Vivreau Vi Tap-2 User manual

Vi TAP Dispensing System

Owner’s Manual

MODELS

Vi TAP-2

Vi TAP-2H

Vi TAP-2HD

Freshly-drawn Traditionally Served Environmentally Friendly Specially Branded

170120

2ViTap Dispensing System Owner’s Manual

© 2017 Vivreau USA

All rights reserved.

Any and all information contained within this document is

subject to change without prior notice.

IMPORTANT ______________

The information contained in this manual is specific to

your system. It is IMPORTANT you READ, FOLLOW and

UNDERSTAND the instructions given.

This manual and all material provided with your system

should be retained in a convenient location for future

reference.

Contact Vivreau if you have any questions regarding

the information contained in this manual.

ViTap Dispensing System Owner’s Manual 3

TABLE OF CONTENTS

SAFETY PRECAUTIONS ...........................................................5

GENERAL INFORMATION .........................................................7

TECHNICAL SPECIFICATIONS ..................................................9

PRE-INSTALLATION REQUIREMENTS ................................... 11

OPERATING INSTRUCTIONS..................................................13

MAINTENANCE........................................................................17

TROUBLESHOOTING...............................................................23

4ViTap Dispensing System Owner’s Manual

ViTap Dispensing System Owner’s Manual 5

Section 1

Safety Precautions

SAFETY PRECAUTIONS

IMPORTANT _________________________

This manual is intended for use only by

personnel trained in the operation of the

Vivreau ViTAP Dispensing System.

WARNING

Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury, or death. Read the

installation, operating, and maintenance

instructions thoroughly before installing,

operating, or maintaining this equipment.

WARNING

Keep the area around the unit

clear of any combustible materials.

WARNING

Do not store or use gasoline

or other flammable vapors or liquids in the

vicinity of this or any other unit.

IMPORTANT _________________________

Carefully read, understand and follow all

safety instructions in this manual and safety

labels on the unit.

• Keep safety labels in good condition and

replace missing or damaged items.

• Learn how to operate the unit and how to use

the controls properly.

• Do not let anyone operate the unit without

proper training.

• In the event of a power failure, do not

attempt to operate this unit.

• Keep unit in proper working condition and

do not allow unauthorized modifications to

the unit.

WARNING

Only trained and certified electrical,

plumbing and refrigeration technicians should

service this unit.

WARNING

ALL WIRING AND PLUMBING

MUST CONFORM TO NATIONAL AND LOCAL

CODES. FAILURE TO COMPLY COULD RESULT

IN SERIOUS INJURY, DEATH OR EQUIPMENT

DAMAGE.

SAFETY PRECAUTIONS ________________

This unit has been specifically designed to

provide protection against personal injury.

To ensure continued protection observe

the following:

WARNING

Disconnect power to the unit

before servicing. Follow all LOCKOUT/TAGOUT

procedures. Verify power to the unit is OFF and

disconnected before any work is performed. Failure

to do so could result in serious injury, death or

equipment damage.

• To protect against electric shock, do not

immerse power cord in water or other

liquid.

• To prevent damage to the power cord, do

not allow cord to hang over the edge of a

table or counter, or come in contact with

hot surfaces.

• Isolate unit from power supply (unplug or

turn OFF breaker) and turn OFF the water

supply when not in use and before cleaning.

• Allow Boiler (if supplied) to cool before

removing any components.

• The use of spare parts and accessories

not recommended by Vivreau may cause

damage and/or injuries.

• Do not operate any unit with damaged

cords, plugs, or after the unit malfunctions

or has been damaged in any manner.

• Do not use outdoors.

• Do not place on or near a hot gas or electric

burner.

• Do not use the unit for anything other than

its intended use.

• Save these instructions.

6ViTap Dispensing System Owner’s Manual

Section 1

Safety Precautions

ViTap Dispensing System Owner’s Manual 7

Section 2

General Information

GENERAL INFORMATION

INFORMATION FOR THE READER

To find specific topics of interest quickly, refer

to the Table of Contents at the beginning of this

manual.

This manual is solely for the use of personnel

trained in the operation of the ViVreau ViTAP

Dispensing System only.

PURPOSE OF THE MANUAL

• Vivreau has produced this manual to provide

necessary information to qualified and

authorized personnel for the safe and proper

installation, operation, and maintenance of

the Vivreau ViTAP-2, ViTAP-2H and ViTAP-2HD

Dispensing Systems.

• Information contained in this manual will

help prevent risks to health and safety, and

the risk of economic losses.

• Keep this manual in a clearly identified and

safe place throughout the working life of the

unit, so that it will always be available as

needed.

• The manufacturer reserves the right to

make modifications to the unit without any

obligation to provide prior notice.

• A number of symbols have been used to

highlight particularly important parts of

the text or important specifications. Their

meaning is as defined below.

DANGER

INDICATES AN IMMINENTLY HAZARDOUS

SITUATION WHICH, IF NOT AVOIDED, WILL

RESULT IN DEATH OR SERIOUS INJURY.

WARNING

Indicates that suitable procedures must be

adopted to avoid putting people’s health and

safety at risk or causing economic losses.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, may result in property

damage, minor or moderate injury.

IMPORTANT _________________________

Indicates important technical information

which must not be overlooked.

8ViTap Dispensing System Owner’s Manual

Section 2

General Information

ViTap Dispensing System Owner’s Manual 9

Section 3

Technical Specifications

TECHNICAL SPECIFICATIONS

GENERAL DESCRIPTION

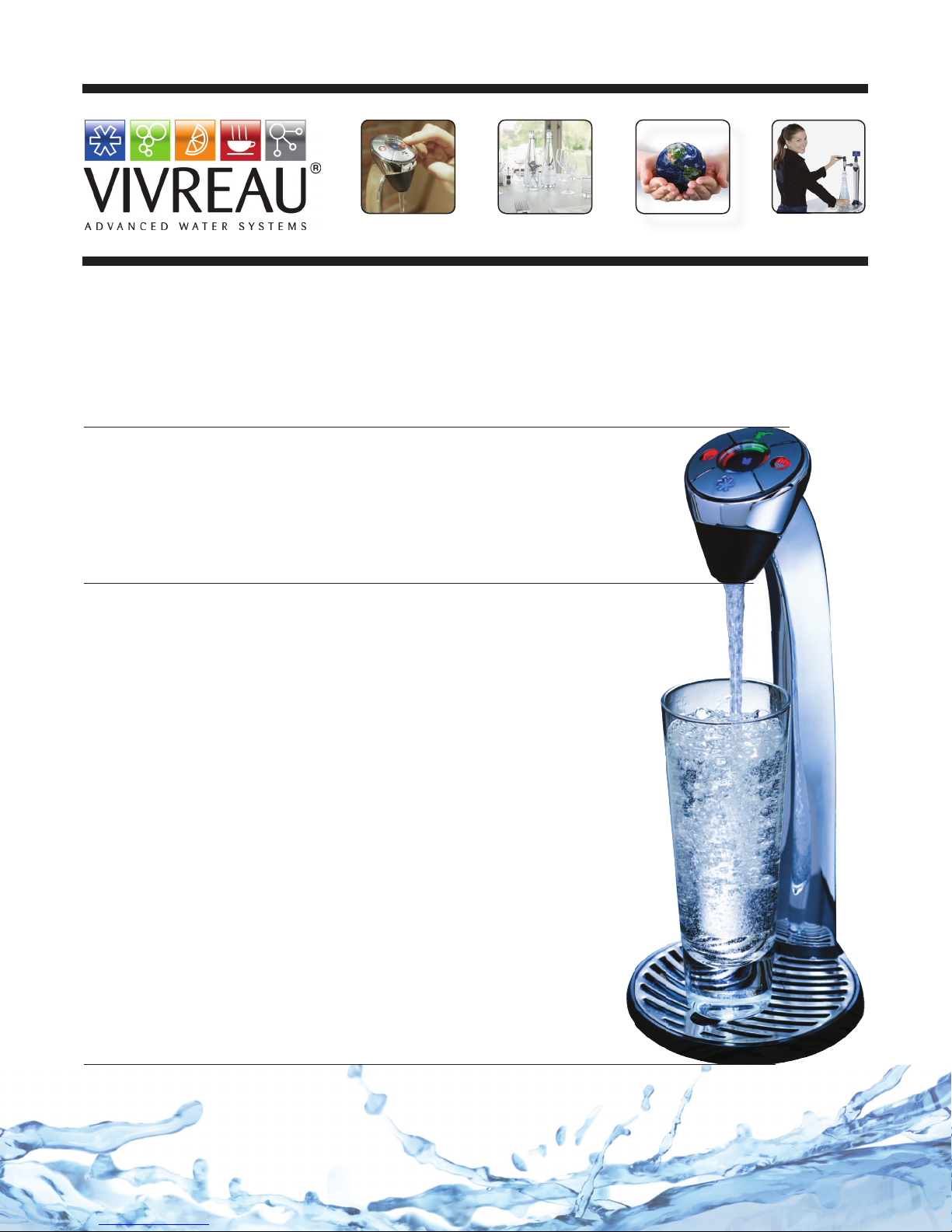

TheVivreauViTAP-2 (H/HD) is a self-serviceWater

Dispensing System designed for under-counter

installation with the Dispenser Head mounted to

the countertop directly above the unit.

The system is made up of several components

(depending on model) that will fit under a standard

base-cabinet section that is 30” wide (min.)

Dispensing Specifications

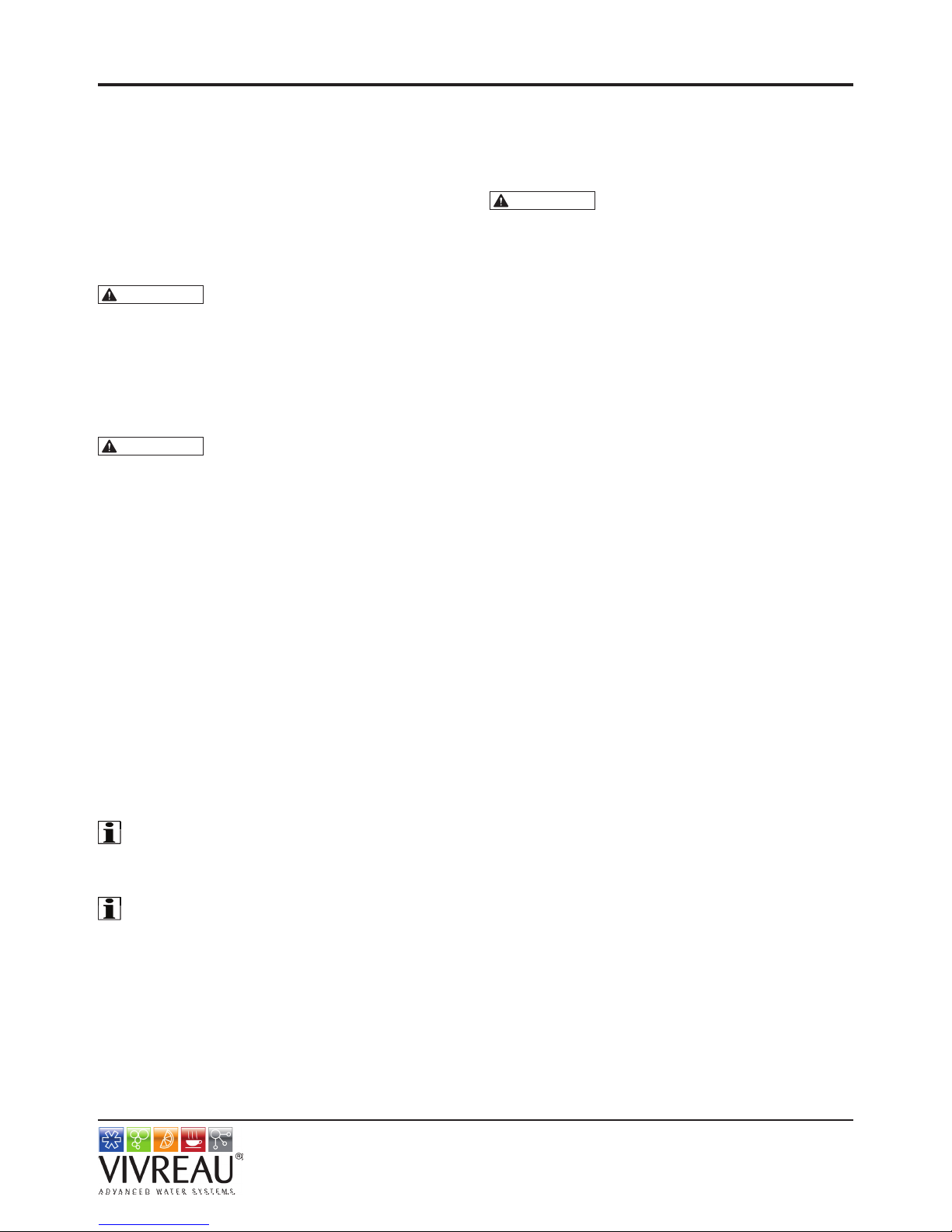

Description Specification ViTap-2 ViTap-2H ViTap-2HD

Chilled still water ΔT=18 °F @ 15.8 gal/h ü ü ü

Chilled sparkling water ΔT=18 °F @ 15.8 gal/h ü ü ü

Hot water 203°F NA ü ü

Hot water, immediate dispense 0.5 gal/h NA ü ü

Hot water, storage capacity 1.2 gal. NA ü ü

Water Pressure at Dispensing Head 5 PSI ü ü ü

Operating Conditions

Description Specification ViTap-2 ViTap-2H ViTap-2HD

Temperature 60 – 90°F ü ü ü

Relative Humidity 60% (max.) ü ü ü

Water Supply Requirements

Description Requirements ViTap-2 ViTap-2H ViTap-2HD

FNPT connection with Ball Valve 1/2” ü ü ü

PSI (min.) 50 ü ü ü

GPH (min.) 80 ü ü ü

Temperature (max.) 60°F ü ü ü

CO2Operating Pressure

Description Requirements ViTap-2 ViTap-2H ViTap-2HD

Pressure 65 – 70 PSI ü ü ü

Supply pressure (Bulk System) 100 PSI (min.) ü ü ü

Dispensing Head Specifications

Description Requirements ViTap-2 ViTap-2H ViTap-2HD

Height 13” ü ü ü

Distance Nozzle to Drip Tray 9.6” ü ü ü

Weight 7.4 lb ü ü ü

10 ViTap Dispensing System Owner’s Manual

Section 3

Technical Specifications

Cooler/Carbonator Specifications

Description Specification ViTap-2 ViTap-2H ViTap-2HD

Width 15” ü ü ü

Height 20” ü ü ü

Depth 18.5” ü ü ü

Weight 39.6 lb. ü ü ü

Voltage 110/120 VAC/60 Hz ü ü ü

Amperage 11 A ü ü ü

Boiler Specifications

Description Specification ViTap-2 ViTap-2H ViTap-2HD

Width 5.25” NA ü ü

Height 22.0” NA ü ü

Depth 15.75” NA ü ü

Weight 30.8 lb NA ü ü

Voltage

110/120 VAC/60 Hz NA üNA

230/240 VAC/60 Hz NA NA ü

Amperage

13A NA üNA

11 A NA NA ü

ViTap Dispensing System Owner’s Manual 11

Section 4

Pre-Installation Requirements

PRE-INSTALLATION REQUIREMENTS

PRE-INSTALLATION

Below are the services required to be in place

prior to the installation of the Vivreau ViTAP

Dispensing System. If you have any questions

regarding these or other services, please contact

Vivreau Service Toll-Free at 877-999-1044.

WATER SUPPLY

A potable 1/2” cold water supply terminating in

a 1/2” Ball Valve, 1/2” female pipe thread.

IMPORTANT _________________________

Ball Valve must be accessible for service

and installation.

Minimum Water Pressure: 50 PSI

Minimum Water Flow: 80 gallons per hour

IMPORTANT _________________________

The Vivreau ViTAP Dispensing System

incorporates backow prevention. Any additional

backow devices required by State or Local

Code must also be supplied by the customer

prior to installation. There must not be any

other Filters/Pre-Filters inline before the unit.

ELECTRICAL OUTLET

Model ViTAP-2

(1) 15 Amp Electrical Recepticle (NEMA 5-15R)

120V, 60 Hz (11 Amps)

Model ViTAP-2H

(1) 15 Amp Electrical Recepticle (NEMA 5-15R)

120V, 60 Hz (11 Amps)

(1) 20 Amp Electrical Recepticle (NEMA 5-20R)

120V, 60 Hz (13 Amps)

Model ViTAP-2HD

(1) 15 Amp Electrical Recepticle (NEMA 5-15R)

120V, 60 Hz (11 Amps)

(1) 20 Amp Electrical Recepticle (NEMA L6-20R)

230V, 60 Hz (11 Amps)

NOTE: ViTAP-2HD will not operate on 208 VAC.

All outlets must be mounted high in the cabinet

to avoid accidental contact with water.

CO2

CO2Cylinder (Customer supplied) - Size should

be selected based on available space.

NOTE: If connecting to a bulk or existing CO2

system, a CO2line terminating at a 1/4” Barbed

Shutoff Valve must be available within 40” of

the unit with 100 PSI minimum pressure.

DRIP TRAY AND DISPENSING HEAD

CUTOUTS

Cut out the holes for the DripTray and Dispensing

Head per the supplied template.

NOTE: The Dispensing Head must be mounted

on the work surface directly above the Chiller/

Carbonator.

DRIP TRAY DRAIN

Drip Tray must be plumbed to a drain. Customer

will need to supply a drain according to State

and Local Codes. Drain must be at least 1-1/4” ID.

LOCATION OF SERVICES

All services must be accessible for installation

and service. Ensure all services are kept within

40” of the ViTAP Dispensing System.

Water Shutoff Valve to be located at low level.

Ensure there is sufficient room for a 6” long

fitting to be connected to the Water Shutoff Valve.

Top of drain should be located between 12” and

18” from floor level.

SHIPPING DAMAGE/MISSING PARTS

Unpack and inspect the unit for shipping

damage and/or missing parts. If any damage

or missing parts are found, contact Vivreau

Service Toll-Free at 877-999-1044 and report

the missing or damaged parts.

12 ViTap Dispensing System Owner’s Manual

Section 4

Pre-Installation Requirements

41/2"

51/8"

Available VIVREAU Grille

11 3/4"

3/8"

PLEASE NOTE

All vents must open to fresh air

in a free and unobstructed area.

Front Ventilation

Showing ventilation

grilles

cut in a standard

door panel

11 "

45/8"

2"

45/8"

2"

Cut-out detail for the

VIVREAU grille, shown in

a 23.5"

(24") wide door

Side Ventilation

Ventilation grilles cut in the side

of a

standard 24" cabinet. The grilles

may be

fitted on either side, provided they

ventilate

into a free, unobstructed area.

Base Ventilation

Ventilation grilles cut in the cabinet's

base panel and base

plinth. Top ventilation will also be required in either the side

panels

or a cut-out in the top of the door.

Base Cutout

Ventilation can be made through the base of the cabinet, with the removal of a

narrow section

of floor immediately behind the door. Trim

with roll edging

strip. Cut-out size must

not be less than 11.0" wide x 1.5" deep

.

Ventilation Options

LOCATION

A suitable location should be chosen within 40”

of the electrical and water supply connections.

Installation Clearance for Chiller Unit

Left side 2”

Right side 2”

Rear 2”

Above Open

Do not obstruct air vents.

Install the system on a firm, level floor or base.

VENTILATION

If the system is to be installed in an enclosed

space or in a cabinet, adequate ventilation must

be provided. Ventilation must be at the top and

bottom of the enclosure for proper air flow.

CAUTION

Failure to provide adequate

ventilation will cause system failure.

This unit is to be installed indoors only.

DISPENSING HEAD

The Dispensing Head with Integral Drip Tray

is installed into a countertop directly over the

Chiller/Carbonator and Boiler (if equipped)

using the supplied template.

Tap Hole

Drain Hole

Front

Mounting Holes

C

L

C

L

11/4"

11/4"

R 2

11

/

16

"

3/16"

x

2 places

23/8"

61/2"

23/4"21/2"

53/8"

1

1

/

4

"

3/16"

115/16"

Dispensing Head Template

ViTap Dispensing System Owner’s Manual 13

Section 5

Operation

OPERATING INSTRUCTIONS

The ViTAP Dispensing System has been

designed for ease of use.

IMPORTANT _________________________

Before operating theViTAP Dispensing System,

make sure the water supply is turned ON and

the unit is plugged in.

BEFORE USE

A LWAYS sanitize your hands.

A LWAYS wear hygienic gloves.

A LWAYS remove anti-bacterial cling film from

the Dispensing Head.

A LWAYS wipe Dispensing Head, Nozzles, Drip

Tray and cabinet work-surface with anti-bacterial

wipes.

LED DISPLAY PANEL

The LED Display Panel is located on the front

panel of the Chiller/Carbonator.

LED Panel

Dispensing Head System LED Display Panel

POWER: When the Dispensing Head System is

plugged in and turned ON, a Blue LED will be

illuminated.

CHANGE CO2: When the CO2supply is low, a

Red LED will illuminate and the unit will beep;

alerting you to change the CO2Cylinder.

CALL SERVICE: If there is a problem, a Red LED

will illuminate and the unit will beep. Please

contact Vivreau Service Toll-Free at 877-999-

1044 immediately.

EMPTY DRIP TRAY: (Not Activated on this Unit):

When the DripTray Container is FULL, a Red LED

will illuminate and the unit will beep; alerting

you to empty the Drip Tray Container located

just inside the cabinet front door or below the

Dispensing Head System.

14 ViTap Dispensing System Owner’s Manual

Section 5

Operation

DISPENSING

IMPORTANT _________________________

Before operating the ViTap Dispensing System,

make sure the Water Supply Valve is open and

the unit is plugged in.

DISPENSING

Before operating the ViTAP Dispensing System,

make sure the Water Supply Valve is open and

the Chiller (and Boiler, if supplied) is plugged in.

Place appropriate container on DripTray beneath

the Dispensing Head.

Chilled Still Water

Press and Hold the Blue Button to dispense

water. Release the button when filled.

Dispensing Chilled Still Water

Chilled Sparkling Water

Press and Hold the Green Button to dispense

water. Release the button when filled.

Dispensing Chilled Sparkling Water

Hot Water (if supplied)

As a safety feature, to dispense Hot Water, Touch

and Release either Red Button, then Press and Hold

the opposite side Red Button within 3 seconds.

Release the button when filled.

OR

OR

1 2

3

Within 3 Sec.

Dispensing Hot Water

WARNING

Water is Hot! Do not place hands

or other body parts beneath Dispensing Head

when dispensing hot water.

AFTER DAILY USE

Remove Dispensing Nozzle and place in a

container of Sanitizing Solution.

Leave Nozzle in Sanitizing Solution for a

minimum of 4 hours.

Ensure protective gloves are worn when in

contact with Sanitizing Solution.

Wipe Dispensing Head, DripTray and countertop

surface with anti-bacterial wipes and sanitizing

spray.

Wrap Dispensing Head with plastic film.

To return the Dispensing Head System to service,

remove the plastic film, rinse Nozzle and install

in Dispensing Head.

IMPORTANT _________________________

Ensure the ViTAP Dispensing System and

surrounding areas are kept clean and sanitary

at all times.

ViTap Dispensing System Owner’s Manual 15

Section 5

Operation

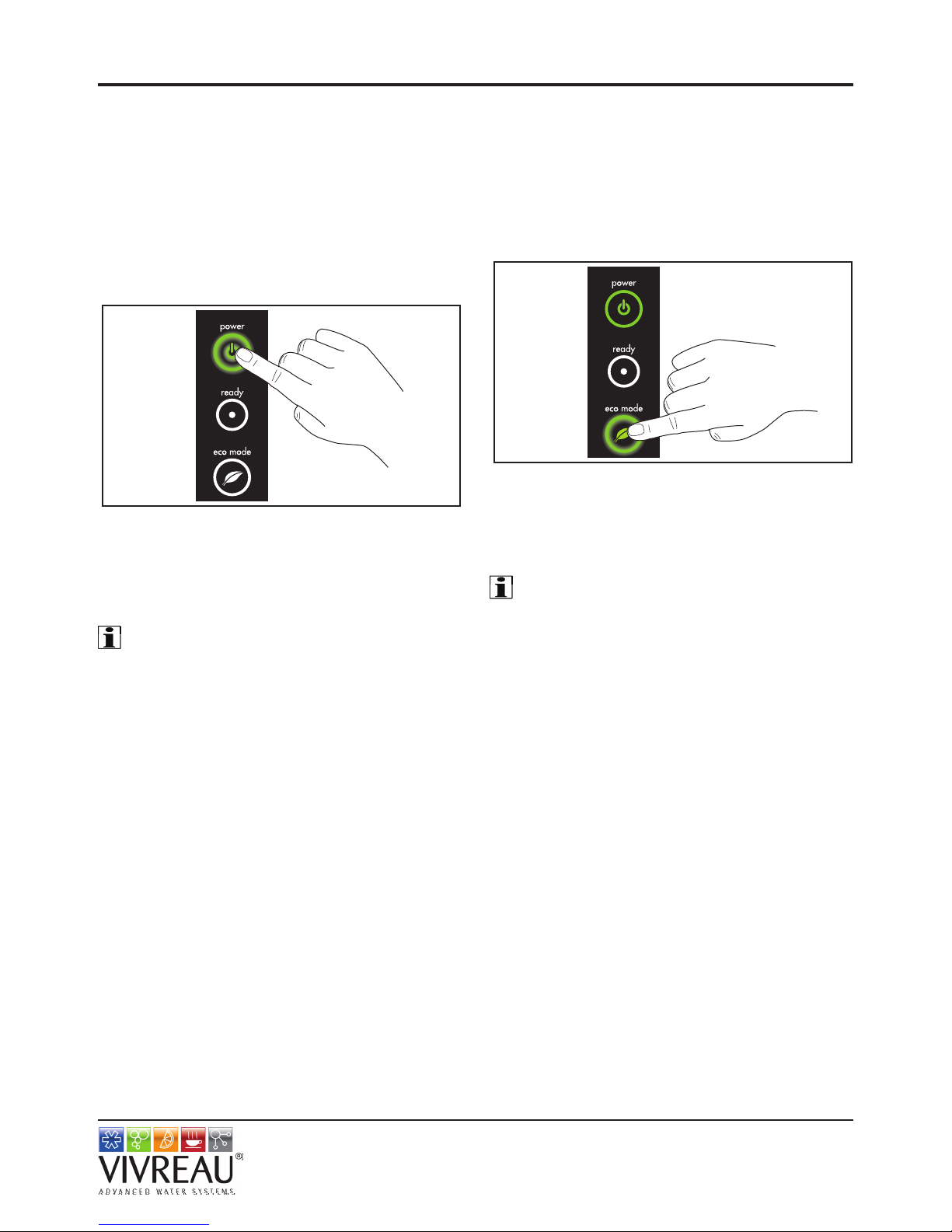

FOR UNITS WITH

OPTIONAL HOT WATER BOILER

Operating Boiler for the First Time:

Make sure installation is correct.

Turn ON the Water Supply Valve.

Plug the Boiler in to an appropriate electrical

supply and press the Power Button on the front

of the unit.

Boiler Start-up

The Power Button will glow green and the unit

will fill to a safe level, above the elements,

before heating.

IMPORTANT _________________________

Boiler has a Water Level Probe Circuit that

must be satisfied before Heating Elements are

energized.

The Ready Light will flash 2 times repeatedly as

theTank fills.

When the correct water level is reached, the

Controller will energize the Heating Circuit.

Once the water is heated to the preset

temperature (203°F), the Boiler will fill until

the temperature drops by 1 or 2 degrees. The

Boiler will then heat again. This Heat/Fill cycle

continues until the Boiler is full.

When theTank is full but still heating, the Ready

Button will remain off. The Ready Button will

glow green when the unit is both full and up to

normal operating temperature.

The Boiler is now ready for use.

ECO MODE

All Boilers incorporate an ECO Mode function.

To Enable ECO Mode:

Press the ECO Mode Button located below

the Ready indicator so that the leaf symbol

illuminates green.

ECO Mode

This mode saves energy by minimizing the

energy wasted during unit down-time.

IMPORTANT _________________________

ECO Mode is most effective in installations

where the unit has a regular OFF period.

To achieve the most benefit from the energy

saving ECO Mode on your ECO Boiler unit,

follow these procedures:

Towards the end of the Boiler’s operating period

for a given day, switch the machine to ECO

Mode. This will maintain water at 203°F and the

unit’s Tank will slowly drop to half full.

At the end of the day, the Boiler should be

turned Off.

During the Off period, as there is less water in

the Tank, there will be less energy lost to the

surrounding environment resulting in an energy

saving.

To Disable ECO Mode:

Press the ECO Mode Button again. The leaf

symbol will no longer be illuminated.

16 ViTap Dispensing System Owner’s Manual

Section 5

Operation

ViTap Dispensing System Owner’s Manual 17

Section 6

Maintenance

MAINTENANCE

MAINTENANCE RECOMMENDATIONS

Keep the unit at peak efficiency by performing

all scheduled maintenance procedures that are

recommended by Vivreau. Proper maintenance

will allow the best performance and a longer

working life.

WARNING

Before performing any

maintenance or service procedure, perform all

safety procedures. In particular, turn OFF the

water supply, disable the electricity at the

main circuit breaker and prevent access to all

devices that might cause unexpected health

and safety hazards if turned ON.

WARNING

Before performing any

maintenance or service that involves electrical

connection or disconnection and/or exposure

to electrical components, ALWAYS follow

the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

At the end of each day or whenever necessary, be

sure to clean:

• Dispensing Head/Nozzle

• DripTray

• The surrounding work area

Every year, have skilled, authorized personnel

perform the following operations:

• General check of the unit

• Identify and replace worn parts

IMPORTANT _________________________

Record all yearly inspections.

IMPORTANT _________________________

Contact the factory, the factory representative

or an authorized service agent to perform

service and repairs.

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

WARNING

Before performing any

maintenance or service procedure that

involves electrical connection or disconnection

and/or exposure to electrical components,

ALWAYS follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury or

death.

The Electrical LOCKOUT/TAGOUT Procedure is

used to protect personnel working on an electrical

unit. Before performing any maintenance or

service that requires exposure to electrical

components, follow these steps:

In Electrical Box, place unit Circuit Breaker into

OFF position.

Place a lock or other device on the Electrical Box

Cover to prevent someone from placing Circuit

Breaker in the ON position.

Place a tag on Electrical Box Cover to indicate

that unit has been disconnected for service

and power should not be restored until tag is

removed by maintenance personnel.

Disconnect the unit’s Power Cord from Electrical

Outlet.

Place a tag on the Power Cord to indicate that

the unit has been disconnected for service

and power should not be restored until tag is

removed by maintenance personnel.

18 ViTap Dispensing System Owner’s Manual

Section 6

Maintenance

STAINLESS STEEL CARE

Cleaning

Stainless steel contains 70-80% iron, which will

rust if not properly maintained. It also contains

12-30% chromium, which forms an invisible

passive, protective film that shields against

corrosion. If the film remains intact, the stainless

steel will remain intact. However, if the film is

damaged, the stainless steel can break down and

rust.To prevent stainless steel breakdown, follow

these steps:

CAUTION

Never use any metal tools. Scrapers,

files, wire brushes or scouring pads (except for

stainless steel scouring pads) will mar the surface.

CAUTION

Never use steel wool, which will

leave behind particles that rust.

CAUTION

Never use acid-based or chloride-

containing cleaning solutions, which will break

down the protective film.

CAUTION

Never rub in a circular motion.

CAUTION

Never leave any food products

or salt on the surface. Many foods are acidic.

Salt contains chloride.

For routine cleaning, use warm water, mild soap

or detergent and a sponge or soft cloth.

For heavy-duty cleaning, use warm water, a degreaser

and a plastic, stainless steel or Scotch-Brite pad.

Always rinse thoroughly.

Always rub gently in the direction of the steel

grain.

Preserving & Restoring

Special stainless steel polishing cleaners can

preserve and restore the protective film.

Preserve the life of stainless steel with a regular

application of a high quality stainless steel

polishing cleaner as a final step to daily cleaning.

If signs of breakdown appear, restore the

stainless steel surface. First, thoroughly clean,

rinse and dry the surface. Then, on a daily

basis, apply a high-quality stainless steel polish

according to manufacturer’s instructions.

Heat Tint

Darkened areas, called heat tint, may appear

on stainless steel exposed to excessive heat,

which causes the protective film to thicken. It is

unsightly but is not a sign of permanent damage.

To remove heat tint, follow the routine cleaning

procedure. Stubborn heat tint will require

heavy-duty cleaning.

To reduce heat tint, limit the exposure of

equipment to excessive heat.

DAILY CLEANING

TheViTAP Dispensing System should be cleaned

once a day.

Vivreau recommends using disinfectant spray

or a sanitizing wipe for cleaning.

If the Dispensing Head becomes soiled with

coffee, tea, milk etc. clean with hot soapy water

using a non-abrasive cloth.

Clean the DripTray Cover and inside the DripTray

using either disinfectant spray (non-chlorine) or

hot, soapy water and non-abrasive cloth.

Keep area around the unit clean and sanitized.

ViTAP equipment in the under-counter area

should be kept free of dust; the ventilation

should not be obstructed restricting free air flow

around the equipment.

The ViTAP Nozzle should be removed daily and

cleaned with hot soapy water and a non-abrasive

cloth.

After completing all cleaning tasks, dispense

water for at least 10 seconds to flush through

the Nozzle.

Use hot water if the unit is equipped with a

Boiler.

DO NOT use any abrasive material on your

ViTAP Dispensing System.

ViTap Dispensing System Owner’s Manual 19

Section 6

Maintenance

Cleaning Schedule

Component Task Frequency Personnel

Dispensing Head/Nozzle Cleaning & Sanitizing Daily End-User

Drip Tray Draining, Cleaning Daily End-User

CO2Cylinder

Fill Level Weekly

End- User

Replace As Needed

Chiller Condenser Grille Cleaning, Degreasing Weekly End-User

Chiller Exterior Cleaning Weekly End-User

Water Filter Replacement TwiceYearly Authorized Service

Dealer

CLEANING SCHEDULE

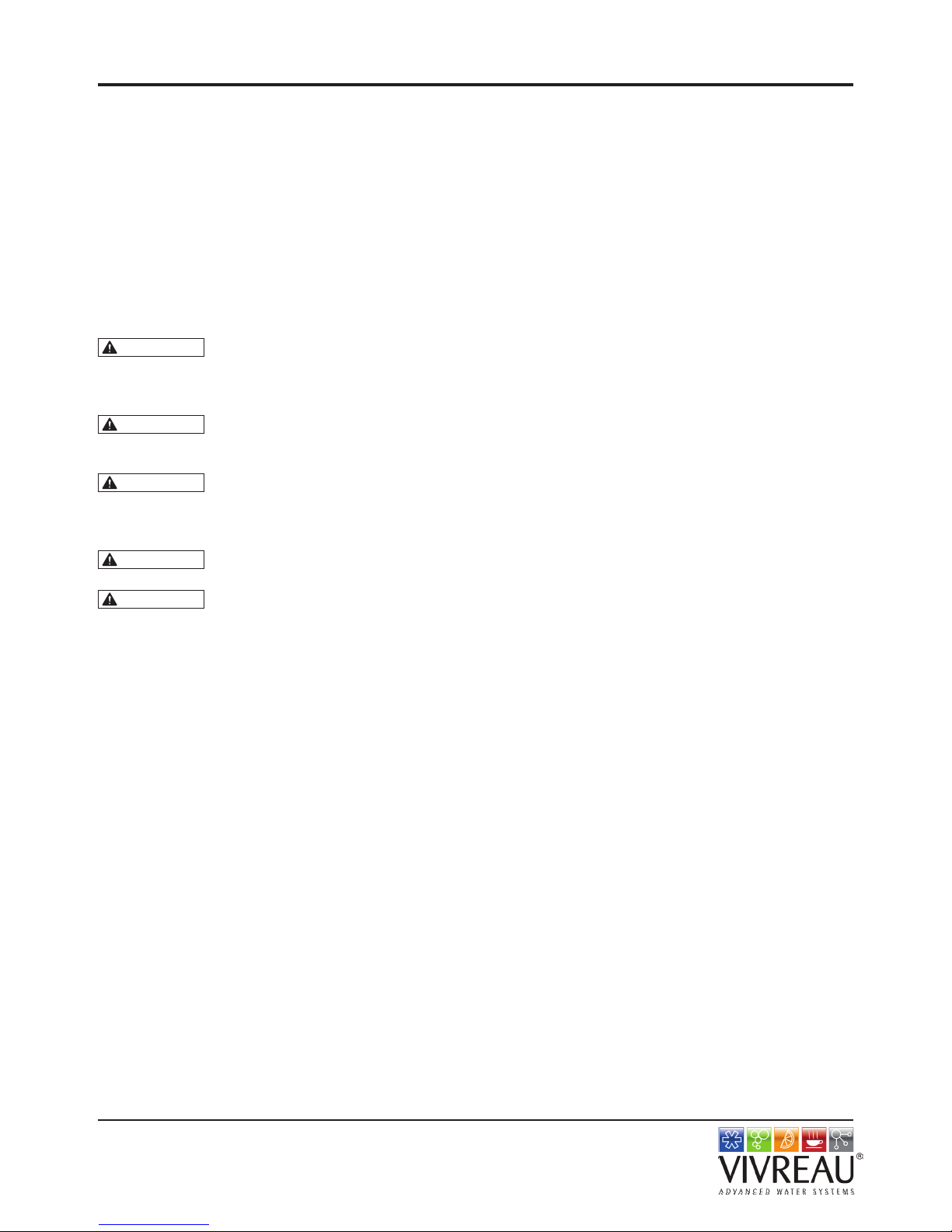

CLEANING NOZZLE & COVER

The Dispensing Head has a removable Nozzle

for ease of cleaning and sanitizing.

WARNING

Wear protective gloves when

handling Sanitizing Solution.

Cleaning Nozzle and Cover

Fill a small container with Sanitizing Solution.

Remove Cover by pulling down.

Unscrew the Nozzle.

Submerge Nozzle and cover in Sanitizing Solution.

Soak for a minimum of 4 hours.

Remove parts from Sanitizing Solution and rinse

thoroughly.

Re-install Nozzle and Cover.

Wipe external surfaces of Dispensing Head, Drip

Tray and countertop with a clean cloth.

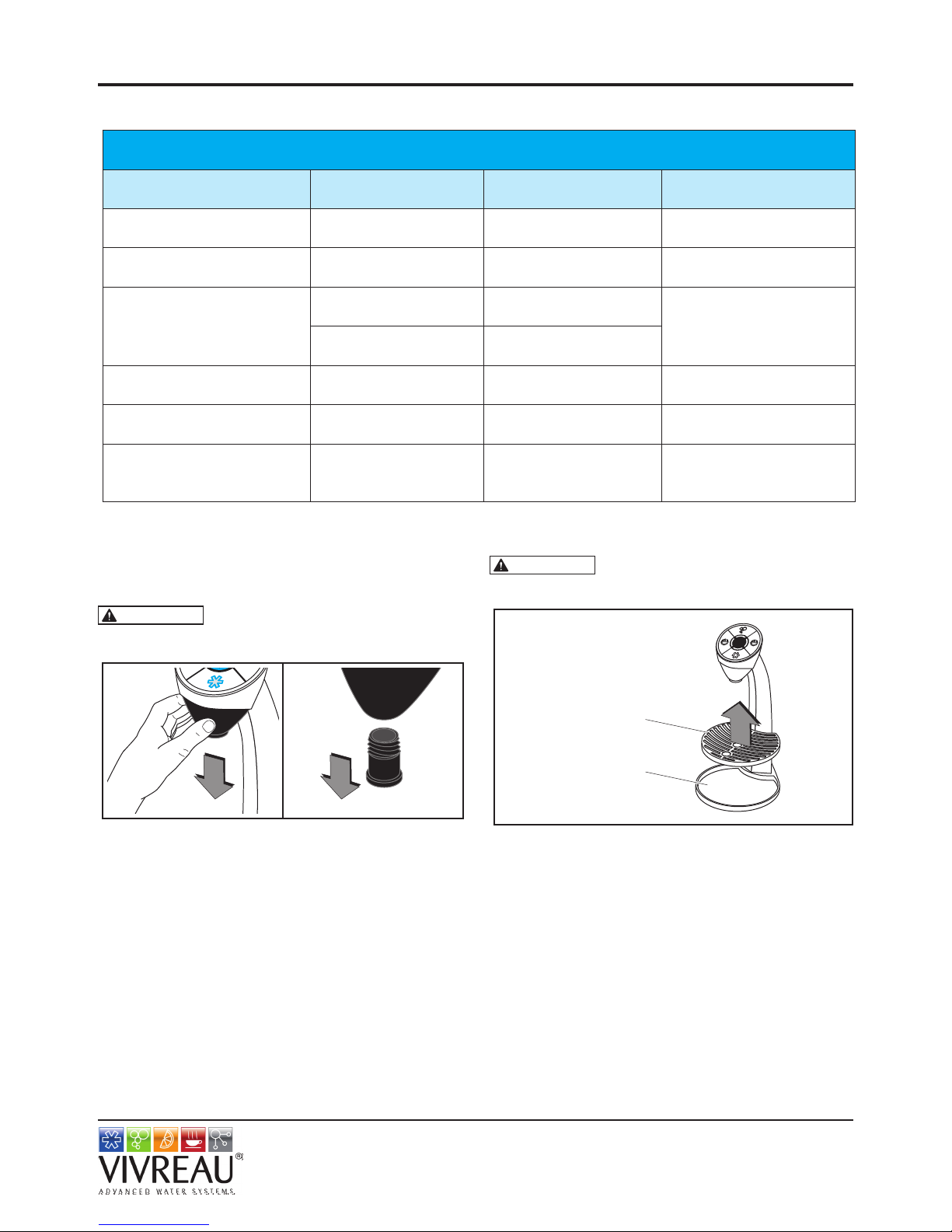

CLEANING THE DRIP TRAY

WARNING

Wear protective gloves when

handling Sanitizing Solution.

Drip Tray

Drip Tray Lid

Cleaning the Drip Tray

Lift DripTray Lid from unit.

Wipe top and bottom of Drip Tray Lid with a

clean cloth and Sanitizing Solution.

Wipe interior of Drip Tray with a clean cloth and

Sanitizing Solution.

Replace DripTray Lid.

20 ViTap Dispensing System Owner’s Manual

Section 6

Maintenance

CLEANING THE COOLING SYSTEM

CONDENSER GRILLE

The Cooling System Condenser Grille is located

on the front side of the Cooler/Carbonator.

Condenser

Grill

Cooling System Condenser Grille Location

CAUTION

Condenser Grille must be kept

clean and unobstructed to allow proper cooling

of components. Damage to the unit will occur

due to overheating!

IMPORTANT _________________________

Never cover the Cooling Fins.

IMPORTANT _________________________

Never place objects in front of the Cooling Fins.

The Cooling Fins should never be blocked and

a minimum distance of 4” to other objects must

be maintained.

Clean the Cooling Fins with a suitable brush or

vacuum cleaner.

Degrease with a soft cloth sprayed with degreaser.

CAUTION

Never spray degreaser or any

other liquid into the Condenser Grille.

EXTERIOR CLEANING

Wipe all surfaces with a soft cloth and a non-

abrasive cleaner.

IMPORTANT _________________________

Never use an abrasive cleaner to clean the unit.

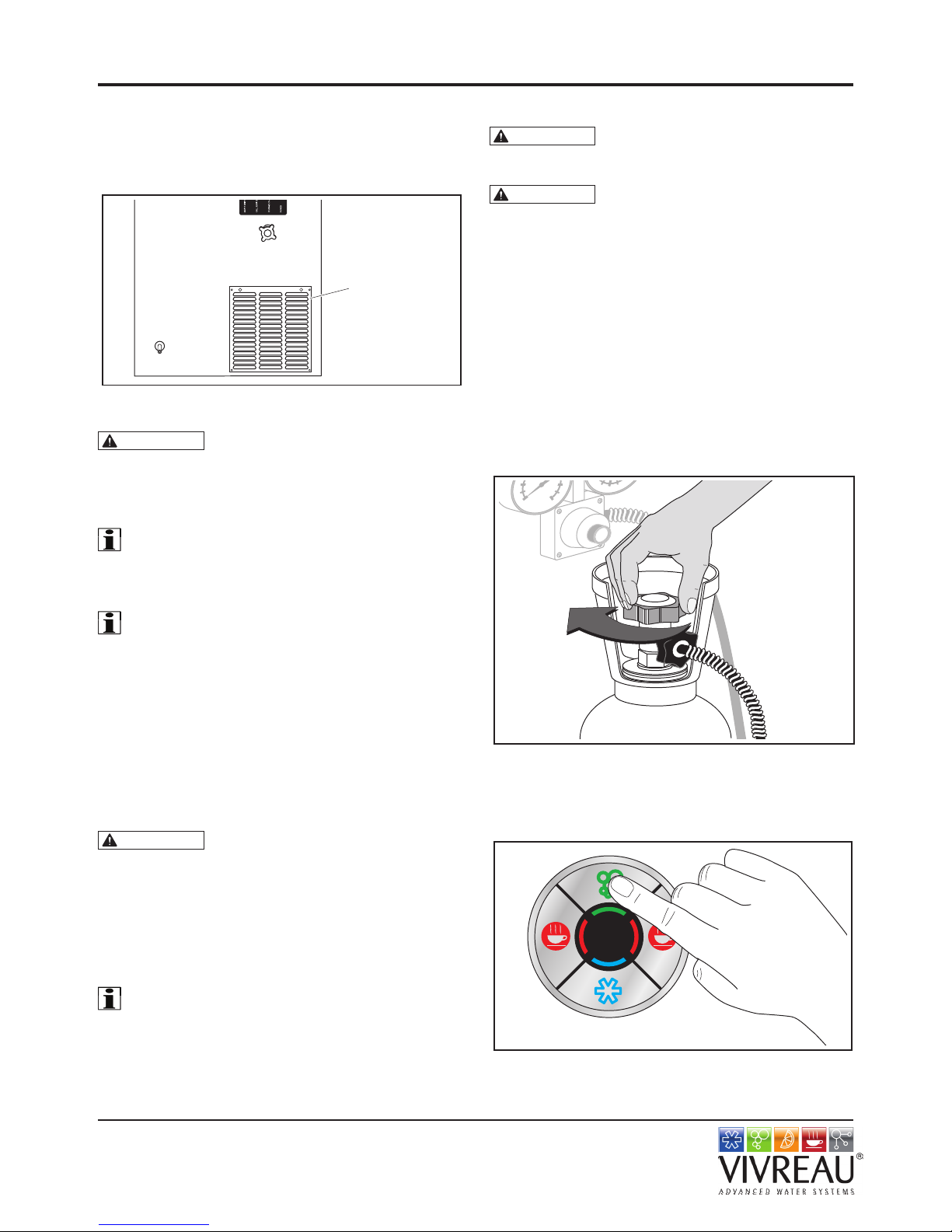

CHANGING THE CO2CYLINDER

WARNING

Wear protective gloves and

safety glasses when changing CO2Cylinders.

WARNING

CO2is a colorless, odorless gas.

A danger of suffocation exists when in high

concentration. Make sure there is adequate

ventilation when exchanging CO2Cylinders.

The CO2Cylinder can either be located inside

the cabinet with the system or outside the in a

remote location.

Regardless of location, the Cylinder is fitted

with a Regulator that has been preset for proper

operation. The Regulator should never be

adjusted by the end-user.

To change the CO2Cylinder close the Valve on

top of the empty Cylinder.

Close Empty Cylinder Valve

Release the line pressure by opening the

Sparkling Water Dispenser until no gas escapes.

Dispensing Chilled Sparkling Water

This manual suits for next models

2

Table of contents

Other Vivreau Dispenser manuals