6

Commercial or industrial use for a purpose other than

the monitoring, operation and optimisation of suppor-

ted, approved systems shall be deemed inappropriate.

Protection against unauthorised access

Protection of the KNX TP against unauthorised

access by third parties

The Vitogate cable must not be routed outside a build-

ing.

Ensure that no unauthorised persons have access to

the Vitogate cable, so that the Vitogate control unit and

the heating system cannot be sabotaged.

Protection of KNXnet/IP (tunnelling) against unau-

thorised access by third parties

KNXnet/IP (tunnelling), which can be reached via UDP

port 3761, has no access protection and must there-

fore always be operated within specially protected net-

works. In particular, UDP port 3761 must not be made

openly accessible from the internet on the router. If you

want to access the Vitogate via the internet, take

appropriate measures to protect KNXnet/IP (tunnel-

ling). To do this, set up VPN access, for example.

If this point is not observed, third parties can take con-

trol of and sabotage the Vitogate and the heating sys-

tem via the internet.

Protection of the LON against unauthorised access

by third parties

Tunnelling the LON over IP networks is in principle

technically possible with corresponding commercially

available LON routers. However, this configuration is

not supported and must not be used.

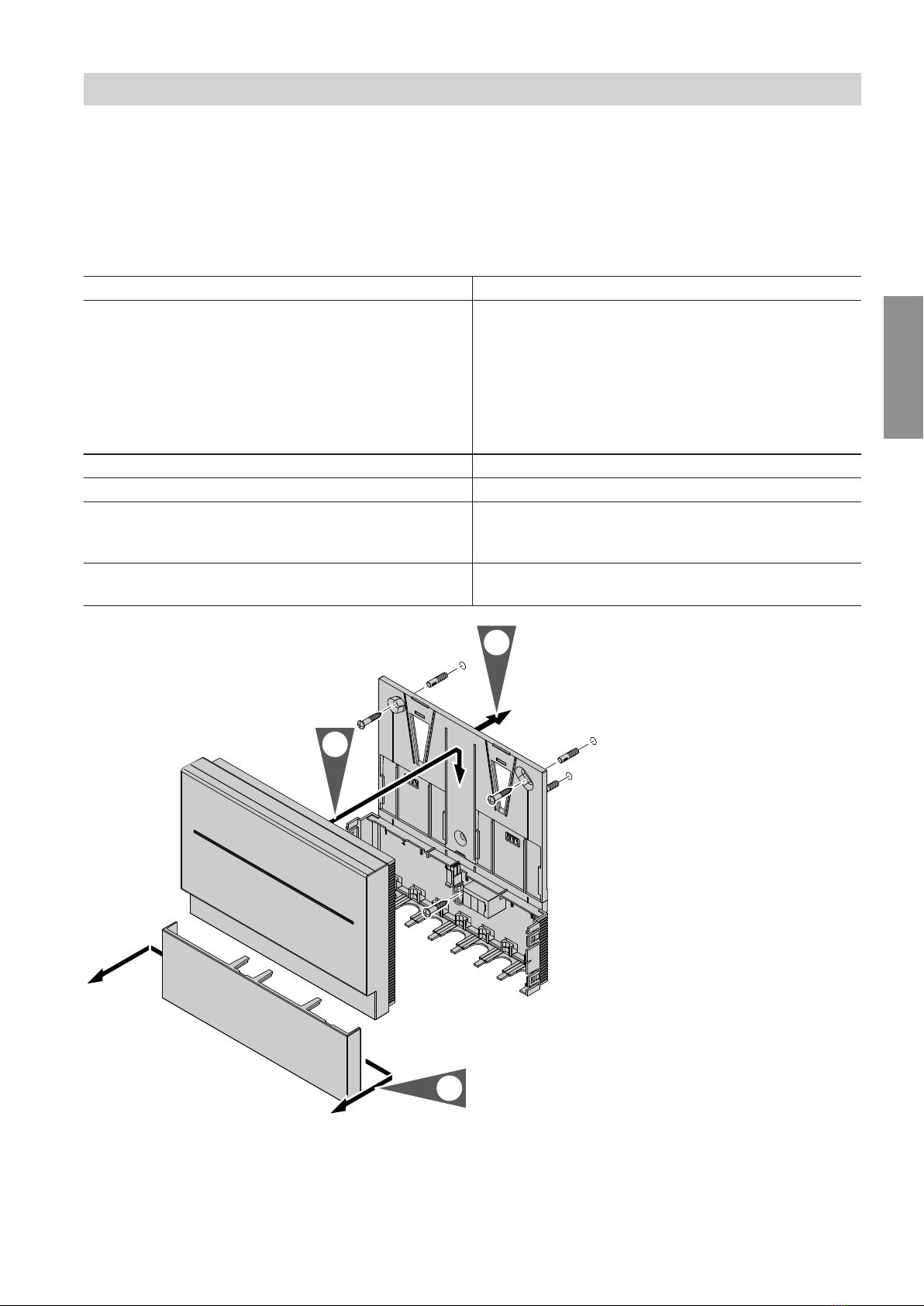

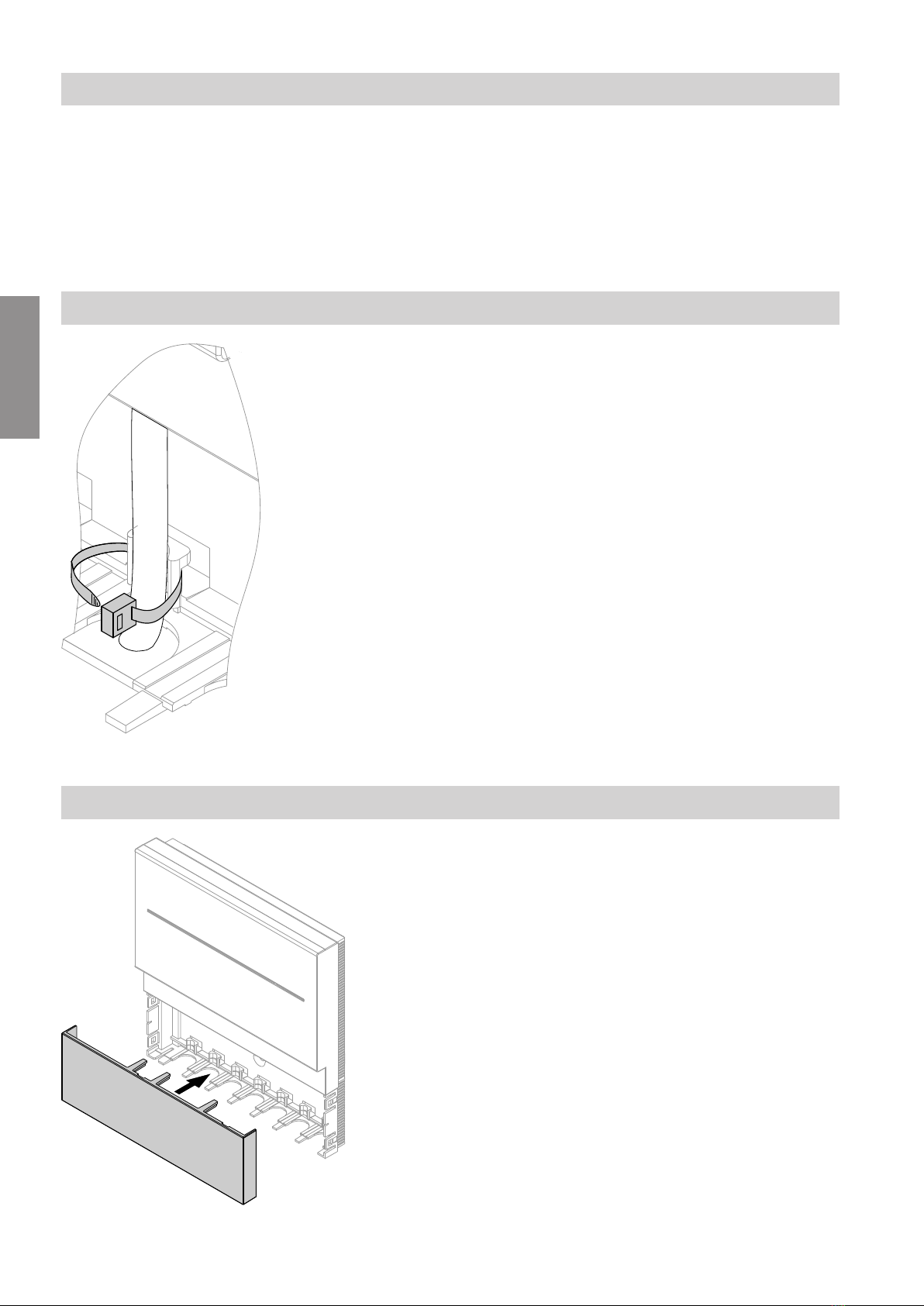

Product information

The following appliances are hooked up to KNX/EIB

systems with the Vitogate 200, type KNX gateway:

■Vitotronic control units with integral LON communica-

tion module (accessory)

The Vitogate 200, type KNX must be integrated into

the KNX/EIB system by an authorised contractor.

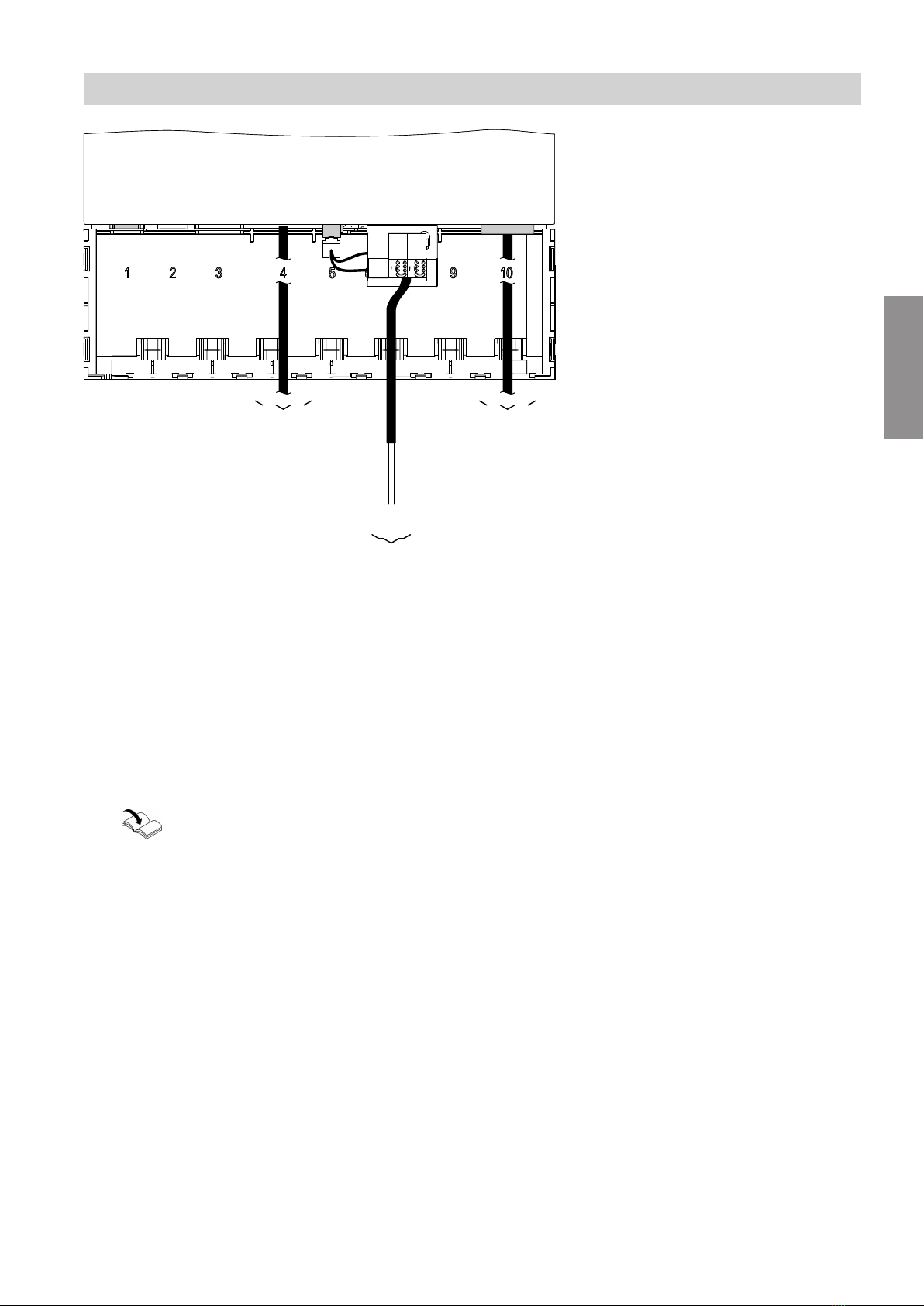

Functions

The Vitogate 200, type KNX enables system users to

utilise the following functions in conjunction with a

KNX/EIB system:

■Transferring heating system operating states

■Specifying set values

■Relaying fault and error messages

■Heat demand-dependent control of the flow tempera-

ture in conjunction with constant KNX/EIB control of

individual room temperature

Spare parts lists

Information about spare parts can be found on the

Viessmann spare parts app.

Information

Intended use (cont.)

5673180

Information