© Allegion 2020

Printed in U.S.A.

941369-00 Rev. 03/20-a

Customer Service

1-877-671-7011 www.allegion.com/us

Test trim function.

15

For FS (Fail Safe) trim (factory default):

A. With the power applied, the trim will move to the locked position. The trim’s lever must be allowed to

be in the resting or home position for the trim to lock.

B. Removing power will cause the trim to move to the unlocked position. The trim’s lever must be

allowed to be in the resting or home position for the trim to unlock. Once the trim unlocks, the lever

may be turned.

C. When key cylinder is present on trim, with power engaged, check to ensure that the key override

feature (night latch) functions properly. Inserting and turning key will temporarily unlock door while trim

lever remains rigid. Door locks when key is removed.

For FSE (Fail Secure):

A. With the power applied, the trim will move to the unlocked position. The trim’s lever must be allowed

to be in the resting or home position for the trim to unlock. Once the trim unlocks, the lever may be

turned.

B. Removing power will cause the trim to move to the locked position. The trim’s lever must be allowed

to be in the resting or home position for the trim to lock.

C. When key cylinder is present on trim, with power disengaged, check to ensure that the key override

feature (night latch) functions properly. Inserting and turning key will temporarily unlock door while trim

lever remains rigid. Door locks when key is removed.

Troubleshooting.

16

With the trim plugged into cable, the electronic control can be verified using indicators located on the backside

of the trim. This is only possible when trim is not mounted on the door.

GREEN LED

Indicates the Power status

ON= Controller is powered by the control signal.

OFF= Controller is not powered by the control signal (if power was recently disconnected, can

take up to one minute for LED to turn off).

RED LED

Flashes ON= Mechanism is moving to the unlocked or locked position.

The locked/unlocked operation is dependent on the Fail-Safe or Fail-Secure Switch Position.

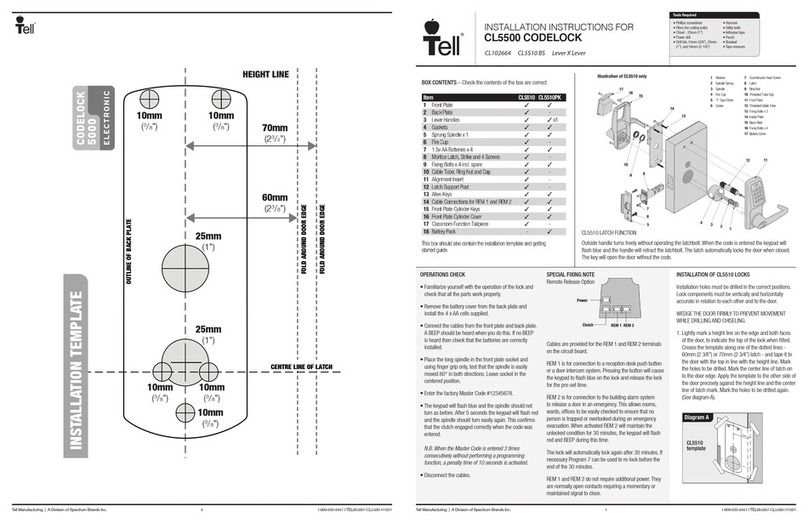

13 Power control

requirements.

The two wires are non-polarized 12/24 VDC input. One wire connects directly to a

12/24 VDC power source (power supply) and the other wire connects to a control

device (card reader, key pad, push button, dry contact, etc.) and then to the power

supply. See diagram below.

Fig. 13-1

+

Power wire runs through

exit device body

Power transfer (EPT2 shown)

M996L

trim

12/24 VDC

output

Power Supply

PS902

A 12/24 VDC

1A minimum

power signal

A 1-second minimum

on-time control pulse

A 1-second minimum

off-time control pulse

Basic wiring information.

Control device

NO contacts for FS

NC contacts for FSE

14