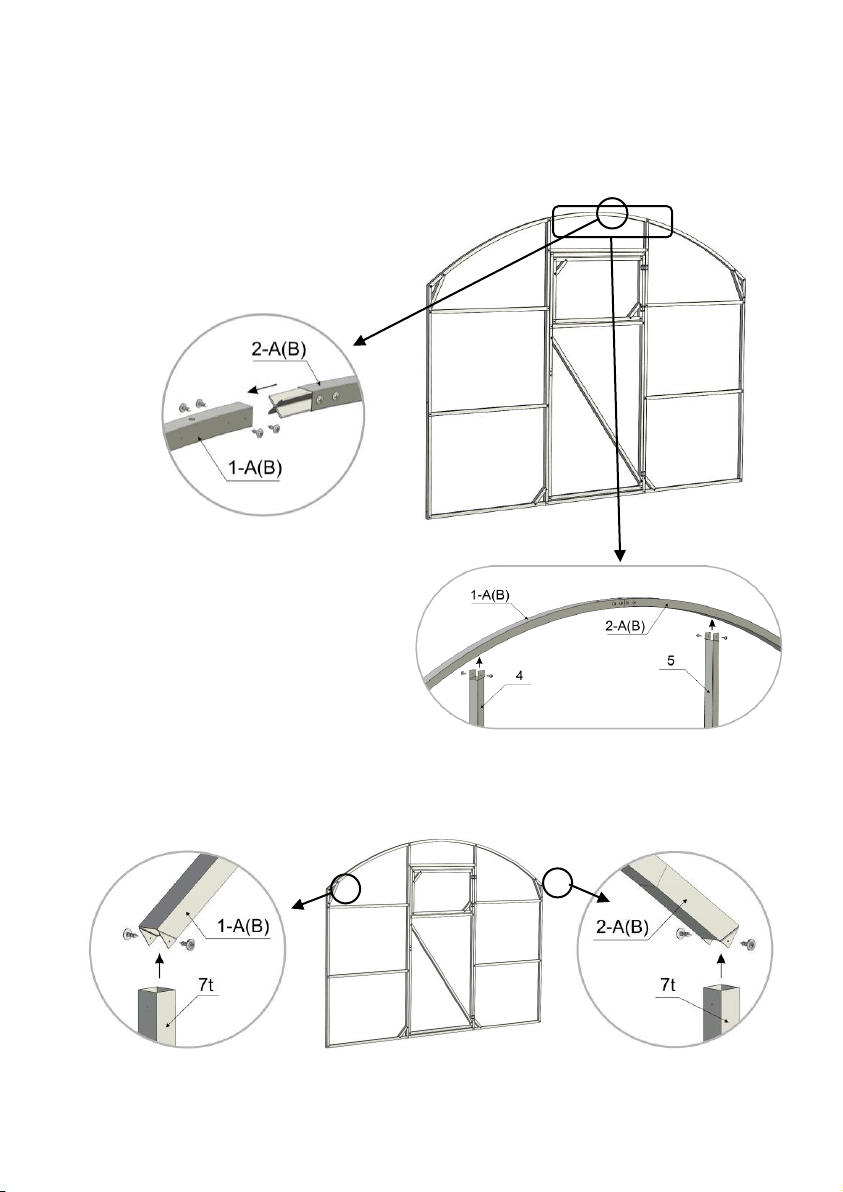

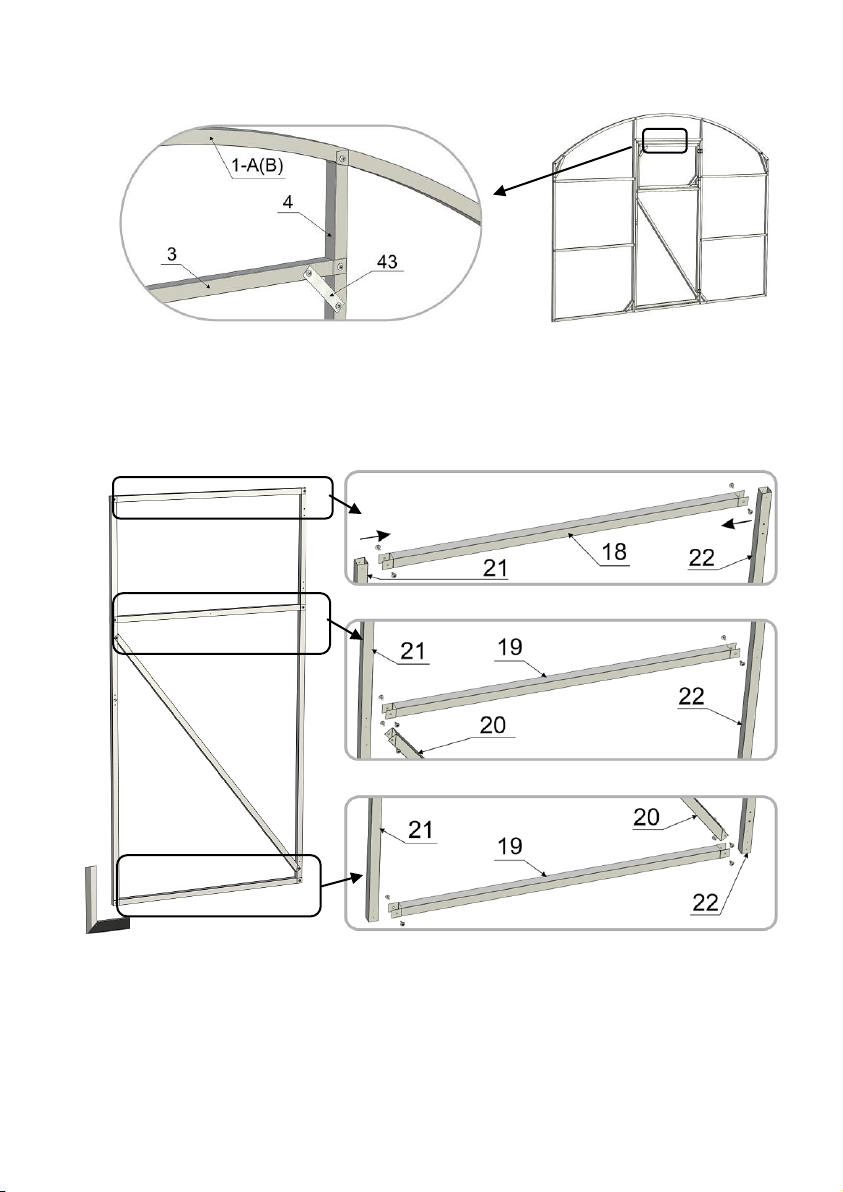

The left-hand part of the bottom

transverse rib of end-face, 1050mm

Middle part of the bottom transverse

rib of the end-face, 900mm

The right-hand part of the bottom

transverse rib of end-face, 1050mm

Grouser post, 20х20х250mm

Intermediate arch half-arc, left-hand

1605mm

Intermediate arch half-arc, right-hand,

1605mm

Intermediate arch diagonal tie,700mm

Door lintel, middle/bottom, 905mm

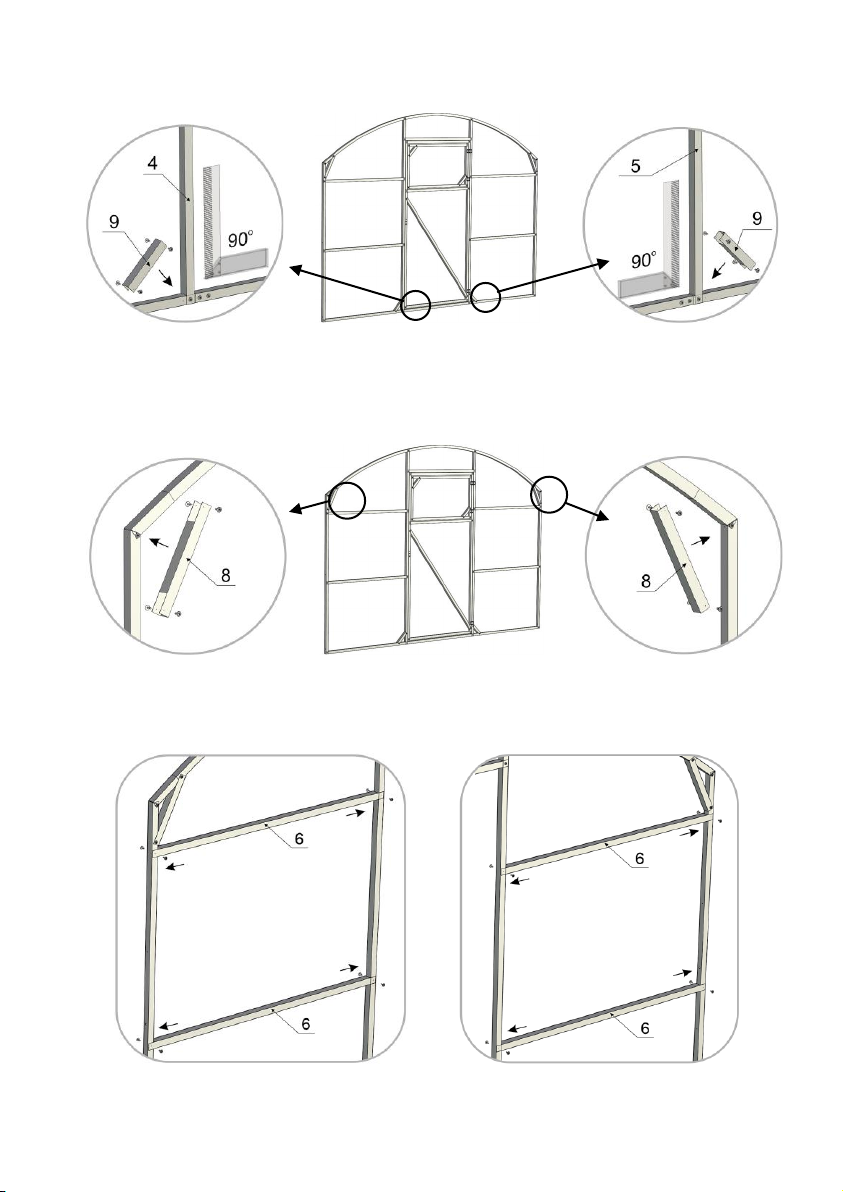

Door post, left-hand, 1780 mm

Door post, right-hand, 1780mm

Air gate lintel, top/bottom, 850mm

Air gate post, left-hand, 470mm

Air gate post, right-hand, 470mm

Longitudinal starting stringer,

2012mm

Longitudinal stringer with X-crimp,

2068mm

Angle piece, side 120°, 2025mm

Angle piece, end-face 90°, 1600mm

Self-tapping screw 4,2х16mm

(To assemble framework)

Self-tapping screw 4,2х19mm

(for polycarbonate fastening)

Thermal-washer with cover cap

Door/Air gate hand lever:

Hand lever –1 pc.; shield–1 pc.;

Locking point –1 pc.; screw М5 –

2pcs.; nut М5 – 2 pcs.