Vivreau V3-204 User manual

1

V3-204 and 205 Dispensing Systems

Service Manual

2 3

Table of contents

Safety Precautions .......... ...................................................................3

General Information..............................................................................4

Technical Specications......................................................................5

Installation.............................................................................................7

Operating Instructions.........................................................................13

Maintenance........................................................................................15

Troubleshooting..................................................................................23

Illustrated Parts List............................................................................33

Wiring Diagrams..................................................................................36

© 2020 Vivreau Water Systems

All rights reserved.

Any and all information contained within this document is subject to

change without prior notice.

IMPORTANT ______________

The information contained in this manual is

specific to your system. It is IMPORTANT

you READ, FOLLOW and UNDERSTAND the

instructions given.

This manual and all material provided with your

system should be retained in a convenient location

for future reference.

Contact Vivreau if you have any questions

regarding the information contained in this

manual.

Safety precautions

IMPORTANT ________________________

This manual is intended for use by qualified

installers and service technicians only.

WARNING

Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury, or death. Read the

installation, operating, and maintenance

instructions thoroughly before installing or

servicing this equipment.

WARNING

Keep the area around the unit

clear of any combustible materials.

WARNING

Do not store or use gasoline

or other flammable vapors or liquids in the

vicinity of this or any other unit.

IMPORTANT ________________________

Carefully read, understand and follow all safety

instructions in this manual and safety labels

on the unit.

• Keep safety labels in good condition and

replace missing or damaged items.

• Learn how to operate the unit and how to use

the controls properly.

• Do not let anyone operate the unit without

proper training. This unit is intended for use by

authorized personnel only.

• In the event of a power failure, do not attempt to

operate this unit.

• Keep unit in proper working condition and do

not allow unauthorized modications to the unit.

WARNING

Only trained and certied electrical,

plumbing and refrigeration technicians should

service this unit.

WARNING

ALL WIRING AND PLUMBING

MUST CONFORM TO NATIONAL AND LOCAL

CODES. FAILURE TO COMPLY COULD RESULT

IN SERIOUS INJURY, DEATH OR EQUIPMENT

DAMAGE.

SAFETY PRECAUTIONS ________________

This unit has been specifically designed to

provide protection against personal injury.

To ensure continued protection, observe

the following:

WARNING

Disconnect power to the unit

before servicing. Follow all LOCKOUT/TAGOUT

procedures. Verify power to the unit is OFF and

disconnected before any work is performed.

Failure to do so could result in serious injury,

death or equipment damage.

• To protect against electric shock, do not

immerse power cord in water or other liquid.

• To prevent damage to the power cord, do not

allow cord to hang over the edge of a table or

counter, or come in contact with hot surfaces.

• Isolate unit from power supply (unplug or turn

OFF breaker) and turn OFF the water supply

when not in use and before cleaning.

• Allow Boiler (if supplied) to cool before

removing any components.

• The use of spare parts and accessories not

recommended by Vivreau may cause damage

and/or injuries.

• Do not operate any unit with damaged cords,

plugs, or after the unit malfunctions or has

been damaged in any manner.

• Do not use outdoors.

• Do not place on or near a hot gas or electric

burner.

• Do not use the unit for anything other than its

intended use.

• Save these instructions.

4 5

INFORMATION FOR THE READER

To nd specic topics of interest quickly, refer

to the Table of Contents at the beginning of this

manual.

This manual is solely for the use of qualied

installers and service technicians.

PURPOSE OF THE MANUAL

• Vivreau has produced this manual to provide

necessary information to qualied and

authorized personnel for the safe and proper

installation, operation, maintenance, and

servicing of the Vivreau V3-204 and V3-205

Dispensing Systems.

• Information contained in this manual will help

prevent risks to health and safety, and the risk

of economic losses.

• Keep this manual in a clearly identied and safe

place throughout the working life of the unit, so

that it will always be available as needed.

• The manufacturer reserves the right to make

modications to the unit without any obligation

to provide prior notice.

• A number of symbols have been used to

highlight particularly important parts of the text

or important specications. Their meaning is as

dened below.

WARNING

Indicates that suitable procedures must be

adopted to avoid putting people’s health and

safety at risk or causing economic losses.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in property

damage, minor or moderate injury.

IMPORTANT ________________________

Indicates important technical information

which

must not

be overlooked.

Technical SpecicationsGeneral Information

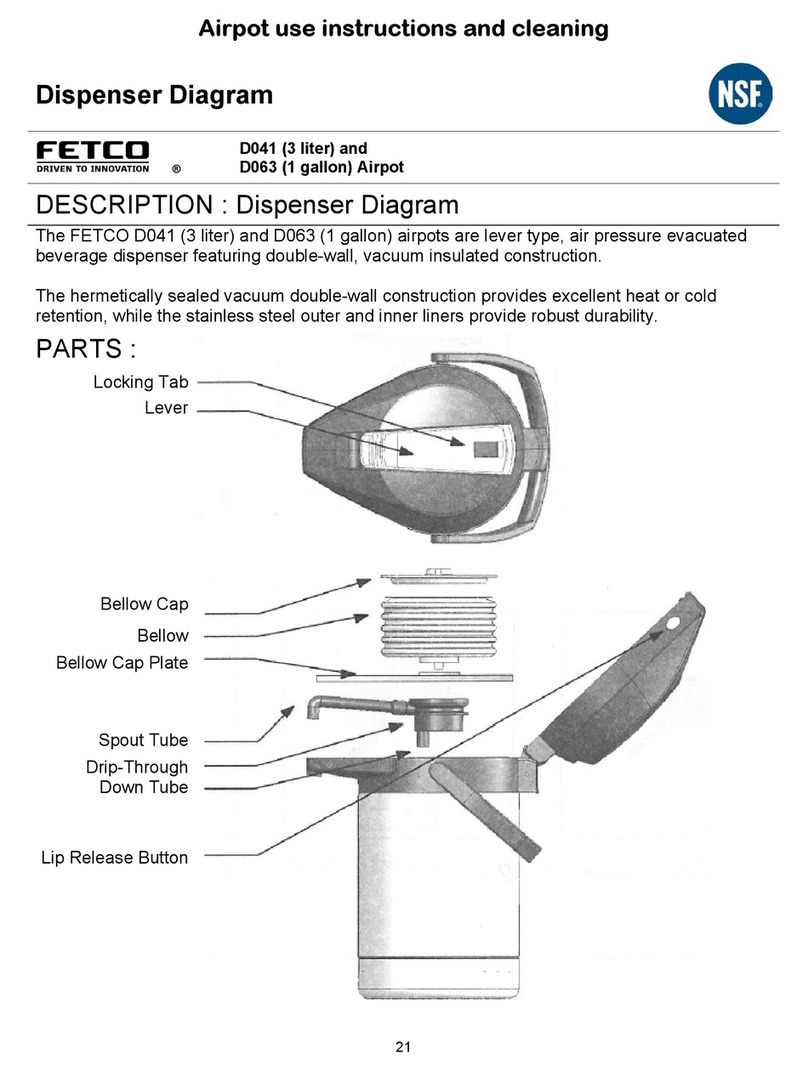

GENERAL DESCRIPTION

The Vivreau V3-204 and V3-205 Dispensing Systems

are designed to provide Chilled Still and Sparkling

Water on demand.

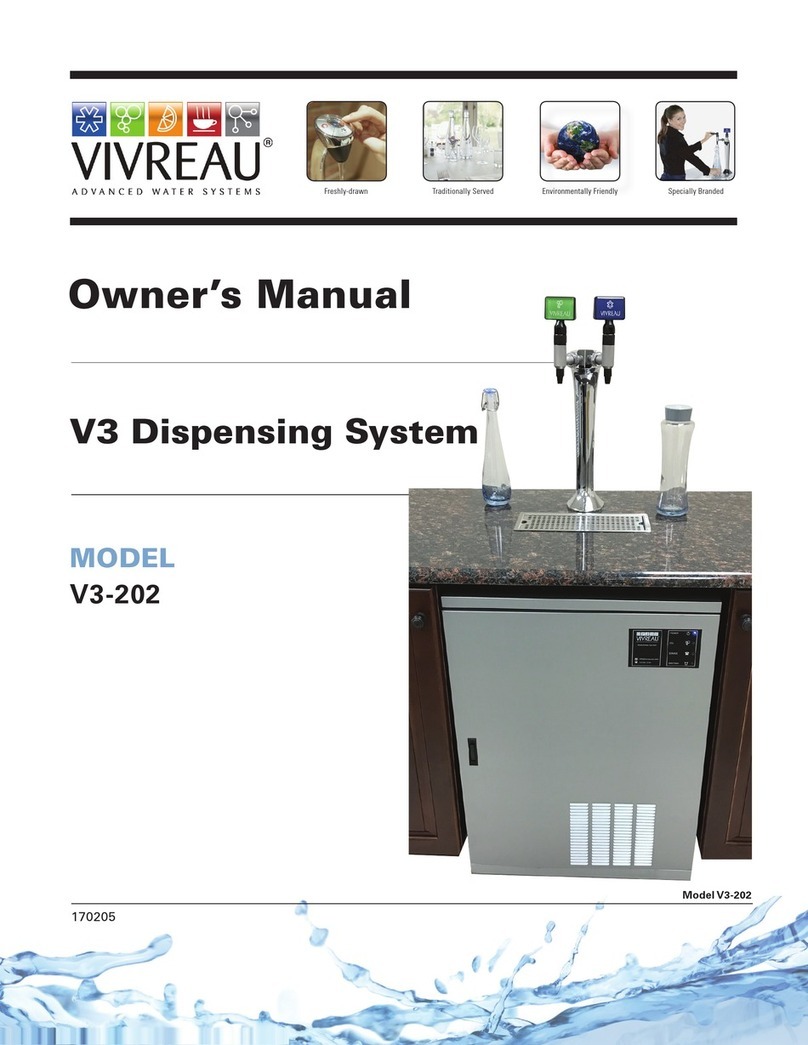

Model V3-204 is a Water Dispensing System designed

for countertop installation with the CO2Cylinder, CO2

Regulator and Water Filter mounted in a cabinet below

the unit.

Model V3-205 is a Self-Service Water Dispensing

System designed for under-counter installation with

the Dispenser Head mounted to the countertop

directly above the unit.

Each unit can be connected to a bulk CO2system, in

lieu of a CO2Cylinder and regulator.

Both systems are made up of several components

that will t under a standard minimum 24” wide base-

cabinet section.

Performance is the same for both models and

selection is based on space available for installation.

The system has been designed for operation at

ambient temperatures up to 90ºF.

Dispensing Specications

Description Specication V3-204 V3-205

Chilled still water ΔT=18 °F @ 15.8 gal/h ü ü

Chilled sparkling water ΔT=18 °F @ 15.8 gal/h ü ü

Water Pressure at Dispensing Head 5 PSI ü ü

Operating Conditions

Description Specication V3-204 V3-205

Temperature 60 – 90°F ü ü

Relative Humidity 60% (max.) ü ü

Water Supply Requirements

Description Requirements V3-204 V3-205

1/2” FNPT connection with Ball Valve 1/2” ü ü

PSI (min.) 50 ü ü

GPH (min.) 80 ü ü

Temperature (max.) 60°F ü ü

CO2Operating Pressure

Description Requirements V3-204 V3-205

Pressure 65-70 PSI ü ü

Supply Pressure (Bulk System) 100 PSI (min.) ü ü

6 7

Installation

INTRODUCTION

The Vivreau V3-204 and V3-205 Dispensing

Systems are countertop and under-counter Water

Dispensing Systems. Chilled water is available

from Dispensers that provide Still and Carbonated

Water from individual faucets.

Vivreau V3-204 and V3-205 Dispensing Systems

PRE-INSTALLATION

Below are the services required to be in place

prior to the installation of the Vivreau V3-204 or V3-

205 Dispensing System. If you have any questions

regarding these or other services, please contact

Vivreau Service Toll-Free at 877-999-1044.

WATER SUPPLY

One (1) potable 1/2” cold water supply terminating in

a 1/2” NPT Ball Valve, 1/2” female pipe thread.

IMPORTANT ________________________

Ball Valve must be accessible for service and

installation.

Minimum Water Pressure: 50 PSI

Minimum Water Flow: 80 gallons per hour

IMPORTANT ________________________

The Vivreau V3-204 and V3-205 Dispensing

System incorporates back-ow prevention. Any

additional back-ow devices required by Federal,

State or Local Code must also be supplied by the

customer prior to installation. There must not be

any other Filters/Pre-Filters inline before the unit.

ELECTRICAL OUTLET

Model V3-204 and V3-205

(1) 20 Amp Electrical Circuit (NEMA 5-20R) 120V,

60 Hz (8 Amps)

CO2

CO2Cylinder (Customer supplied) - Size should

be selected based on available space. A 20 lb.

cylinder is typical.

NOTE: If connecting to a bulk or existing CO2

system, a CO2 line terminating at a 1/4” Barbed

Shutoff Valve must be available within 40” of the

unit with 100 PSI minimum pressure.

DRIP TRAY AND DISPENSING HEAD

CUTOUTS (Model V3-205 Only)

Cut out the holes for the Drip Tray and Dispensing

Head per the supplied template.

NOTE: The Dispensing Head must be mounted

on the work surface directly above the Chiller/

Carbonator.

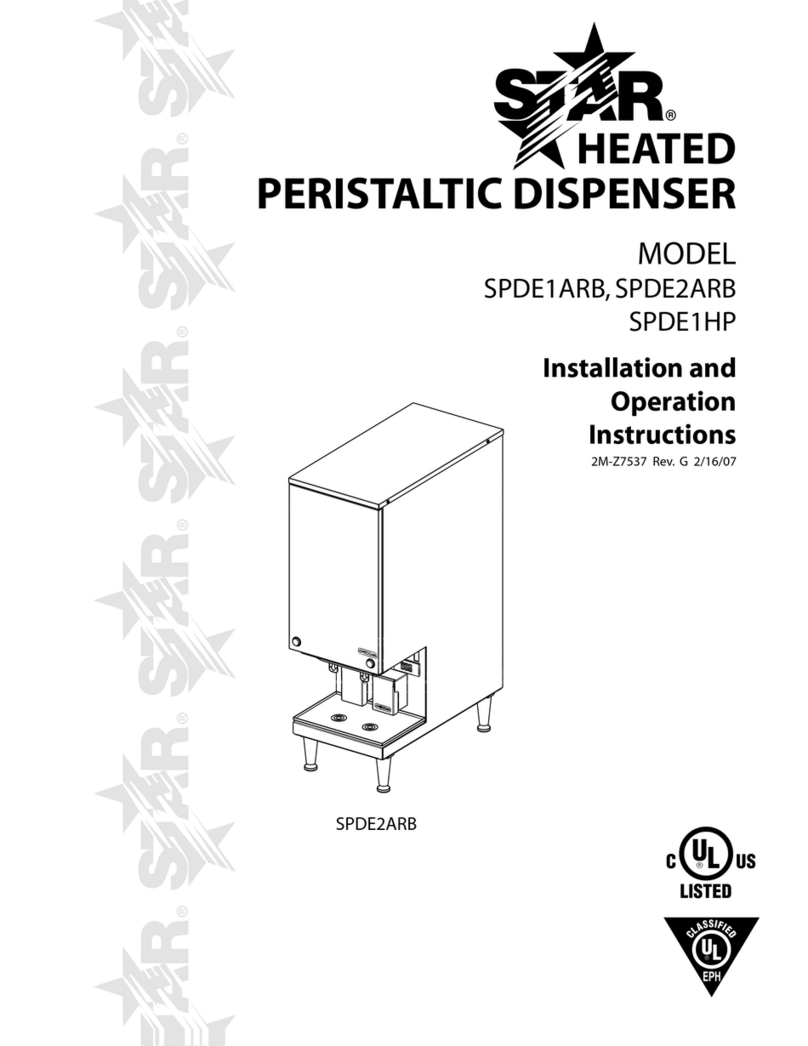

15/8"

27/8"

37/8"51/8"

121/8"

Dispensing Head Dimensions

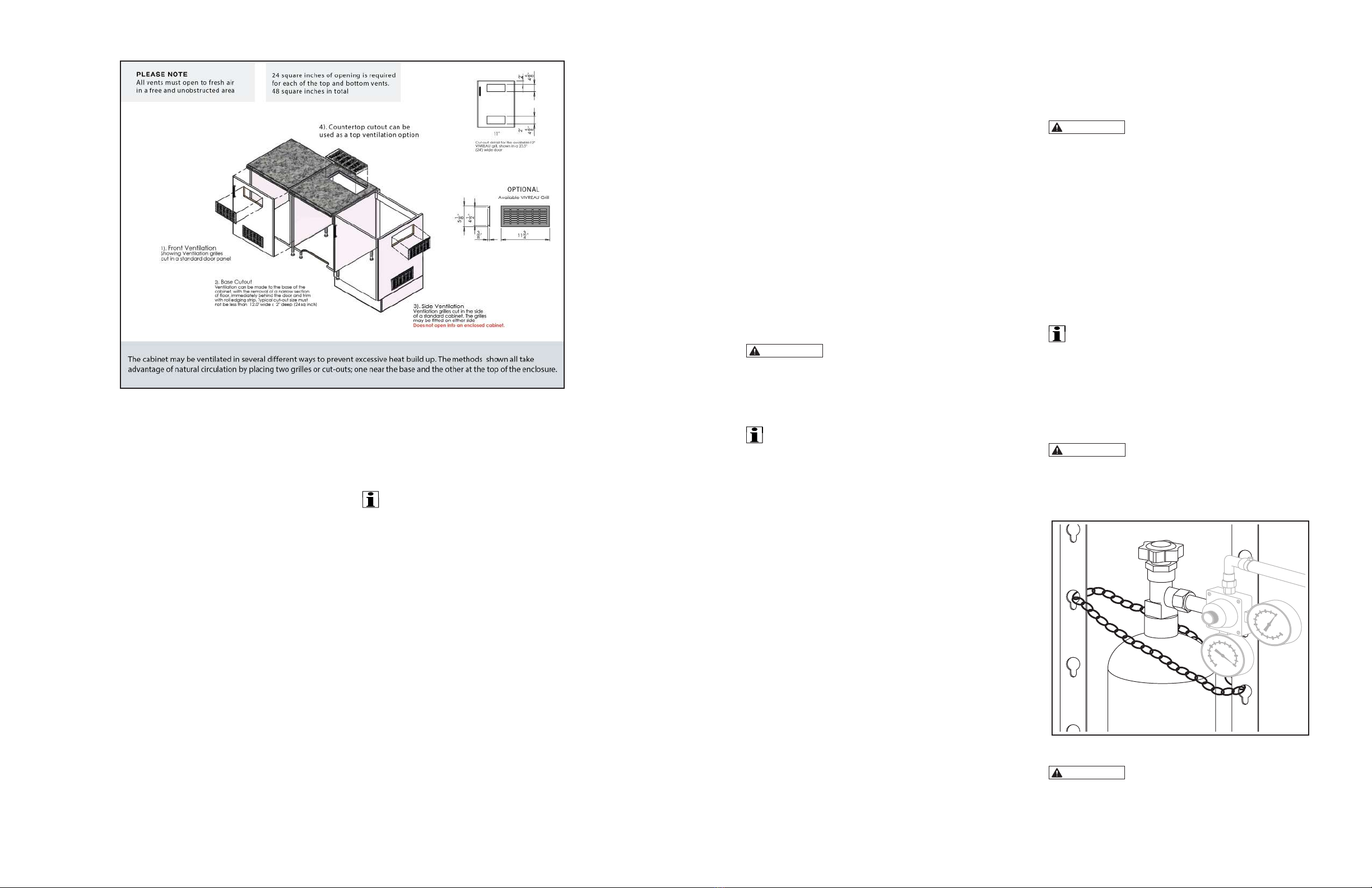

VENTILATION

If the system is to be installed in an enclosed space or

in a cabinet, adequate ventilation must be provided.

Countertop units require a 1” minimum clearance on

each side for proper ventilation.

CAUTION

Failure to provide adequate

ventilation will cause system failure.

This unit is to be installed indoors only.

Cooler/Carbonator Specications

Description Specication V3-204 V3-205

Width

14.7” ü—

14.2” —ü

Height

21.3” ü—

18.5” —ü

Depth

19.5” ü—

17” —ü

Weight 72.6 lbs. üNA

Voltage 110/120 VAC/60 Hz ü ü

Amperage

8A ü—

11A —ü

Dispenser Head Specications

Description Requirements V3-204 V3-205

Height

21.25” ü—

19.3” —ü

Distance Nozzle to Drip Tray 12.3” ü ü

Weight 7.4 lbs. NA ü

NA = Not Available

8 9

LOCATION OF SERVICES

All services must be accessible for installation

and service. Ensure all services are kept within 40”

of the V3-204 and V3-205 Dispensing Systems.

Water Shutoff Valve to be located at low level.

Ensure there is sufcient room for a 6” long tting to

be connected to the Water Shutoff Valve.

Top of drain should be located between 12” and

18” from oor level.

SHIPPING DAMAGE/MISSING PARTS

Unpack and inspect the unit for shipping damage

and/or missing parts. If any damage or missing

parts are found, contact Vivreau Service Toll-

Free at 877-999-1044 and report the missing or

damaged parts.

INSTALLER’S CHECKLIST

Below are the services required to be in place

prior to the installation of the Vivreau Dispensing

System. Please review and check all services

before beginning work. If anything is missing

or not correct, do not start the installation. Call

Vivreau Service for instructions at 877-999-1044.

WATER SUPPLY

A potable 1/2” cold water supply terminating in a

1/2” Ball Valve, 1/2” female pipe thread.

IMPORTANT ________________________

Ball Valve must be accessible for service and

installation.

Any water line or valve less than 1/2” is not

acceptable. Must be a direct supply with no

other Inline Filters.

ELECTRICAL OUTLET(S)

All Electrical Outlets must be within 40” of unit. No

Extension Cords.

Model V3-204 and V3-205

(1) 20 Amp Electrical Circuit (NEMA 5-20R) 120V,

60 Hz (8 Amps)

CO2

CO2 Cylinder (Customer supplied) must t within

the allotted space.

CO2Cylinder must always remain vertical.

If connecting to a bulk or existing CO2system, a

CO2 line terminating at a 1/4” Barbed Shutoff Valve

must be available within 40” of the unit with 100

PSI minimum pressure.

DRIP TRAY AND DISPENSING HEAD

CUTOUTS (Model V3-205 Only)

For under-counter units, cut out the holes for the Drip

Tray and Dispensing Head per the template.

The Dispensing Head must be mounted on the work

surface directly above the Chiller/Carbonator.

The Dispensing Head lines must never be extended.

DRIP TRAY DRAIN (Model V3-205 Only)

Drip Tray must be plumbed to a drain. Customer

will need to supply a properly trapped drain

according to Federal, State and Local Codes. The

drain must be large enough to accommodate a 1”

OD exible pipe.

VENTILATION

If the system is to be installed in an enclosed

space or in a cabinet, adequate ventilation must

be provided.

CAUTION

Failure to provide adequate

ventilation will cause system failure.

This unit is to be installed indoors only.

INSTALLATION

IMPORTANT ________________________

Installation must be performed by properly trained

and qualied persons and comply with Federal,

State and Local Codes for connection to electrical

supplies, water supplies and pressurized gas

systems.

Note: Vivreau cannot be held responsible for any

damage caused by improper installation.

LOCATION

A completed Pre-installation Checklist must be

available prior to installation. The Vivreau Dispensing

System must be installed indoors where the ambient air

temperature will not exceed 90°F.

The Vivreau Dispensing System should not be

exposed to spills, spray, steam or high humidity.

A suitable location should be chosen within 40” of

the electrical and water supply connections.

Vivreau Model V3-204 is designed to be installed with a

minimum 1” clearance on the left and right sides.

Allow adequate space in the rear of the unit for

connections. This will allow for proper ventilation.

Vivreau Model V3-205 is designed to be installed

in an under-counter cabinet with adequate

ventilation for component cooling.

Do not obstruct air vents.

Install the system on a rm, level oor or base.

CONNECTIONS

WARNING

This unit must be electrically

grounded.

ELECTRICAL

Power Supply: 120V 60Hz

Power Supply Connection Type: NEMA 5-20 plug

Grounded, with proper circuit protection.

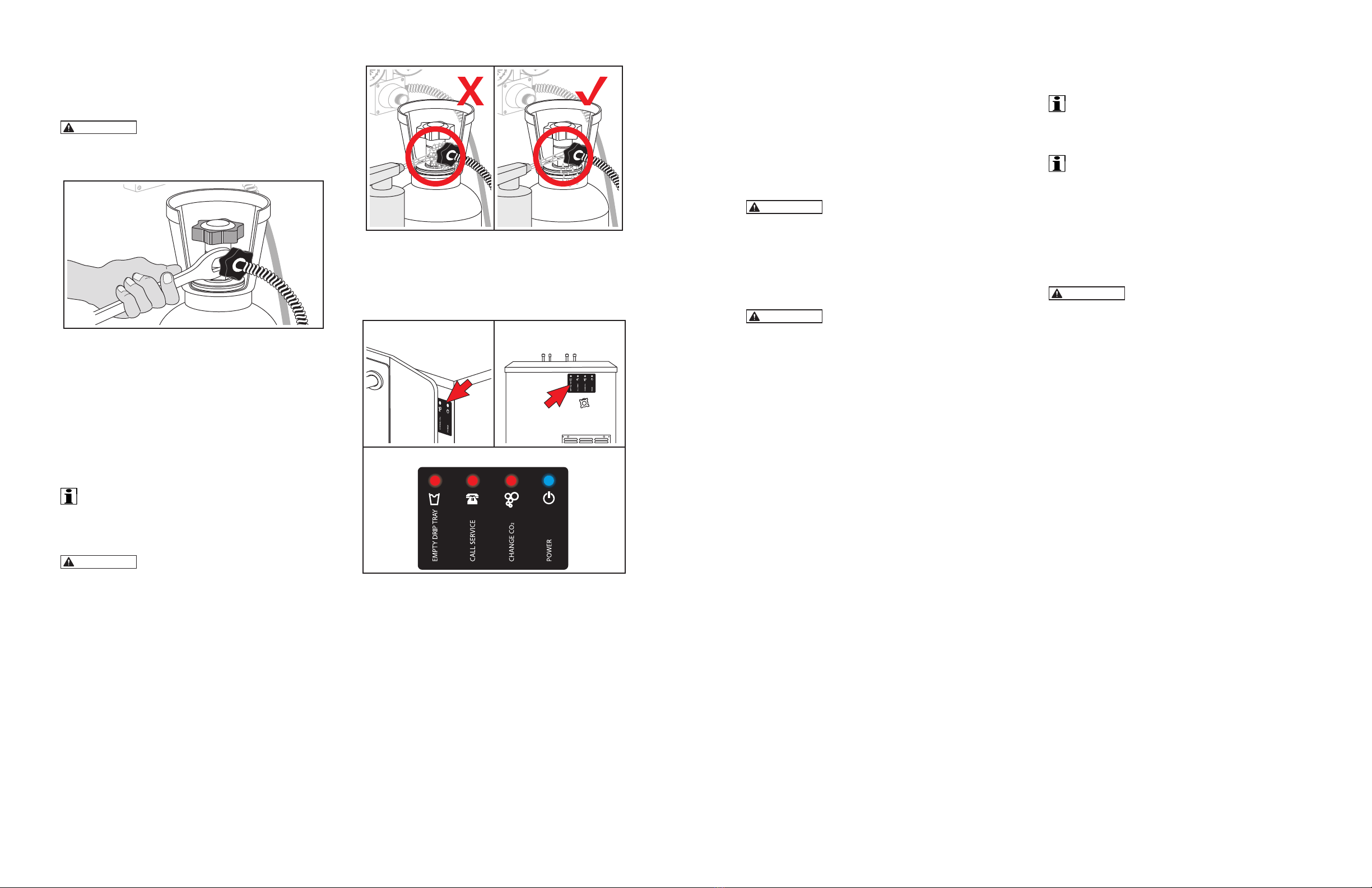

CO2

Mount the CO2Regulator in a secure location

where it will not be subject to damage.

A Cylinder of food-grade CO2gas is required. Only

use non-syphon type Cylinders.

IMPORTANT ________________________

Before connecting, with the Cylinder Outlet

turned away, open Valve for short blast and

close immediately. This will clear any debris

from the outlet.

CO2Cylinder must be installed vertically and

secured with a Chain, Strap or Bracket.

CAUTION

CO2Cylinders should always be

secured in the vertical position with the Outlet

Valves positioned at the top. This will help

prevent injury caused by the entry of liquid

Carbon Dioxide into the Pressure Regulator.

CO2Cylinder Installation

WARNING

Never open the Gas Cylinder

Valve without the Gas Regulator installed.

Ventilation Options

10 11

Ensure the Sealing Washers are positioned

between the Gas Regulator / Regulator Hose and

Cylinder and connect the Cylinder.

Regulator

Sealing

Washers

CO2Cylinder

Sealing Washer Locations

Connect the Regulator to the unit using the supplied

Installation Kit. Tighten all connections.

In the event of a CO2leak, close the Cylinder Valve,

retighten connection(s) and retest. If leak persists,

report leak to Vivreau.

CO2Pressure: 65 - 70 PSI. Adjust Regulator as

needed.

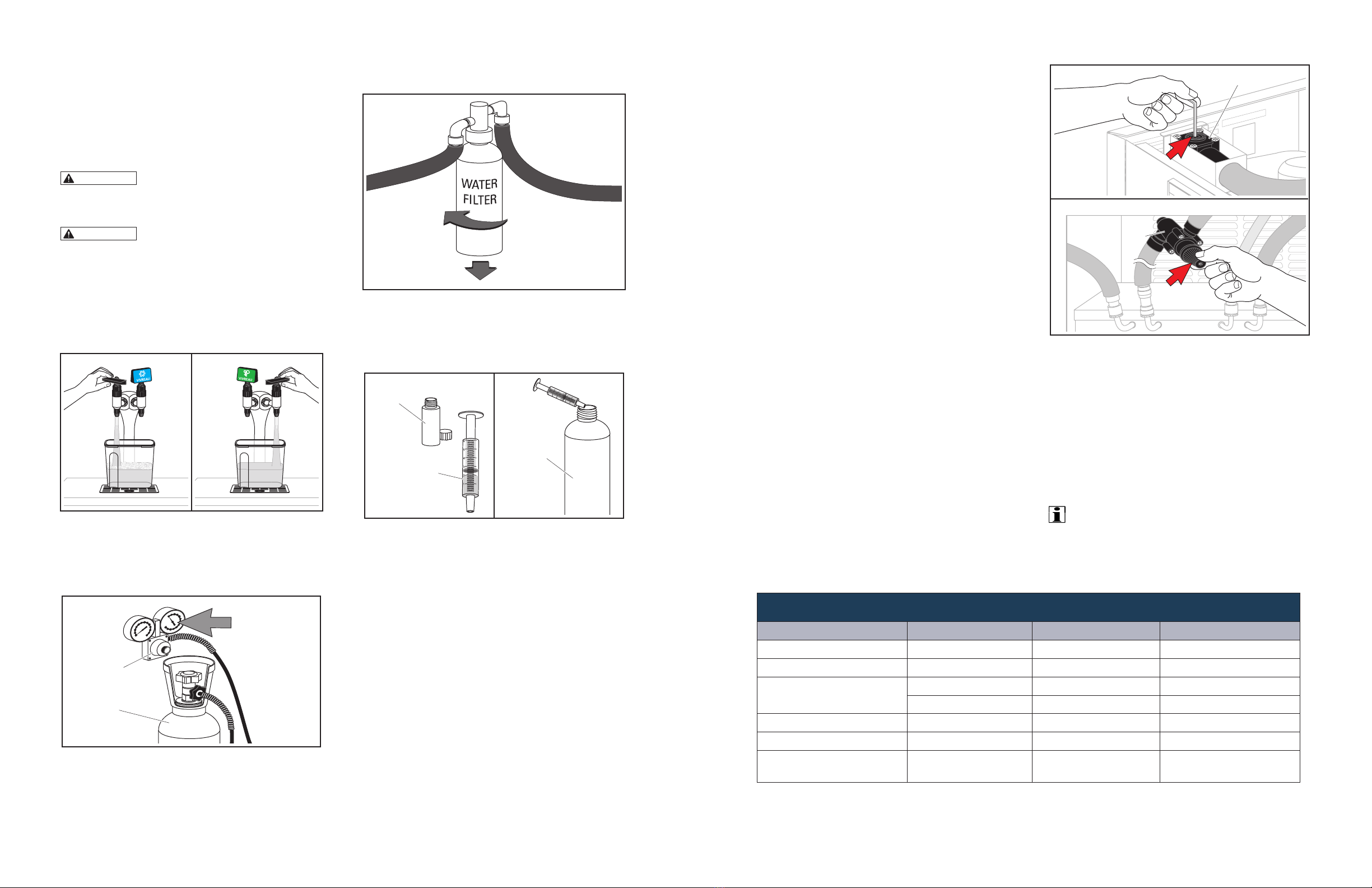

WATER

The Vivreau V3-204 andV3-205 DispensingSystems

provide back-flow prevention, however, it must

be installed with adequate back-flow protection to

comply with applicable Federal, State and Local

Codes. Additional back-flow prevention must be

installed prior to connecting the unit to the water

supply.

The water supply to the unit must be cold, potable

water with an accessible Shutoff Valve.

Water connection to the supply is 1/2” FNPT.

Water Inlet connection to the unit is 3/8” tube. A

Retaining Clip must be used to attach the tube to

the connection on the unit.

CO2

In

Still

Out

Sparkling

Out

Water In

From Filter

V3-205V3-204

Retaining Clip

Water

Connection

CO2

Connection

Connecting Water Supply

Insulate the pipe to prevent condensation.

The supply water pressure must be 50 PSI minimum

with a minimum ow of 1.5 gal/min. A Booster Pump

(for low pressure) or Pressure Regulator (for high

pressure) may be required to ensure the pressure.

IMPORTANT ________________________

Only connect water supply to the unit after

filling the Internal Water Tank with the water

supply line.

DISPENSING HEAD

The Dispensing Heads for Model V3-204 come

assembled and connected to the front of the unit.

Assemble and mount Dispensing Heads for Model

V3-205, making sure Dispensers are tight and

straight.

V3-205V3-204

V3-204 and V3-205 Dispensing Heads

COUNTERTOP INSTALLATION

(Model V3-204)

Place the unit on a at, level surface; use adjustable

feet to level if necessary.

Position Drip Tray beneath Dispensers.

Mount Filter Head nearby (under-counter cabinet,

rear wall, etc.) and secure.

Select a location for the CO2Cylinder where it can

be secured in an upright position.

UNDER-COUNTER INSTALLATION (Model

V3-205)

The Under-Counter Cooler/Carbonator System

is intended to be located directly under the

Dispensing Head.

The Drip Tray is positioned in the counter under

the Dispensing Head and should have lateral play

of no more than 1/8”.

Dispensing Head Connection Tubes are to be

build-up.

connected to the Under-Counter System directly

using the Installation Kit supplied by Vivreau.

Adequate ventilation must be provided in under-

counter installations to prevent excessive heat

build-up.

DRIP TRAY DRAIN (MODEL V3-205 ONLY)

Connect exible hose to Drip Tray Drain Fitting and

route to existing drain. Drain should be a Stand-

Pipe with a trap, 1.25” diameter.

FILLING THE WATER TANK

WARNING

Disconnect unit from electrical

power supply.

Before making the nal water connection to the unit:

Remove the Overow Plug, located on the Rear Panel on

Model V3-204 and Front Panel on Model V3-205.

Prop the side opposite the Overow Plug up about 1”.

Slowly ll the Water Tank using the Water Supply Line.

Catch any water that overows.

Remove

Overflow

Drain

Tube Plug

Water

Supply

Line

Drain Overow

Level the unit.

Replace the plug.

Connect Water Supply Line to unit.

Clean up any spills.

CAUTION

Do not leave the Water Hose

unattended while filling.

Make sure no water spills onto electrical

components.

Unless approved by Vivreau, do not use de-ionized

water or add any substance to the water.

CAUTION

The installer must stay on site

until a full icebank has formed. Water will be

displaced and exit from the overflow.

CONNECTING THE CO2

Ensure both Dispensers are in the closed

(UP) position.

Open the units door for access and connect the CO2

Regulator to the CO2Cylinder or bulk system. Ensure

the Sealing Washer is used for each connection.

V3-205

Regulator

CO2tank

Sealing

Washers

Connect the CO2Cyliner

Open the CO2 Cylinder Valve or turn ON bulk CO2

supply and check for leaks.

Set Regulator Pressure to 65 - 70 PSI.

CARBONATOR BOWL ACCESS

To access the Carbonator Bowl, remove the two (2)

Screws across the rear of the Top Panel and remove

panel.

Top Panel Removal s

12 13

Carbonator

Bowl

Carbonator Bowl Location

Vent the Carbonator Bowl for two (2) seconds. To

do this, lift the Carbonator Relief Valve located on

the Carbonator Bowl.

Carbonator Relief Valve Location

Make sure adequate Water Supply Pressure of 50

PSI minimum is present.

Connect the water supply to the Inlet Fitting on the

rear of the unit.

Secure with a Retaining Clip, and turn ON the

water.

Replace Back and Service Panels, Clamp and

Panel Screws.

Plug in the Power Cord to the electrical outlet.

Proceed with sanitizing the water system. Follow

Vivreau Sanitizing Process Instructions.

IMPORTANT ________________________

The Sanitizing and Filter Change Procedure

should only be performed by qualified and

authorized personnel.

After sanitizing, unplug unit. Remove Back and

Service Panel, and install the normal service Filter

Cartridge.

Reinstall Back and Service Panels and plug in unit.

Dispense two (2) gallons of water through each

Dispenser, Still and Sparking, to ush all Sanitizing

Solution from system.

Flushing the Sanitizing Solution

(Model V3-205 Shown)

Taste test samples from each Dispenser. Continue

to ush, if needed.

unit is ready for service.

Fill out Installation Checklist and return to Vivreau..

DISPENSING

Before operating either the Vivreau V3-204 or

V3-205 Dispensing System, make sure the Water

Supply Valve is open and the unit is plugged in.

Place appropriate container on Drip Tray beneath

Dispensing Head.

Chilled Still Water

Pull DOWN on Blue Dispenser Handle. Push

Dispenser Handle UP when full.

Dispensing Chilled Still Water (Model V3-205 Shown)

Chilled Sparkling Water

Pull DOWN on Green Dispenser Handle. Push

Dispenser Handle UP when full.

Dispensing Chilled Sparkling Water

(Model V3-205 Shown)

The Dispenser Handles should be fully opened

when filling and fully closed when filling is

complete.

IMPORTANT ________________________

Do not allow the Dispenser Handles to slam shut.

The Dispenser Handles must be closed after each

Bottle is lled.

The Vivreau V3-204 and V3-205 Dispensing Systems

are designed to ll Bottles of up to one (1) liter, one

Bottle at a time.

Vivreau Bottles should be lled to the line in the

neck just below the Cap.

IMPORTANT ________________________

Sparkling Water requires room for the CO2gas

to expand.

At the end of service, remove the Black Dispenser

Nozzles and soak in Sanitizing Solution.

The Dispensers and unit should be wiped down

with Sanitizing Solution to keep the Dispensing

System clean and in hygienic condition.

Once the unit is wiped down and Nozzles removed,

both Dispensers must be wrapped in plastic wrap

to prevent contamination and misuse while not in

service.

To return the Vivreau V3-204 or V3-205 Dispensing

System to service, remove all plastic wrap and rinse

Dispenser Nozzles.

Reinstall the Nozzles into the Dispenser Head.

CHANGING A CO2CYLINDER

WARNING

Wear protective gloves and

safety glasses when changing CO2Cylinders.

Close the Valve on top of the empty Cylinder.

Close Empty Cylinder Valve

Operating Instructions

14 15

Using the proper wrench, loosen the Nut on the

Cylinder to disconnect the High-Pressure Hose or

Primary Regulator. Allow residual gas to escape

from the hose.

WARNING

The line is pressurized.

Pressure will be released while performing this

procedure. Handle carefully.

Disconnect High-Pressure Hose

Place the Regulator within safe reach.

SECURE CYLINDER

Move empty Cylinder to storage area and secure

safely.

Remove the plastic plug or tape from the new full

Cylinder outlet and discard it.

IMPORTANT ________________________

To avoid confusion, do not replace plastic

plugs in the outlet of empty CO2Cylinders.

WARNING

Wear protective gloves and safety

glasses when purging Cylinder. Be sure to point

the Cylinder outlet away from your body.

Purge the replacement Cylinder by quickly opening

and closing the Valve on top to clear any dust or

moisture from the outlet.

Connect the High-Pressure Hose or Primary

Regulator. Make sure the Sealing Washer is seated

correctly.

Tighten the Nut rmly using a wrench.

Open the Valve on top of the Cylinder.

Check for leaks using a solution of soapy water or

a commercial equivalent.

Checking for Leaks

LED DISPLAY PANEL

The LED Display Panel indicates the status of the

unit and is located on the front panel of the unit.

V3-205V3-204

LED PANEL LIGHTS

LED Display Panel Location and Lights

POWER: When the Dispensing System is plugged

in and turned ON, a Blue LED will be illuminated.

CHANGE CO2: When the CO2supply is low, a Red

LED will illuminate and the unit will beep; alerting

you to change the CO2Cylinder.

CALL SERVICE: If there is a problem, a Red LED will

illuminate and the unit will beep. Please contact Vivreau

Service Toll-Free at 877-999-1044 immediately.

EMPTY DRIP TRAY (Not Activated on this unit):

When the Drip Tray Container is FULL, a Red LED will

illuminate and the unit will beep; alerting you to empty

the Drip Tray Container located just inside the cabinet

front door or below the Dispensing System.

MAINTENANCE RECOMMENDATIONS

Keep the unit at peak efciency by performing

all scheduled maintenance procedures that

are recommended by the manufacturer. Proper

maintenance will allow the best performance and a

longer working life.

WARNING

Before performing any service

procedure, perform all safety procedures. In

particular, turn OFF the water supply, disable

the electricity at the main circuit breaker

and prevent access to all devices that might

cause unexpected health and safety hazards

if turned ON.

WARNING

Before performing any service

that involves electrical connection or

disconnection and/or exposure to electrical

components, ALWAYS follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all

circuits. Failure to comply can cause property

damage, injury or death.

At the end of each day or whenever necessary, be sure

to clean:

• Dispensing Head/Nozzle

• Drip Tray

• The surrounding work area

Every year, have skilled, authorized personnel

perform the following operations:

• General check of the unit

• Identify and replace worn parts

IMPORTANT ________________________

Record all yearly inspections.

IMPORTANT ________________________

Contact the factory, the factory representative

or an authorized service agent to perform

maintenance and repairs.

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

WARNING

Before performing any service

that involves electrical connection or

disconnection and/or exposure to electrical

components, ALWAYS follow the Electrical

LOCKOUT/TAGOUT Procedure. Disconnect all

circuits. Failure to comply can cause property

damage, injury or death.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

unit. Before performing any maintenance or service

that requires exposure to electrical components,

follow these steps:

In Electrical Box, place unit Circuit Breaker into

OFF position.

Place a lock or other device on the Electrical Box

Cover to prevent someone from placing Circuit

Breaker in the ON position.

Place a tag on Electrical Box Cover to indicate

that unit has been disconnected for service and

power should not be restored until tag is removed

by maintenance personnel.

Disconnect the unit’s Power Cord from Electrical

Outlet.

Place a tag on the Power Cord to indicate that the

unit has been disconnected for service and power

should not be restored until tag is removed by

maintenance personnel.

Maintenance

16 17

STAINLESS STEEL CARE

Cleaning

Stainless steel contains 70-80% iron, which will

rust if not properly maintained. It also contains 12-

30% chromium, which forms an invisible passive,

protective lm that shields against corrosion. If the

lm remains intact, the stainless steel will remain

intact. However, if the lm is damaged, the stainless

steel can break down and rust. To prevent stainless

steel breakdown, follow these steps:

CAUTION

Never use any metal tools. Scrapers,

les, wire brushes or scouring pads (except for

stainless steel scouring pads) will mar the surface.

CAUTION

Never use steel wool, which will

leave behind particles that rust.

CAUTION

Never use acid-based or

chloride-containing cleaning solutions, which

will break down the protective film.

CAUTION

Never rub in a circular motion.

CAUTION

Never leave any food products

or salt on the surface. Many foods are acidic.

Salt contains chloride.

For routine cleaning, use warm water, mild soap or

detergent and a sponge or soft cloth.

For heavy-duty cleaning, use warm water, a degreaser

and a plastic, stainless steel or Scotch-Brite pad.

Always rinse thoroughly.

Always rub gently in the direction of the steel grain.

Preserving & Restoring

Special stainless steel polishing cleaners can

preserve and restore the protective lm.

Preserve the life of stainless steel with a regular

application of a high quality stainless steel

polishing cleaner as a nal step to daily cleaning.

If signs of breakdown appear, restore the stainless

steel surface. First, thoroughly clean, rinse and

dry the surface. Then, on a daily basis, apply a

high-quality stainless steel polish according to

manufacturer’s instructions.

Heat Tint

Darkened areas, called heat tint, may appear on

stainless steel exposed to excessive heat, which

causes the protective lm to thicken. It is unsightly

but is not a sign of permanent damage.

To remove heat tint, follow the routine cleaning

procedure. Stubborn heat tint will require heavy-

duty cleaning.

To reduce heat tint, limit the exposure of equipment

to excessive heat.

DAILY CLEANING

The Vivreau V3-204 and V3-205 Dispensing

Systems should be cleaned once a day.

Vivreau recommends using disinfectant spray or a

sanitizing wipe for cleaning.

If the Dispensing Head becomes soiled with coffee,

tea, milk, etc., clean with hot soapy water using a

non-abrasive cloth.

Clean the Drip Tray Cover and inside the Drip Tray

using either disinfectant spray (non-chlorine) or

hot, soapy water and non-abrasive cloth.

Keep area around the unit clean and sanitized.

Viverau V3-204 and V3-205 Dispensing Systems

equipment in the under-counter area should be

kept free of dust; the ventilation should not be

obstructed restricting free air ow around the

equipment.

The VivreauV3-204 and V3-205 Dispensing Systems

Nozzles should be removed daily and cleaned with

hot soapy water and a non-abrasive cloth.

After completing all cleaning tasks, dispense water

for at least 10 seconds to ush through the Nozzle.

DO NOT use any abrasive material on your Vivreau

V3-204 or V3-205 Dispensing System.

SERVICE INFORMATION

The CO2Cylinder is located inside the cabinet

door.

IMPORTANT ________________________

Maintenance and repairs must only be

performed by qualified and trained personnel

and comply with Federal, State and Local

Codes for connection to electrical supplies,

water supplies and pressurized gas systems.

WARNING

Always electrically disconnect

the Vivreau system before removing covers or

carrying out any work.

IMPORTANT ________________________

If the unit malfunctions, develops a leak,

sustains physical damage or component

failure, UNPLUG THE POWER CORD.

If any maintenance or service is required, refer

to the troubleshooting chart, wiring diagram and

exploded parts drawings contained in this manual.

IMPORTANT ________________________

Only use Vivreau recommended spare parts

for cooler maintenance. Failure to do so will

invalidate cooler approvals and warranty.

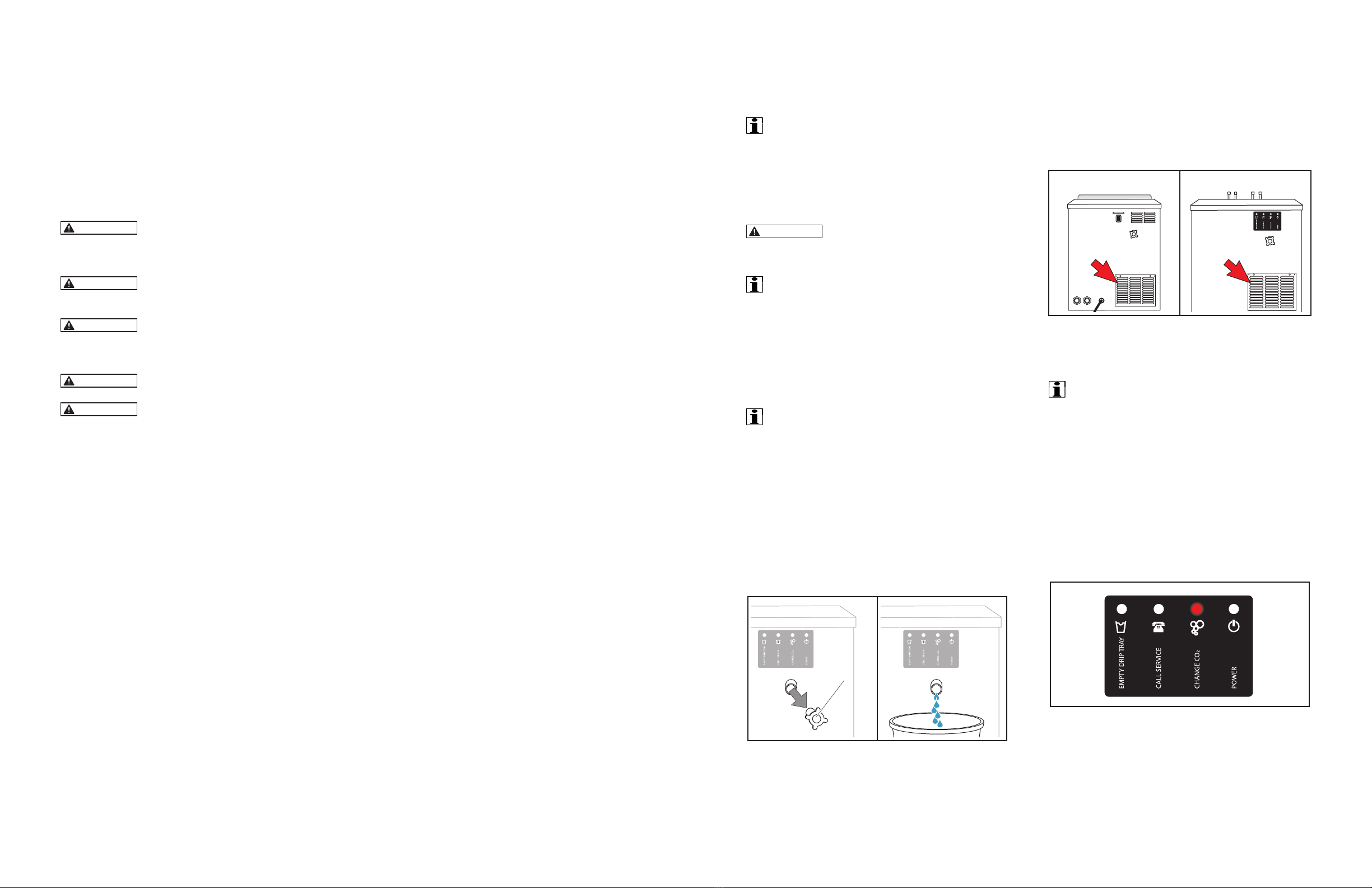

MAINTENANCE

Chiller Unit

Check that the Water Level in the Tank is up to the

Overow Plug. Tip unit, if necessary, to observe

the Water Level.

Remove

Overflow

Drain

Tube Plug

Check Water Level

CONDENSER GRILLE

The Cooling System Condenser Grille should be

cleaned regularly, a minimum of every three (3)

months, with a vacuum cleaner or soft brush to

ensure the equipment can breathe. The Condenser

is located on the front of the unit behind the cabinet

door.

V3-205V3-204

Condenser Grille Location

CARBONATOR PUMP PROTECTION

IMPORTANT ________________________

The Carbon Vane Pump located on the

Carbonator Motor should never be run dry.

This will cause permanent damage to the unit.

To reduce this risk, the Controller has a timer

circuit that will automatically turn OFF the

Motor and Solenoid after running continuously

for approximately two (2) minutes.

If there is a problem, a Red LED will illuminate and

the unit will beep. Please contact Vivreau Service

Toll-Free at 877-999-1044 immediately.

LED Display Panel CALL SERVICE

18 19

WATER FILTRATION

Replace the Water Filter after 25,000 gallons or

every 6 months of use, whichever comes first.

Follow ALL Sanitizing and Filter Change Procedures.

SANITIZING AND FILTER CHANGE

WARNING

Make sure Do Not Use sign is

displayed throughout the entire sanitation

process.

WARNING

Always wear safety glasses

while handling the sanitizing chemicals.

Turn the main Water Supply OFF and unplug the

Power Cord.

To drain both Still and Sparkling Water, pull down

the Blue and Green Dispensing Handles until the

water stops.

Pull Down to Drain Still and Sparkling Water

(Model V3-205 Shown)

Conrm the proper CO2Pressure, 65 - 70 PSI, at

the Regulator and adjust if necessary.

Regulator

CO2Cylinder

CO2Pressure

65-70 PSI

Conrm CO2Pressure

Remove the old Filter Cartridge by turning counter-

clockwise and pulling down.

Remove Old Water Filter

Using the supplied Syringe, ll Sanitizing Cartridge

with 2ml (about 1/2 teaspoon) of Sanitizing Solution

and insert Sanitizing Cartridge into Filter.

Sanitizing

Solution

Sanitizing

Cartridge

2 ml

Insert Sanitizing Solution

Turn the water supply back ON.

Pull down the Blue Still Dispenser Handle and

dispense water until the Sanitizing Solution

appears. Push up on the Dispenser Handle to stop.

Plug in the Power Cord and allow the Carbonator

to cycle completely.

Unplug the Power Cord.

Pull down the Sparkling Water Dispenser

Handle until Sanitizing Solution is dispensed.

Leave Sanitizing Solution in the lines for at least

10 minutes.

Check all ttings and connections for leaks.

Clean and wipe the entire system with a soft

cloth using anti-bacterial spray; you can also use

disposable sanitizing wipes. Pay close attention to

the Drip Tray and inside the Drip Tray; remove any

scale deposits found.

Clean Condenser Grille with a soft brush and

remove any dust or grease.

When the sanitizing time has elapsed, turn the

Water Supply OFF and drain the Still Water from

the Dispensing Head until the water stops.

Remove Sanitizing Cartridge and install a new

Filter.

Turn Water Supply ON and dispense at least ve (5)

gallons of Still Water or until the water is clear and free

of any Sanitizing Solution.

Pull down the Green Sparkling Dispenser Handle

and ush until water stops and only CO2gas is

dispensed.

Plug in the Power Cord and allow the Carbonator

to cycle completely.

Unplug the Power Cord.

Pull down the Green Sparkling Dispenser Handle

again until just CO2gas is dispensed. Repeat this

process at least four (4) times to ensure all of the

Sanitizing Solution has been ushed out.

Plug in Power Cord.

Make sure the Refrigeration System is operating

properly.

Check the Sparkling Water ow-rate. It should

dispense one liter in 20 seconds.

Adjust the ow regulator if needed.

Flow Regulator

V3-205

Flow Regulator

V3-204

Flow Regulator Adjustment

Replace all panels

Before putting the Vivreau Dispensing System back

into service, taste test both the Still and Sparkling

water. If any residual taste, continue ushing and

retest.

Remove the DO NOT USE Sign and carefully

inspect the water system for leaks.

The Vivreau Dispensing System is ready for use.

IMPORTANT ________________________

Make sure to complete the Vivreau Service

Checklist recording all information required.

Cleaning Schedule

Component Task Frequency Personnel

Dispensing Head/Nozzle Clean and Sanitize Daily End-User

Drip Tray Drain, Clean Daily End-User

CO2Cylinder Fill Level Weekly End-User

Replace As Needed End-User

Chiller Condenser Grille Clean, Degrease Weekly End-User

Chiller Exterior Clean Weekly End-User

Water Filter Replacement Twice Yearly Authorized Service

Dealer

20 21

CLEANING THE DISPENSER NOZZLES

The Vivreau V3-204 and V3-205 Dispensing

Systems are equipped with removable Nozzles for

ease of cleaning and sanitizing.

IMPORTANT ________________________

The Nozzles must be cleaned separately in

Sanitizing Solution.

WARNING

Wear protective gloves when

handling Sanitizing Solution.

Fill a small container with Sanitizing Solution.

Unscrew the Nozzle.

Dispensing Nozzles (Model V3-205 Shown)

Submerge Nozzle and cover in Sanitizing Solution.

Soak for a minimum of 4 hours.

Remove parts from Sanitizing Solution and rinse

thoroughly.

Re-install sanitized Nozzles.

Wipe external surfaces of Dispenser Handles.

CLEANING THE DRIP TRAY

Lift Drip Tray Lid from unit.

V3-205

V3-204

Clean the Drip Tray

Wipe top and bottom of Drip Tray Lid with a clean

cloth and Sanitizing Solution.

Wipe interior of Drip Tray with a clean cloth and

Sanitizing Solution.

Replace Drip Tray Lid.

INSPECTING THE CO2CYLINDER

Open the Front Door and inspect the CO2Regulator

Gauge.

Make sure Cylinder Valve is open.

If the CO2 Cylinder is nearly empty, the Needle on

the Gauge will be in the Red Zone.

CO2Regulator Gauge

CO2Regulator Gauge

Replace Cylinder if needed.

CLEANING THE COOLING SYSTEM

CONDENSER GRILLE

The Cooling System Condenser Grille is located on

the front of the unit.

CAUTION

Condenser Grille must be kept

clean to allow proper cooling of components.

Unit damage will occur due to overheating!

The Cooling Fins must not be blocked and must

maintain a minimum distance of 4” to other objects.

Never cover the Cooling Fins.

Never place objects in front of the Cooling Fins.

Clean the Cooling Fins with a suitable brush or with

a vacuum cleaner.

Degrease with a soft cloth sprayed with degreaser.

CAUTION

Never spray degreaser or any

other liquid into the Condenser Grille.

EXTERIOR CLEANING

Wipe all surfaces with a soft cloth and non-abrasive

cleaner.

IMPORTANT ________________________

Never use abrasive cleaners to clean the

equipment.

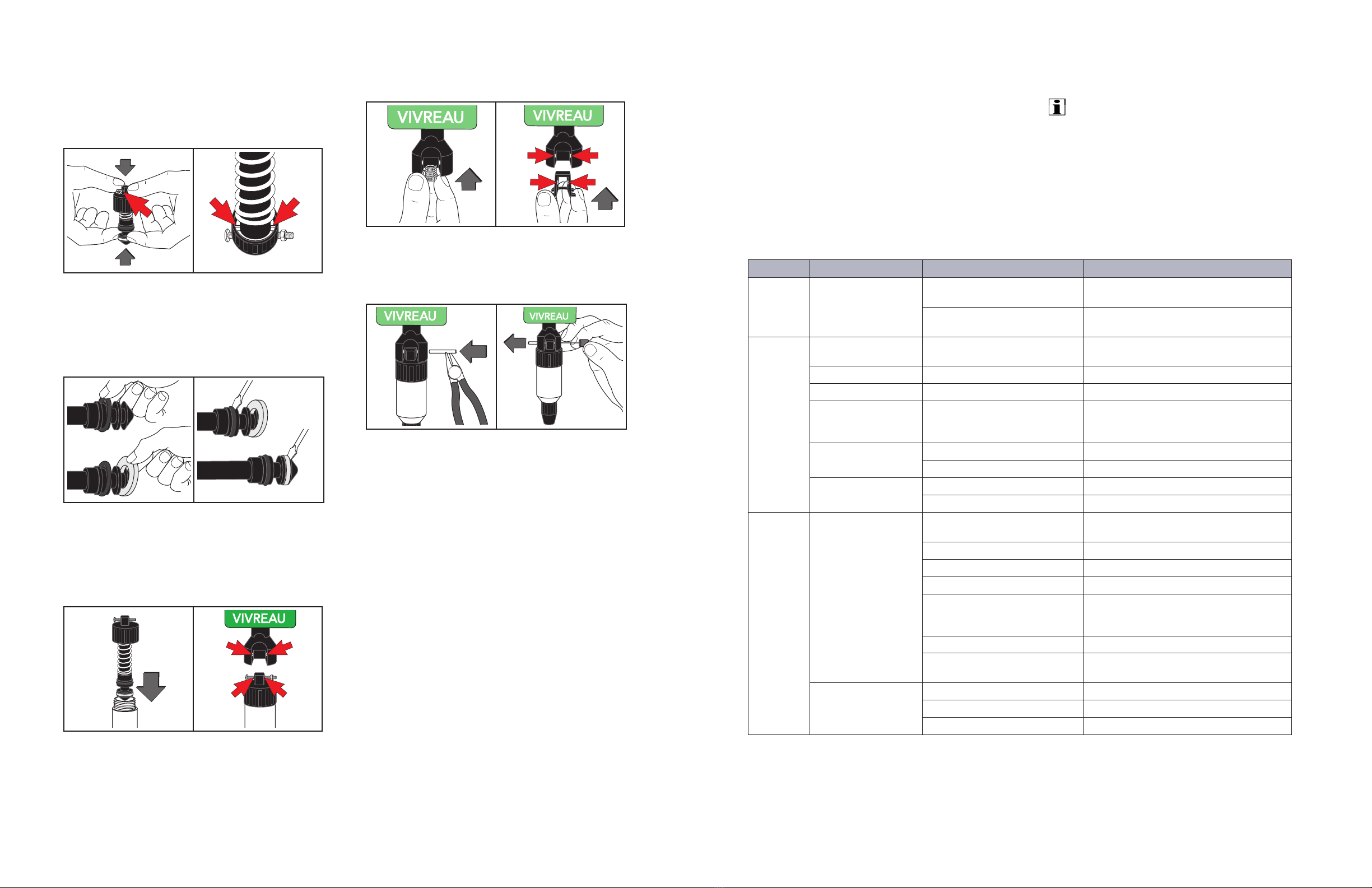

DISPENSER HANDLE ASSEMBLY CLEANING

Disassembly

Use Drift Pin to push the Roll Pin from the Dispenser

Handle

Remove the Roll Pin using pliers. Remove

Dispenser Handle.

Spring

Removing Roll Pin and Dispenser Handle

Secure with Screw and Nut to ensure it stays

together.

Rotate the top counter-clockwise. Remove

Assembly up from Dispenser Body.

Secure with Screw and Nut and

Rotate Top Counter-Clockwise

IMPORTANT ________________________

Wrap the metal Dispenser Body with plastic

film to prevent dirt from entering.

Press Dispenser Collar down rmly.

Remove Screw and release spring pressure gently.

Dispenser Collar and Screw Removal

REMOVING THE SEALS

With a at edged tool, pry the Seal from groove.

Remove Seal from groove.

Replace the Seal, if damaged.

Pry and Remove Seals from Groove

22 23

Reassemble the Dispenser

Press Dispenser Collar down rmly, reinsert screw

and release the spring pressure gently.

Alignment of the dimple and hole illustrated by the

position of the Screw.

Dimple and Hole Alignment

Gently feed into position and then work the

remainder around the piston into groove.

Use a at edged tool to ensure the Seal is located

correctly.

Position Seal with Flat Edged Tool

Reassemble Piston to Dispenser Body.

Screw the Cap onto the body. Ensure the Screw is

positioned properly to allow internal components

to align.

Reassemble Piston and Cap

Insert spring in Dispenser Handle.

Push in Plastic Insert and position with Screw.

Insert Spring and Position Plastic Insert

Position Dispenser Handle and align holes.

Drive Roll Pin back into position.

Dispenser Handle Roll, Pin In Position

Troubleshooting

The information provided in this section is intended

to assist in the identication and correction of any

irregularities and malfunctions which might occur

during operation.

IMPORTANT ________________________

Maintenance and repairs must be carried out by

properly qualied and trained personnel only.

Always switch OFF and unplug the equipment

before performing any service or repair

procedures.

CHILLER/CARBONATOR SYSTEM

Problem Possible problem Possible cause Action

Water

will not

dispense

Water frozen in Coil Ice bank too large

Faulty ice bank control

Replace

Poorly positioned/ faulty Ice

Sensor

Re-position/Replace Ice Sensor

No

sparkling

water

Water Pump or Motor

failure

Pump or Motor failure Replace Pump or Motor

Unit not switched ON Turned OFF Turn on to activate the carbonation system

Water Inlet Valve Faulty Replace Valve

Controller timed out Leak in system or too much water

dispensed in a short period

Check for leaks before re-setting Controller

– Achieved by interrupting the electrical

supply

CO2alarm sounds Low or no CO2supply Replace CO2supply

Faulty Pressure Switch Replace Switch

No dispense Fuse blown Check and replace

No electrical supply Check and resolve

Water

warm

Reduced ice weight or

long time to form ice

Faulty ice bank control Replace (taking care to not damage the

Sensor Bulb)

Fuse blown Check and replace

No electrical supply Check

Refrigeration system failure Replace base unit

Poor condenser cooling Check clearance around Cooler and Fan

Motor operation. Check Condenser and

clean if necessary

Insufcient water in Tank Top off water level

Supply voltage out of

specication

Check and resolve

Poor agitation of water

onto Cooling Coils

Motor failure Replace Motor/Pump

Motor Impellor failed Replace

Excessive algae growth in Tank Clean Tank and Coil outer surface

(continued on next page)

24 25

CHILLER/CARBONATOR SYSTEM (continued)

Problem Possible Problem Possible Cause Action

CO2

volume too

low

CO2pressure too low Regulator set incorrectly Reset CO2Regulator

Water warm Refer to ‘Water warm’ section Refer to Water warm section

Air in Carbonator System not purged during

connection

Vent Carbonator for ve (5) seconds

No CO2 Cylinder empty Reconnect to a new Cylinder

Regulator or Cylinder Valve

closed

Ensure both are open

Dispensing

Head

leaking

CO2pressure too high Regulator set incorrectly Reset CO2Regulator

Dispensing Head Seals blown

out of their position

Follow Dispensing Head maintenance

procedure to re-position Seals

Incorrect assembly

post cleaning process

Seals damaged or positioned

incorrectly

Re-perform Dispensing Head Assembly

and replace parts as required

Water

leaking

from the

green pipe

on front of

the unit

Check Valve failure Debris in Vented Check Valve

sited on the Carbonator Pump

Strip and clean as per instructions

contained in the Maintenance Section

Dispense

ow

incorrect

Incorrectly set Flow

Control

Not adjusted correctly Reset ow rate

IMPORTANT ________________________

Refrigeration System Failure Modes, Compressor Start Device, Over-Temperature Device in

Compressor, Open Circuit on Compressor Motor Windings, Refrigerant loss, Capillary Tube

blockage etc. are best diagnosed and repaired off-site in a shop environment.

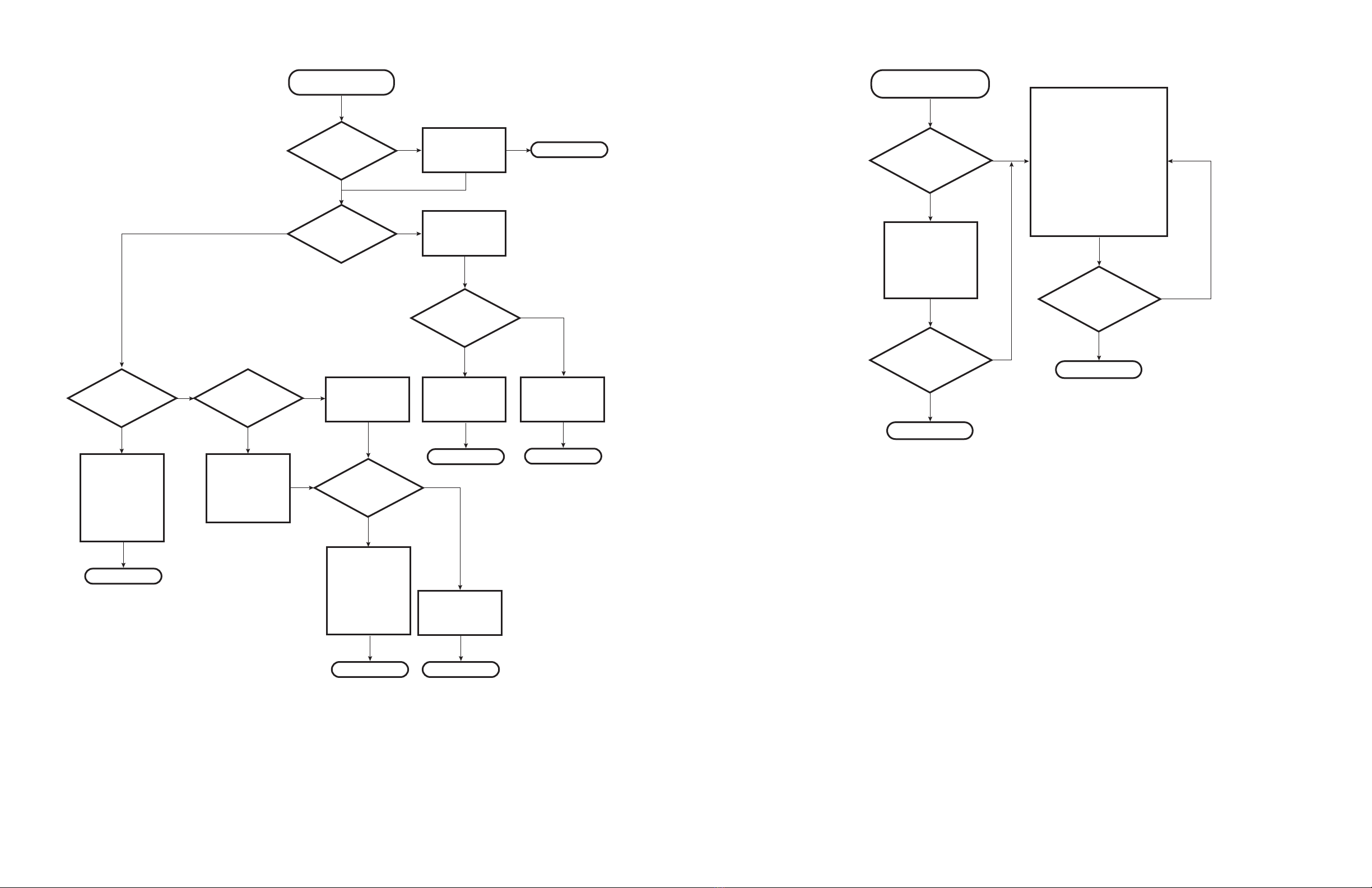

Yes

No

Is

Water Supply Valve

fully Open?

Change Filter

Open Valve and

Check for Proper

Operation

Still Water is Slower

Than Normal and/or

Carbonator is Running

Very Loud.

No Still Water

Thawing once should solve

the issue. If unit

continues to freeze up after

thawing, theThermostat

may need adjusting or

replacing.

Can 3 Liters

of Sparkling Water

be dispensed?

Still Water Coil is frozen. With

Power ON, open both

Dispensers and continue to

run Sparkling Water until Still

Water dispenses.This is the

fastest and only way to thaw

the Still Water.

Yes

Note

If only CO2

dispenses, there is a water

supply issue. Confirm that

Water Supply Valve to unit is

Open and working before

Dispatching ServiceTech.

Once water supply issue is

resolved, reset Carbonator.

Unplug the

Chiller/Carbonator and plug

back in to power the system

OFF and back ON again.

On Older Model,

check Water Block.

No

Note

Note

Problem resolved

Problem resolved

Problem resolved

Problem resolved

26 27

Water Leak

Confirm the leak is

coming from the

Vivreau System.

Repair leak.

Problem resolved

No Sparkling Water

Is CO2gas

dispensing

when Sparkling

Tap is open?

Yes

Yes

Confirm CO2

Cylinder Valve is

Open and Cylinder

is full. Confirm

pressure readings

on CO2Regulator.

Confirm CO2

Cylinder Valve is

Open and Cylinder

is full. Confirm

pressure readings

on CO2Regulator.

Make sure Power

Cord is plugged in

and the Outlet is

working.

No

Carbonator must

be reset to get the

Sparkling Water to

work again.

Unplug the

Chiller/Carbonator

and plug back in to

power the system

OFF and back ON

again.

Problem resolved

Problem resolved

Is Outlet Working? Resolve Power

Issue.

No Problem resolved

Service Light is ON

Does

Still Water

dispense from Still

Dispenser?

Yes Yes

Is Water

Supply Valve to

System Open and

working?

On Older Model,

check Water Block.

Remove and bypass

Water Block

No No

Is Still Water

slower than

normal?

Is water

restored?

Yes

No

No

Problem resolved

Carbonator must

be reset to get the

Sparkling Water to

work again.

Unplug the

Chiller/Carbonator

and plug back in to

power the system

OFF and back ON

again.

Sanitize and replace

Filter.

Yes

Problem resolved

Problem resolved

28 29

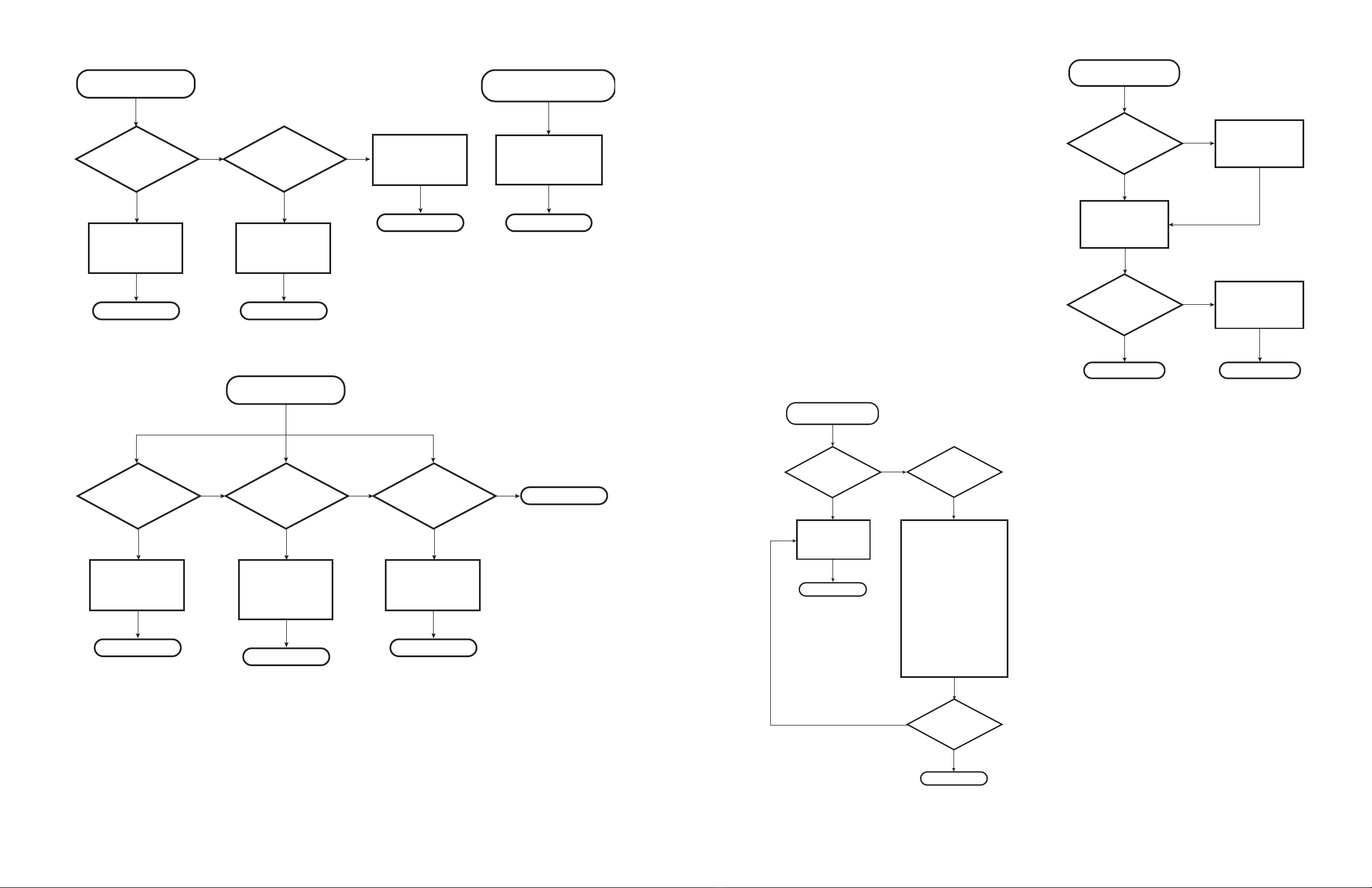

Water

Is Dispensing Warm

Is unit

plugged into a

working outlet? (Blue

Power Light

ON.)

Is Compressor

running?

Is Compressor

running?

Is water

being chilled?

No

No

No

No

No

Jump out

Terminals on

Thermostat

No Plug in unit

Replace

Thermostat

Yes

Once unit is

powered ON, it

may take up to 45

Minutes for the

water to dispense

cold and 4-6 Hours

to maintain a cold

Dispensing

Temperature.

Is the

Condenser Grille

clogged or

obstructed?

No

Yes

Clean the

Condenser Grille

with a Soft Brush

or Cloth and

remove any

obstructions to the

airflow.

Problem resolved

Problem resolved

Problem resolved

Once unit is

powered ON, it

may take up to 45

minutes for the

water to dispense

cold and 4-6 hours

to maintain a cold

Dispensing

Temperature.

Problem resolved

Yes

Yes

Yes

Yes

Confirm the Water

Supply Feeding

the unit is a Cold

Water Supply.

Yes

Is water

being

chilled?

Yes

Replace

Chiller

Problem resolved

Replace

Chiller

Problem resolved

No

Sparkling Water is Flat

Is CO2

Cylinder empty?

(CO2LED Illuminated)

or below 70 PSI on

Gauge.

Yes

No

No

No

Problem resolved

Flush the Sparkling Water:

1. Switch the Cleaning Mode

Switch OFF.

2.Touch and Hold the

Sparkling Button until only

Gas is dispensed.

3. Release the Button and

turn the Cleaning Mode

Switch back ON.

4. Let the unit cycle for 30

seconds and check the

Sparkling Water again.

Replace CO2

Cylinder and/or

make sure CO2

Cylinder Valve and

Secondary Shutoff

Valve (if equipped)

are open.

Yes

Is the

Sparkling

Water OK?

Yes

Problem resolved

Is the

Sparkling

Water OK?

Yes

30 31

Yes

No No

Replace CO2

Cylinder.

Is the CO2Cylinder

empty?

CO2LED is ON.

Yes

Is CO2

Cylinder Valve or

Secondary Shutoff

Valve closed?

Yes

No

Is the noise

constant and never

stops?

Yes

No No

Is the

noise after or

during dispensing

Sparkling Water

only?

Yes

Is the

noise during or

after dispensing either

Still or Sparkling

Water?

Open CO2Cylinder

and/or Secondary

Shutoff Valve.

Problem resolved

Check CO2Pressure

Switch and change

if needed.

Problem resolved

Problem resolved

Check for faulty

Agitator.

Problem resolved

Check Refrigeration

System.

Problem resolved

Problem resolved

Confirm Water

Supply Valve is fully

open before

checking for a

clogged Filter.

Problem resolved

Unit makes Loud Noise.

Drip Tray Light is ON.

Empty Internal or

External DripTray

Container.

Problem resolved

Is the Gasket

between the

Regulator andTank

in place?

Connect a new CO2

Cylinder. Monitor

CO2level over the

next 24-48 hours

Yes

No

Did new CO2

Cylinder hold

pressure?

Yes

No Find and correct

CO2leak.

Replace Gasket.

Problem resolved Problem resolved

CO2Leak

Problem resolved

Do both

Still and Sparkling

Water have a bad

taste?

Yes

No

No

Sanitize and replace

Filter.

Water Tastes Bad

Yes

Does only

Sparkling Water

have a bad

taste?

Yes

Is the issue

resolved?

Bad CO2Cylinder

Turn OFF the Power Switch

on the back of the unit and

dispense Sparkling Water

until only CO2is dispensed.

Turn OFF the CO2Cylinder

and dispense Sparkling Water

to release all CO2pressure.

Replace CO2Cylinder and

open Valve, dispense the

Sparkling Water for 5 seconds

to flush any residual CO2.

Turn the Power Switch back

ON and allow carbonator to

cycle.

Retest.

Problem resolved

32 33

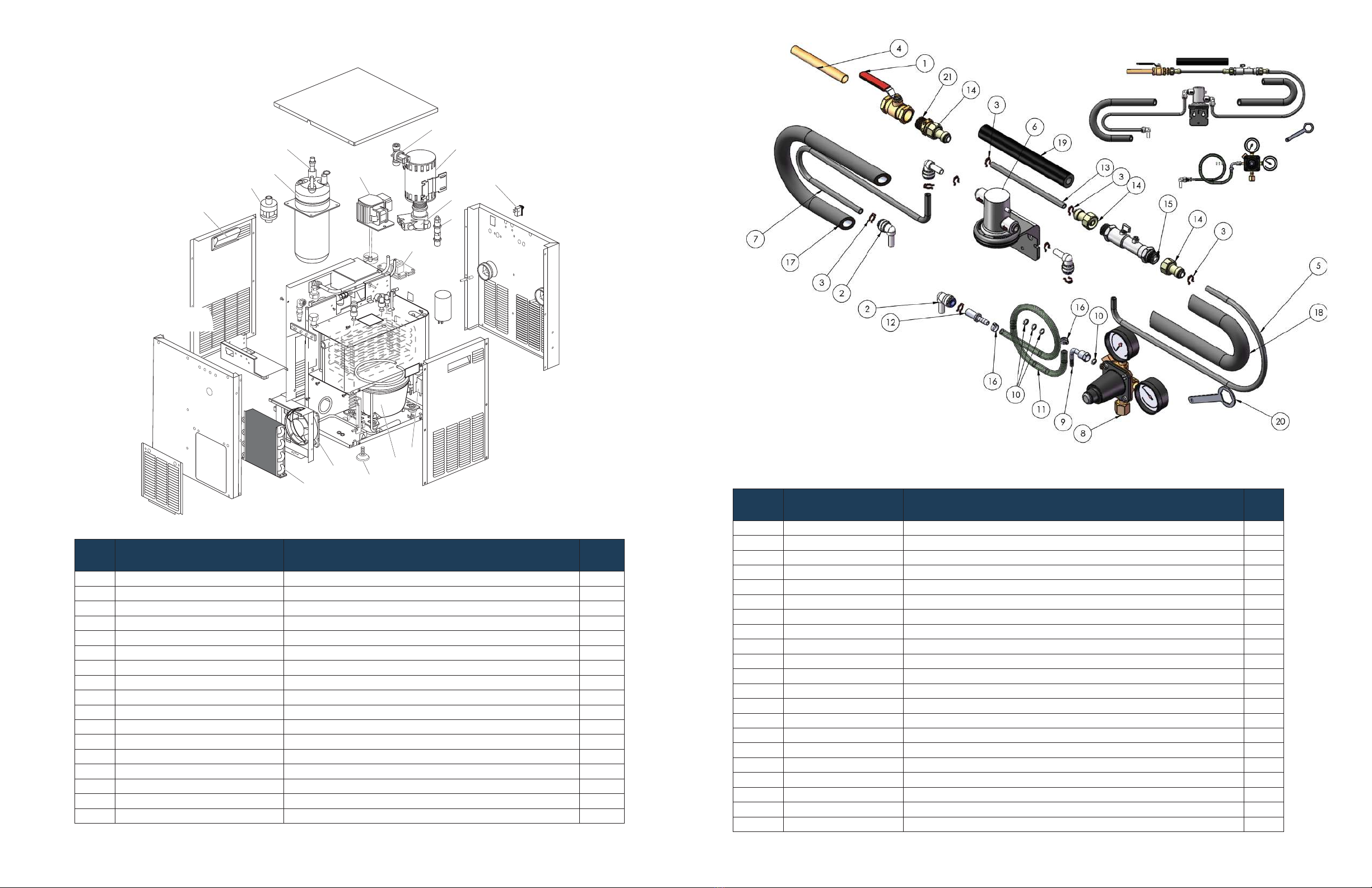

Illustrated Parts List

GENERAL INFORMATION

HOW TO USE ILLUSTRATED PARTS LIST

Ordering Parts

Use this parts list to order parts for your Vivreau V3-

204 and V3-205 Dispensing System.

For your convenience, part numbers have been

included for all replaceable parts.

Illustrations

Item numbers on illustrations correspond with parts

listings on pages that accompany the drawings.

Notes are included on illustrations where needed.

Parts Listings

Parts listings identify serviceable parts with the

following categories:

Item - corresponds with numbers on illustrations

for part identication.

Description - species part name or description

of the item.

Quantity (Qty) - quantity required for assembly.

11

7

8 9 10

12

13

14

15

16

17a & 17b

18

19

21

20a & 20b

22

23

1

2

3

4

5

6

V3-204 Dispensing System Exploded View

Item

No. Part Number Description Qty

1 N/A Compressor Set THB1335YS LST 120V NA

2 1017463 Thermostat NA

3 1040297 Mini Bottler Cassette Fan NA

4 N/A Condenser NA

5 N/A Molded Handle NA

6 1017462 JG 3/8 x 5/16 Flow Regulator NA

7 1029135 AGIT-MOTOR-V3-204-US NA

8 1040270 Water Inlet Solenoid NA

9 N/A Level Probe NA

10 N/A Carbonator Bowl NA

11 1046015 Carb Motor NA

12 1040276 Vented Dual Check 3/8” mpt in 3/8” male are NA

13 1046076 Carb Pump NA

14 N/A Splash Cover – Controller NA

15 1040271 PCB Controller NA

16 N/A Inll Panel For Fascia NA

17a 1029146 Still Tap Lense US-BT-SP NA

17b 1029145 Sparkling Tap Lense US-BT-SP NA

18 N/A Water Tap NA

20b N/A Fascia Panel Blue Frost NA

21 N/A Drip Tray – Grill NA

22 1034117 Mini Bottler Drip Tray NA

23 N/A Adjustable Leg NA

NS 1046143 Co2 Reg Tank Kit NA

NS 1017470 Main Bottler LED-Buzzer Kit BT102-BT-SP NA

NS N/A Cleaning Mode Switch NA

NS 1040704 Pentair Stainless Steel 65psi PRV NA

NS 1023695 Tap Nozzles NA

V3-204 Dispensing System Parts List

34 35

Vertical Cooler/Carbonator Under-Counter Range (120V 60Hz) Exploded View

5

3

16

1

2

4

15

96

7

10

13

11

14

8

12

Vertical Cooler/Carbonator Under-Counter Range (120V 60Hz) Parts List

Item

No. Part Number Description Qty.

1 N/A Compressor TL4G (120V; 50/60Hz) - Secop 1

2 1017463 Thermostat 1

3 1040297 Mini Bottler Cassette Fan 1

5 N/A Condenser 1

6 1029135 AGIT-MOTOR-V3-204-US 1

7 1040270 Water Inlet Solenoid 1

8 N/A Level Probe 1

9 N/A Carbonator Bowl 1

10 1046015 Carb Motor 1

11 1040276 Vented Dual Check 3/8” mpt in 3/8” male are 1

12 1046076 Carb Pump 1

13 1040271 PCB Controller 1

14 N/A Rocker Switch 273 235 1

15 1017465 ViTap Dual Solenoid Assembly 1

16 1030554 PCB Board NA VT-SP Vitap 1

17 1040704 Pentair Stainless Steel 65psi PRV 1

18 N/A Foot M8 Adjust Lvl RS750-777 1

Item

No. Part Number Description Qty.

1 Shut off valve Supplied By Client 1

2 1019479 Gray Acetal Plug In Elbow 3/8 Stem - 3/8 Tube 4

3 1046036 Locking Clip, 3/8 9

4 Water supply Supplied By Client 1

5 1046021 LLDPE Tubing 3/8 OD, Black (500 ft. Roll) 1

6 1025659 VH-3 Filter Head 1

7 1025665 .380 Whiteline Braided Bev Tube (300’ roll) 1

81040294 Reg Pri WM 160 W/6’ Hose Attchd 1

91040289 Swivel ELL 1/4 Barb x 1/4 FFL 1

10 1040281 Nylon Washer White 1/4 4

11 1040283 .265 Whiteline Braided Bev Tube (500’ roll) 1

12 1024849 Tube To Hose Stem 3/8 Stem - 1/4 Hose 1

13 1046021 LLDPE Tubing 3/8 OD, Black (500 ft. Roll) 1

14 1019480 Gray Acetal Female Connector 3/8 X 1/2 BSPP (Cone End) 3

15 1025656 Dual Check Valve With Shutoff 1

16 1040284 12.3 Stepless Clamp (100 pack) 2

17 1045998 Insulation Pipe 3/8” ID x 3/8” x6 1

18 1046002 6’ Pipe Insulation 1

19 1046002 6’ Pipe Insulation 1

20 1025664 CO2 Regulator Wrench 1

21 1025667 Hose Nipple 1/2 Mpt x 1/2 Mpt Hex 1

204 Installation Parts

No Water-block

36 37

Wiring Diagrams Contact Info

Phone Number:

+1 877 999 1044

Email:

InfoUSA@vivreau.com

InfoCanada@vivreau.com

Or visit vivreauwater.com

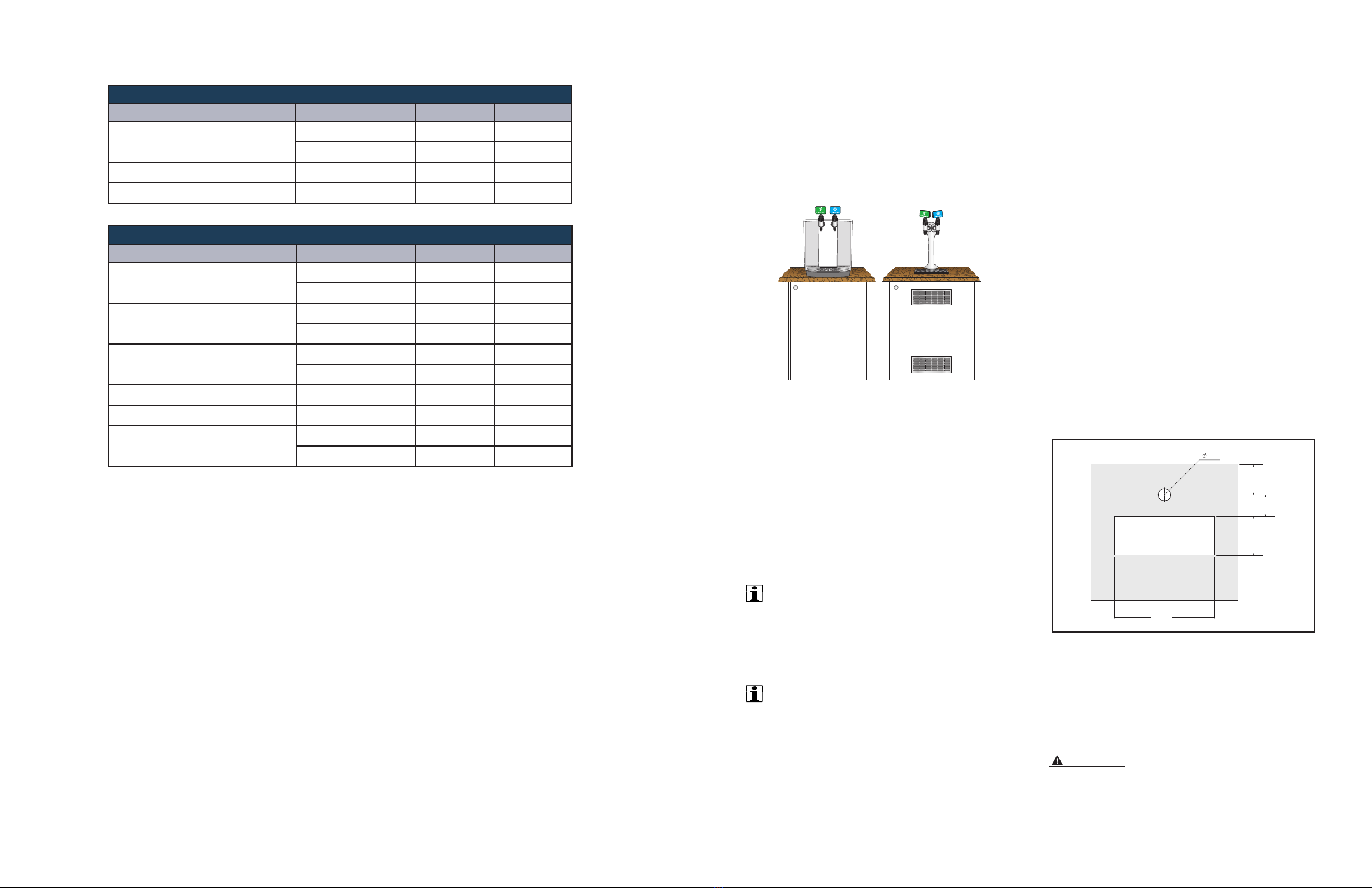

LNE

INDICATOR PANEL – NOT VISIBLE

COLOR KEY:

WHITE = WHT

BLACK = BLK

BLUE = BLU

BROWN = BRN

RED = RED

ORANGE = ORG

GREEN = GRN

GREEN/YELLOW = G/Y

LOW

HIGH

SIGNAL

CONTROLLER

314015000-100

INPUT

115V L2

L1

CONDENSER

FAN

WIRING SCHEMATIC

WATER

BOOST

PUMP

SOLENOID

CO2

SWITCH

PROBE

EARTH

MAINS INPUT

TERMINAL

BLOCK

CHASSIS

EARTH BASEPLATE

ICEBANK

THERMOSTAT COMPRESSOR AGITATOR

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

WHT

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BRN BRN

BLU

G/Y

G/Y

G/Y G/Y

G/Y

G/Y

CARBONATOR

BOWL

GRN

RED

ORG

LABEL: 06-0-388312-1 PLUMBING SCHEMATIC

WATER

BOOST

PUMP

SOLENOID

VALVE

DOUBLE

CHECK

VALVE

CO2

CHECK

VALVE

FLOW

CONTROL

WATER COIL

WATER COIL

CARBON DIOXIDE (CO2)

CARBONATOR

BOWL

PRV

TAP

TAP

WATER

IN

COOLER

Vivreau V3-204 and V3-205 Wiring Diagram and Plumbing Schematic

Other manuals for V3-204

2

This manual suits for next models

1

Table of contents

Other Vivreau Dispenser manuals