GLT-299-7-17 R ev.1

Jan 24, 2022

1

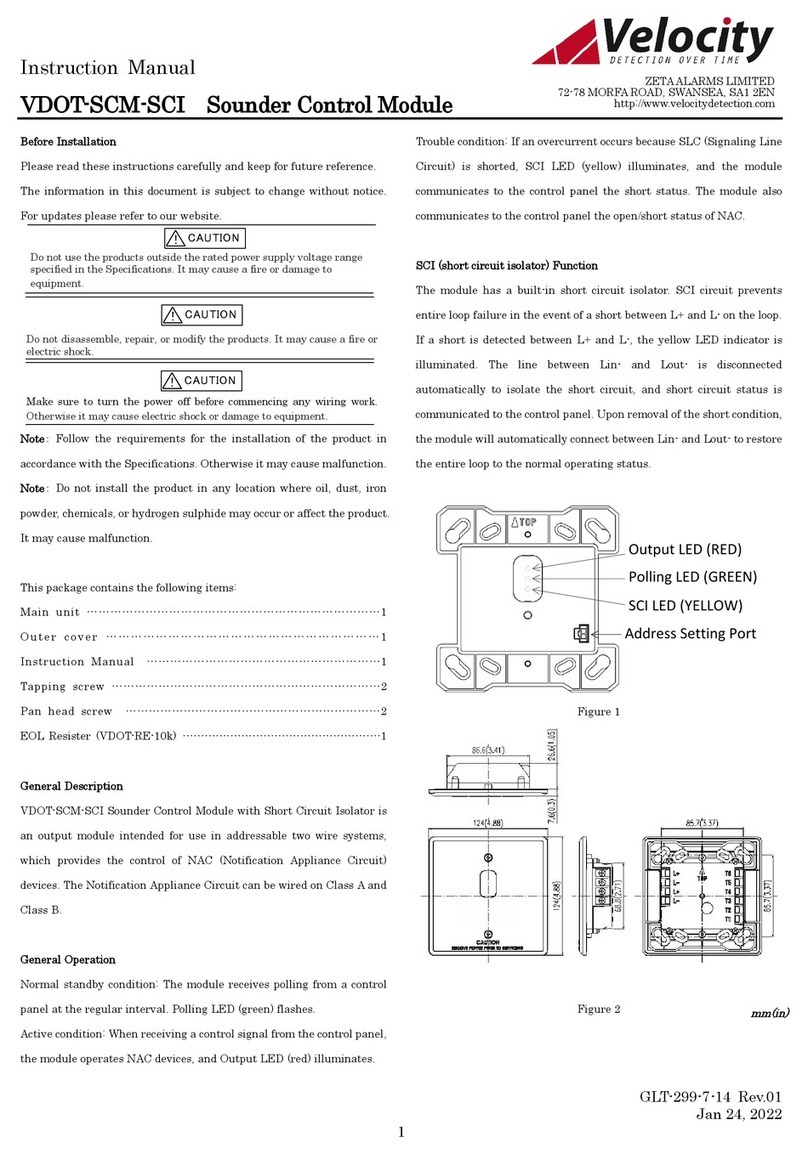

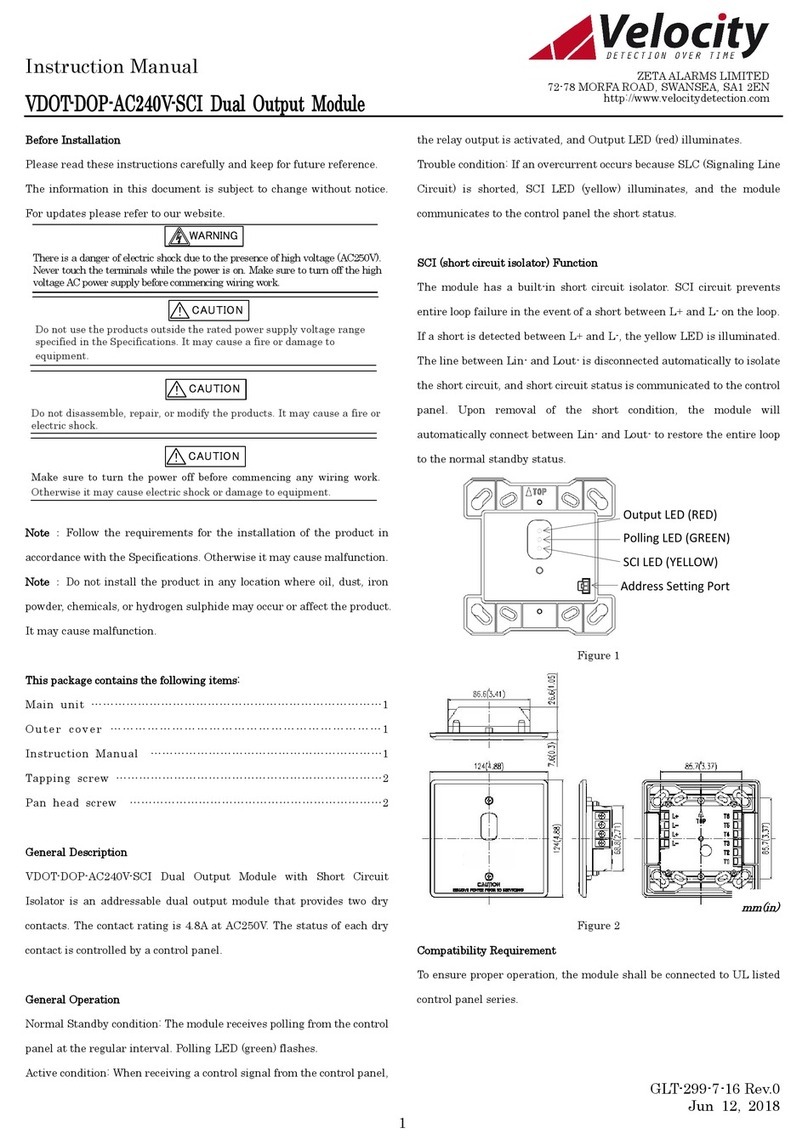

ADDRESS SETTING PORT

Instruction Manual

VDOT-Mini IP Mini Input Module

Before Installation

Please read these instructions carefully and keep for future reference.

The information in this document is subject to change without notice.

For updates please refer to our website.

Note:Follow the requirements for the installation of the product in

accordance with the Specifications. Otherwise it may cause damage to

equipment.

Note:Do not install the product in any location where oil, dust, iron

powder, chemicals, or hydrogen sulphide may occur or affect the product.

It may cause damage to equipment.

This package contains the following items:

Main unit……………………………………………………………………1

Instruction Manual ………………………………………………………1

EOL Resistor (VDOT-RE-10k)………………………………………………1

Sealing label…………………………………………………………………1

General Description

VDOT-MiniIP Mini Input Module is intended for use in addressable two

wire systems. The module monitors and transmits the status (normal,

open, short, or active) of devices equipped with NC/NO dry contacts to a

control panel. The initiating device circuit (IDC) can be wired on

Class B.

General Operation

Normal standby condition: The module receives polling from the control

panel at the regular interval.

Active condition: When the external input is activated, the module

communicates to the control panel the active status.

Trouble condition: The module communicates to the control panel the

open/short status of IDC, depending on the Subtype Setting described

below.

Figure 1

Compatibility Requirement

To ensure proper operation, the module shall be connected to UL listed

control panel series. Any conventional detector cannot be connected

with the module.

Before Installing

Disconnect power to the control panel before installing the module. If

the module is installed in an existing operational system, inform the

operators and local authorities that the system will be temporarily out

of service.

Mounting

Mount or place the module on the back or inside of monitored unit. Its

small size and light weight allow it to be installed without rigid

mounting.

Setting

・Address Setting

Use VDOT-AD2 Programmer for setting the address of the module prior

to installation. VDOT-MiniIP has an address given at random from

factory. Connect the Programmer with the address setting port to

change the address to any of 1-254 (dec), with reference to the

instruction manual of VDOT-AD2 Programmer. The address can be set

regardless of whether power supply from the control panel is turned on

or off. Refer to Figure 1.

72-78 MORFA, ROAD, SWANSEA, SA1 2EN

http://www.velocitydetection.com

Do not use the products outside the rated power supply voltage range

specified in the Specifications. It may cause a fire or damage to

equipment.

CAUTION

!

Do not disassemble, repair, or modify the products. It may cause a fire or

electric shock.

CAUTION

!

Make sure to turn the power off before commencing any wiring work.

Otherwise it may cause electric shock or damage to equipment.

CAUTION

!

mm(in)