Vogal Spreadmax EX500 User manual

SPREADMAX EX500

1

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

DOUBLE YOUR SPREADER WARRANTY TO TWO YEARS

By going online: rataindustries.co.nz/register-product

RATA INDUSTRIES GROUP LTD

PO BOX 2032

WASHDYKE

NEW ZEALAND 7941

ACQUISITION AND WARRANTY

On delivery of the spreader carefully check for transit damage and report any defects immediately.

The commencement of warranty is based on the purchase date of your machine, provided you are

registered with Rata Industries within 14 days of the purchase date. Warranty claims will only be

processed upon receipt of proof of purchase and warranty registration within 14 days.

If you wish you may complete the following and post to the address shown.

MODEL

SPREADMAX EX500

SERIAL NUMBER

OWNER

NAME

ADDRESS

EMAIL

PHONE

PURCHASE DATE

DEALER

COMPANY NAME

SIGNATURE

I, the new owner of the above product, accept the above details are correct and that I

have received sufficient training to operate the machine safely and correctly

OWNER SIGNATURE

Lifestyle Block Dairy Farm Drystock Orchard/Vineyard

How did you hear of Vogal?

SPREADMAX EX500

2

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

CHECKLIST FOR VOGAL WHOLEGOODS

Model Spreadmax EX500 Serial Number

Pre dispatch Pre Delivery

Manufacturer Dealer

All Bolts Tight

Drive Engagement Greased & Aligned Correctly

Oil Level Correct In Gear Box(s)

Operators Manual Attached to Machine

Checked and Test Run

Alignment of Agitator is Correct

Spinner Disc Spins Freely

Signed off by: Signed off by:

Vogal Dispatcher

Date

Dealer Dispatcher

Date

Installation Check

Acquisition Warranty (p.t.o) completed and returned to Vogal

Drive Shaft Correct Length for Tractor

PTO Speed Correct for Machine

Signed off by:

Dealer Deliverer Date

SPREADMAX EX500

3

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

SPREADMAX EX500

Operation Maintenance

& Parts Manual

Rata Industries

Ferrier Rd

Winchester

South Island

New Zealand

Phone 0800 4 VOGAL (0800 486 425)

SPREADMAX EX500

4

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

DEAR CUSTOMER

Rata Industries would like to take this opportunity to welcome you as the new owner of a Vogal Spreader.

We want your spreader to be the most efficient and reliable piece of equipment you have. This manual

has been produced to assist in the correct operation, maintenance and care of your machine.

The safe operation and maintenance of your spreader is very important to prevent any personal injury

and/or damage. Read and fully understand the following instructions before using your machine or

carrying out any maintenance.

WARRANTY

Rata Industries warrants new products sold by it, to be free from defects in material and workmanship for

a period of 12 months after the date of purchase to the initial user. This warranty is for the replacement

or repair of any part found to be defective during the warranty period. This warranty only applies to new

Vogal products.

If the product is purchased for commercial use or hire gain, then the warranty is reduced to three

months. Should the product fail as a result of a fault in material or sub-standard workmanship by the

manufacturer within the warranty period then Rata Industries will agree to repair this product subject to

the conditions of this warranty.

This warranty excludes any transport costs or damage and excludes all normal maintenance costs.

Rata Industries will not pay for mileage, freight, courier costs, oil, grease or any other expendable

materials.

As the use of the Vogal product is outside our control, Rata Industries accepts no liability for lost earnings

or down time directly or indirectly caused by the machines performance.

Replacement parts provided under the terms of this warranty are covered for the remainder of the

warranty period applicable to the product in which they were installed as if such parts were original

components of that product.

No warranty work is to be started without first getting approval and following the correct warranty

procedures as set out by Rata Industries. Rata Industries will not under any circumstances pay for or

repair any damage caused by misuse or neglect of any machine.

All warranty issues and claims are totally at the discretion of Rata Industries.

Warranty Exclusions: loose bolts and screws including worn holes for the same, belts, tyres, blades, PTO

shafts, disc bearings and hydraulic hoses, these parts are generally not covered by this warranty.

DELIVERY

The machine is delivered fully assembled, however, before use carefully check the entire machine for

transit damage and report any problems immediately.

Rata Industries thanks you for buying our product.

We are sure you will be impressed!

SPREADMAX EX500

5

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

GENERAL

Spreadmax fertiliser spreaders have been designed to spread general Granulated fertilisers, Urea, Grass

seed, and particularly Causemag, plus other similar products. The wide wheel base and strong frame

design of the Spreadmax Fertiliser ensure safety and stability when towed behind four wheeled ATV’s.

CAPACITY AND DIMENSIONS

Model

Hopper

Capacity

(Litres)

Max

Load

Capacity

(Kg)

Wheel

Size

Gearbox

Oil Type

Gearbox

Oil

Capacity

(Litres)

Max Road

Speed with

Spinner

UNENGAGED

Overall

Width of

Machine

Loading

Height

Spreadmax EX500

500

380KG

20x10x8

EP 90

0.3

20kpH

1800

1500

SAFETY INSTRUCTIONS

WARNINGS AND CAUTIONS

1. Throughout this manual the word WARNING is used to alert the operator and others to the risk of

personal injury during the operation of the equipment. CAUTION indicates the possibility of

damage to the machine.

2. Carefully read and take note of the following warnings before attempting to tow or operate the

spreader.

Warning: Ensure the spreader tow hitch is in good repair and suitable for towing.

Warning: Check that all moving parts are in good repair and that all the fasteners are correctly

tightened.

Warning: Never allow any person to ride on the spreader.

Warning: Never tow the spreader with the spinner drive engaged at a speed greater than 20kpH.

NOTE Maximum towing speed with the drive DISENGAGED is 20kpH.

Warning: Do not exceed the maximum weight/capacity specified by the manufacturer of the towing

vehicle.

Warning: Foreign objects can cause extensive damage to the machine and result in injury to the

operator. Make sure that the contents of the hopper are clean and free of debris and

foreign objects before use.

Warning: Before using the spreader the operator should ensure that this manual is read and fully

understood.

SPREADMAX EX500

6

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

INSTALLATION

PRE –START CHECKS

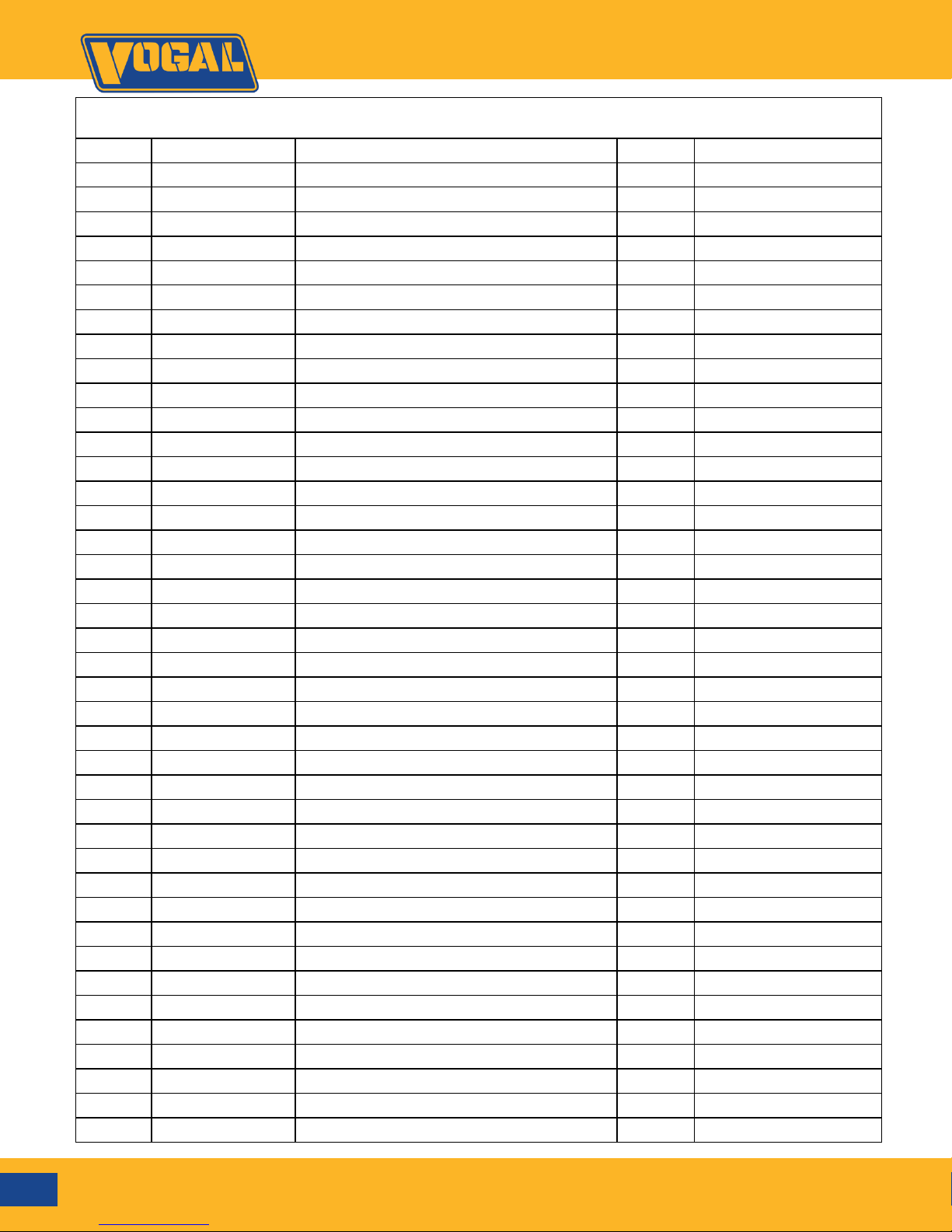

1. Ensure that the towball on the vehicle is compatible with the spreader. The spreader is designed

to accept a 1-7/8” diameter towball.

2. Check the operation of all controls (A).

3. Ensure the ride height is correctly set for the ATV towing the spreader (B).

4. Check that the tyre pressure (C) 10psi minimum to 25psi maximum dependant on load size. Check

the condition of the tyres. Look for signs of wear, cuts and impact damage.

5. Check the free operation of the lower shutter (D)

6. Check the condition of the hopper cover (E)

7. Check that all grease points have been greased.

8. Check the gearbox for oil leaks, if an oil leak is evident do not use the spreader and carry out

repairs immediately.

9. Check that the agitator is movable, free from debris and well-greased.

A

B

D

E

C

SPREADMAX EX500

7

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

INSTALLATION

PRE –START CHECKS

10. Ensure that the towball on the vehicle is compatible with the spreader. The spreader is designed

to accept a 1-7/8” diameter towball.

11. Check the operation of all controls.

12. Ensure the ride height is correctly set for the ATV towing the spreader.

13. Check that the tyre pressure, 10psi minimum to 25psi maximum dependant on load size. Check

the condition of the tyres. Look for signs of wear, cuts and impact damage.

14. Check the free operation for the upper and lower shutters Y & Z.

15. Check the condition of the hopper and cover.

16. Check that all grease points have been greased.

17. Check the gearbox for oil leaks, if an oil leak is evident do not use the spreader and carry out

repairs immediately.

Check that the agitator is movable, free from debris and well greased.

CALIBRATION

To precisely calibrate the spreader carefully read and perform the following instructions.

1. Place a measured amount of fertiliser in the hopper e.g. 10kg (A).

2. Choose an aperture setting to suit the rate required for the type of fertiliser being used, e.g.

Setting 6 (B).

3. Obtain the desired travel speed (12 to 15kpH) and open the aperture to pre-set setting 6 e.g. 200

metres (C).

NOTE Maintain a constant speed and coverage width, e.g. 8 metres (D).

4. Check the effective spread coverage width, e.g. 8 metres (D).

5. Measure the amount of fertiliser left in the hopper, e.g. 4kg (E).

SPREADMAX EX500

8

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

6. Then perform the following calculations:-

Measured amount of fertiliser initially loaded in hopper (A) 10kg

Deduct any remaining fertiliser (E) 4kg

Balance Used 6kg

Multiply width of spread (D) 8 metres

By the metres travelled (C) x 200 metres

= 1,600sq. Metres

Divide 10,000 by the answer (1,600) 10,000 / 1,600 = 6.30

Multiply the sum (6.30) by the test quantity used (B) 6kg (B) x 6.30 = 37.80kg

The figure achieved is the sowing rate per hectare at the constant speed

selected for the test.

7. Due to the variations of seeds and fertiliser types, it is recommended the test be carried out for

each product being used

8. Record all results to ensure accurate speed rates for future reference and minimal wastage.

CALIBRATION SETTINGS

Calibrated at a speed of 20kph (kg/ha)

Setting

1

2

3

4

5

6

7

Urea

-

-

9.40

21.90

37.50

59.40

75.00

Super

-

-

12.50

34.80

59.50

90.60

100.00

DAP

-

-

9.40

25.00

40.60

62.50

68.80

Calibrated at a speed of 15kph (kg/ha)

Setting

1

2

3

4

5

6

7

Urea

-

-

12.50

25.00

43.80

68.80

75.00

Super

-

-

21.90

40.60

71.90

109.40

175.00

DAP

-

-

12.50

31.30

50.00

81.30

93.80

Note: These calibrations are a guide only and should be checked to confirm accuracy.

SPREADMAX EX500

9

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

OPERATING

VARI-PORT FLOW CONTROL

The Vogal Spreadmax EX500 has a new Vari-Port aperture

which can be altered to compensate for different types of

fertiliser ensuring accurate placement. The Vari-Port allows

you to tune your spreader to spread more fertiliser to the left

or to the right depending on what is required for the type of

fertiliser being used.

The amount and spread direction of the fertiliser is controlled

by two control shutters, upper shutter (Y) controlling the

direction of spread and lower shutter (Z) controlling the

flow rate. Once the direction and initial flow rate has

been set, the rate of flow can be changed or closed to fill

the hopper by moving the shutter lever (A) on the front

of the spreader.

To adjust the Vari-Port control shutter:

1. Before filling the hopper lift the shutter lever pin

(X) out of the index slots. Rest it on top of the

hopper base frame.

2. Set the upper shutter (Y) to the letter desired.

Setting ‘A’ will spread more to the left and setting ‘G’ will spread more to the right. ‘D’ is standard setting.

3. Place the shutter lever pin (X) into the index

slot lettered with the same letter selected for

upper shutter (Y).

4. If the lower shutter (Z) is indexed to position

“C” then set the upper shutter (Y) to position

“C”. The upper shutter index must be the same

as the lower shutter index letter. This then

allows the shutter control lever to regulate the

flow of the product to be spread.

5. Vary the settings of the upper shutter (Y) to

suit the direction of spread.

6. Use the shutter lever to regulate the desired flow and to shut off the flow of fertiliser for filling the

hopper. 0 is the off position and 6 fully open

7. The spreading pattern will vary between different types of fertiliser.

8. Ensure the shutter lever is in position 0 before filling.

A

X

Y

Z

SPREADMAX EX500

10

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

MAINTENANCE

1. Maintenance should be undertaken regularly, good

maintenance extends the life of the spreader.

2. Check the wheel bearings for play and pack with

grease every six months.

3. Open the aperture and clean around the aperture

blades and holes.

4. Periodically remove the agitator by removing the

retaining pin located under the hopper.

5. Lift the agitator, clear of the shaft any remove any

residue, grease and replace the agitator. Ensure the

retaining pin is refitted and held in place by the

spring clip.

6. Check the condition of the engagement mechanism

and grease daily. Use the following procedure, firstly

engage the drive, and then pump grease into the

grease point.

7. Check the condition of the drive operating lever and the lever plastic liner tube (A).

8. Check the oil level in the gearbox. To check turn the spreader on its side, remove the filler plug

located in the base, check that the oil is level with the rim of the hole, top up if necessary.

9. Change the gearbox oil (EP 90) every six months with normal use, or every three months under

extreme conditions. The quantity of oil required is 300ml.

SPREADMAX EX500

11

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

REPLACEMENT PARTS

1. To order replacement parts please quote the spreader type, serial number and date of purchase.

2. The serial number is located on the spreader tow bar as shown below.

3. The follwing pages detail the replacement parts available.

SERIAL NUMBER

SPREADMAX EX500

12

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

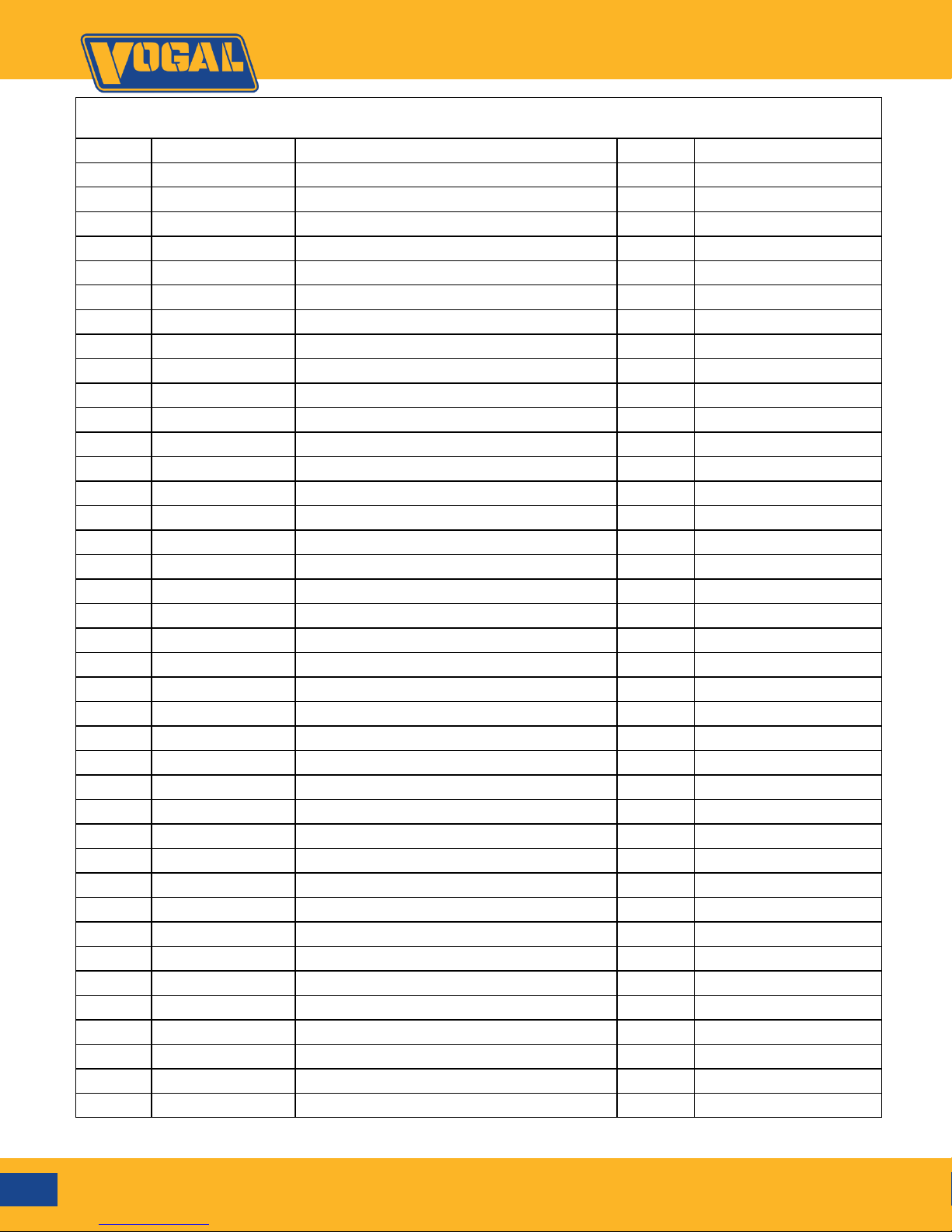

17

16

14

11

10

4

1

15

18

12

13

3

2

8

6

7

5

9

19

20

SPREADMAX EX500 PARTS LIST

SPREADMAX EX500

13

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

SPREADMAX EX500 PARTS LIST

Item

Part No.

Description

Qty

Notes

13

SP136-001

Main Frame

1

SP100-033

Drive Engage Liner Tube

1

SP100-034

Drive Axle Key

1

SP100-035

Pointer

1

12

SP100-036

Index Box

1

SP136-003

Shutter Lower Z

1

14

SP136-004

Spinner Disc

1

15

SP136-005

Spinner Fin

6

SP136-008

Agitator

1

17

SP136-009

Bearing Housing

1

18

SP136-015

Drive Operating Lever

1

SP136-024

Hopper Cross Stay

1

SP136-029

Towbar Bush Liner

1

SP136-031

Drive Axle Spacer Liner

1

SP136-032

Drive Axle Spacer

1

19

SP136-112

Shutter Lever

1

SP136-113

Drive Handle

1

20

SP141-010

Towbar

1

16

SP175-007

Drive Axle

1

SP175-014

Towbar Adjuster

1

SP175-016

Bolt on Stub Axle

1

SP193-052

Front Hopper Bracket

1

10

SP100-015

Drive Slider

1

11

SP100-016

Drive Stub

1

SP100-020

Shaft Guard (trailed spreader)

2

SP136-028

Agitator Bush 550

1

9

2893

Hopper Only Yellow

1

3

1807

Spinner Shield Blue

1

7

2791

Cover Canvas

1

4

2121

Gearbox RV010

1

1939

Upper Shutter

1

5

2190

Non-Drive Wheel 20x10-8

1

6

2191

Drive Wheel 20x10-8

1

8

2801

Hub Cap

2

1226

Coupling WBB 2000 1 7/8

1

1573

Drive Axle Bearing

2

1

1093

D Pin

2

1094

Spring

1

2

1644

Grip Handle 22mm

2

1651

Tri Knob Female 8mm

1

SPREADMAX EX500

14

Phone 0800 4 VOGAL (0800 486 425)

E: sales@rataindustries.co.nz W: www.rataindustries.co.nz

SPREADMAX EX5OO PARTS LIST

Item

Part No.

Description

Qty

Notes

1679

Felt Washer

1

1241

Spring Wire Coil 14.9OPx59Lx1

1

2790

Plastic Bungy Hook

2

4150

M6 Nut S/S

12

4152

M6 Nut Nyloc Zinc

2

4156

M6x16 Bolt Zinc

2

4157

M6x16 Coach Bolt S/S

12

4187

M6 Washer Spring S/S

12

4192

M6 Washer (12x1) S/S

12

4254

M8 Nut Nyloc Zinc

3

4258

M8x16 Bolt S/S

3

4266

M8x30 Bolt Zinc

2

4268

M8x35 Bolt Zinc

2

4272

M8x50 Bolt Zinc

1

4280

M8 Washer Spring S/S

3

4284

M8 Washer (16x1.2) S/S

3

4285

M8 Washer (16x1.2) Zinc

3

4353

M10 Nut Nyloc Zinc

9

4363

M10x35 Bolt & Nut Galv

3

4366

M10x40 Bolt & Nut Galv

1

4379

M10x70 Bolt Zinc

1

4384

M10x120 Bolt Zinc

4

4390

M10 Washer Spring Galv

3

4398

M10 Washer (24x3) HD Galv

3

4399

M10 Washer (24x3) HD Zinc

5

4453

M12 Nut Nyloc Zinc

11

4465

M12x35 Bolt Zinc

4

4468

M12x40 Bolt Zinc

7

4498

M12 Washer (24x1.6) Zinc

11

4655

M16 Nut Nyloc Zinc

2

4685

M16x200 Bolt Galv

1

4690

M16 Washer (35x3) HD Black

2

5010

Rivet 6-12 73 ASL

13

5020

Roll Pin 6x30 Bissel S/S

1

5024

Roll Pin 6x60 Bissel S/S

1

5042S/S

Circlip 45mm External Zinc

1

5049

Grease Nipple M10x1.0 Straight

1

2803

Decal Silver Graph Set

1

3015

Decal "550

1

Table of contents

Other Vogal Spreader manuals

Popular Spreader manuals by other brands

Trynex

Trynex SnowEx PWX-200 Onwer / Operator's Manual

Buyers

Buyers SaltDogg 1470601SSE installation instructions

Millcreek

Millcreek 57G Operator's manual

TurfEx

TurfEx TS-85 Owner's/operator's manual

Brinly

Brinly P20-500BH owner's manual

LEHNER

LEHNER SuperVario X Operating instructions with spare parts list