13. Never carry portable tools by the cord.

14. Use the right tool. Do not force a

small tool or attachment to do the job

of a heavy-duty tool.

15. Do not force tool. It will do the job

better and safer at the rate for which

it was designed.

16. Do not use damaged tools. A damaged

tool that does not operate correctly is

a safety hazard and should be fixed

before any further use.

17. Repairs and service should be

performed by a certified technician.

Use only identical replacement parts.

18. Do not alter or misuse the tool. Stop

any operation immediately if you

notice anything abnormal.

19. Practice proper maintenance. Keep all

tools sharp, clean and well lubricated

for the best and safest results. Sharp

blades minimize stalling, kickback,

and burning. They perform faster,

better and safer than dull blades.

20. Keep hands away from moving

parts until they have come to a

complete stop and the power has been

disconnected.

21. Always disconnect the tool from the

power source when changing cutters

or blades, or when performing any

general maintenance activities (such

as adjusting or cleaning).

22. Handle blades with care.

23. Unless otherwise specified, always

insert the shank as far as possible into

the chuck in order to provide proper

support. Tighten the chuck securely.

24. Remove all nails from a workpiece

before performing any operation on it.

25. Hold workpiece firmly in a vise or clamp.

26. Ensure that depth and any other

adjustments are tight.

27. Remove adjusting keys and wrenches

before use.

28. Maintain good balance.

29. Do not remove workpiece or cut-off

pieces from tool during a cut while

the cutter is moving.

30. Do not leave tool until it comes to a

complete stop.

31. When not in use, power tools should

be stored in a dry area, elevated and

locked so that they are out of the

reach of children.

3

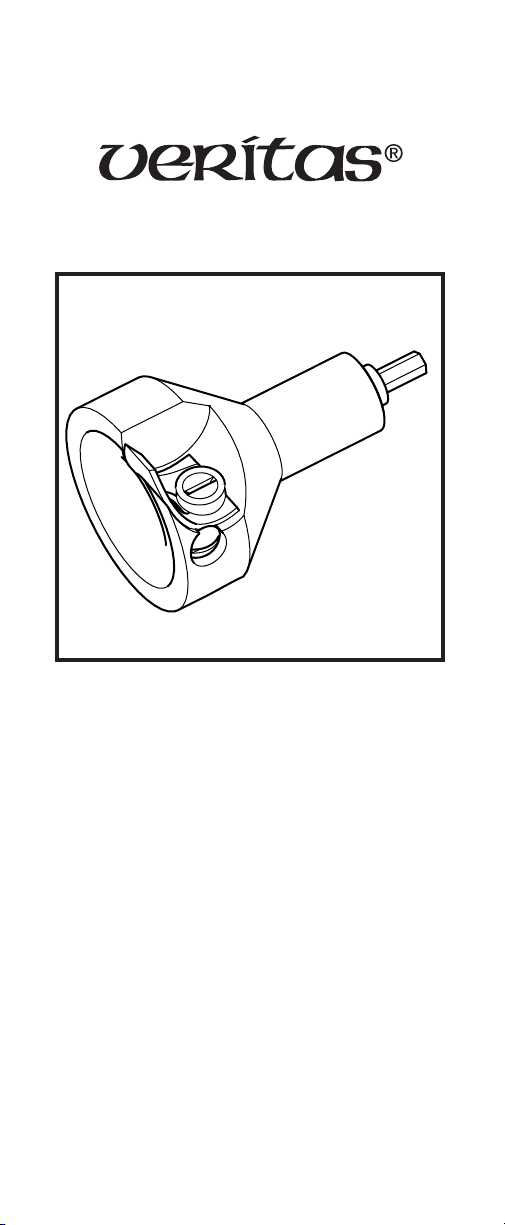

The Veritas®Power Tenon Cutters make

round tenon cutting for rustic furniture quick,

accurate and easy. Each has been balanced to

minimize vibration while being driven with

an electric drill, and an integral level vial

helps you keep the tenon cutter level. The

blade is adjustable to cut the exact size of

tenon required. It is easy to sharpen the blade

with the integral sharpening jig that holds the

blade at the optimum angle.

Veritas®Tenon Cutters are for use in a hand

electric drill. They are not to be used in a drill

press for several reasons.

1) Because the workpiece must be rigidly

clamped in line with the equally rigid

axis of the drill-press chuck, any

misalignment or movement can create

high side loads on the tenon cutter,

leading to the shank failing. Any quill

run-out in the drill press contributes

further to the problem.

2) Because there is much less feel as to how

the cutter is performing when using a

drill press, it is possible to overload the

tenon cutter without realizing it. This too

can lead to the shank failing.

3) Overloading the tenon cutter or operating

it at high speeds can also lead to

overheating the high-carbon steel blade,

resulting in edge failure, loss of hardness,

and a useless blade.

Taking a Test Cut

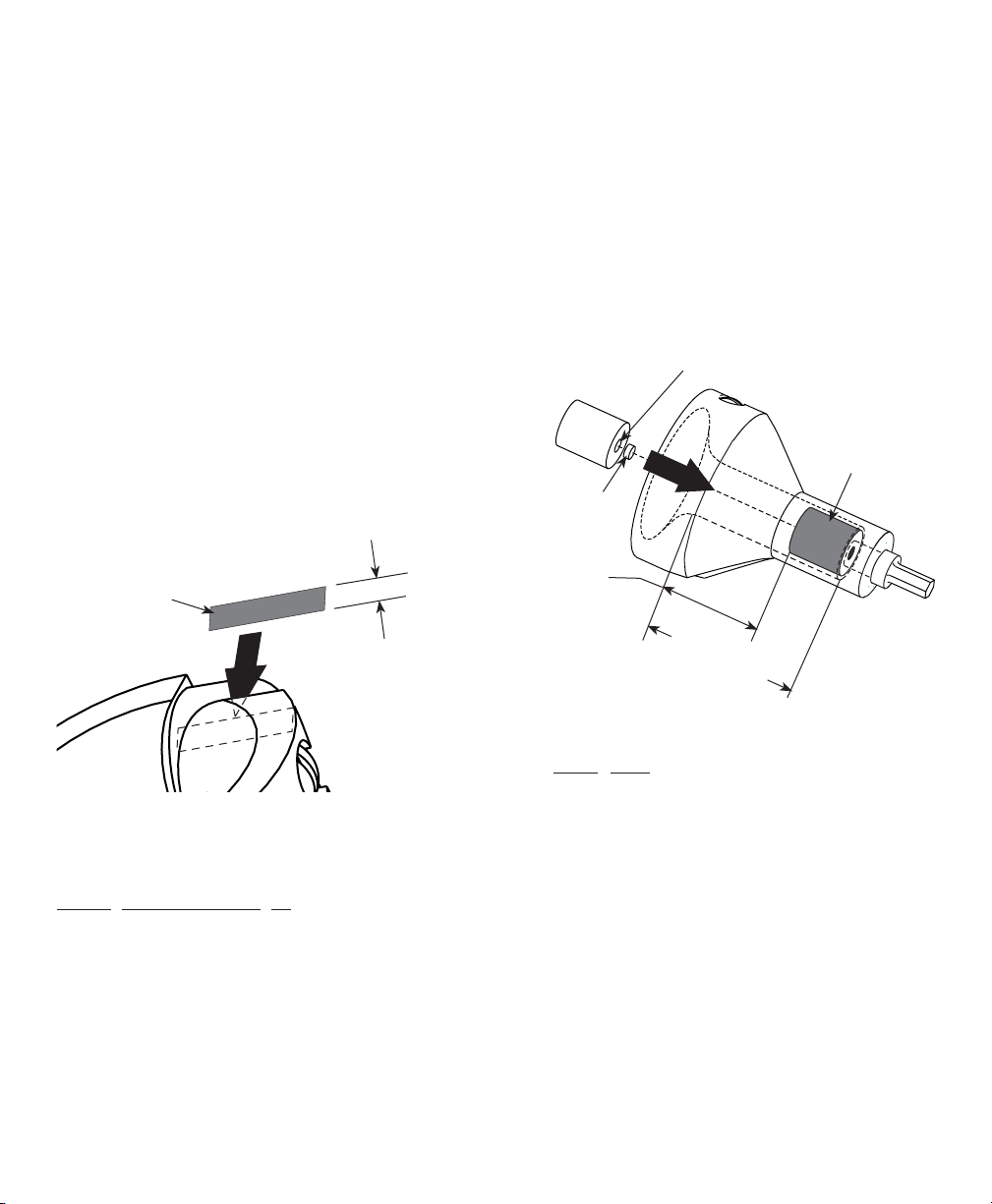

Firmly tighten the tenon cutter in the chuck

of an electric drill. For the large-size tenon

cutters (11/4"to 2"dia.) a minimum 1/2"

chuck is required, and a high-torque, low-

speed (~500 rpm) drill is recommended.

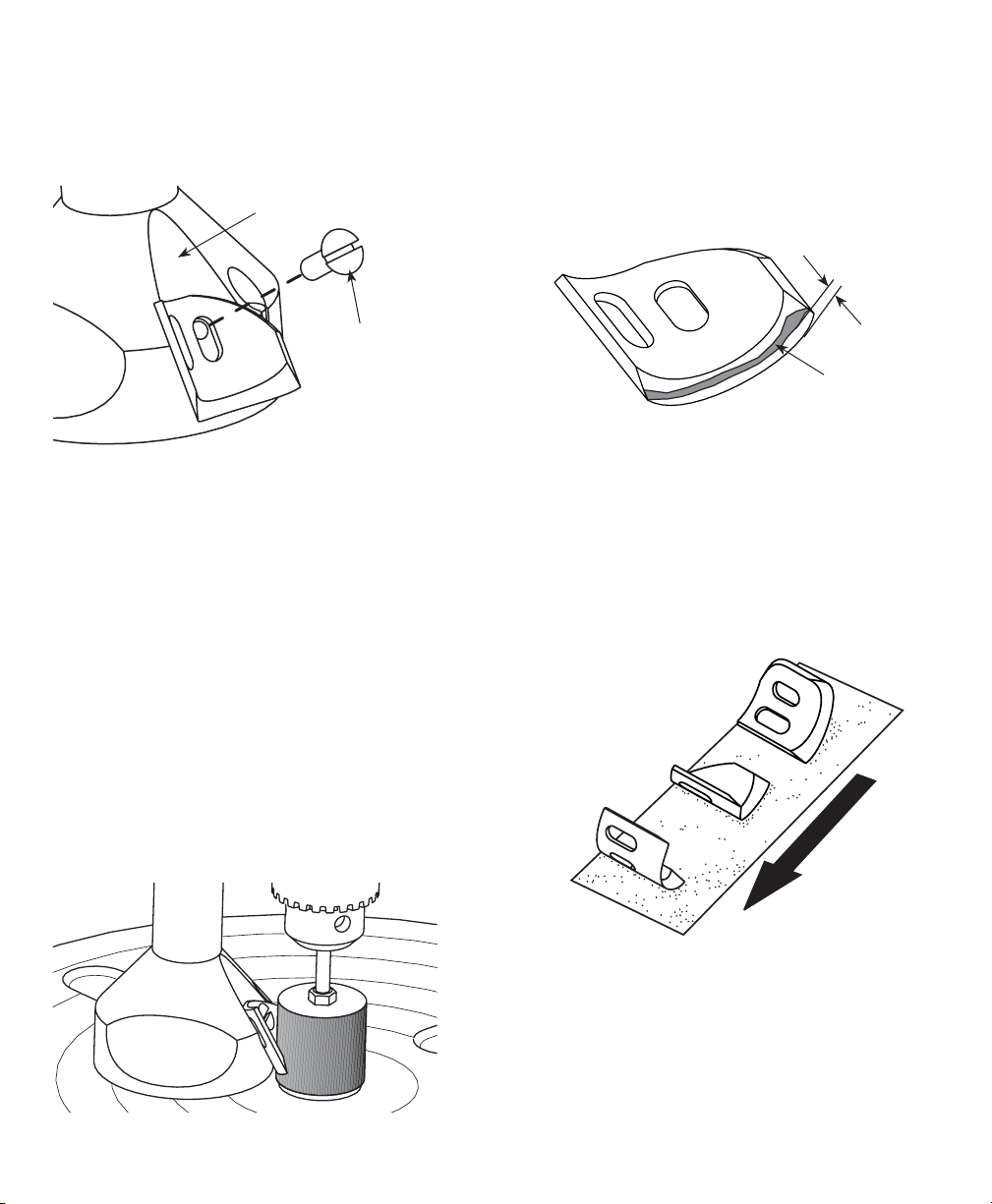

Clamp a piece of wood horizontally in a vise

at about waist height. Use a piece no larger

than the diameter specified in Table 1 for the

tenon cutter to be used. Ensure the end is cut

square. Putting a substantial chamfer on the

end of a piece of wood that is at or close to the

upper limit of the tenon cutter’s capacity will

make starting the cut much easier.

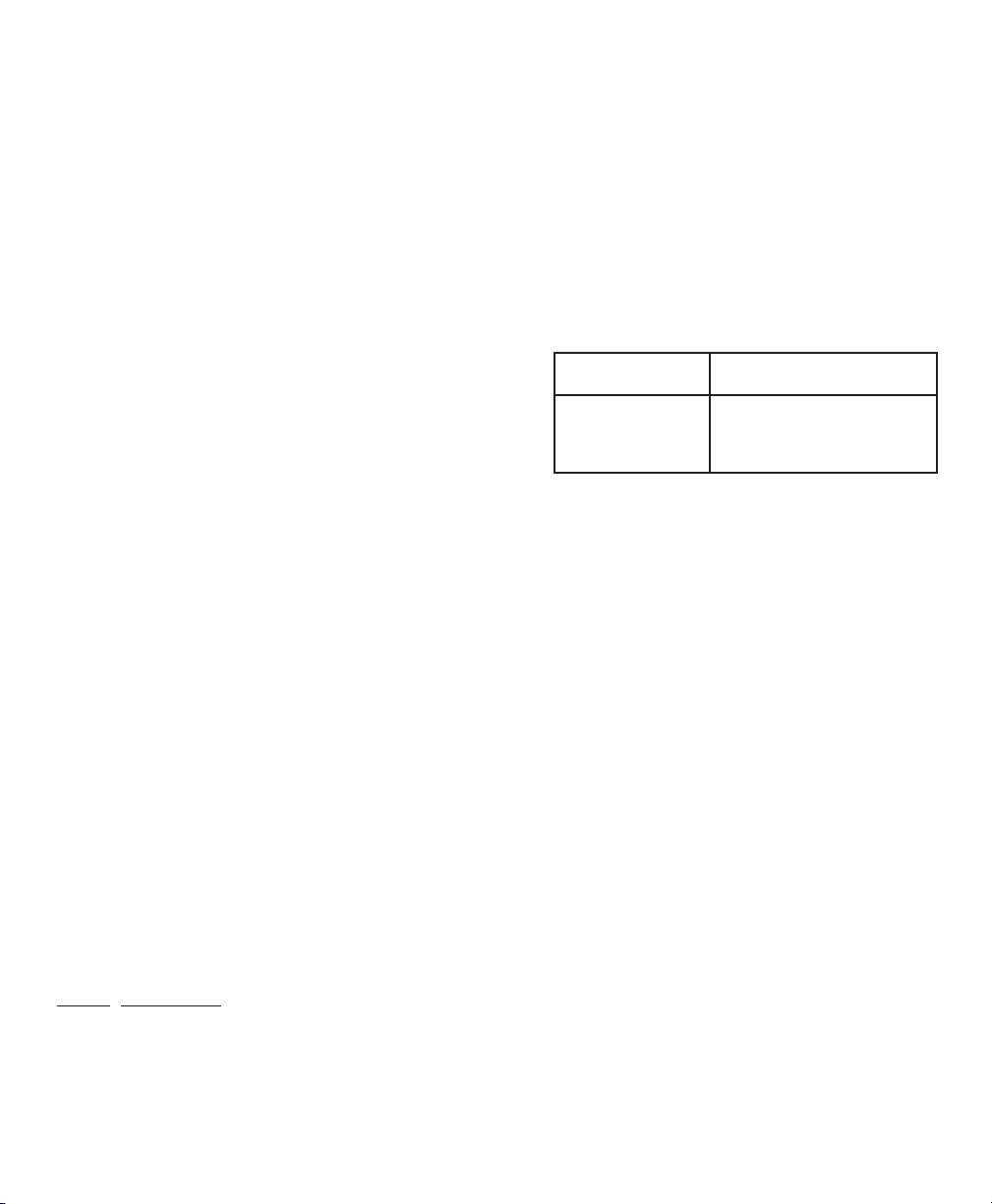

Table 1: Maximum Wood Diameter for Tenon

Cutter Diameter.

Hint: If you do not have a vise, you

can improvise with a piece of 2×4 with

various sizes of V-shaped notches cut in

it and two C-clamps. Place the piece of

wood in a notch slightly smaller than its

diameter, and clamp the 2×4 to a bench or

any large stable surface.

Place the tenon cutter on the end of the piece

of wood and rotate the tenon cutter by hand

until the level vial is at the top. Raise or lower

the drill until the bubble is centered in the

vial. Adjust the drill left or right by eye so that

it is in line with the piece of wood.

It is important to realize that the tenon cutter

will cut tenons in line with the axis of the

drill. If you wish to have a tenon come off the

end of the piece of wood at an angle, clamp

the piece in a vise at the desired angle (using

an inclinometer if necessary). Cut the tenon

while holding the tenon cutter straight and

level, using the level vial as an indicator.

4

Tenon Dia. Max. Stock Dia.

5/8"to 1"Tenon Dia. + 11/8"

1

1/4"to 2"Tenon Dia. + 11/2"