Ultimus I-III Dispenser Pressure Readout,

VacuumReadout, and Dispense Timer Validation

Instructions

Introduction

These instructions provide the pressure, vacuum, and dispense timer validation procedures for the following dispensers:

• Ultimus™I: P/N 7017041 • Ultimus II: P/N 7002003 • Ultimus III P/N 7017068 (legacy)

Specification List

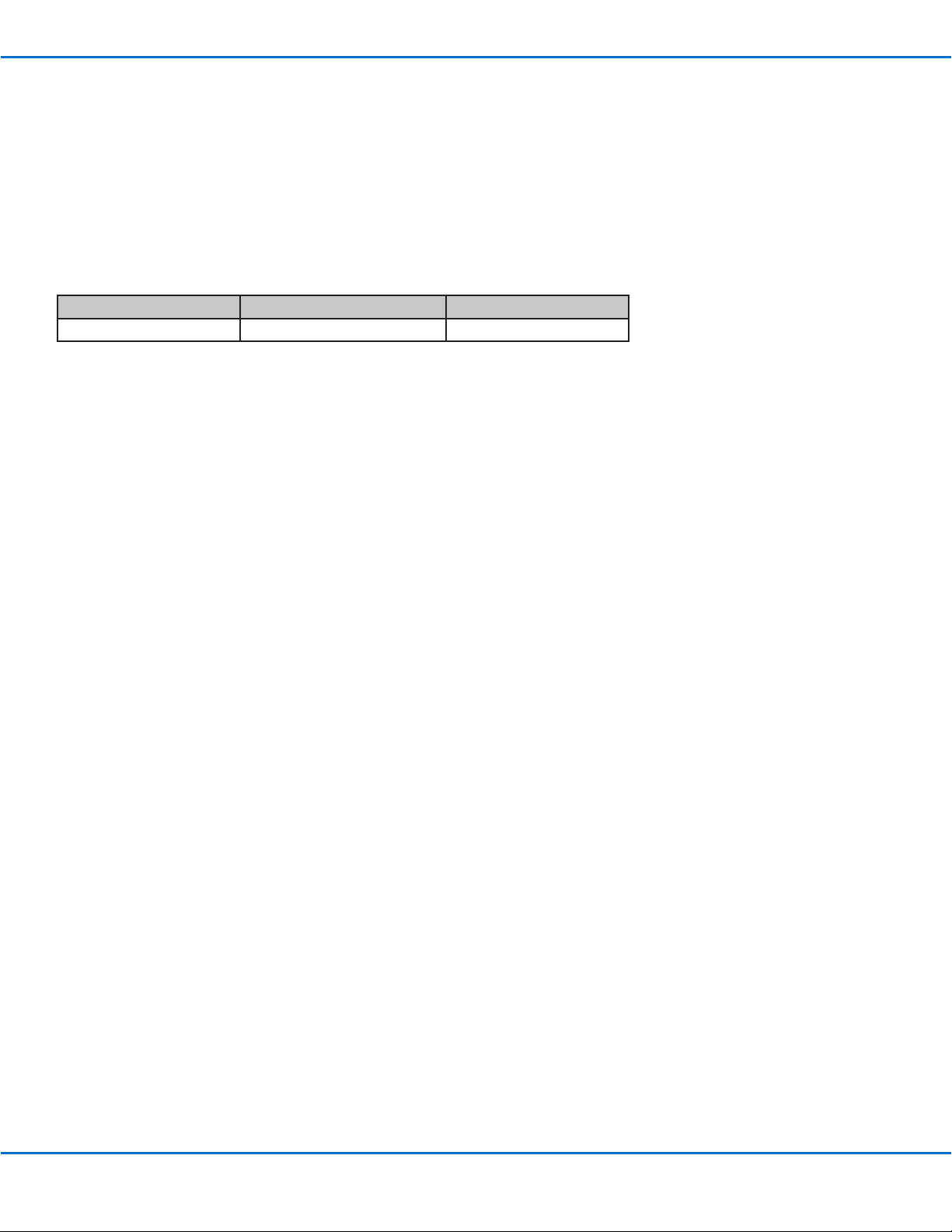

Model Pressure Accuracy Vacuum Accuracy Timer Accuracy

Ultimus I ±2.0 psi, 0–100 psi ±2.0 inH2O, 0–6 inH2O ±0.05%

Ultimus II ±0.3 psi, 0–15 psi ±2.0 inH2O, 0–6 inH2O ±0.05%

Ultimus III ±0.3 psi, 0–5 psi ±2.0 inH2O, 0–6 inH2O ±0.05%

Required Tools and Supplies

The following equipment is required for the performance of these procedures.

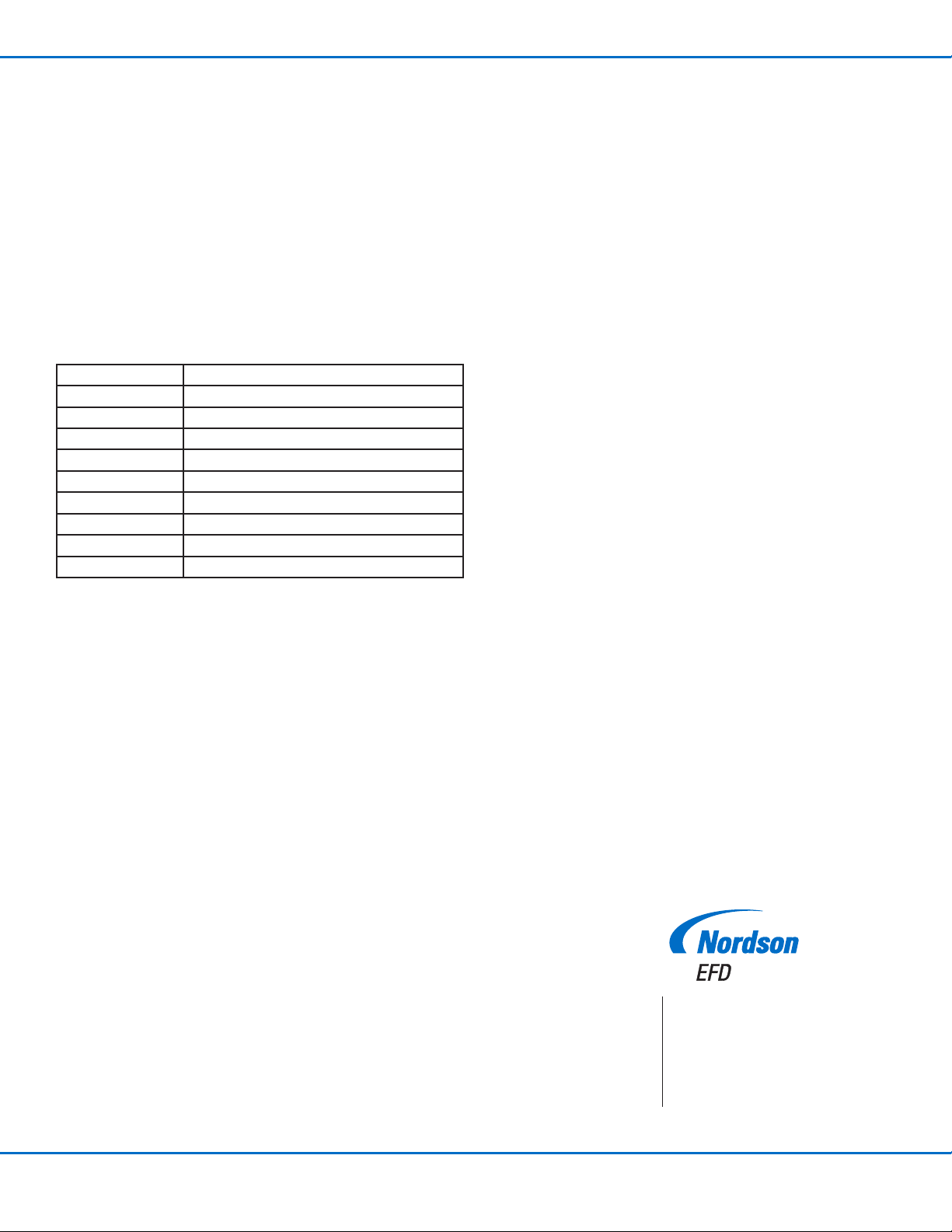

# Description Minimum Accuracy Requirement Suggested

Equipment Purpose

1* Precision pressure

and vacuum test

gauge

±0.05 psi at 0–100 psi

±0.33" H2O

Fluke, model 700G06

pressure and vacuum

test gauge

Reference standard for 100/15 psi

pressure and 6" H2O vacuum

2 0–100 psi test gauge,

±0.25% full scale

accuracy

±0.25 psi WIKA®, model 312.20 6,

P/N 9746892

Reference standard for validating the

Ultimus I pressure readout

3 0–15 psi test gauge,

±0.25% full scale

accuracy

±0.05 psi WIKA®, model 312.20 6,

P/N 9746867

Reference standard for validating the

Ultimus II and III pressure readouts

4 Slack tube

manometer, 18-0-18"

±0.33" H2O Dwyer Instruments,

model 1211-36

Reference standard for validating the

Ultimus I, II, and III vacuum readouts

5 Function generator,

triggered 10 s pulse,

±1 ppm accuracy

±20 ppm for a 10 s triggered pulse;

5–24V for ON,

0V for OFF

Load: 1,200 ohms

Tektronix®, AFG 3021B Reference standard for validating the

Ultimus I, II, and III dispense timer

*Item 1 is the preferred equipment and can be used in place of items 2-4. When item 1 is used, only item 5 is also required.

Optional Accessories

The following recommended Nordson EFD accessories are available to support the performance validation and field validation of the

vacuum display.

Accessory Description Nordson EFD

Part Number Purpose

Input / output (I/O) cable,

Ultimus I, II, III

8-pin DIN cable, color coded

leads, stripped and tinned lead

ends, 1.9 m (6 ft)

7017143 Connection to Ultimus I, II, or III from the function

generator for validation of the dispense timer

Vacuum calibration kit,

Ultimus I, II, III

Nordson EFD vacuum

calibration software, USB to

RS-232 converter, RS-232 to

modular plug cable

7028817 Adjustment of the Ultimus I, II, or III vacuum

readout validation; kit provides hardware and

software for site-specific validation of the digital

vacuum readout