VEVOR KH-375 User manual

Other VEVOR Cutter manuals

VEVOR

VEVOR k110D User manual

VEVOR

VEVOR CT-174 User manual

VEVOR

VEVOR AY-420 User manual

VEVOR

VEVOR 8102E-8L User manual

VEVOR

VEVOR 10190010215 User manual

VEVOR

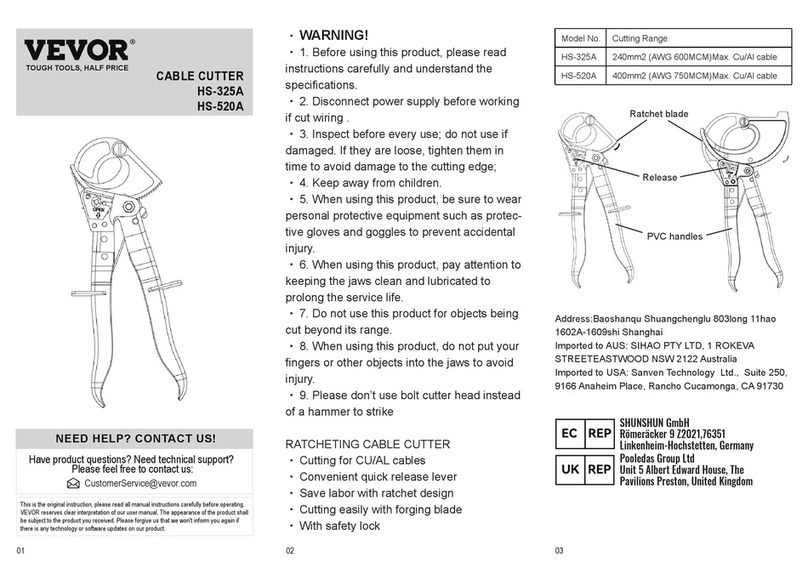

VEVOR HS-325A User manual

VEVOR

VEVOR CT-650 User manual

VEVOR

VEVOR RC-16 User manual

VEVOR

VEVOR YT-160AS User manual

VEVOR

VEVOR SL-400 Installation instructions

Popular Cutter manuals by other brands

Milwaukee

Milwaukee HEAVY DUTY M12 FCOT Original instructions

SignWarehouse.com

SignWarehouse.com Bobcat BA-60 user manual

Makita

Makita 4112HS instruction manual

GEISMAR STUMEC

GEISMAR STUMEC MTZ 350S manual

Hitachi

Hitachi CM 4SB2 Safety instructions and instruction manual

Dexter Laundry

Dexter Laundry 800ETC1-20030.1 instruction manual