6

Alternatively, you can sharpen the blade held at a 30° angle against a belt sander (fitted with

a 180x belt for rough sharpening, progressing to 15µ or finer for finishing). Do not hold the

blade in contact with the belt for extended periods of time (more than few seconds) or you may

overheat the blade. Use indelible marker as described above to ensure that the entire bevel has

been sharpened and remains square to the side edge of the blade.

Remove the blade from the holder. To remove the wire burr from the edge of the blade, draw the

face across a fine grit (1000x or higher) sharpening stone or a piece of silicon carbide abrasive

paper on a flat surface.

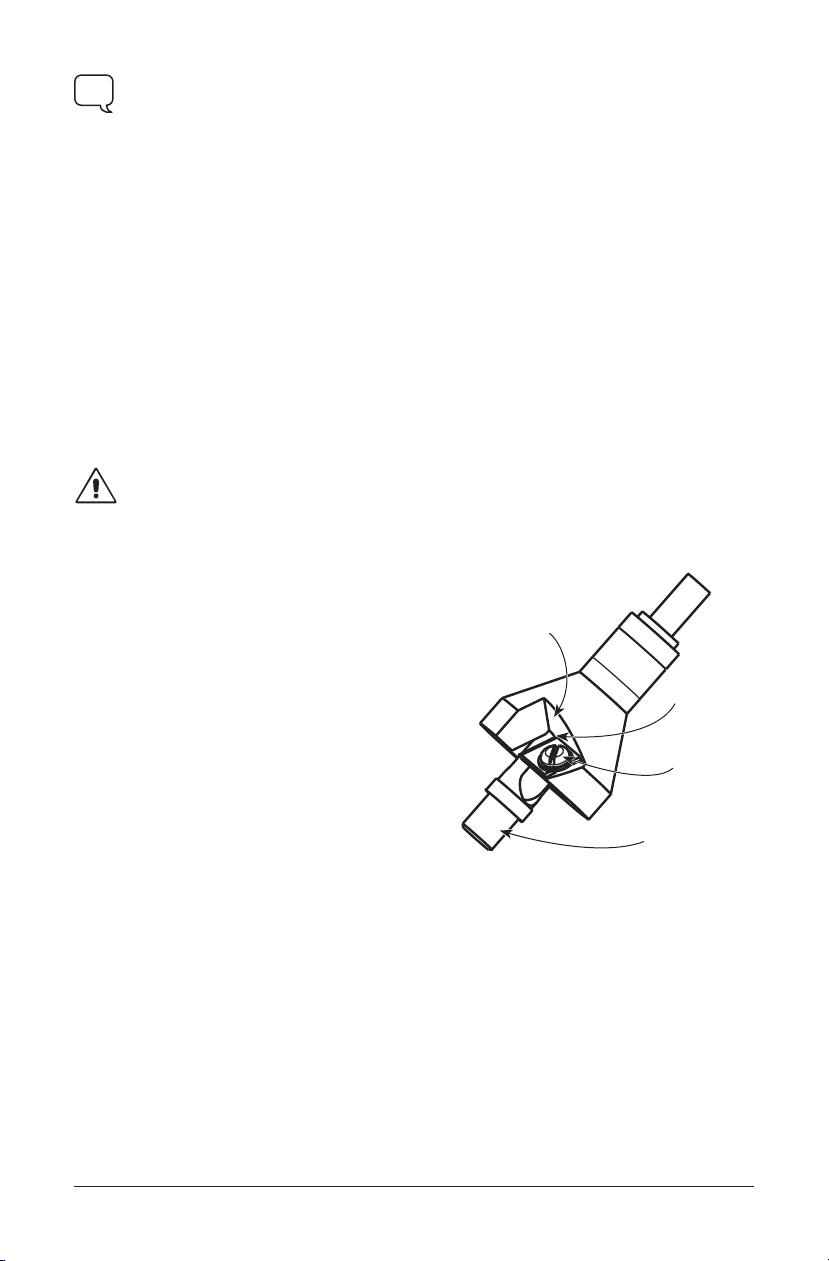

The right-hand corner of the blade determines the final tenon diameter. To increase its longevity

between sharpenings, you may wish to “break” this corner very slightly. Just draw it against a

4000x stone or 5µ abrasive paper with one or two passes.

Troubleshooting

Uneven tenons: This is usually caused by one of two things:

1. An unsteady drill position while cutting. Reduce your drill speed and concentrate on

holding the drill steady while cutting.

2. Growth ring structure. If the corner of the blade is cutting tangential to a very consistent

diameter growth ring, the blade may peel that layer, much the same way veneer is cut from

a log. This will result in uneven or undersized tenons. An extremely sharp blade is just

about the only preventive measure.

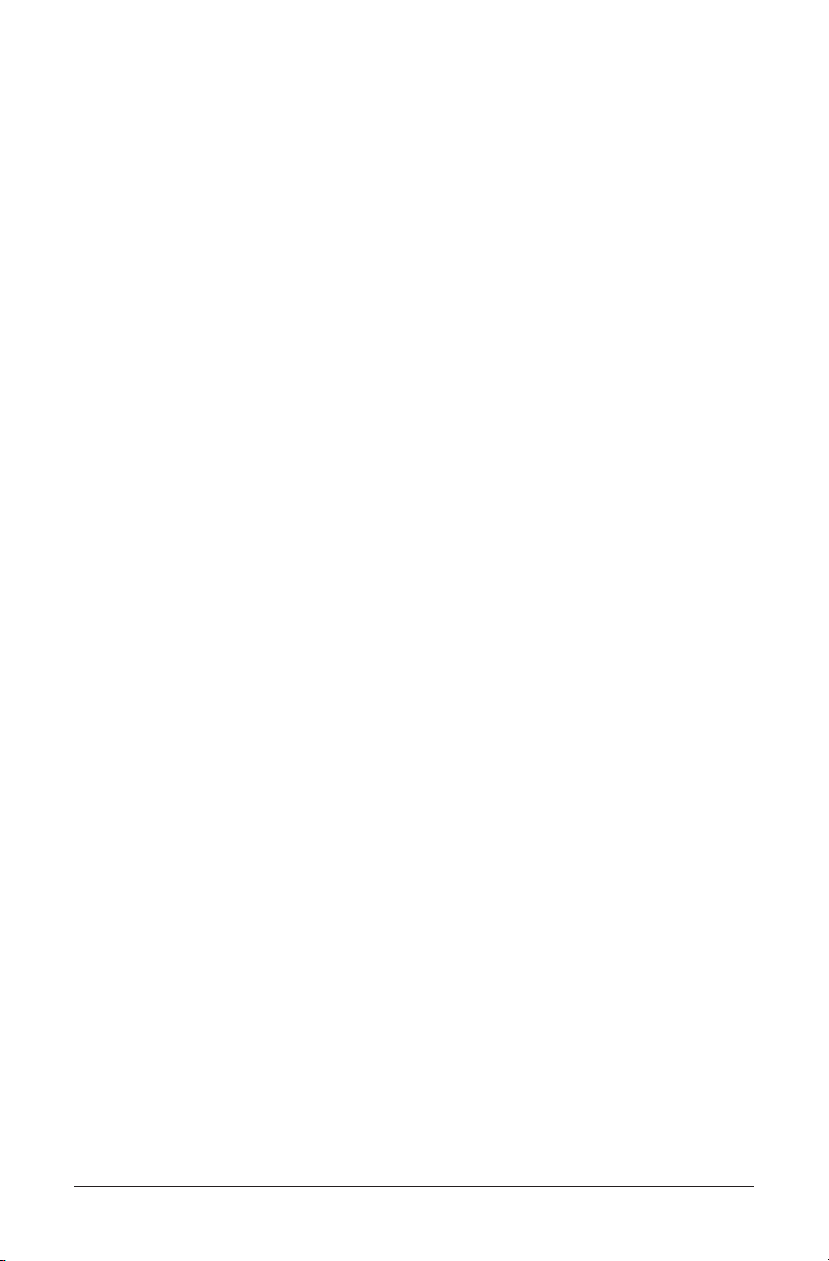

Undersized tenons: They usually indicate a blade that has been advanced too far. This is most

often caused by loosening the blade clamping screw too much, which allows the blade to ride

up on the plug gauge and bend slightly once tightened against the gauge. When the gauge is

removed the blade will drop to its unstressed position and produce undersized tenons. Readjust

the blade.

Oversized tenons: These usually arise when cutting green wood, where some compression

takes place. When the tenon cutter is removed, the tenon will spring back to an oversize

condition. Adjust the blade using the gauge as you normally would, but then back off the blade

clamping screw just enough to tap the blade in a bit further, then retighten. Note that you can

use this sprung oversize tenon to your advantage, as it will shrink as it dries.

Scalloped tenons: Applying excessive force while cutting the tenon can result in the cutter

advancing at a rate fast enough to make the tenon look like a coarse thread. Reduce the inward

force applied to the drill.

Continuing to rotate the tenon cutter clockwise while withdrawing it from the tenon can also

cause the blade to cut on its return pass, leaving similar scallops. This is especially so on green

wood, where some compression may have taken place as the tenon was being cut. Instead, pull

the tenon cutter off the tenon with the drill switched off, either without rotating it, or by slowly

rotating it counterclockwise.

Off-center tenons: Nothing can be done about the most common cause of off-center tenons –

natural variations in wood density and growth patterns.

Partial tenons: If the tenon cutter starts cutting, then fades and eventually stops cutting,

this indicates that a minor blade adjustment is required. Swivel the blade to produce a

thicker shaving.

Uneven grind when sharpening: This usually happens when the blade bevel is not held

parallel to the belt or stone. Adjust the jig until the bevel is parallel to the belt or stone.