GLT-299-7-16 R ev.0

Jun 12, 2018

3

Confirm that the module goes back to the initial status after the

module is reset. (In the normal status, the contact between N/C1

and COM1 (or between N/C2 and COM2) is closed, and the contact

between N/O1 and COM1 (or between N/O2 and COM2) is open.

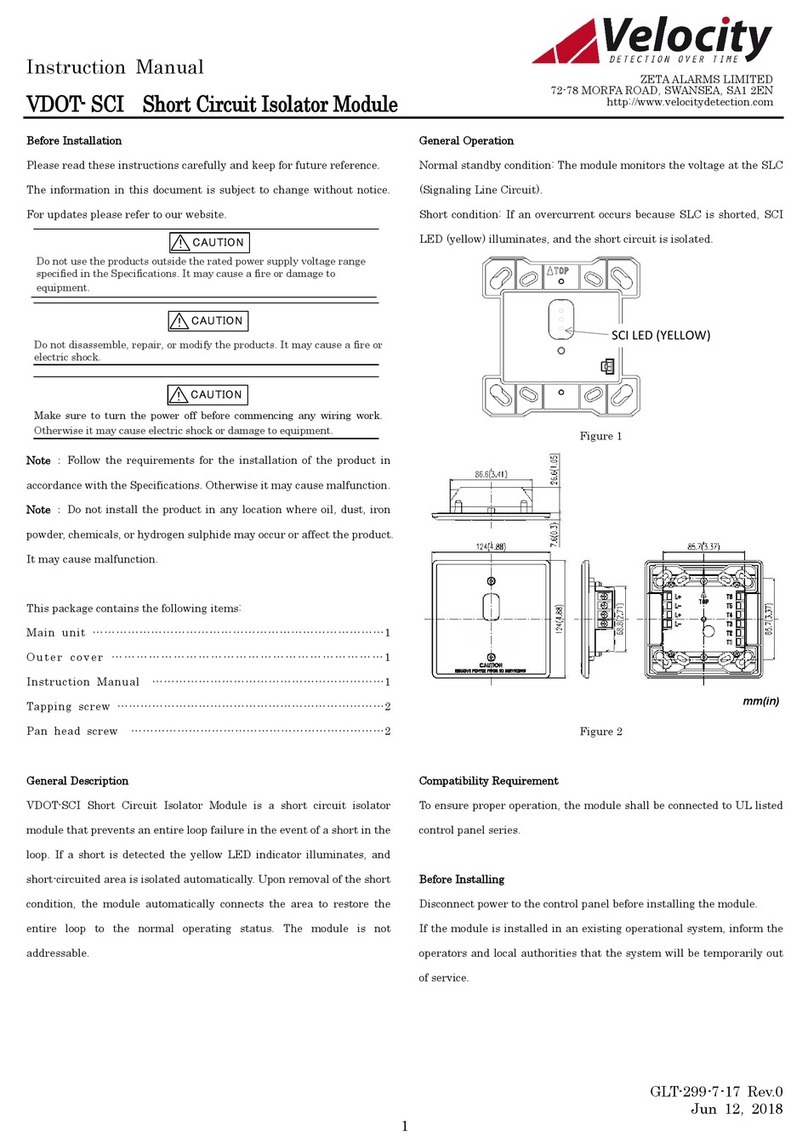

5) Short between terminal Lin+ (Lout+) and Lin- (Lout-), and the SCI

LED (yellow) is illuminated. The short circuit isolator isolates the

devices connected after the short-circuited area, which makes

these devices have no response. Upon removal of the short

condition, the area is automatically connected to go back to the

normal standby status, and the SCI LED (yellow) turns off.

FOR WARRANTY SERVICE, RETURN TO:

ZETA ALARMS LIMITED

72-78 MORFA ROAD, SWANSEA, SA1 2EN

http://www.zetaalarmsystems.com

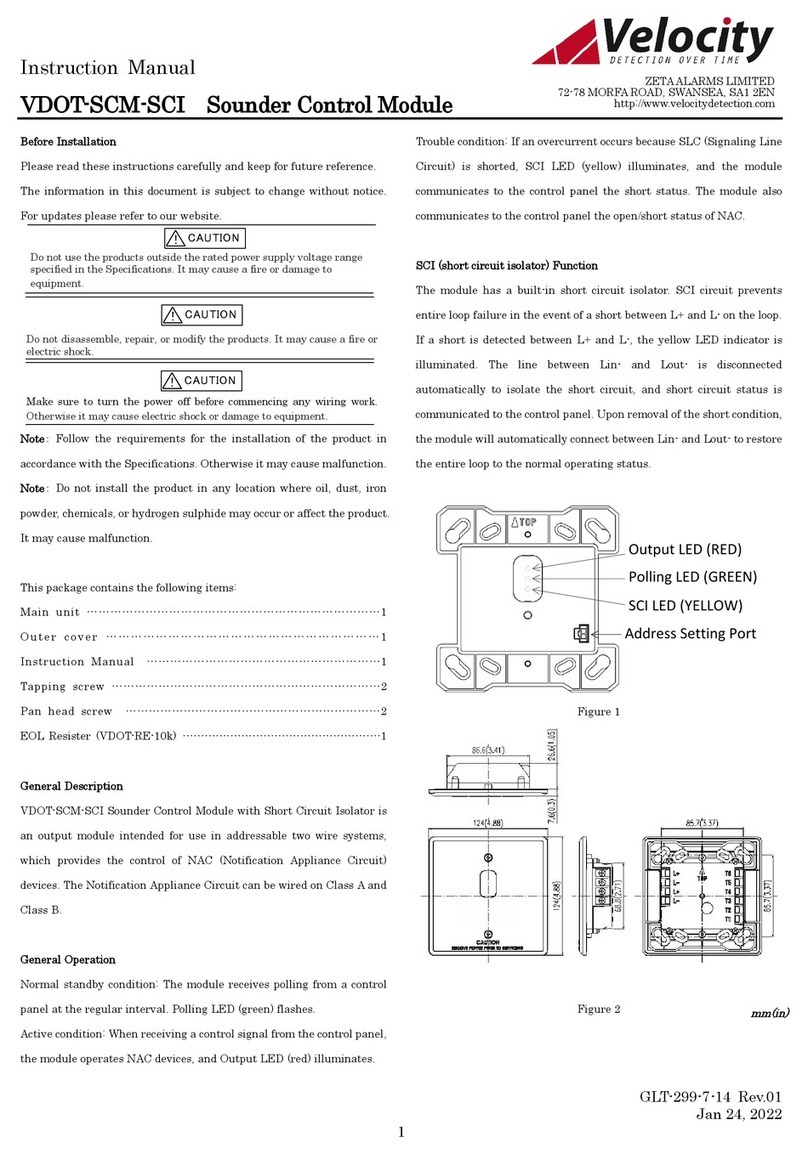

Specifications

SLC Applied Voltage Rated range 20 to 38VDC

SLC Current Consumption Standby 0.6mA

Activated 3.3mA (max)

SLC Line Impedance Up to 50 ohms

Relay (Programmable) Switching capacity AC250V/4.8A

SCI on Resistance 0.2 ohms (max)

Threshold

10V (min)

SCI Isolation Current 22mA (max)

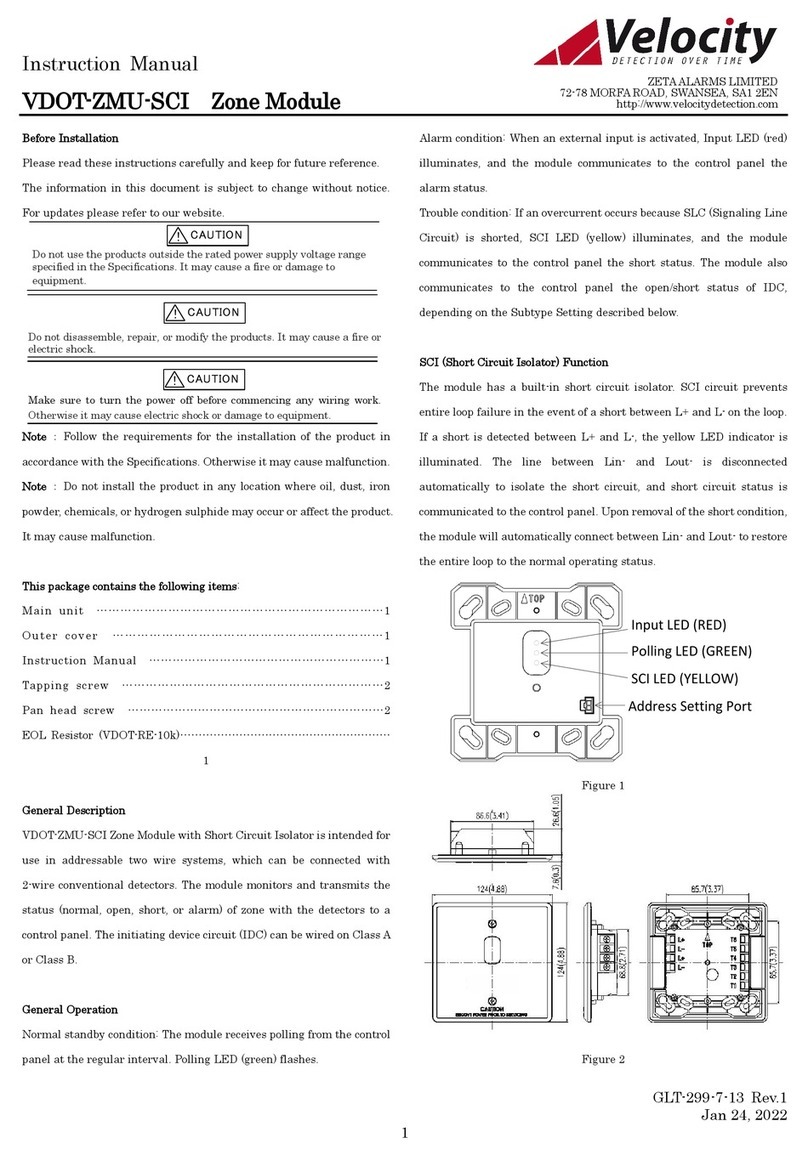

LED)

Polling LED (GREEN)

Output LED (RED)

SCI LED (YELLOW)

Ambient Installation

Temperature

0℃to 49℃(32°F to 120°F)

Storage Temperature -20℃to 60℃(-4°F to 140°F)

Max Relative Humidity Up to 93%RH,non-condensing

Environment Indoor dry use only

Max. quantity per loop 127 units

Terminal Screw AWG12 to 22

Address Setting VDOT-AD2 Address Programmer

Dimensions 124mm H x 124mm W x 34.5mm D

(4.882’’ H x 4.882’’ W x 1.358’’ D)

(4’’ square by 2⅛’’ deep)

Weight Approximately 172g (6.1oz)

Conformity UL864

Warranties

1.1 Zeta warrants to the customers that:

(a) all products supplied hereunder will be of merchantable quality

and will comply with any specification agreed between Zeta and

customer.

(b) it is not aware of any rights of any third party in the market which

would or might render the sale of the products, or the use of any of

the trade marks on or in products, or the use of any of the trade

marks on or in relation to the products, unlawful.

1.2 In the event of any breach of the Zeta’s warranty in Clause 1.1(a)

whether by reason of defective materials, production faults or

otherwise, Zeta’s liability shall be limited to:

(a) replacement of the products in question; or

(b) at the Zeta’s option, repayment of the price where this had been paid.

And the warranty period is three (3) years from the shipment from

Zeta’s factory.

1.3 Notwithstanding anything to the contrary in this warranty terms,

Zeta shall not be liable to the customer by reason of any

representation or implied warranty, condition or other term or any

duty at common law, or under the express terms of this warranty

terms, for any consequential loss or damage whether for loss of

profit or otherwise and whether occasioned by the negligence of Zeta

or its employees or agents or otherwise, arising out of or in

connection with any act or omission of Zeta relating to Zeta or

supply of the products, their use by any customer.

1.4 Customer shall indemnify Zeta against all loss, damages, liabilities,

costs and expenses which Zeta may suffer or incur as a result of or

in connection with any breach by customer of this warranties terms

or any laws or regulations of any jurisdiction or any rules of any

governing authorities.