Vogal SPREADMAX TPL500 User manual

1

DOUBLE YOUR SPREADER WARRANTY TO TWO YEARS

By completing and returning this Acquisition and

Warranty form to:

RATA INDUSTRIES GROUP LTD

PO BOX 2032

WASHDYKE

NEW ZEALAND 7941

ACQUISITION AND WARRANTY

On delivery of the spreader carefully check for transit damage and report any defects immediately. Please

complete the following form and send to the address detailed on this page. The commencement of warranty

is based on the purchase date of your machine, provided this page is received at Rata Industries within 14

days of the purchase date. Warranty claims will only be processed upon receipt of proof of purchase and

return of this warranty registration form within 14 days of purchase.

MODEL

SPREADMAX TPL500

SERIAL NUMBER

OWNER

NAME

ADDRESS

EMAIL

PHONE

PURCHASE DATE

DEALER

COMPANY NAME

SIGNATURE

I, the new owner of the above product, accept the above details are correct and that I have received

sufficient training to operate the machine safely and correctly

OWNER SIGNATURE

Lifestyle Block Dairy Farm Drystock Orchard/Vineyard

How did you hear of Vogal?

SPREADMAX TPL500

2

CHECKLIST FOR VOGAL WHOLEGOODS

Model Spreadmax TPL500 Serial Number

Pre dispatch Pre Delivery

Manufacturer Dealer

All Bolts Tight

Drive Engagement Greased & Aligned Correctly

Drive Shaft Greased & Attached to Machine

Oil Level Correct In Gear Box(s)

Operators Manual Attached to Machine

Checked and Test Run

Alignment of Agitator is Correct

Spinner Disc Spins Freely

Warning Label Attached

Re: Drive Shaft Length and Oil Levels

Signed off by: Signed off by:

Vogal Dispatcher

Date

Dealer Dispatcher

Date

Installation Check

Acquisition Warranty (p.t.o) completed and returned to Vogal

Drive Shaft Correct Length for Tractor

PTO Speed Correct for Machine

Signed off by:

Dealer Deliverer Date

SPREADMAX TPL500

4

DEAR CUSTOMER

Rata Industries would like to take this opportunity to welcome you as the new owner of a Vogal Spreader.

We want your spreader to be the most efficient and reliable piece of equipment you have. This manual has

been produced to assist in the correct operation, maintenance and care of your machine.

The safe operation and maintenance of your spreader is very important to prevent any personal injury

and/or damage. Read and fully understand the following instructions before using your machine or carrying

out any maintenance.

WARRANTY

Rata Industries warrants new products sold by it, to be free from defects in material and workmanship for a

period of 12 months after the date of purchase to the initial user. This warranty is for the replacement or

repair of any part found to be defective during the warranty period. This warranty only applies to new Vogal

products.

If the product is purchased for commercial use or hire gain, then the warranty is reduced to three months.

Should the product fail as a result of a fault in material or sub-standard workmanship by the manufacturer

within the warranty period then Rata Industries will agree to repair this product subject to the conditions of

this warranty.

This warranty excludes any transport costs or damage and excludes all normal maintenance costs.

Rata Industries will not pay for mileage, freight, courier costs, oil, grease or any other expendable materials.

As the use of the Vogal product is outside our control, Rata Industries accepts no liability for lost earnings or

down time directly or indirectly caused by the machines performance.

Replacement parts provided under the terms of this warranty are covered for the remainder of the warranty

period applicable to the product in which they were installed as if such parts were original components of

that product.

No warranty work is to be started without first getting approval and following the correct warranty

procedures as set out by Rata Industries. Rata Industries will not under any circumstances pay for or repair

any damage caused by misuse or neglect of any machine.

All warranty issues and claims are totally at the discretion of Rata Industries.

Warranty Exclusions: loose bolts and screws including worn holes for the same, belts, tyres, blades, PTO

shafts, disc bearings and hydraulic hoses, these parts are generally not covered by this warranty.

DELIVERY

The machine is delivered fully assembled, however, before use carefully check the entire machine for transit

damage and report any problems immediately.

Rata Industries thanks you for buying our product.

We are sure you will be impressed!

SPREADMAX TPL500

5

SAFETY INSTRUCTIONS

WARNINGS AND CAUTIONS

1. Throughout this manual the word WARNING is used to alert the operator and others to the risk of

personal injury during the operation of the equipment. CAUTION indicates the possibility of damage

to the machine.

2. Carefully read and take note of the following warnings before attempting to tow or operate the

spreader.

Warning: Never dismount tractor while machine is engaged.

Warning: Check that all moving parts are in good repair and that all the fasteners are correctly

tightened.

Warning: Never allow any person to ride on the spreader.

Warning: Never tow the spreader with the spinner drive engaged at a speed greater than 20kpH.

NOTE Maximum towing speed with the drive DISENGAGED is 30kpH.

Warning: Do not exceed the maximum weight/capacity specified by the manufacturer of the towing

vehicle.

Warning: Foreign objects can cause extensive damage to the machine and result in injury to the

operator. Make sure that the contents of the hopper are clean and free of debris and foreign

objects before use.

Warning: Before using the spreader the operator should ensure that this manual is read and fully

understood.

SPREADMAX TPL500

6

PRE-START CHECKS

1. Check the general condition of the machine,

check for cracks, loose bolts and worn or

damaged components.

2. Check the condition of the gearbox input shaft

(A) wear and damage to the splines.

3. Check & grease (B) drive shaft on an 8-hour

basis

OPERATING

The Vogal TPL500 MKII has been designed for a good distribution of the fertiliser across the ground to

obtain optimum performance.

The following conditions should be complied with:

1. Maintain the P.T.O. speed at 450 RPM (This speed

affects the spreading width).

2. Keep the machine horizontal with the broadcast plate

700mm above the ground.

3. Identify and keep to the distance between the outward and return passes (marking is

recommended). You should obtain full width coverage of the ground approximately 16 –18 metres

behind the spreader.

SPREADMAX TPL500

7

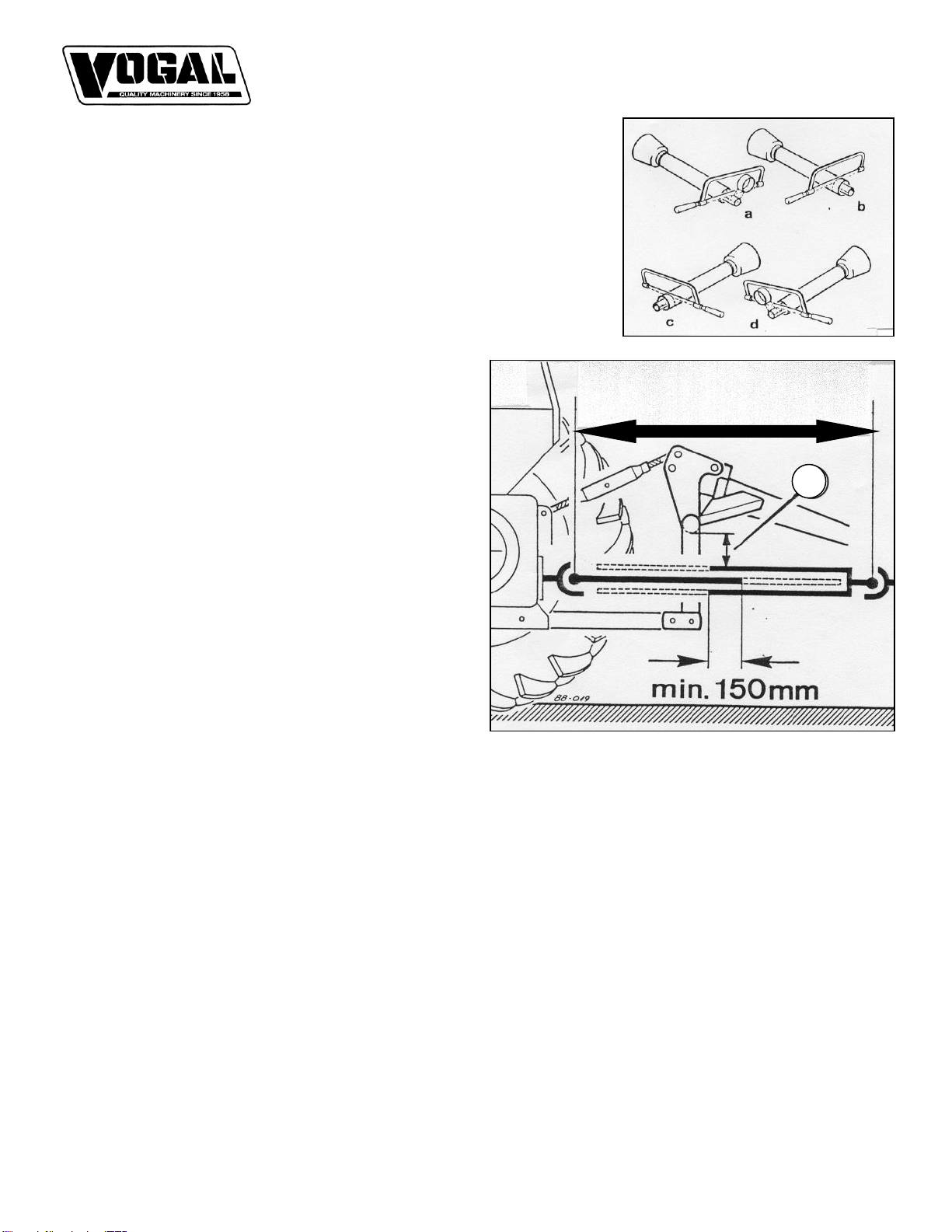

SHORTENING THE DRIVE SHAFT

When shortening the PTO shaft the four parts A, B, C and D must be

shortened equally. After shortening the tube and shaft ends have to be

filed off, cleaned of filings and lubricated.

DRIVE SHAFT LENGTH

1. Ensure drive shaft (C) is the correct length to

suit the tractor.

CAUTION A drive shaft to long will bottom out

when being lifted by the tractor causing

severe damage to the tractor or

machine.

2. Ensure the drive shaft has a minimum of

150mm overlap as per photo.

MAINTENANCE

Maintenance should be carried out on a regular basis.

This will extend the life of the machine and save any

unnecessary down time.

Things to check:

Covers Check they are in place and serviceable.

Gearbox Check oil is clean and filled to correct level. NB: Change oil annually.

Grease Nipples The external nipples should be greased before each use. The internal nipples (under

the covers) should be checked and greased every 50 hours operating time.

Warning: Do not attempt to work on the machine in any way without disconnecting the PTO

shaft from the tractor.

C

SPREADMAX TPL500

8

Calibration

To precisely calibrate the machine, carefully read and perform the following instructions:

1. Place a measured amount of fertiliser in the hopper, e.g. ……..kg (A)

2. Choose an aperture setting to suit the rate required for the type of fertiliser being used e.g. Setting 6

(B).

3. Obtain the desired travel speed (12 to 15 km/hr) and open the aperture to preset setting 6, e.g. 200

metres (C). Note: Maintain a constant speed and coverage width, e.g. 8 metres (D).

4. Check the effective spread coverage width, e.g. 8 metres (D).

5. Measure the amount of fertiliser left in the hopper, e.g. 4kg (E).

6. Then perform the following calculations:

Measured amount of fertiliser initially loaded in hopper (A) 10kg

Deduct any remaining fertiliser (E) 4kg

Balanced used 6kg

Multiply width of spread (D) 8 metres

By the meters traveled (C) x 200 metres

= 1,600 square metres

Divide 10,000 by the answer (1,600) 10,000 ÷ 1,600 = 6.30

Multiply the sum (6.30) by the test quantity used (B) 6kg (B) x 6.30 = 37.80kg

The figure achieved is the sowing rate per hectare at the constant speed selected for the test.

Due to the variations of seeds and fertiliser types, it is recommended the test be carried out for each product

being used.

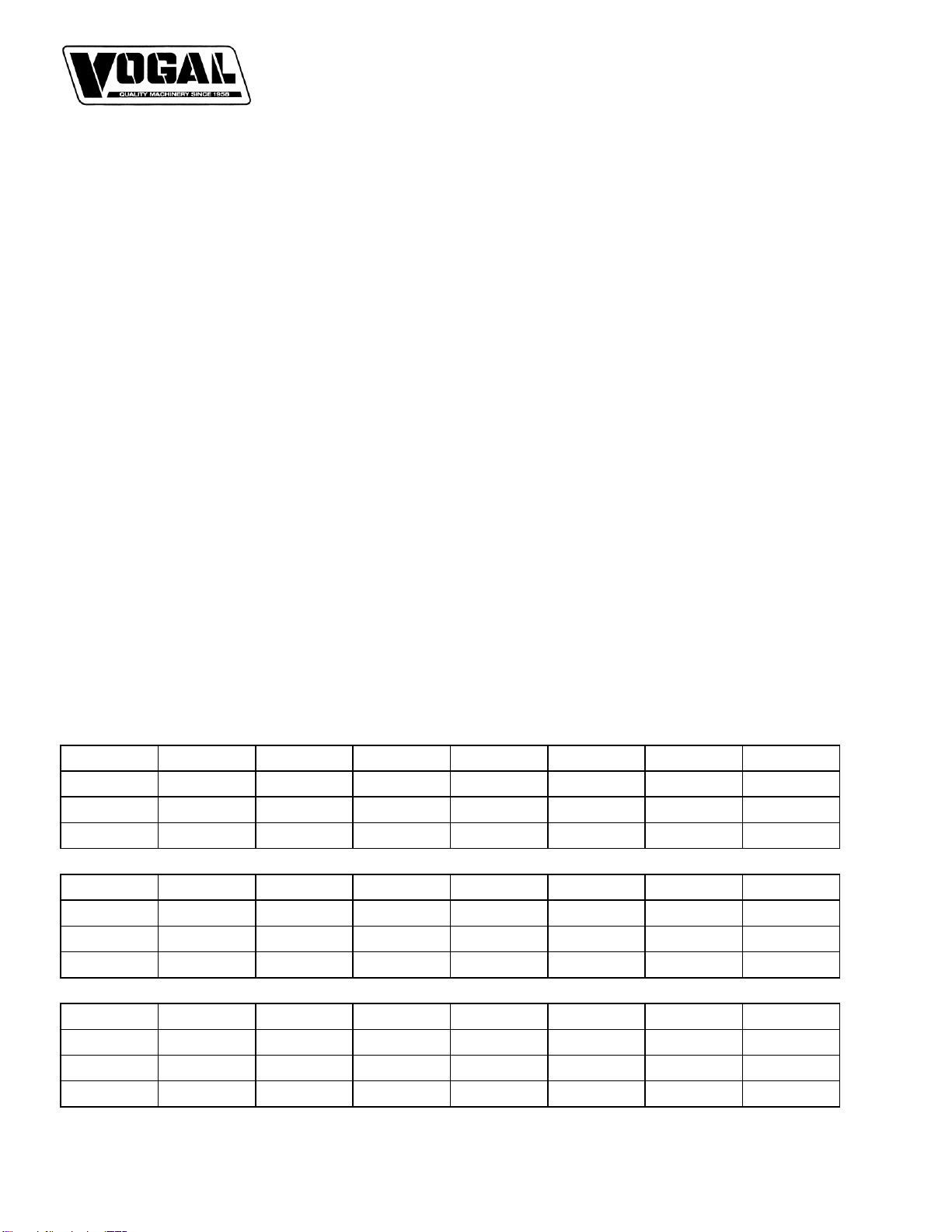

Spreadmax TPL500 MKII Calibration Settings

Tractor P.T.O. run at 450rpm (kg/ha) Ground Speed 15kph

Setting

1

2

3

4

5

6

7

Urea

-

-

10.00

25.00

40.00

57.50

75.00

Super

-

-

11.65

26.64

46.62

68.26

84.91

DAP

-

-

17.50

32.50

52.50

72.50

95.00

Tractor P.T.O. run at 500rpm (kg/ha) Ground Speed 15kph

Setting

1

2

3

4

5

6

7

Urea

-

-

10.00

25.00

42.50

62.50

80.00

Super

-

-

11.65

29.97

49.95

69.93

93.24

DAP

-

-

12.50

27.50

50.00

77.50

95.00

Tractor P.T.O. run at 550rpm (kg/ha) Ground Speed 15kph

Setting

1

2

3

4

5

6

7

Urea

-

-

12.50

27.50

50.00

65.00

85.00

Super

-

-

14.98

33.30

56.61

81.58

96.57

DAP

-

-

12.50

30.00

52.50

72.50

100.00

Note: These calibrations are a guide only and should be checked to confirm accuracy.

SPREADMAX TPL500

9

REPLACEMENT PARTS

1. To order replacement parts please quote the spreader type, serial number and date of purchase.

2. The serial number is located on the spreader tow bar as shown below.

3. The following pages detail the replacement parts available.

Serial Number

SPREADMAX TPL500

10

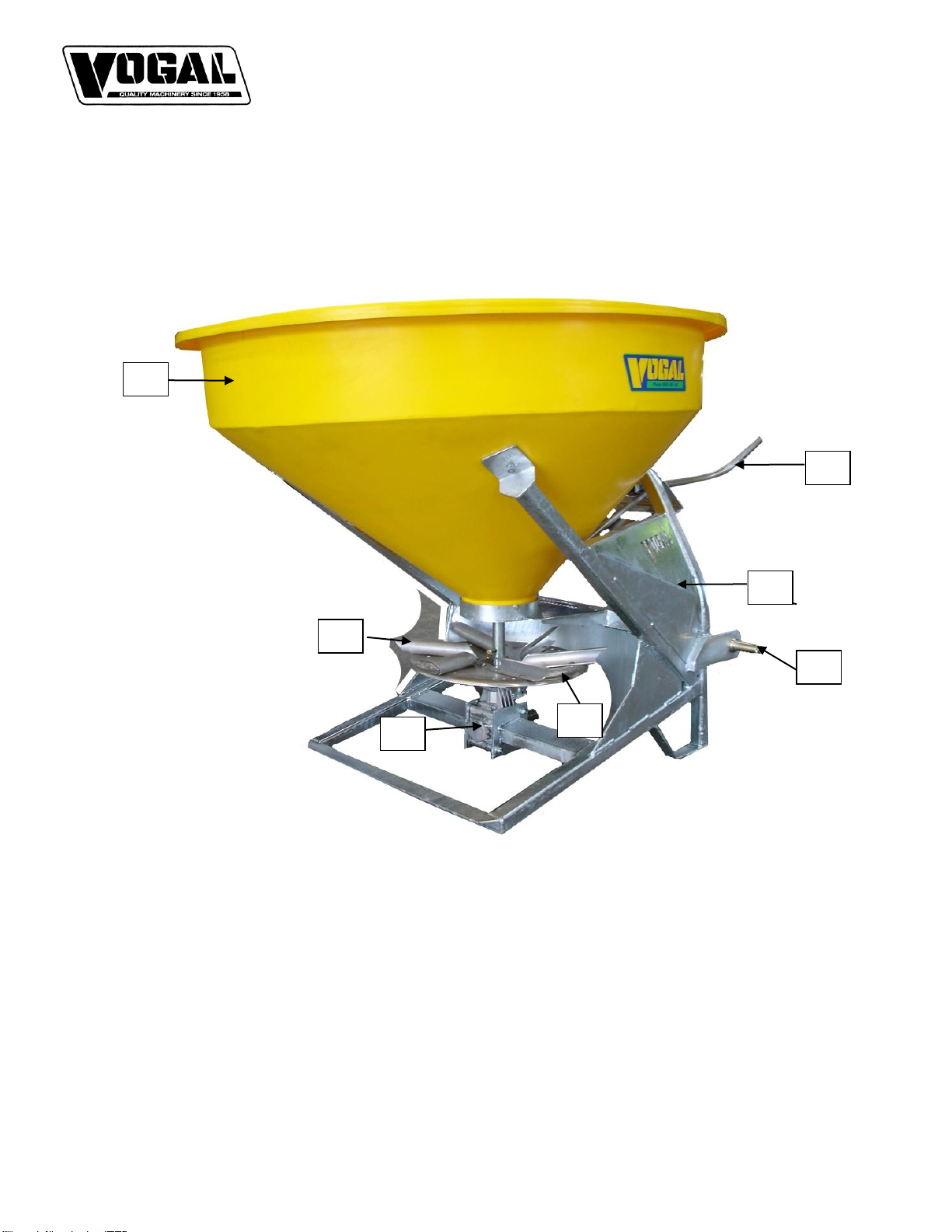

SPREADMAX TPL500 PARTS LIST

6

5

4

7

2

3

1

SPREADMAX TPL500

11

SPREADMAX TPL500 PARTS LIST

Item

Part No.

Description

Qty

Notes

4

SP106-001

Main Frame

1

SP100-035

Pointer

1

SP106-004

Front Hopper Bracket

1

SP106-005

Internal Hopper Brace

1

5

SP106-012

Shutter Lever

1

SP120-013

Shutter Lever Extension

1

6

SP136-004

Spinner Disc

1

7

SP136-005

Spinner Fin

6

SP136-008

Agitator

1

SP100-003

Agitator Bush

1

SP100-020

Shaft Guard (trailed spreader)

2

2

2893

Hopper Only Yellow

1

2791

Cover Canvas

1

3

3137

Gearbox RV010

1

3136

Shutter Plate

1

1

1085

Lower Link Pin Cat 2 7/8"

1

1093

D Pin

1

1094

Spring

1

3375

Drive Shaft - Quick hitch

1

1645

Grip Handle 25mm

1

1651

Tri Knob Female 8mm

1

1679

Felt Washer

1

4150

M6 Nut S/S

12

4152

M6 Nut Nyloc Zinc

2

4156

M6x16 Bolt Zinc

2

4157

M6x16 Coach Bolt S/S

12

4187

M6 Washer Spring S/S

12

4192

M6 Washer (12x1) S/S

12

4258

M8x16 Bolt S/S

3

4280

M8 Washer Spring S/S

3

4284

M8 Washer (16x1.2) S/S

3

4285

M8 Washer (16x1.2) Zinc

1

4353

M10 Nut Nyloc Zinc

3

4359

M10x30 Bolt & Nut Galv

2

4363

M10x35 Bolt & Nut Galv

4

4366

M10x40 Bolt & Nut Galv

4

4379

M10x70 Bolt Zinc

1

4385

M10x130 Bolt Zinc

2

SPREADMAX TPL500

12

SPREADMAX TPL500 PARTS LIST

Item

Part No.

Description

Qty

Notes

4390

M10 Washer Spring Galv

6

4396

M10 Washer (21x1) Zinc

1

4398

M10 Washer (24x3) HD Galv

4

4399

M10 Washer (24x3) HD Zinc

3

5042S/S

Circlip 45mm External S/S

1

1742

Decal 11-0 TPL Shutter Numbers

1

1750

Decal 540RPM Max

1

3007

Decal "TPL500"

1

2715

Serial Number Plate

1

2998

Manual Tube

1

Manual

1

Table of contents

Other Vogal Spreader manuals

Popular Spreader manuals by other brands

A.M.Leonard

A.M.Leonard AM50P owner's manual

SSC

SSC 2150 Assembly & operation

Fisher

Fisher QUICK-CASTER 300W Owner's manual and installation instructions

The Andersons

The Andersons LCO-1000 Assembly, use and care

EINHELL

EINHELL GE-US 18 Li Original operating instructions

Meyer's

Meyer's 125A INSTRUCTION AND PARTS BOOK