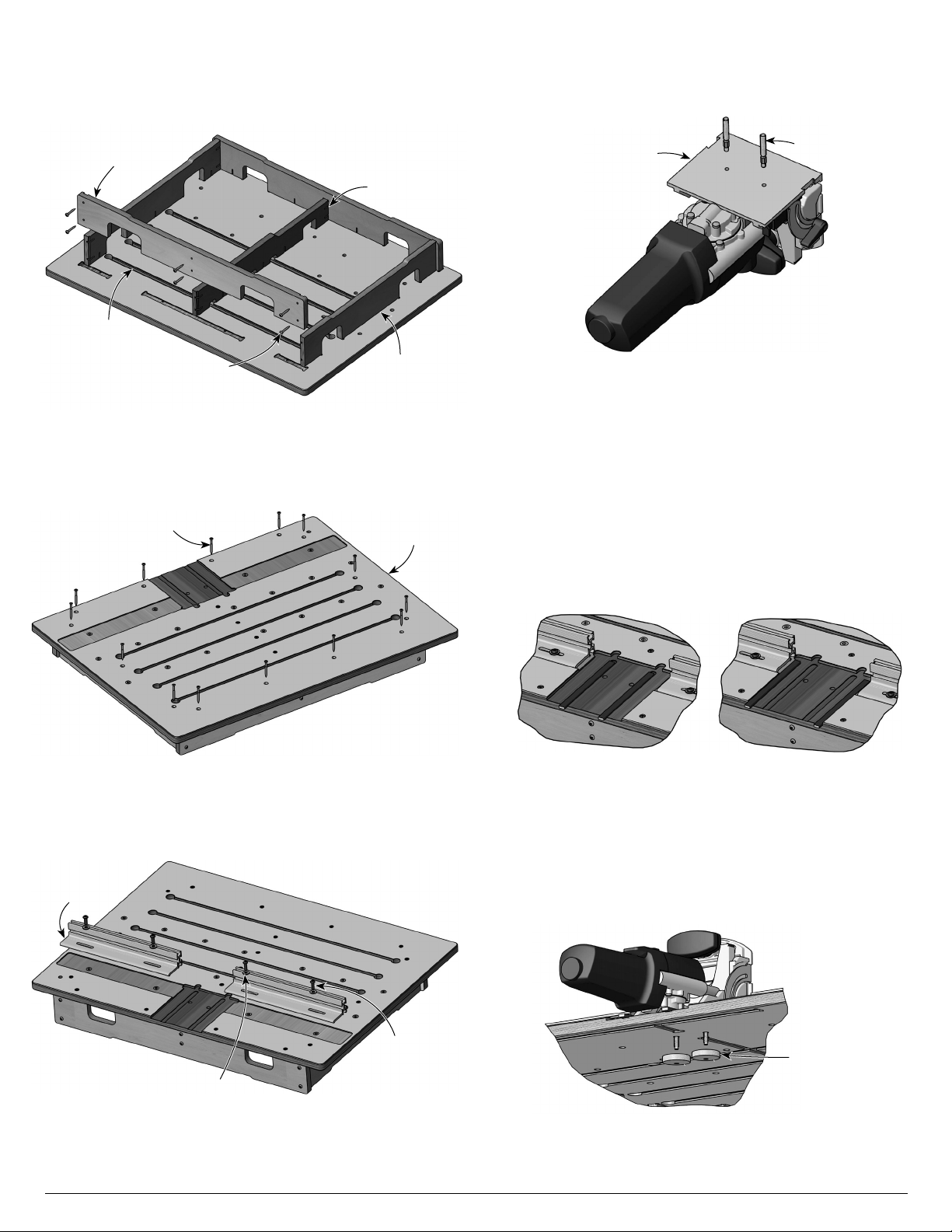

9. Lorsque la mortaise de gauche est fraisée sur les quatre

pièces, insérer la pige de réglage dans le guide coulissant et

appuyer son talon contre la butée rétractable la plus éloignée

sur la fraiseuse.

10. Bloquer le réglage de la pige, retirer celle-ci du guide

coulissant et la mettre de côté.

Remarque : L’avant de la fraiseuse Domino comporte plusieurs

éléments pouvant servir de point de référence pour les réglages.

Il est bon de toujours employer le même point de référence. Dans

cet exemple, le point de référence choisi est le côté intérieur de

la butée rétractable la plus éloignée.

11. Repositionner le guide coulissant du côté droit de la

fraiseuse et insérer la pige de réglage dans le trou du guide.

12. Faire glisser le guide jusqu’à ce que le talon de la pige

de réglage s’appuie contre le côté intérieur de la butée

rétractable la plus éloignée.

13. Veiller à ce que le guide coulissant s’appuie bien contre le

guide fixe. Serrer le guide coulissant en place avec les

poignées à 3 branches.

14. Retirer la pige de réglage.

15. Faire un test avec une pièce de rebut du cadre pour vérifier

la précision du réglage et pour s’assurer que les mortaises

correspondantes sont bien alignées.

16. Si tout convient, fraiser les mortaises droites des quatre pièces.

Dans le cas contraire, apporter les correctifs nécessaires.

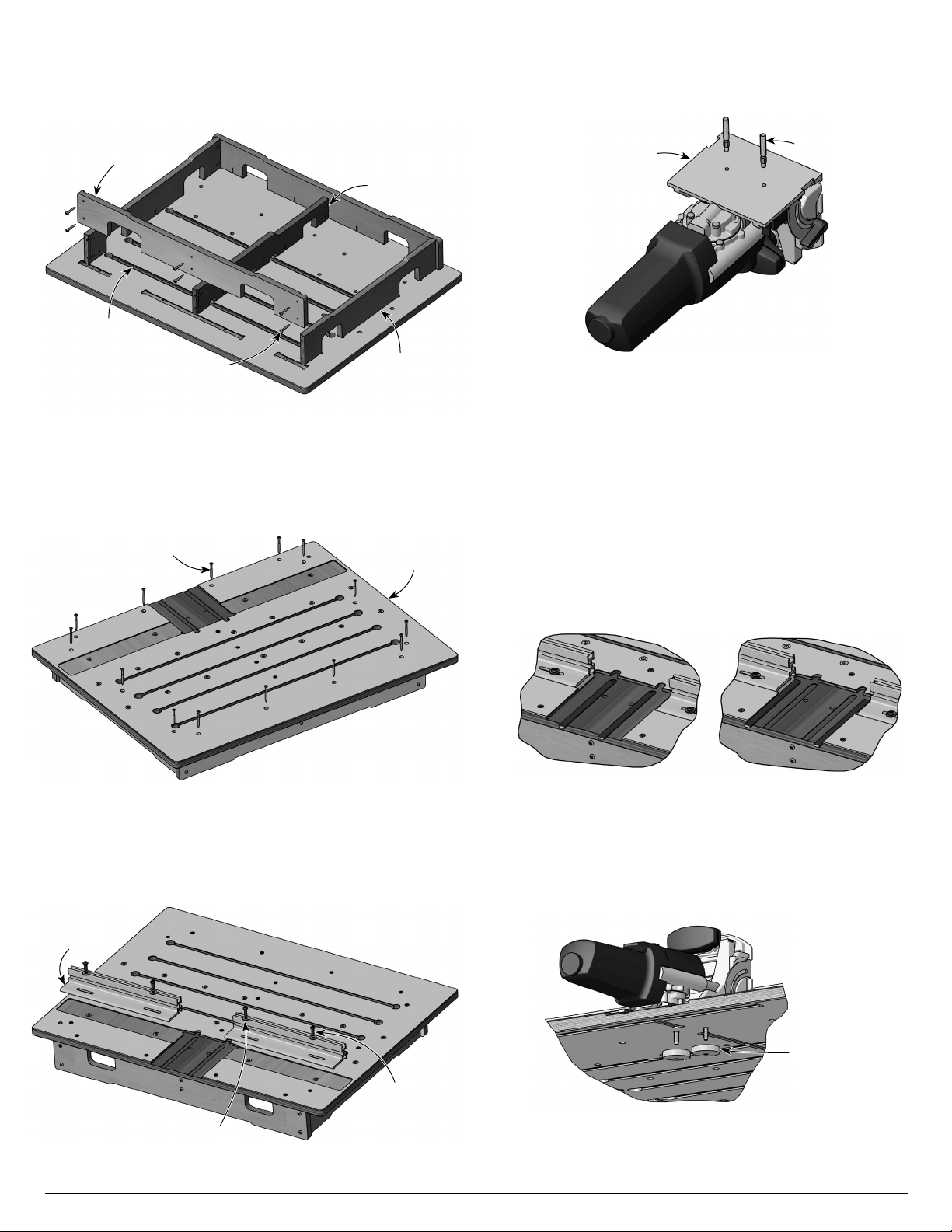

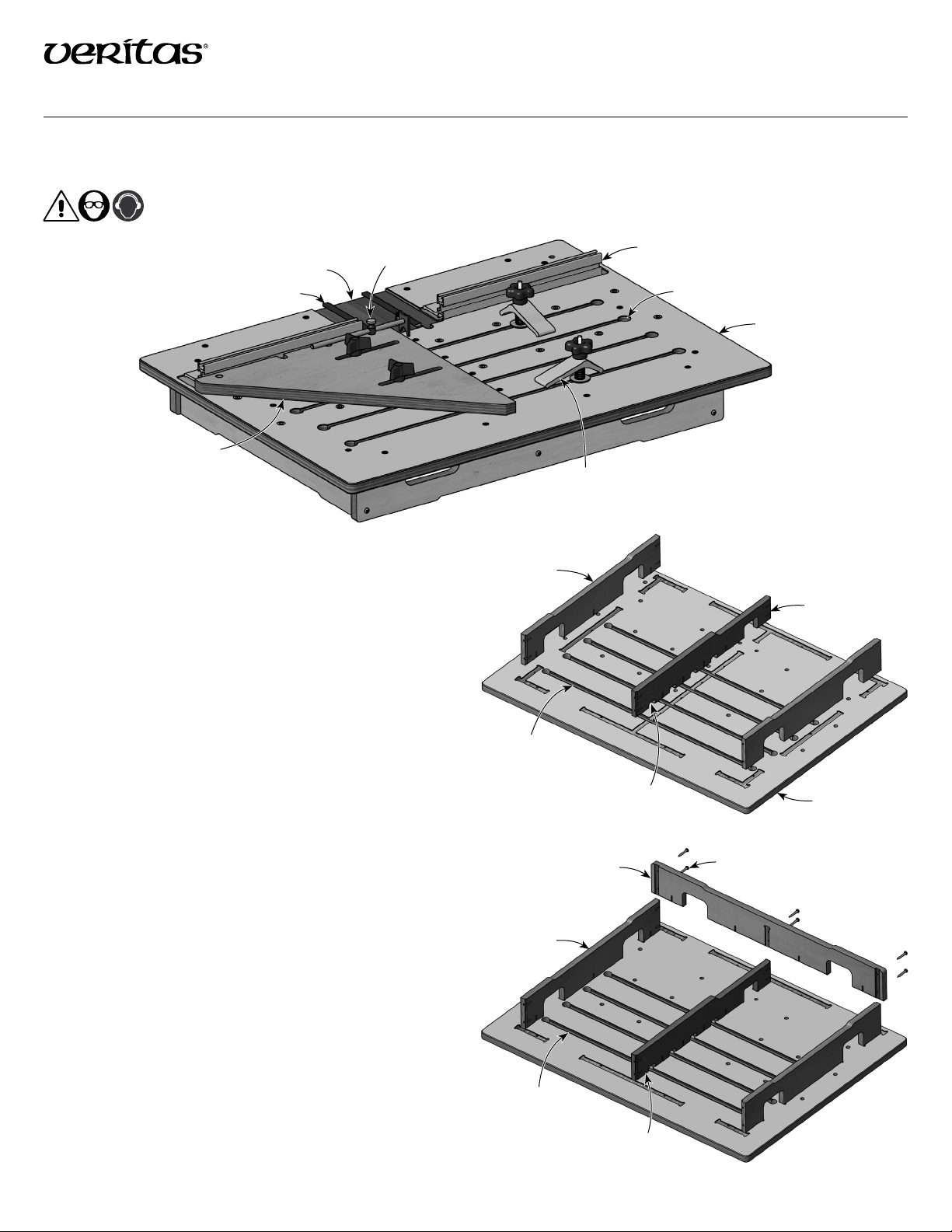

Fraisage d’un assemblage à angle droit

Assembler un cadre à angle droit requiert un peu plus d’attention,

car le marquage nécessite de bien distinguer le côté gauche du

côté droit d’une pièce.

Remarque : Dans tous les cas d’usinage mécanisé, il est bon

de disposer de pièces supplémentaires pour tester les réglages

initiaux. Cela est particulièrement important pour régler

l’installation avant d’usiner la seconde moitié des assemblages.

1. Couper toutes les pièces du cadre à la longueur voulue.

2. Placer les pièces pour former le cadre et marquer la position

des mortaises en plus d’indiquer le dessus et l’extérieur de

chaque pièce. Dans cet exemple, la position des mortaises

est marquée d’une double ligne chevauchant les joints et

parallèle à l’extérieur du cadre. De chaque côté de cette

double ligne, une ligne perpendiculaire indique le côté

extérieur du cadre.

3. Sur au moins un des joints, il faut marquer avec précision le

centre de la mortaise. Bien identifier cette marque de

référence, par exemple à l’aide d’une lettre R. Cette marque

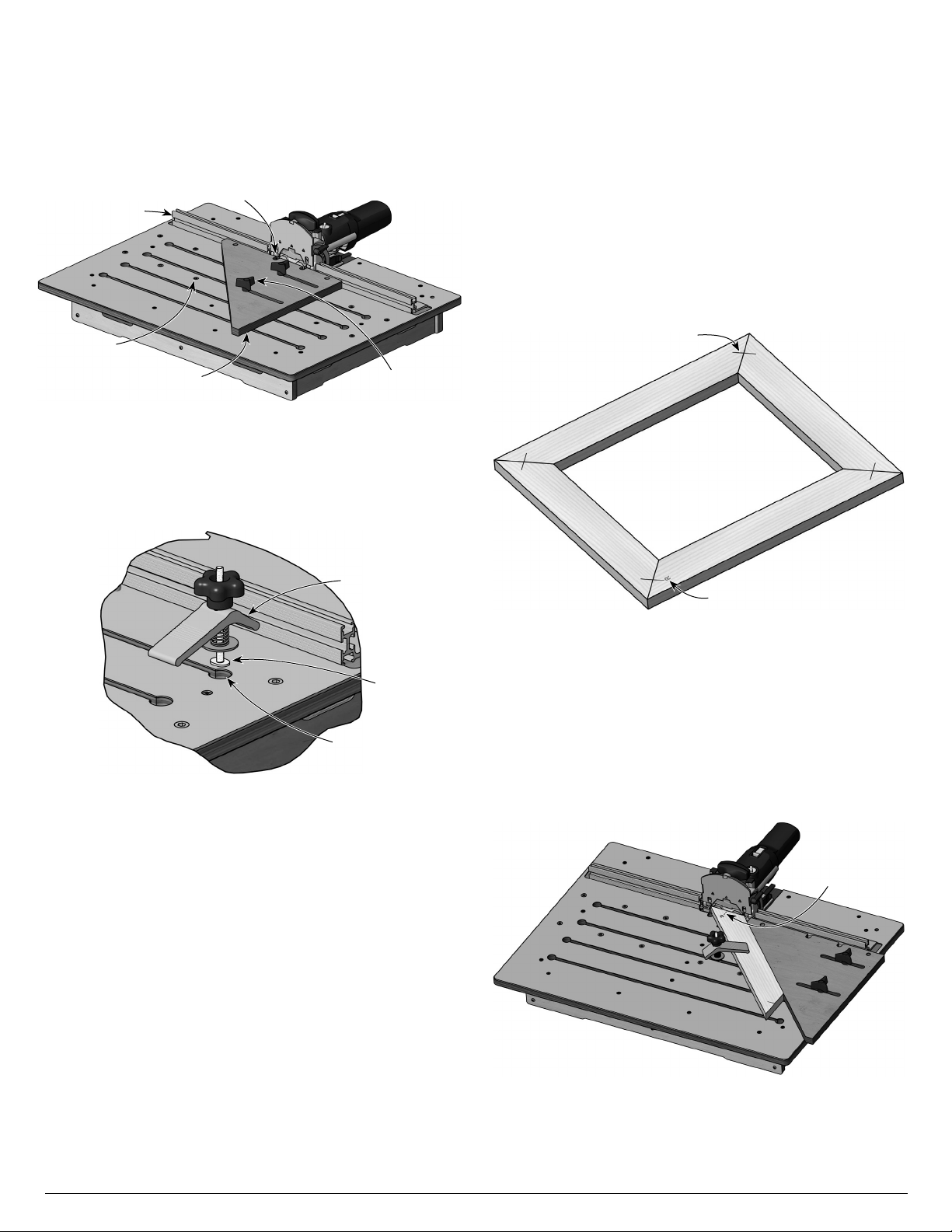

de référence servira au réglage de la table d’usinage.

4. Prendre la pièce spécifiquement marquée pour le réglage

initial et aligner la marque de référence avec le repère

central gravé sur la fraiseuse.

5. Bien appuyer la pièce contre le guide fixe et l’immobiliser

avec au moins une serre de retenue.

6. Appuyer le guide coulissant contre le bout de la pièce

marqué comme étant l’extérieur du cadre, en veillant aussi à

bien l’appuyer contre le guide fixe. Immobiliser le guide

coulissant en serrant les poignées à 3 branches.

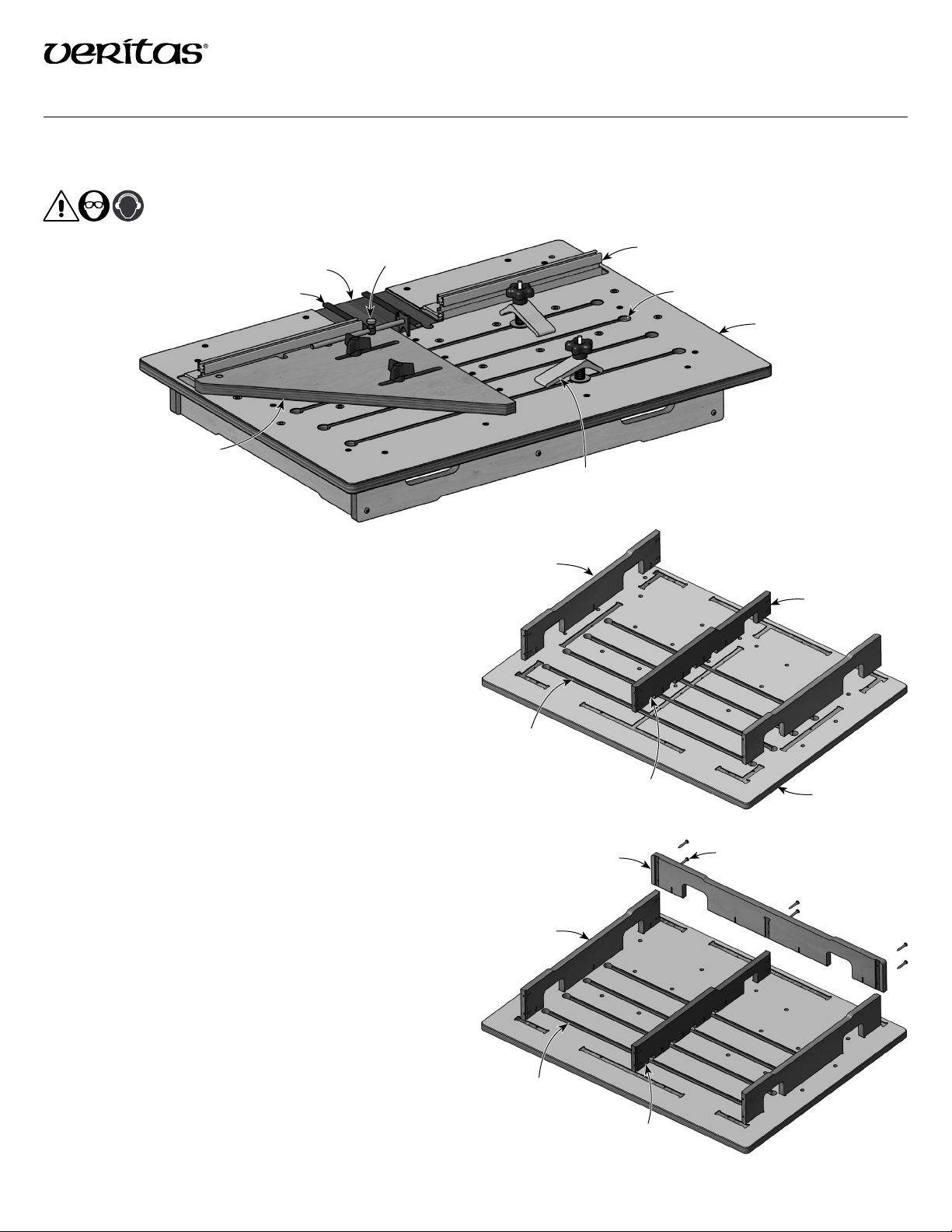

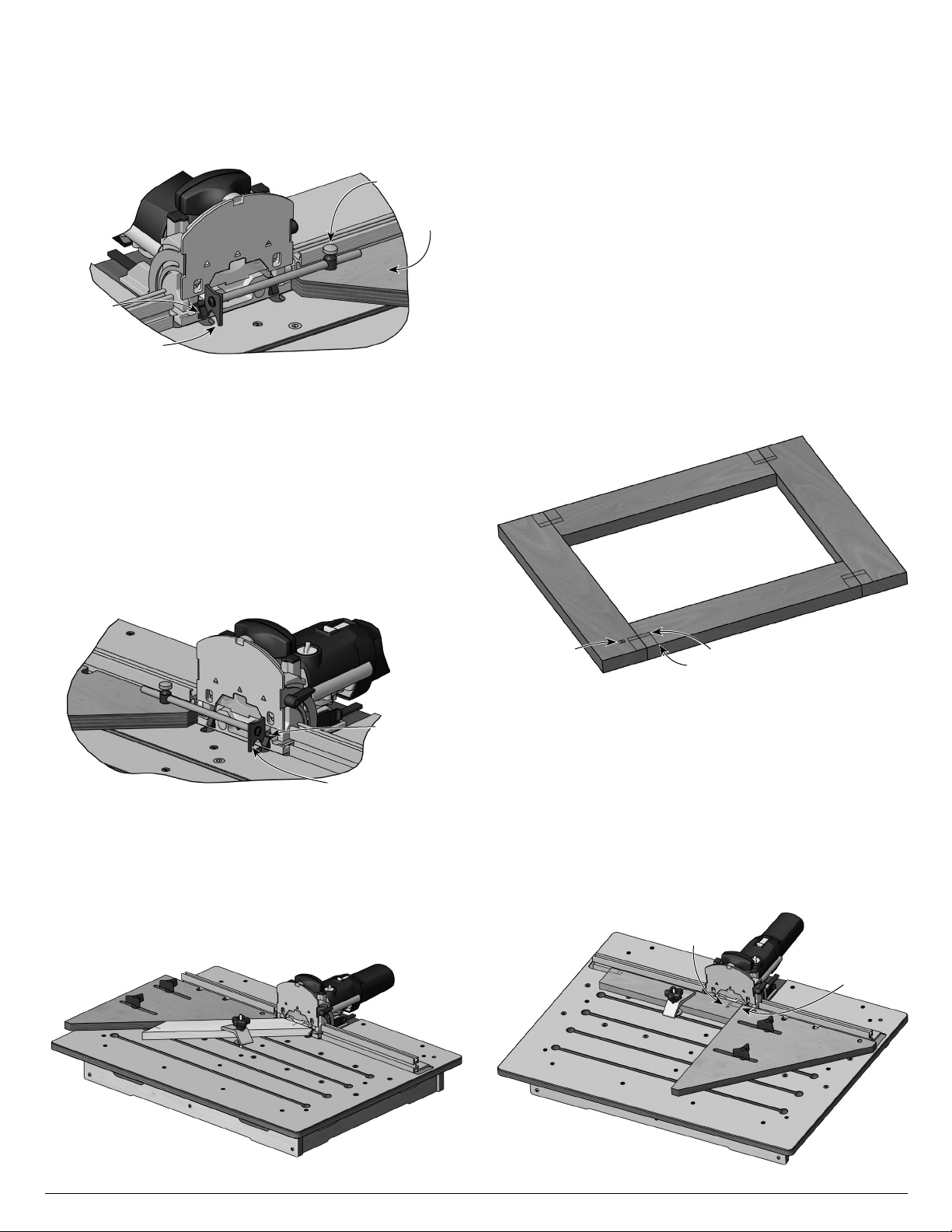

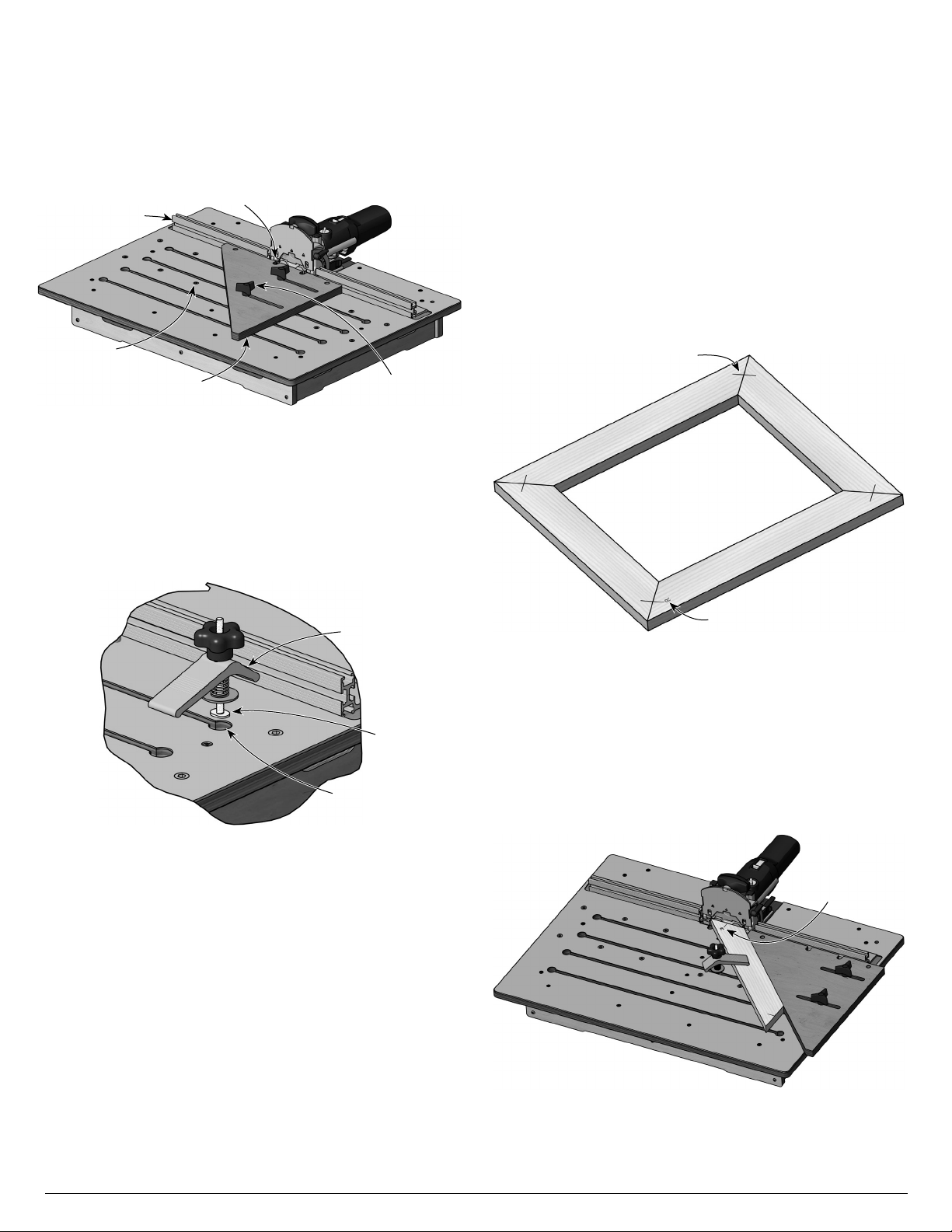

Figure 16 : Fraisage des mortaises opposées

Figure 14 : Ajustement de la pige de réglage

Butée

rétractable

Pige de

réglage

Talon

Guide

coulissant

Figure 15 : Ajustement de la position inversée du guide coulissant

avec la pige de réglage

Butée

rétractable la

plus éloignée

Talon

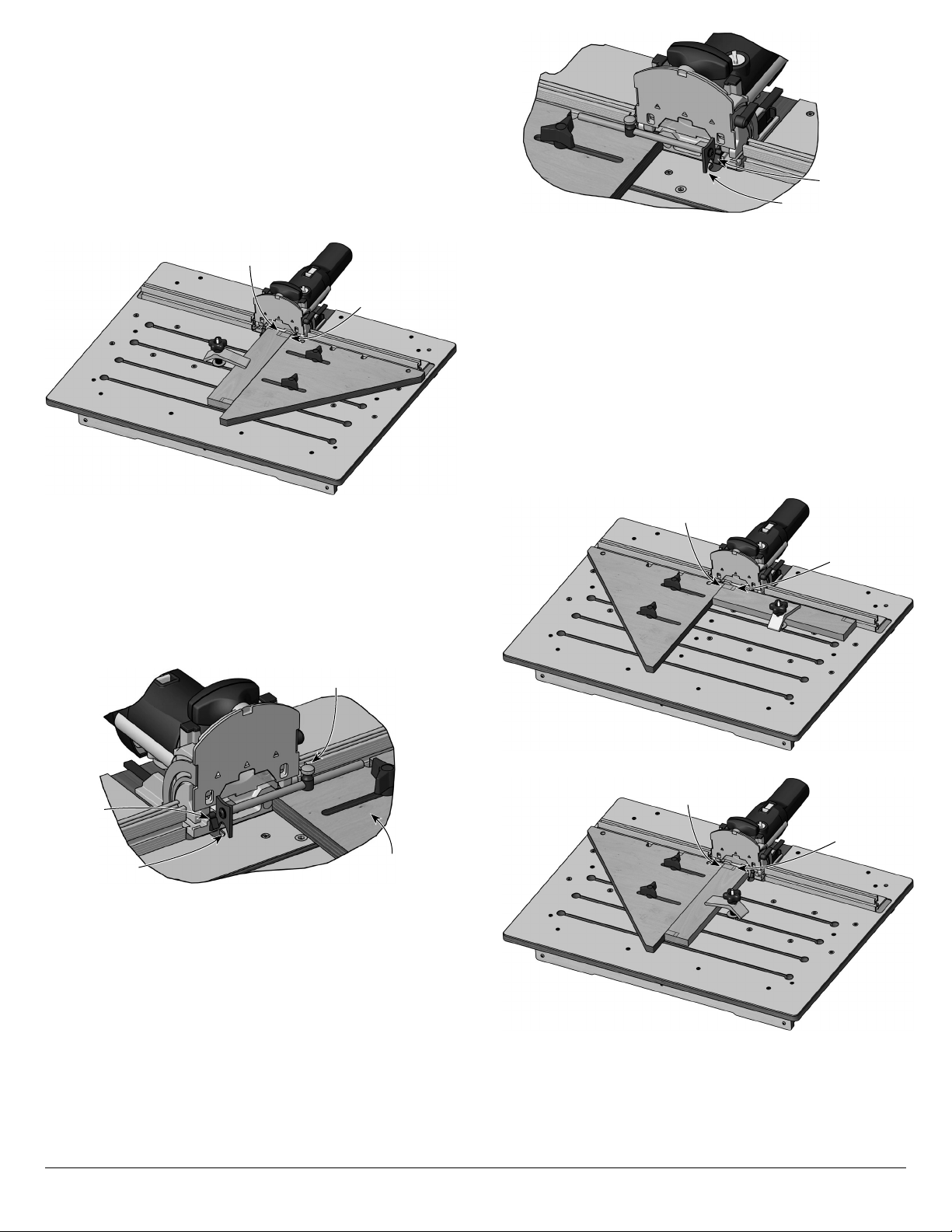

Figure 17 : Cadre assemblé à angle droit avec l’emplacement

des mortaises marqué d’une ligne double et l’extérieur du cadre

marqué d’une ligne simple

Marque de

référence Marque de mortaise

Marque du côté extérieur

Figure 18 : Fraisage de la première mortaise sur chant

Marque de

référence Marque extérieure

contre le guide

coulissant

4