en-US/CA

3

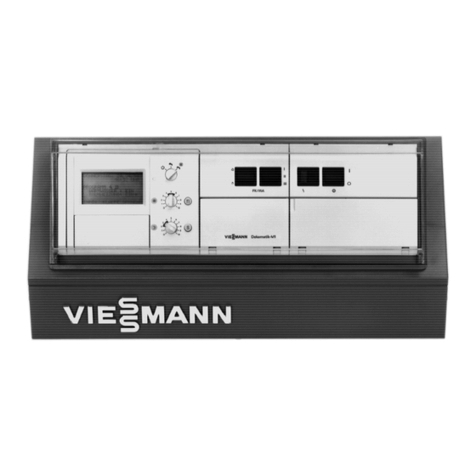

1 Overview

• Extra large graphic display

• 4 relay outputs

• 5 sensor inputs

• Data logging onto SD card

• Thermal disinfection

• Time-controlled thermostat function

• VBus®

• Energy-saving switch-mode power supply

Included:

1 x SCU345

1 x accessory bag

3 x screw and wall plug

8 x strain relief and screws

1 x manual

2 x temperature sensors - FKP6 (-58 °C to +356 °F)

2 x temperature sensors - FRP6 (+23 °C to +176 °F)

Note

For more information about accessories,

see p. 55.

Technical data

Housing: plastic, PC-ABS and PMMA

Protection type: IP 20 / EN 60529

Protection class: I

Ambient temp.: 0 ... 40 °C [32 ... 104 °F]

Dimensions:

204 x 170 x 47 mm [8.03" x 6.69" x 1.85"]

Mounting: wall mounting, also suitable for mounting

into patch panels

Display: System-Monitoring-Display for system visu-

alization, 16-segment display, 7-segment display, 9 sym-

bols, control lamp (directional pad) and background

illumination

Operation:

7 push buttons at the front of the housing

Functions: Controller for multi-tank solar thermal

systems. Functions such as: ∆T control, pump speed

control,energy metering,operating hours counter for

the solar pump, evacuated evacuated tube collector

function, thermostat function, vertical tank loading,

priority logic, heat dump function, thermal disinfec-

tion function, function control according to BAFA

guidelines.

Inputs: 5 inputs for Pt1000 temperature sensors,

1V40 impulse input

Outputs: 3 semiconductor relays, 1 standard relay

Interfaces: VBus®, SD card slot

Power supply: 100... 240V~, 50 ... 60 Hz

Switching capacity per relay:

1 (1) A 100 ... 240V~ (semiconductor relay)

2 (1) A 100 ... 240V~ (standard relay)

Total switching capacity: 4 A

Standby power consumption: < 1W

Mode of operation: type 1.Y

The cTUVus certification confirms

that the controller meets the

demands of the UL 60730-1:2009

and CSA B60730.1:2002 standards.

cTUVus certified!

Letter of equivalency

Dear Sirs,

Dear AHJ Inspector,

TÜV Rheinland of North America, Inc. (TÜV) hereby confirms

that the cTUVus Mark and Certificate assigned by us on and

for this product exceeds or is equivalent to the Listing Process

and Labeling Mark of the Underwriter Laboratories, Inc

.

We as a Nationally Recognized Testing Laboratory, authorized

by the Occupational Safety & Health Administration (OSHA),

have evaluated this Product for fire, shock and life safety in

accordance to the appropriate standard(s) contained within

our scope as accredited by the Occupational Safety and

Health Administration (OSHA).The cTUVus Mark is accepted

by city, state, country, federal and provincial authorities and

merchants throughout the U.S. and Canada.

Please do not hesitate to contact us for further questions.We are

always glad to be at your disposal.

TÜV Rheinland of North America