6

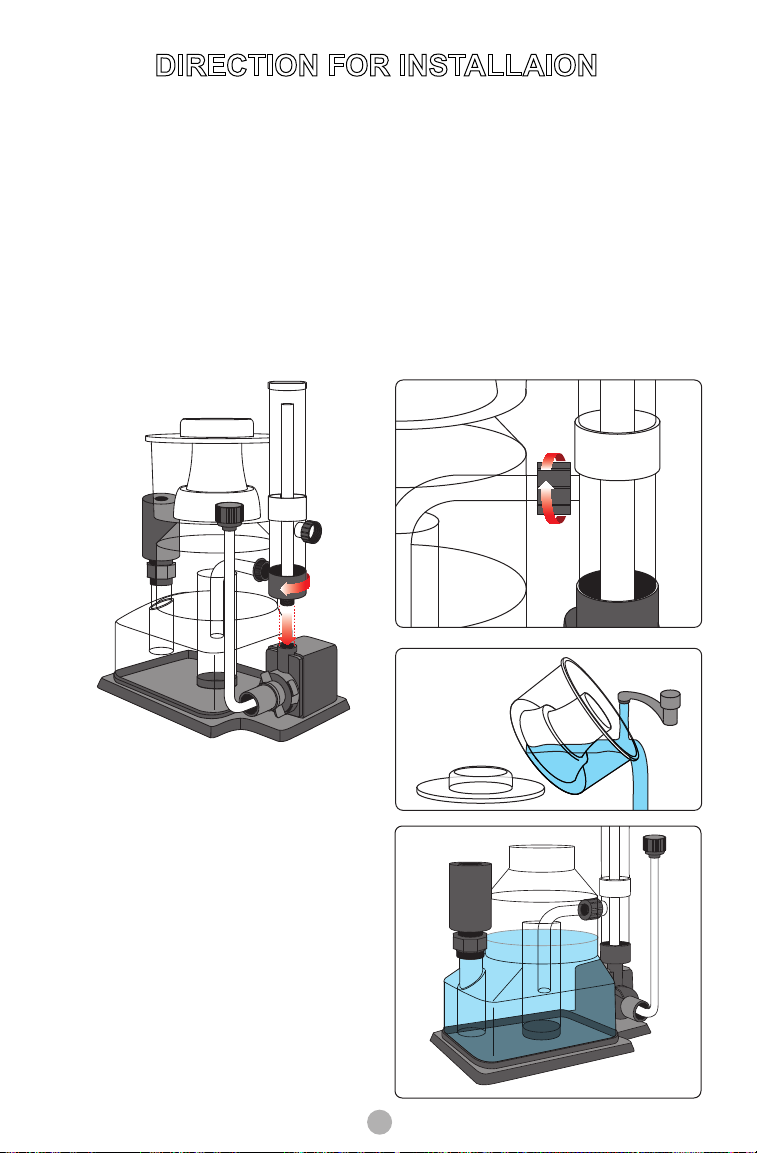

COLLECTING WATER AND NO PROTEIN

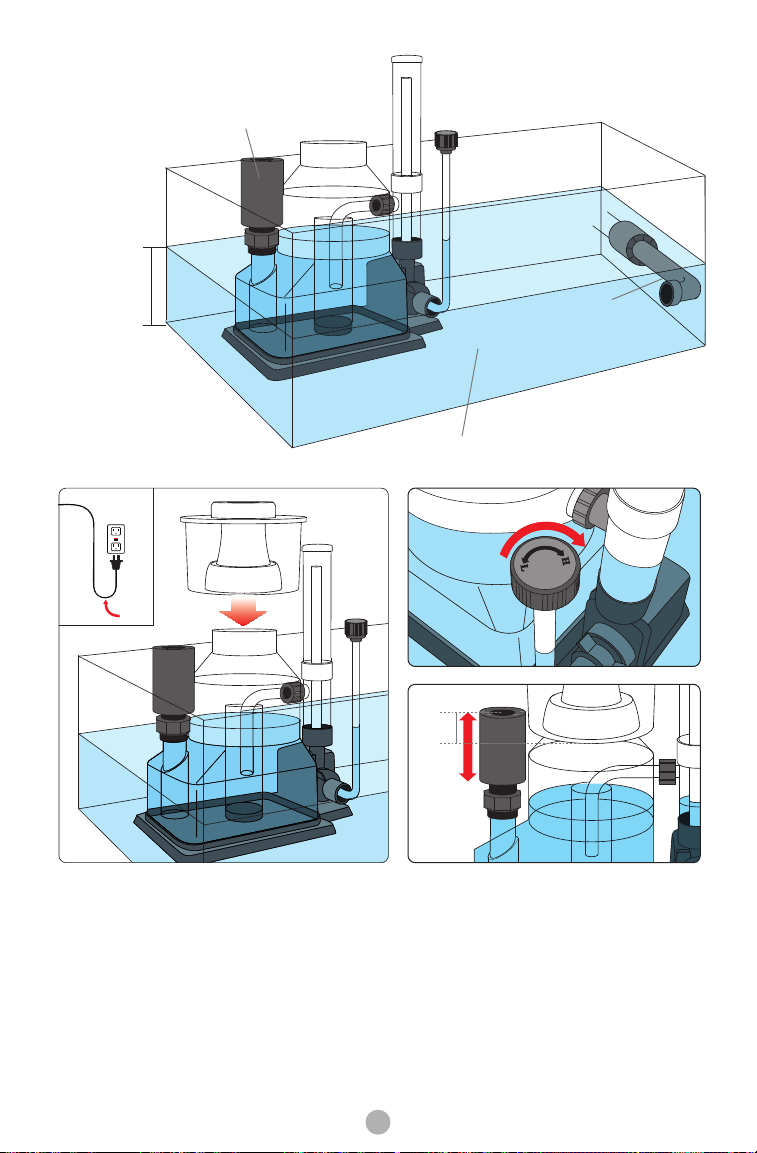

1. Lower the variable discharge tube in ½”increments until the bubbles stop

overflowing into the collection cup and the unit begins to skim. Loosen the

discharge compression nut and lower variable discharge tube.

Tighten discharge compression nut to set.

2. If the variable discharge tube is as low as possible and water is still collecting

in the cup, then start to increase the volume of air by turning the air control

valve towards the H by a 1⁄8of a turn until the unit begins to skim. By increasing

the air volume it will decrease the water level and speed of the water entering

and exiting the skimmer.

Note:

• Set salinity at 10.0022-10.0025.

• The use of certain water conditioners will cause excess bubbles and

the skimmer to collect excessive water. This will occur until the water

conditioner is completely removed. Certain water conditioners that

increase slime coat are more prone to affect to the skimmer.

• The use of medications will cause excess bubbles and the skimmer

to collect excessive water. This will occur until the medication in the

water is completely removed.

• if the water level in the sump is too high that above 5.5”-9.5”, It will

cause the skimmer to collect excessive water.

NOT SKIMMING AND NOT COLLECTING ANY PROTEIN

1. Decrease air volume by turning the air control valve towards the L by a 1⁄8of a

turn until the unit begins to skim.

2. Raise the variable discharge tube in ½”increments until the bubbles reach

halfway up the neck of the collection cup. Loosen the discharge compression

nut and raise the variable discharge tube. Tighten discharge compression nut

to set. Wait a short period of time and if skimming does not begin, raise the

variable discharge tube a small amount (approximately 1⁄8”). Continue to raise

the variable discharge tube until the unit begins to skim.

Note:

• Set the salinity at 10.0022-10.0025.

• There must be a biological load. In short there must be livestock in

the aquarium.

• The collection cup has not been washed with a mild detergent.

• Water level in the sump is too low, around 5.5”-9.5”.