FREEDOM®RESIDENTIAL

CONCEALED PENDENT

SPRINKLER VK494 (K4.9)

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services:

877-384-5464

Fax:

269-818-1680

Email:

[email protected]Visit the Viking website for the latest edition of this technical data page www.vikinggroupinc.com

Page 1 of 8

Form No. F_012116 Rev 01 September 7, 2022

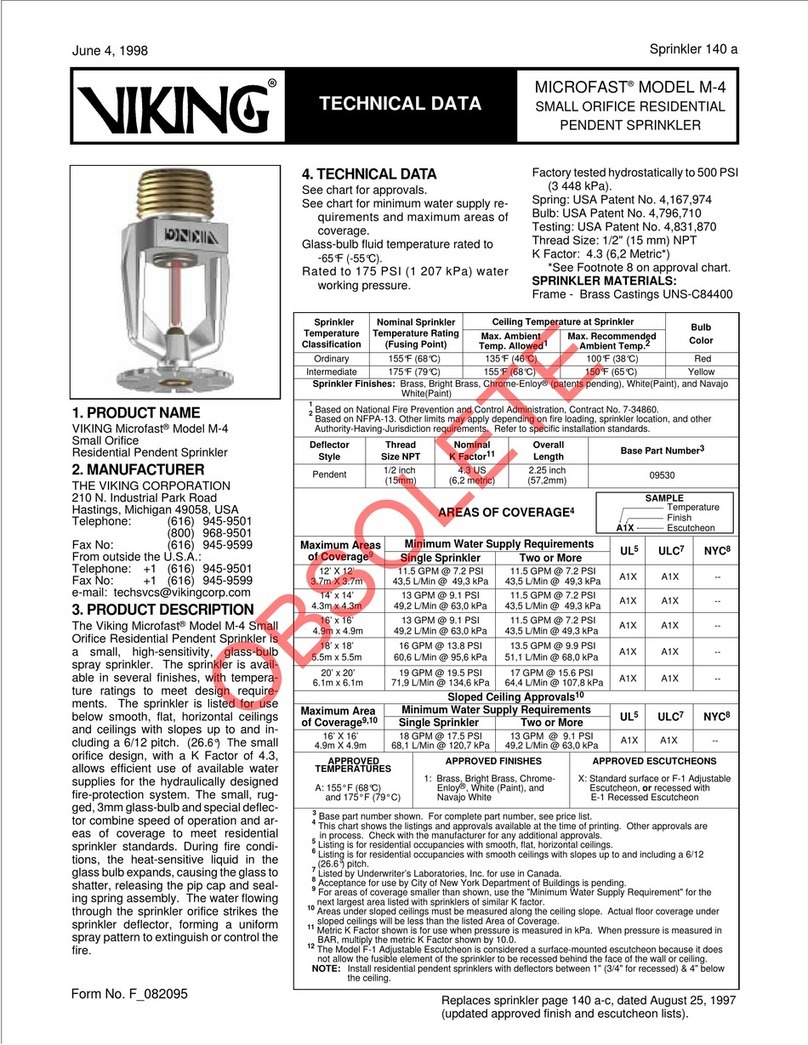

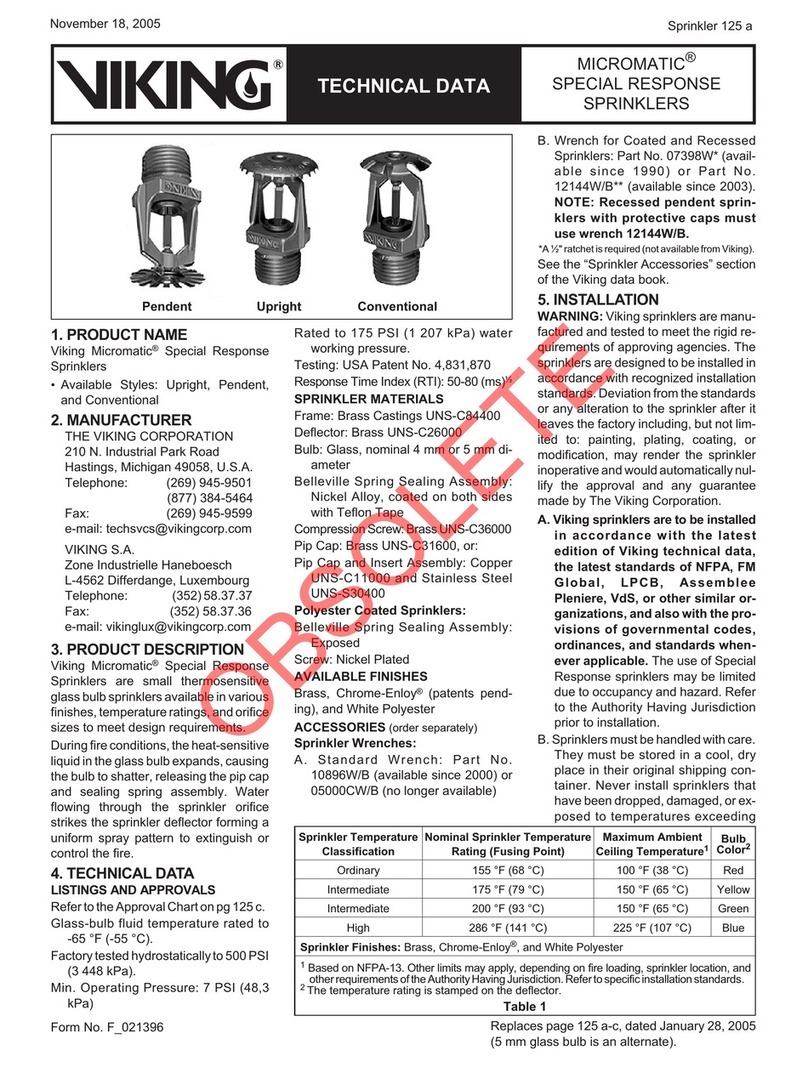

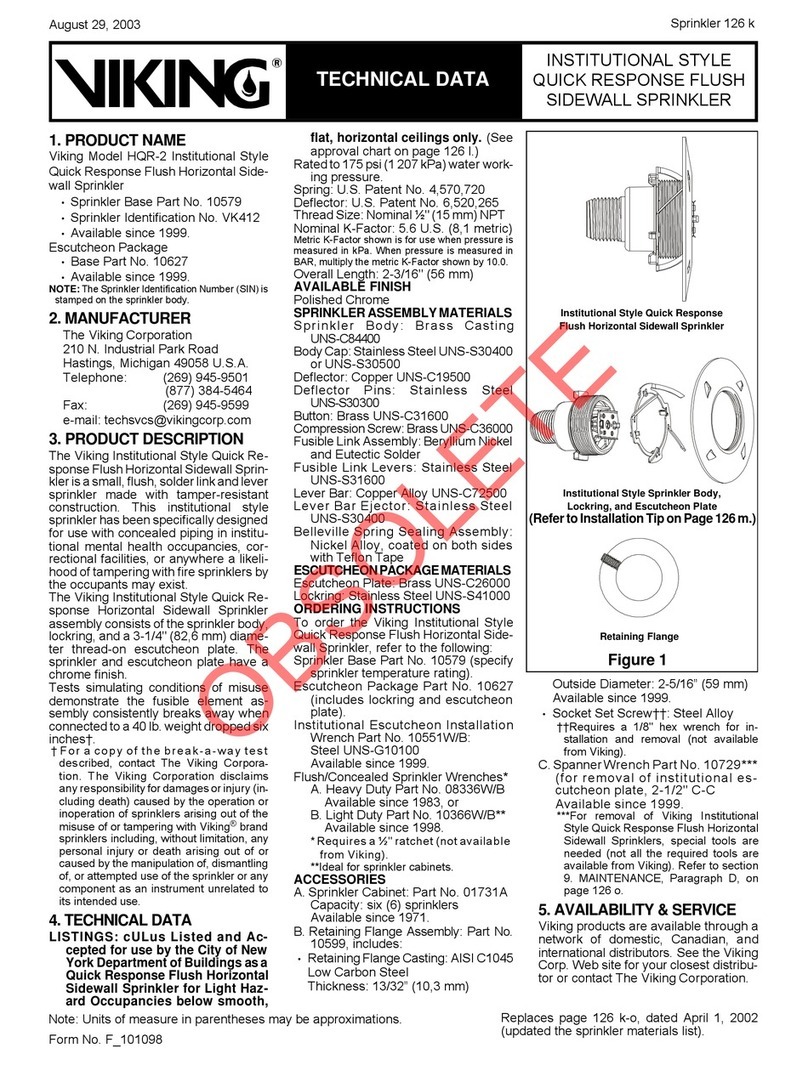

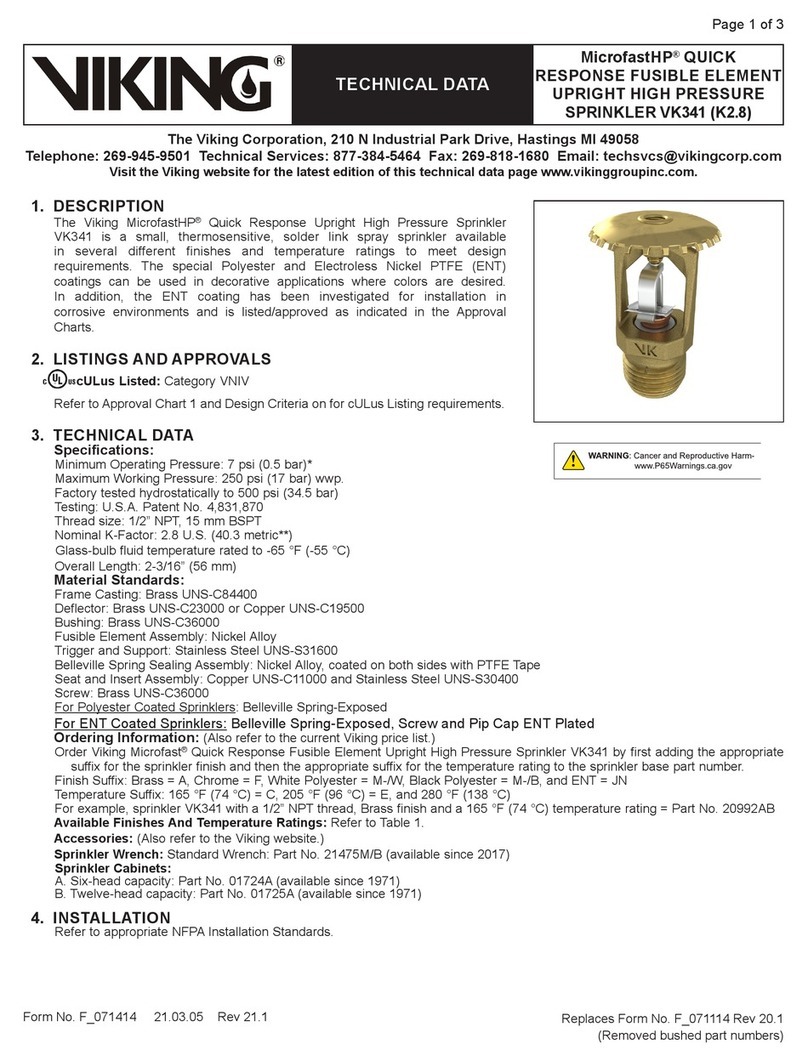

1. DESCRIPTION

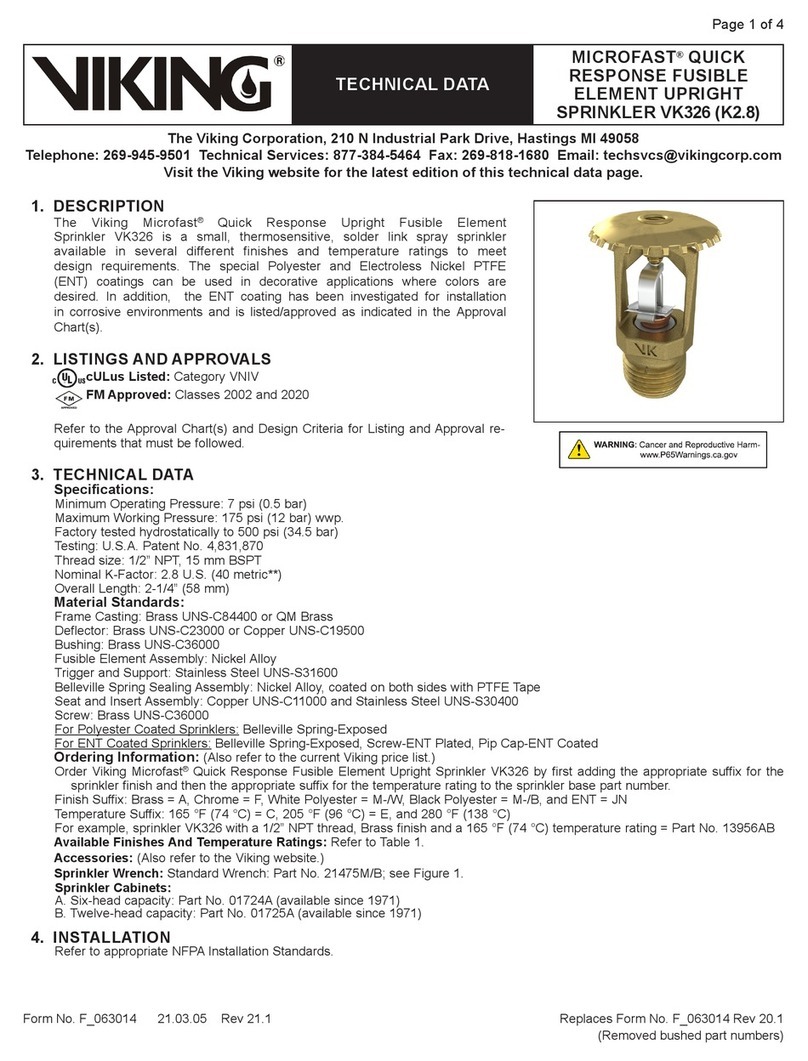

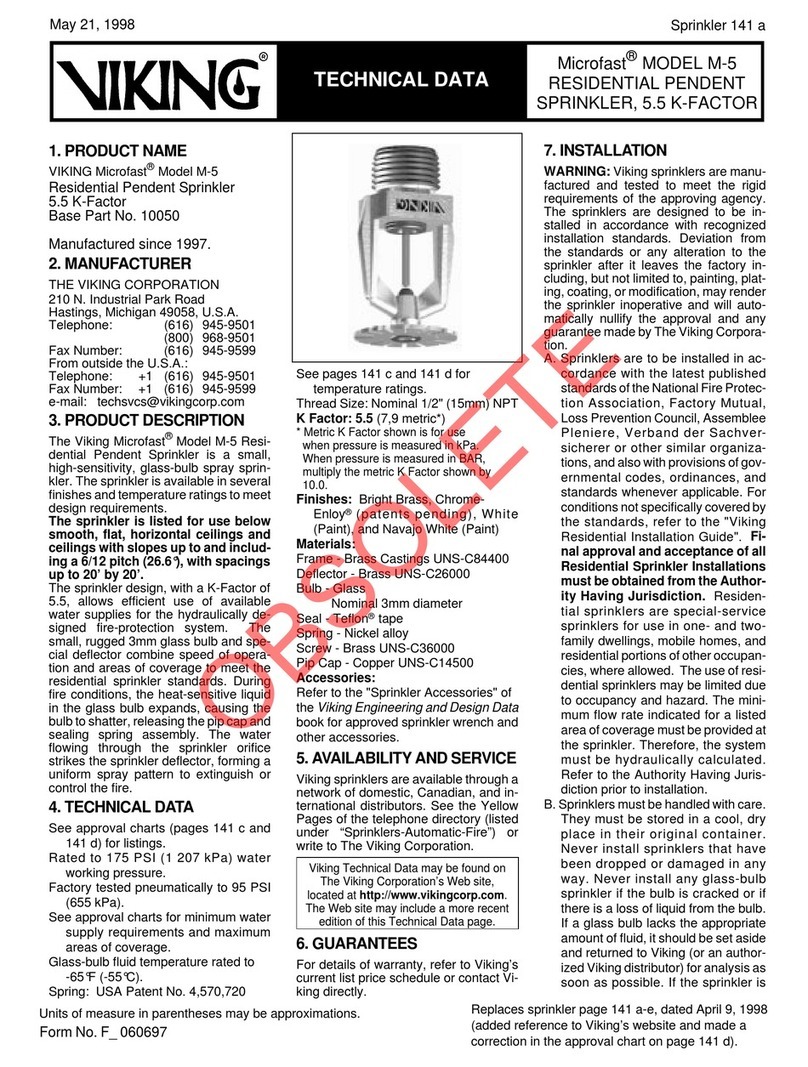

Viking Freedom® Residential Concealed Pendent Sprinkler VK494 is a small

thermosensitive, glass-bulb residential sprinkler designed for installation on

concealed pipe systems where the appearance of a smooth ceiling is desired. The

orifice design allows the sprinkler’s efficient use of available water supplies for the

hydraulically designed fire-protection system. The glass bulb operating element

and special deflector characteristics meet the challenges of residential sprinkler

standards.

Features:

• K4.9 (70.6 metric)

• Fast response glass bulb operating element.

• Integral threaded adapter cup accepts push-on or thread-on cover plates.

• Low-profile, small diameter, removeable cover plates offer almost flush

appearance upon installation and allow ease of maintenance.

• Protective cap prevents damage during installation and finishing and keeps

errant overspray from coating internal parts.

• Various finishes available to meet design requirements.

• Optional Electroless Nickel PTFE (ENT) coating provides corrosion resistance

(see Approval Chart).

2. LISTINGS AND APPROVALS

cULusEU Listed: Category VKKW

Refer to the Approval Charts and Design Criteria for C-UL-US-EU Listing

requirements that must be followed.

3. TECHNICAL DATA

Minimum Operating Pressure: Refer to the Approval Chart.

Maximum Working Pressure: 175 psi (12 bar). Factory tested hydrostatically to 500 psi (34.5 bar).

Thread size: 1/2” (15 mm) NPT

Nominal K-factor: 4.9 U.S. (70.6 metric*)

Glass-bulb fluid temperature rating: to -65 °F (-55 °C)

* Metric K-factor measurement shown is in Bar. When pressure is measured in kPa, divide the metric K-factor shown by 10.0.

Sprinkler Body: Brass UNS-C84400 or QM Brass

Deflector: Phosphor Bronze UNS-C51000

Deflector Pins: Stainless Steel UNS-S30200

Button: Brass UNS-C36000

Pip Cap and Insert Assembly: Copper UNS-C11000 and Stainless Steel UNS-S30400

Compression Screw: 18-8 Stainless Steel

Yoke: Phosphor Bronze UNS-C51000

Belleville Spring Sealing Assembly: Beryllium Nickel Alloy, coated on both sides with PTFE Tape

Cover Adapter: Cold Rolled Steel JIS G3141 and Carbon Steel UNS-G10100 (per JIS G3141)

Shipping Cap: High Density Polyethylene

Vibration damper ring: Buna-N Rubber SAE AS-568-017

Cover Plate Assembly: Copper UNS-C11000 and Brass UNS-C26800 or Stainless Steel UNS-S30400

Spring: Beryllium Nickel

Solder: Eutectic

4. INSTALLATION

Refer to appropriate NFPA Installation Standards.

5. OPERATION

During fire conditions, when the temperature around the sprinkler approaches the cover plate’s nominal temperature rating, the

cover plate detaches and releases the deflector. Continued heating of the exposed sprinkler causes the heat-sensitive liquid in the

glass bulb to expand. When the temperature reaches the sprinkler’s nominal temperature rating, the glass bulb shatters releasing

the yoke, pip cap assembly and sealing spring. Water begins flowing through the sprinkler orifice and strikes the deflector form-

ing a uniform spray pattern over a specific area of coverage, which is determined by the water supply pressure at the sprinkler, in

order to extinguish or control the fire.

Sprinkler Body Brass UNS-C84400 or QM Brass

Deector Phosphor Bronze UNS-C51000

Deector Pins Stainless Steel UNS-S30200

Buon Brass UNS-C36000

Pip Cap and Insert Assembly Copper UNS-C11000 and Stainless Steel UNS-S30400

Compression Screw 18-8 Stainless Steel

Yoke Phosphor Bronze UNS-C51000

Belleville Spring Sealing Assembly Beryllium Nickel Alloy, coated on both sides with PTFE Tape

Cover Adapter Cold Rolled Steel UNS-G10080 with Clear Chromate over Zinc Plang

Shipping Cap High Density Polyethylene

Replaces Form No. F_012116 Rev 21.2

(Updated UL cover plate temperature rating; corrected sprinkler base part number.)