VTSSC72

06.11.2012 ©Velle an nv

6

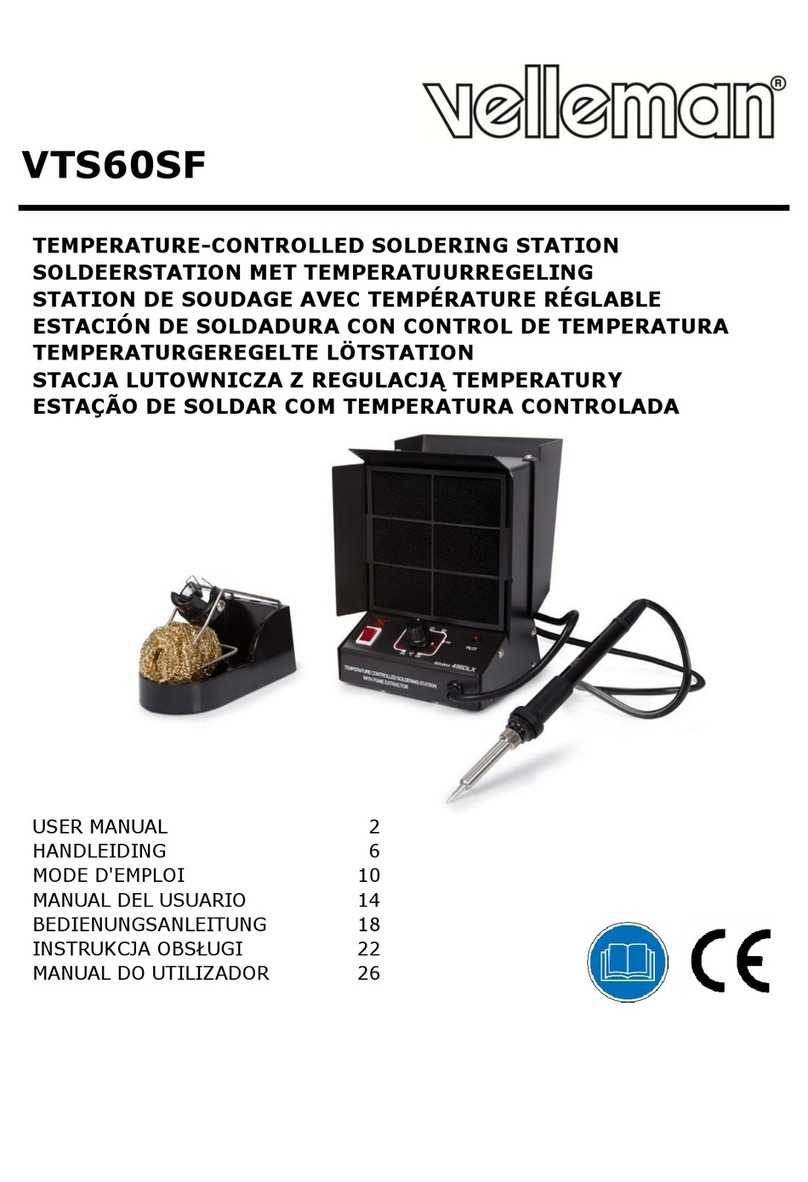

SOLDERING

IMPORTANT NOTE

Do not use te peratures in excess of 410°C (770°F) for nor al soldering purposes. The device can be

used at higher te peratures for short periods of ti e. EXERCISE GREAT CAUTION WHEN DOING SO.

CAUTION

Do not touch the etal parts of the soldering iron while the unit is being used or while it is cooling in

order to avoid burns.

•Set the power switch [8] to the “ON”-position.

•Set the iron/tweezers switch [7] to TWZ for tweezers para eter settings or to SIA for regular

soldering iron configuration.

•Press the up-button (▲) [4] until the display [1] indicates 250°C (or 482°F). When the te perature

is stable, the heating indication [C] is off. The unit [B] is shown next to the te perature [A].

Not : to change the indicated unit, see § para eter settings above.

•Tin the surface of the soldering tip by applying a new protective layer of solder.

•Set the iron or tweezers to the desired working te perature.

•When using the tweezers, always lift co ponents perpendicular to the PCB.

•Always return the soldering iron and tweezers to their stand between uses.

9. Common caus s for tip failur

•The te perature of the tip exceeds 410°C (770°F)

•The tip is not sufficiently tinned

•Wiping the tip on a surface with a high sulphur content or on a dirty or dry sponge

•Contact with organic or che ical substances such as plastic, resin, silicone and grease

•I purities in the solder and/or a low tin content

10.Tip maint nanc

The soldering iron and tweezers use extre ely high te peratures. Make sure that the unit is switched off

for aintenance purposes.

Re ove the tip and clean it after heavy or oderate use. We reco end cleaning the tip daily if the

station is used frequently.

The supplied soldering tip is ade of copper covered with a layer of iron. It will retain its projected life

span if used properly.

•Always tin the tip before returning it to the holder, prior to turning off the station or to storing it for

long periods of ti e. Wipe the tip on a wet sponge or use our tip cleaner before activating the device.

•Using excessive te peratures ( ore than 400°C or 750°F) will shorten the life span of the tip.

•Do not exercise excessive pressure on the tip while soldering, as this ay cause da age to the tip.

•Never clean the tip with a file or with abrasive aterials.

•Do not use flux containing chloride or acid. Use only resinous fluxes.

•If an oxide fil has for ed, you should re ove it by buffing carefully with a 600-800 grit e ery

cloth or by using isopropyl alcohol and consequently applying a new protective layer of solder.

•Set the desired te perature after allowing the unit to idle at 250°C for three inutes. The station

will be ready for use once the set te perature is reached.

IMPORTANT

Re ove and clean the tip daily. Re ove excess solder fro the barrel nut asse bly when installing a

new tip, otherwise the tip ay be fused to the heating ele ent or to the retaining asse bly.

11. Maint nanc

•Soldering tips can be replaced si ply by unscrewing the barrel nut asse bly. Turn off the station and

allow it to cool down first. Da age to the soldering station ay occur if the syste is left on and the

re oved tip has not been replaced.

•After re oving the tip, you should blow out any oxide dust that ay have for ed in the tip

receptacle. Be careful not to get dust in your eyes. Replace the tip and tighten the screw. Pliers can

be used to avoid contact with hot surfaces BUT SHOULD BE USED WITH CAUTION because over-

tightening ay cause da age to the ele ent or fuse the tip to the ele ent.

•Tweezers tips can be replaced by releasing the screws on top. Make sure to align the new tips

properly and do not tighten the screws to hard to avoid da age.

•The outer cover of the tweezers, iron and station ay be cleaned with a da p cloth using s all

a ounts of liquid detergent. Never sub erse the unit in liquid or allow any liquid to enter the case of

the station. Never use any solvent to clean the case.

•If the tweezers, iron or station should beco e faulty or, for so e reason does not operate nor ally,

the syste should be returned to the service depart ent of your authorized dealer or service agent.