Vinotemp VT-DS300SS-2Z User manual

Other Vinotemp Kitchen Appliance manuals

Vinotemp

Vinotemp Element EL-32COMM-B User manual

Vinotemp

Vinotemp element EL-168COMML User manual

Vinotemp

Vinotemp Element EL-BWC108-SS-L User manual

Vinotemp

Vinotemp Element EL-WCU103-02 User manual

Vinotemp

Vinotemp element EL-100SBB User manual

Vinotemp

Vinotemp element WCU103-01 User manual

Vinotemp

Vinotemp element EL-WCU102-01 User manual

Vinotemp

Vinotemp Element EL-12TEDCS User manual

Vinotemp

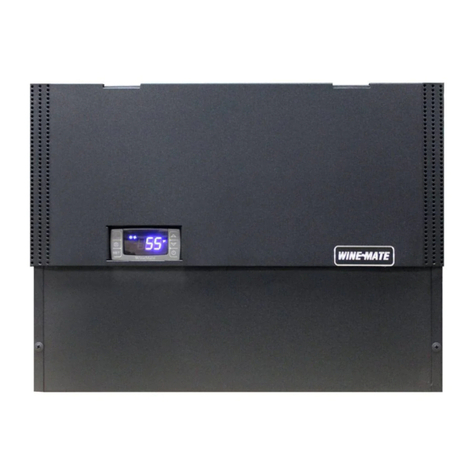

Vinotemp WINE-MATE WM-1500SLIM Instructions for use

Vinotemp

Vinotemp VT-BLKBEV User manual

Vinotemp

Vinotemp Element EL-BF23F User manual

Vinotemp

Vinotemp Element EL-36TD180 User manual

Vinotemp

Vinotemp element EL-6SILST User manual

Vinotemp

Vinotemp element VT-100MBWB User manual

Vinotemp

Vinotemp VT-12TEDi User manual

Vinotemp

Vinotemp element EL-168WCGM User manual

Vinotemp

Vinotemp ELEMENT EL-54SDTH User manual

Vinotemp

Vinotemp VT-WINEDISP4 User manual

Vinotemp

Vinotemp element EL-200ZZ-B User manual

Vinotemp

Vinotemp VT-32TSFE-SM User manual

Popular Kitchen Appliance manuals by other brands

Tayama

Tayama TYG-35AF instruction manual

AEG

AEG 43172V-MN user manual

REBER

REBER Professional 40 Use and maintenance

North American

North American BB12482G / TR-F-04-B-NCT-1 Assembly and operating instructions

Presto

Presto fountain popper instruction manual

Westmark

Westmark 1035 2260 operating instructions