PUSH THE 5/16” I.D. HOSE ONTO THE 90° #6 FITTING. (SEE HOSE ROUTING ILLUSTRATION ON PG. 7).

INSTALL THE FITTING ONTO THE EXPANSION VALVE (FINGER TIGHT). PUSH THE 1/2” I.D. HOSE ONTO THE

STRAIGHT #10 FITTING, AND INSTALL THE FITTING ONTO THE #10 LINE ON THE EVAPORATOR (SEE HOSE

ROUTING ILLUSTRATION PG. 7).

AT THIS TIME, TRY TO DETERMINE WHERE YOU WANT YOUR LINES TO GO THROUGH THE FIREWALL. MOVE

THE HOSES TO THAT POINT. HOLD THE FITTINGS UP TO THEIR RESPECTIVE HOSES, AND DETERMINE IF THE

HOSES WILL CONFORM TO THE LOCATION FOR THE BULKHEAD FITTINGS OR OPTIONAL BULKHEAD PLATE

(VINTAGE AIR PART #34215-VUQ OR 34217-VUQ). THE 1/2” HOSE IS HARD TO BEND AT A SHARP ANGLE,

AND THE FITTINGS TAKE UP A CERTAIN AMOUNT OF SPACE. BEFORE YOU DRILL HOLES IN YOUR FIREWALL,

MAKE SURE THAT YOU CAN MAKE THE HOSES FIT WHERE YOU HAVE PLANNED. THE ENGINE COMPARTMENT

APPEARANCE IS A CONSIDERATION WHEN CHOOSING THIS LOCATION.

WHEN YOU HAVE DECIDED WHERE YOU WANT TO PLACE YOUR BULKHEAD FITTINGS, MARK THESE POINTS

WITH A GREASE PENCIL AND MAKE A TEMPLATE FROM THE INSIDE, LOCATING WHERE THE HOLES WILL BE

CUT. WITH THIS TEMPLATE, LOCATE THE SAME POINTS ON THE OUTSIDE OF THE FIREWALL. MARK THESE

POINTS WITH A GREASE PENCIL.

DETERMINE THE BEST LOCATION FOR THE DRIER THAT WILL ALLOW ADEQUATE ROOM FOR THE HOSE AND

FITTINGS THAT CONNECT THE DRIER TO THE BULKHEAD FITTING.

MOUNT THE DRIER (KEEP THE DRIER CAPPED AS MUCH AS POSSIBLE. IF YOU MUST SCREW THE FITTING TO

THE DRIER, TAPE IT CLOSED).

AT THIS POINT, CUT HOLES FOR BULKHEAD FITTINGS, AND INSTALL THEM.

USING THE HOSE ROUTING ILLUSTRATION AS A GUIDE, ROUTE REMAINING A/C LINES, AND CUT TO

LENGTH.

INSTALL A/C VENTS THAT WILL BE USED AT THIS TIME.

CENTER OUTLET: YOU MAY USE THE CENTER PANEL FURNISHED, OR YOU CAN MOUNT THE VENTS IN DASH.

IF YOU USE THE CONTROL PANEL, THE TOP MOUNTING LIPS SHOULD BE BACK 1/4” X 1/2” FROM LOWER

LEADING EDGE OF DASH. LOCATE THE 2 ½” I.D. HOSE, AND ROUTE FROM THE DASH VENTS TO THE

EVAPORATOR.

AT THIS TIME, YOU SHOULD HAVE THE REFRIGERATION HOSES CUT TO THEIR PROPER LENGTH. PAY CLOSE

ATTENTION TO THE ORIENTATION OF ANY HOSE WITH TWO ANGLED FITTINGS. ANY HOSE WITH TWO

ANGLED FITTINGS MUST BE MARKED FROM THE HOSE TO THE FITTINGS TO ASSURE THEY WILL REMAIN IN

THIS POSITION AFTER CRIMPING. THE RUBBER HOSE IS ONLY CAPABLE OF A MINIMAL AMOUNT OF TWIST

TO AID ALIGNMENT.

REMOVE HOSES AND CRIMP ENDS. IF YOU DO NOT HAVE ACCESS TO THE PROPER EQUIPMENT, VINTAGE AIR

RECOMMENDS TAKING THEM TO A QUALIFIED A/C SERVICE CENTER FOR CRIMPING (SEE CRIMPING

INSTRUCTIONS SUPPLIED WITH THE HOSE KIT).

WITH THE EVAPORATOR TRIAL FIT COMPLETE, REMOVE THE UNIT AND LOWER INTO THE VEHICLE.

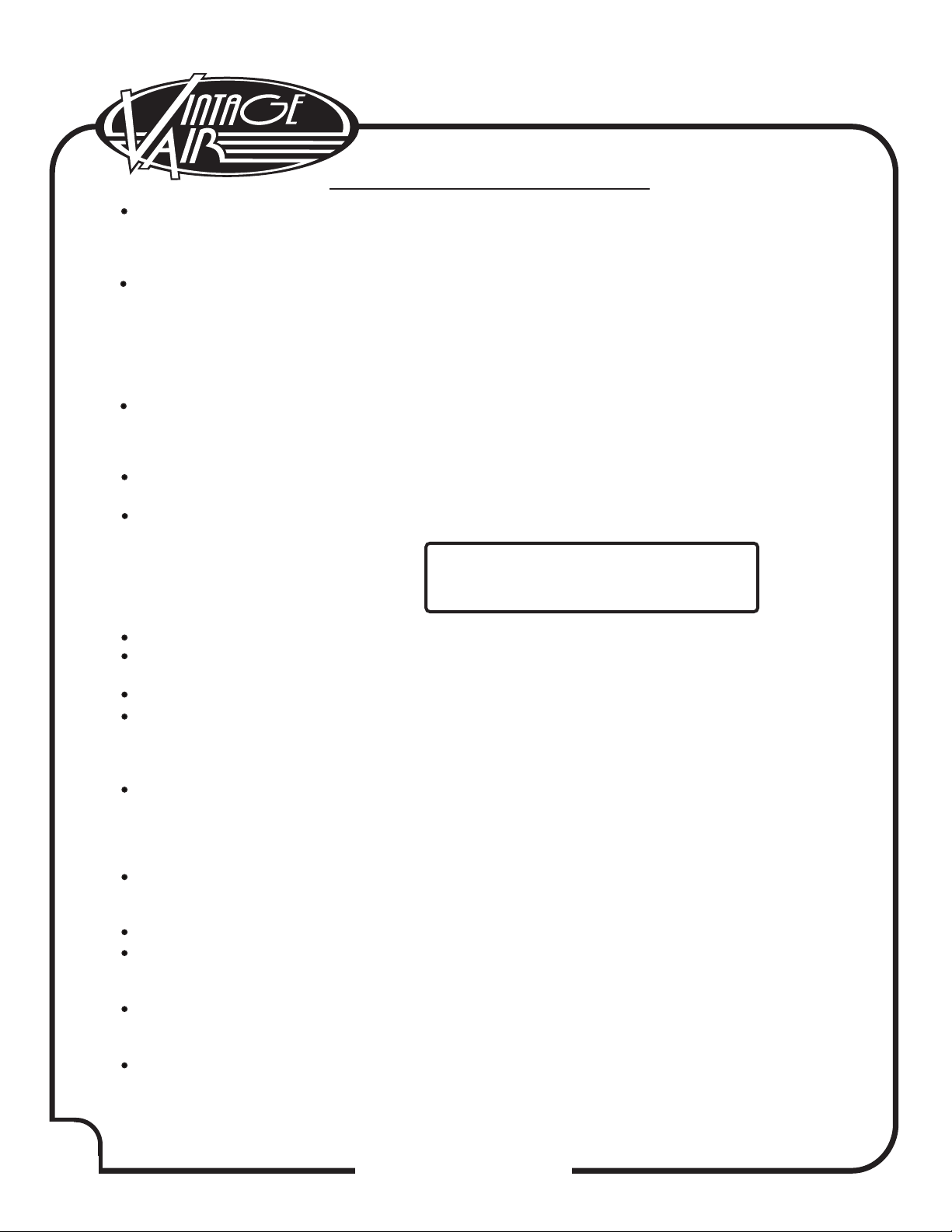

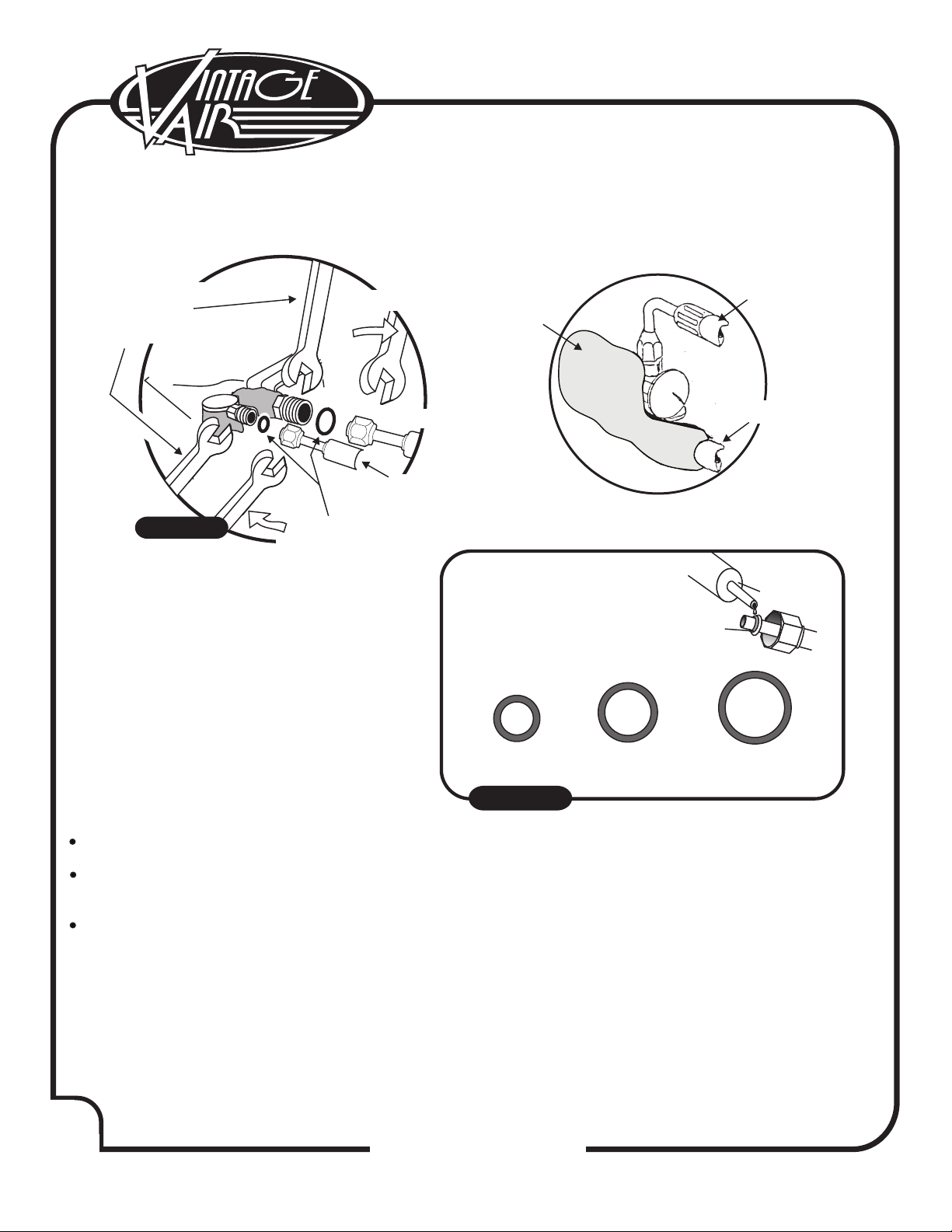

AFTER CRIMPING HOSES, LOCATE THE #6 A/C HOSE WITH THE 90° FITTING. LUBRICATE A #6 A/C O-RING

AND THE THREADS ON THE FITTING, AND INSTALL ON THE EXPANSION VALVE. TIGHTEN CAREFULLY. REFER

TO FIGURES 3 & 3a, PAGE 8.

LOCATE THE #10 A/C HOSE WITH THE STRAIGHT FITTING. LUBRICATE A #10 O-RING AND THE THREADS ON

THE FITTING, AND INSTALL ON THE #10 LINE OF THE EVAPORATOR. TIGHTEN CAREFULLY. REFER TO FIGURES

3 & 3a, PAGE 8.

WRAP THE #10 FITTING WITH PRESS TAPE, AND COVER ALL EXPOSED METAL SURFACES. (DO NOT WRAP THE

#6 HOSE, FITTING, OR THE HEATER CORE TUBES). SEE FIGURE 3, PAGE 8.

6

MINI SLIMLINE HEAT/COOL

900301 REV D 10/28/14, MINI SLIMLINE HC PG 6 OF 12

NOTE: THE DRIER IS USUALLY MOUNTED WHERE YOU HAVE ROOM FOR IT.

JUST REMEMBER TO MOUNT IT IN THE COOLEST SPOT POSSIBLE, AND

VERTICALLY SO THE SIGHT GLASS IS DIRECTLY ON TOP (NOT NEXT TO

THE EXHAUST MANIFOLD). IT CAN BE MOUNTED INSIDE THE VEHICLE

AS WELL.

INSTALLATION (CONTINUED)