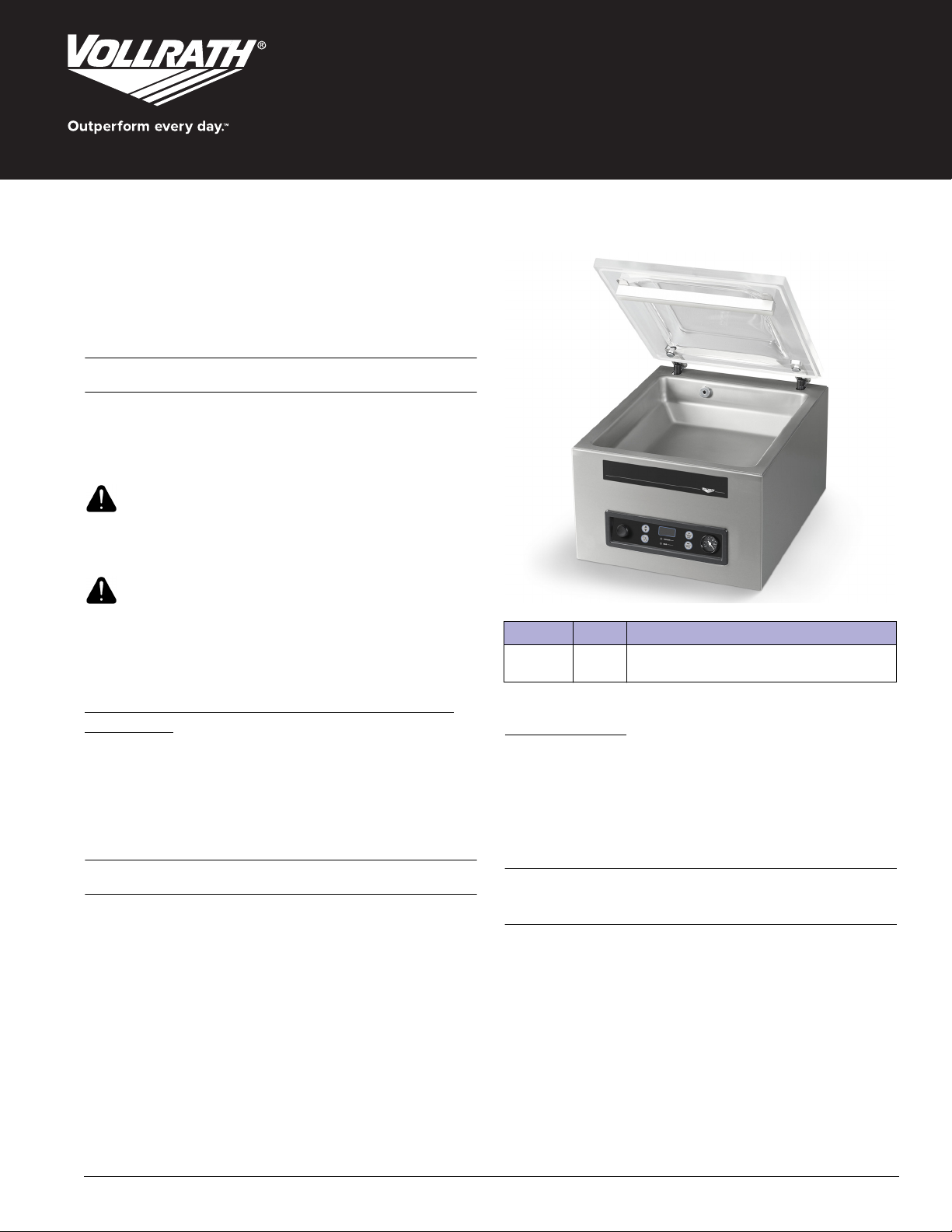

4 Vacuum Packing Machine with 12" Sealing Bar Operator’s Manual

Packing Liquid Products

Special care must be taken when packing liquids.

1. Cool food before packing. Hot food quickly reaches the boiling

point, which can lead to an insufficient seal.

NOTICE: Hot products create condensation, which can damage

the pump.

2. Watch the vacuum process through the clear lid.

3. Press as soon as bubbles appear in the product.

This stops the vacuum and starts the seal step.

NOTICE: Do not let products boil. Boiling will increase the

amount of moisture that enters the pump, which can

lead to corrosion.

4. Run the Pump Conditioning Program at the end of the work day.

CLEANING

NOTICE: Do NOT tilt the machine. Tilting could enable oil to flow out of the pump and cause damage to the machine.

NOTICE: If the machine will be idle for more than one month, the oil should be drained from the pump. Moisture in the oil could corrode the

pump.

Daily

Run the Pump Conditioning Program

The Pump Conditioning Program removes any moisture that may have

accumulated in the pump. During the program, the pump and oil reach

operating temperature, which evaporates any moisture in the pump.

1. Press .

2. The display shows .

3. Close the lid.

4. The program starts. Moving dots appear on the display.

5. The program runs for approximately 15 minutes. Do not interrupt

the program. If the program is interrupted, it must be run again to

ensure completion.

Clean the exterior and interior

NOTICE: Do not use cleaners containing ammonia, alcohol, acetone

or dry cleaning products. Cleaners with these chemicals

will damage Plexiglas®, acrylic and other plastics. These

will damage the finish.

NOTICE: Do not use paper towels, abrasive materials, scratching

cleansers, razor blades, brushes, steel wool or scouring

pads, such as Scotch Brite™ pads.These will damage the

finish.

NOTICE: Do not use WD-40®or petroleum, industrial or commercial

cleaning products. These will damage the finish.

1. Unplug the machine. Allow it to cool.

2. Wipe the vacuum chamber, lid, sealing bar, silicone holder and

exterior with a soft, lint free or microfiber cloth and warm water, or

a mixture of warm water and a small amount of mild dish

detergent.

3. Thoroughly wipe off any mild soap or chemical cleaners. Residue

could corrode the surface of the unit.

vac

stop

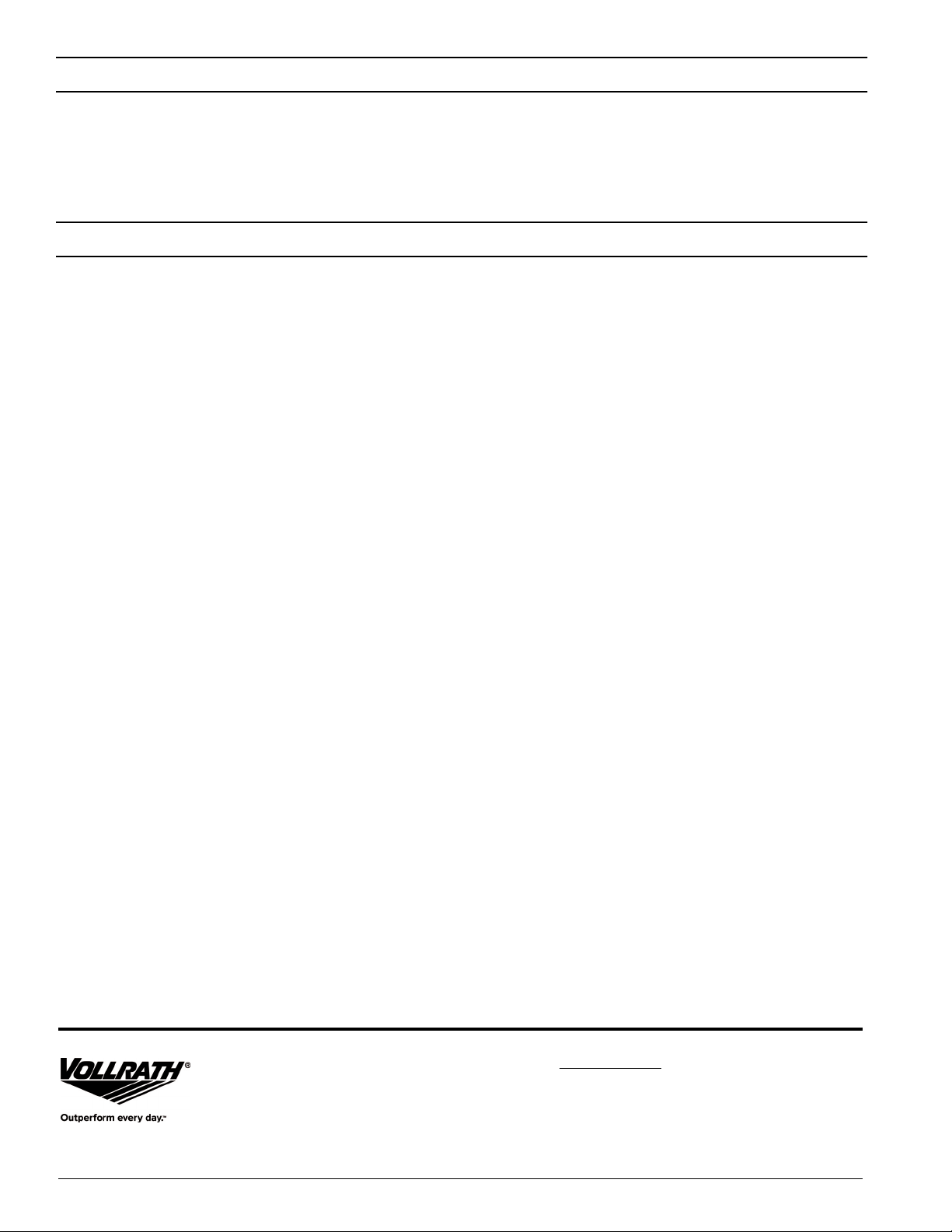

WARNING

Electrical Shock Hazard

Keep water and other liquids from entering the inside of the

equipment. Liquid inside the equipment could cause an

electrical shock. Do not spray water or cleaning products.

Liquid could contact the electrical components and cause a

short circuit or an electrical shock.

CAUTION

Burn Hazard

Allow equipment to cool before moving or cleaning.