2

IMPORTANT - PLEASE READ AND FOLLOW

•• Before beginning, please read these instru tions ompletely and arefully.

• Do not remove permanently affixed labels, warnings, or plates from the produ t. This may void the warranty.

• Please observe all lo al and national odes and ordinan es.

• Please ensure that this produ t is properly grounded.

• The installer should leave these instru tions with the onsumer who should retain for lo al inspe tor’s use and for future referen e.

It is your responsibility to be sure your wine cellar is:

• lo ated so the front is not blo ked to restri t in oming or dis harge air flow.

• properly leveled.

• lo ated in a well ventilated area.

• onne ted to the proper kind of outlet, with the orre t ele tri supply and grounding. A 115V, 60 Hz, 15 amp fused ele tri al

supply is required. NOTE: Time delay fuse or circuit breaker is recommended.

• not used by anyone unable to operate it properly.

• used only for its intended purpose.

• properly maintained.

•SAVE THESE INSTRUCTIONS•

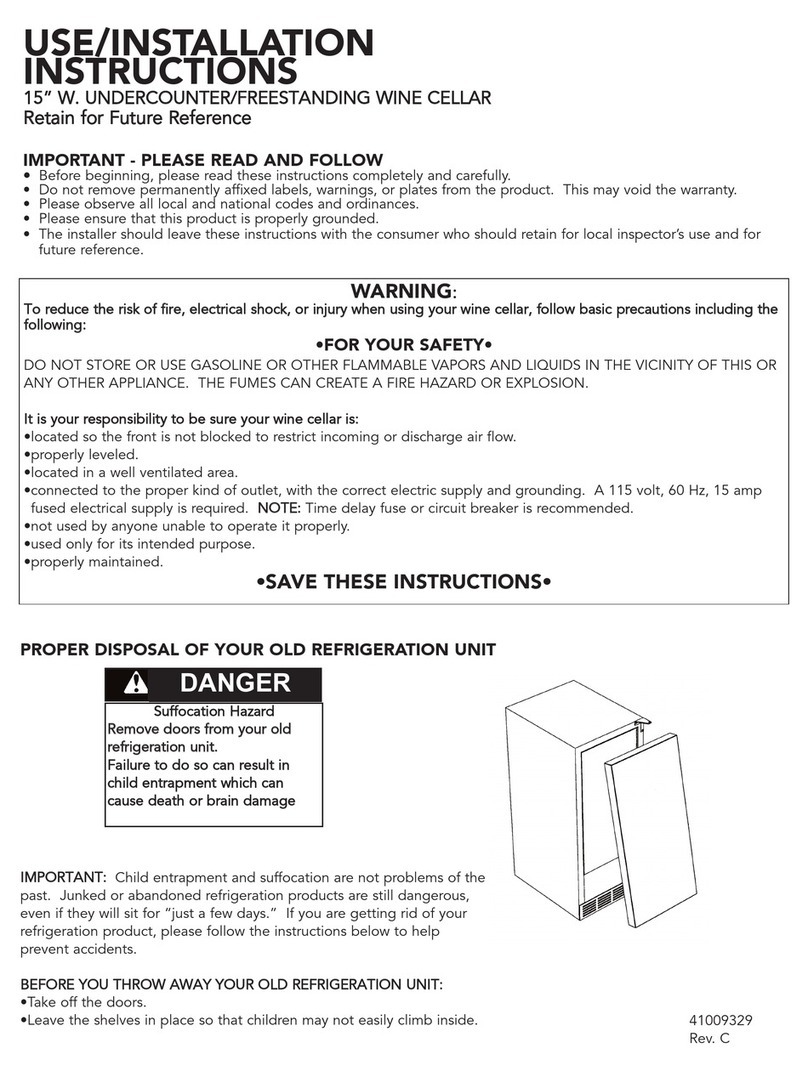

PROPER DISPOSAL (OF OLD REFRIGERATION UNIT)

WARNING

To re uce the risk of fire, electric shock, or injury when using your unit, follow these basic precautions:

• Read all instru tions before using the unit.

• Never allow hildren to operate, play with, or rawl inside the unit.

• Never lean unit parts with flammable fluids. The fumes an reate a fire hazard or explosion.

• Always turn the power on/off swit h (lo ated behind the air grille on top right side) to the OFF position before attempting to hange

light bulbs, lean, or servi e the unit.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE. THE FUMES CAN CREATE A FIRE HAZARD OR EXPLOSION.

DANGER

RISK OF CHILD ENTRAPMENT

Before You Throw Away Your Ol Refrigeration Unit:

• Take off the doors.

• Leave the shelves in pla e so that hildren may not easily

limb inside.

IMPORTANT: Child entrapment and suffo ation are not problems of the past.

Junked or abandoned refrigeration units are still dangerous... even if they will sit for

“just a few days.”

IMPORTANT:

Now that you have a new wine ellar, it is extremely important that you dispose of your

old applian e in a way that minimizes the possibility that hildren will find it. There

have been many ases in years past of hildren rawling inside junked and abandoned

refrigeration units and be oming trapped or suffo ated.

Conta t your muni ipal waste disposal authority to find out the best and safest way to

dispose of your old refrigeration unit.

A GFI shall be used if required by NFPA-70 (National Electric Code), federal state local laws, or local

ordinances.

• The required use of a GFI is normally related to the lo ation of a re epta le with respe t to any

signifi ant sour es of water or moisture.

• Viking Range Corporation will NOT warranty any problems resulting from GFI outlets whi h are not

installed properly or do not meet the requirements below.

If the use of a GFI is required, it should be:

• Of the re epta le type (breaker type or portable type NOT re ommended)

• Used with permanent wiring only (temporary or portable wiring NOT re ommended)

• On a dedi ated ir uit (no other re epta les, swit hes or loads in the ir uit)

• Conne ted to a standard breaker of appropriate size (GFI breaker of the same size NOT re ommended)

• Rated for Class A (5 mA +/- 1 mA trip urrent) as per UL 943 standard)

• In good ondition and free from any loose-fitting gaskets (if appli able in outdoor situations)

• Prote ted from moisture (water, steam, high humidity) as mu h as reasonably possible