These installation instructions provide essential information for installing VESDA VLC Aspirating Smoke Detectors in accordance with the system design. Additional installation and

product documentation is listed below in the Reference Documents section.

VESDA VLC-500 and VLC-505 Installation Instructions

System Components

The detector is shipped with the following components:

• 1 aspirating smoke detector

• 1 mounting bracket

• 1 installation instruction sheet

• 1 product guide

Prerequisites

• A completed system design documents

• A 24V DC Power Supply, compliant with local codes and standards

• Screws and inserts that are appropriate for the mounting suface

• RS-232 9-way serial cable for VLC-500, sliding windows HLI (VHX - 0200) for

VLC-505

• Labelsasspeciedinthesystemdesign

• Cable glands that are compliant with the IP rating of the detector

• Conduit,asspeciedinthesystemdesign

• 0.2 mm2to 2.5 mm2(24 - 14 AWG) wiring for relays

• APCorlaptopinstalledwithXtralisVSCforinitialconguration

• Standard connection instructions for where the detectors are to be added to a corporate

network

Standards Compliance

UL

Foropenareaprotectiontherealarmthreshold(signal)thatinitiatesanevacuation

procedure via the Fire Alarm Panel must not be set less sensitive than 0.625%/ft. The

detector can send this signal via the Fire Alarm Panel Output signal or the Pre-Alarm

output signal.

Throughvalidationtesting,UnderwritersLaboratoriesInc.hasveriedthatVESDAECO

gasdetectors,wheninstalledwithinthesamplepipenetwork,presentnosignicant

effects on the smoke detection performance of VESDA. The use of theASPIRE calculation

software is required to verify system design performance with all devices included in the

design.

European Installations

The product must use a power supply conforming to EN54: Part 4.

The product is compliant with EN 54-20 sensitivity requirements provided the following

conditions are met:

• For a Class A detector, hole sensitivity must be better than 1.5% obscuration/m and

transport time less than 60 seconds

• For a Class B detector, hole sensitivity must be better than 4.5% obscuration/m and

transport time less than 90 seconds

• For a Class C detector, hole sensitivity must be better than 10% obscuration/m and

transport time less than 120 seconds

TheselimitsshouldbeveriedusingASPIREduringthedesignofthesamplingpipe

network.

TheproductiscompliantwithEN54-20owmonitoringrequirementsprovidedthe

following conditions are met:

• Theminorlowandminorhighowthresholdsshouldbesetat85%and115%

respectively

• TheowthroughthedetectorpredictedbyASPIREshouldbeintherange20to65

lpm

Power Consumption (18 - 30 VDC Supply)

Power Consumption 5.4 W during normal operation, 5.9 W with alarm on

Environmental Requirements

• Temperature

• Ambient: 0°C to 39°C (32°F to 103°F)

• Sampled Air: -20°C to 60°C (-4°F to 140°F)

• Tested to: -10°C to 55°C (14°F to 131°F)

UL:0°to38°C(32°Fto100°F)

• Humidity: 10-95% RH, non-condensing

Note: Please consult your Xtralis representative for information on operation outside

these parameters or where sampled air is continually above 0.05% obs/m

(0.015% obs/ft) under normal operating conditions.

Reference Documents

Additional installation and product information is contained in the following documents,

which are available for download in the Xtralis partner extranet at www.xtralis.com.

• 10280-VESDAVLCProductGuide

• 10195 - VESDA Commissioning Guide

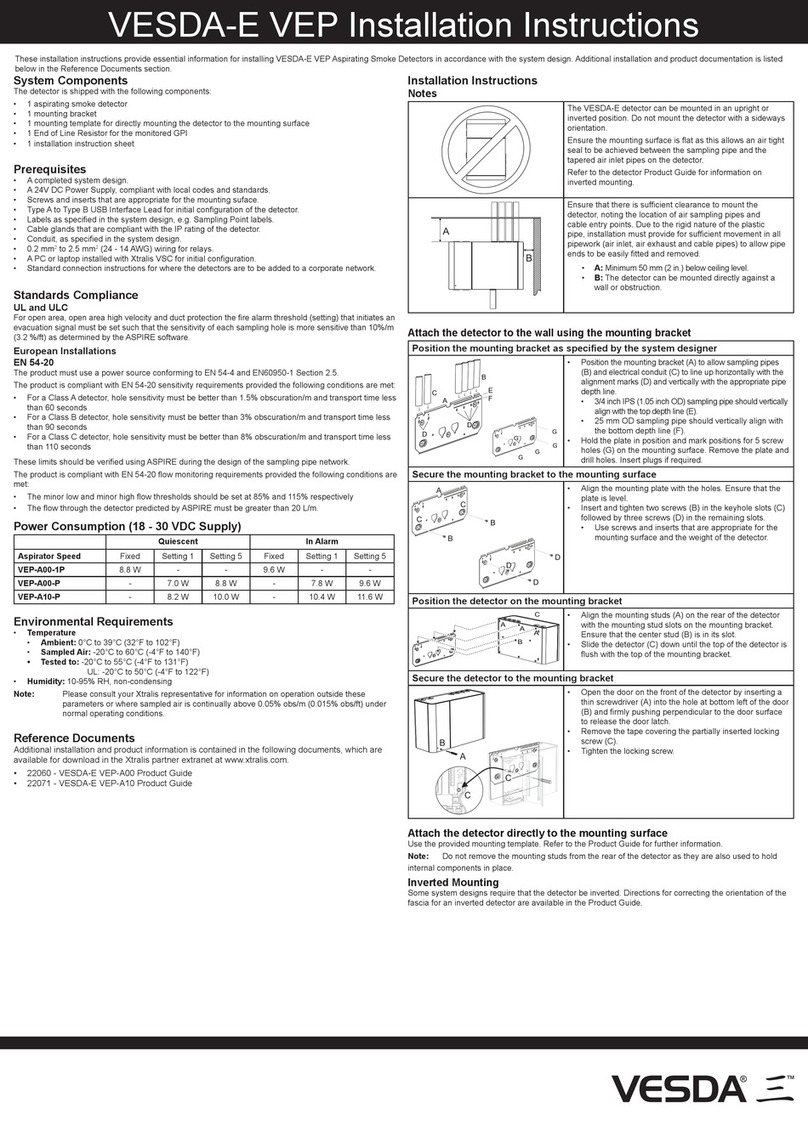

Installation Instructions

Notes

The VESDA detector can be mounted in an upright

or inverted position. Do not mount the detector with

a sideways orientation.

Ensurethemountingsurfaceisatasthisallowsan

air tight seal to be achieved between the sampling

pipe and the tapered air inlet pipe on the detector.

Refer to the detector Product Guide for information

on inverted mounting.

Ensurethatthereissufcientclearancetomount

the detector, noting the location of air sampling

pipes and cable entry points. Due to the rigid nature

of the plastic pipe, installation must provide for

sufcientmovementinallpipework(airinlet,air

exhaust and cable pipes) to allow pipe ends to be

easilyttedandremoved.

• A: Minimum 50 mm (2 in.) below ceiling level.

• B: The detector can be mounted directly

against a wall or obstruction.

Secure the mounting bracket to the mounting surface

• The mounting bracket for the VESDA VLC is

always mounted in the UP direction. It is clearly

marked with the word “UP” and an upward

pointing arrow.

• Secure the mounting bracket to the surface

using appropriate fasteners, ensuring that the

bracketishorizontallystraightandsitsushon

the surface.

• Determine the ports for cable entry. Press out the

tabs for the cable entry, air inlet and air exhaust

ports.

Install the detector

• VESDA VLC detector.

• Remove the front cover and if necessary

separate it from the enclosure box. The back

of the enclosure box is slotted over the four

mounting bracket tabs. Slide the detector

downwards until it slides onto the tabs.

• Screwintheanti-tamperscrew.Checktoconrm

that the detector does not slide off the mounting

bracket.

Inverted Mounting

Some system designs require that the detector be inverted. Directions for correcting the

orientation of the fascia for an inverted detector are available in the Product Guide

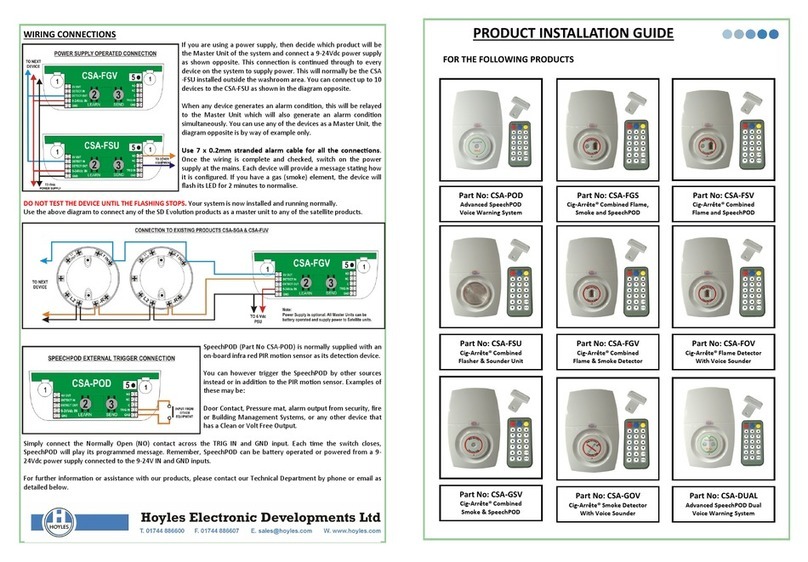

Prepare Detector: Wiring, Pipe Inlet and Exhaust Ports

Remove the appropriate plugs for electrical cable installation (J), air sampling pipe inlet

port (K), and exhaust port (F).

• Ensure that pipes are clean and their ends are square and smooth.

AProgramming socket

15 Pin for VLC-505

9 Pin for VLC-500

B Termination card

C VESDAnet number

DAirltercartridge

EFilter screw

FAir exhaust port

GAspirator

H1.6 Amp fuse

IAnti tamper screw

JCable entry ports

KAir inlet port

LWire terminal strips

• Insert the inlet and exhaust pipes (if used) into the correct inlet ports (K) and

exhaust port (F).

• Feed the electrical wiring connections through the cable entry ports.

• Usethecorrectcableglandsizetotintothe26mm(1”)cableentryport.Use

correctly rated cable glands to maintain the required IP rating.

Note: Do not glue the inlet and exhaust pipe into the detector ports. The product

warranty will be void if the pipes are glued.