WARNING

Please read and understand these Safety Warnings, Safety Symbols and Instructions carefully and retain

for future use

GENERAL SAFETY INFORMATION.

WARNING! Read all safety warnings

and all instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious injury.

Please retain all warnings and instructions

for future reference.

The term “tool” in the warnings refers

to your Compressed Air operated tool.

INTENDED USE.

This Tool is intended for domestic

use only and should not be used for

commercial or industrial purposes.

This tool is not intended for use by

persons with reduced physical, sensory or

mental capabilities, or lack of experience

and knowledge, unless they have

been given supervision or instructions

concerning the use of the tools by a

person responsible for their safety.

Children should be supervised to ensure

they do not play with the tool.

WORK AREA SAFETY.

Keep your work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate tools in explosive

atmospheres such as in the presence of

flammable liquids, gases or dust. Tools

create sparks which may ignite the dust

or fumes.

Keep bystanders, children and animals

away whilst operating a tool. Distractions

can cause you to lose control.

BEFORE USE.

Stay alert, watch what you are doing, and

use common sense when operating a

tool. Do not use tools whilst you are tired

or under the influence of drugs, alcohol

or medication. A moment of inattention

while operating tools may result in serious

personal injury.

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as a dust mask, non-

skid safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce the risk of personal

injury.

Always wear eye protection. Any tool can

throw foreign objects into your eyes and

cause permanent eye damage. Always

wear safety goggles (not glasses) that

comply with ANSI safety standard Z87.1.

Every day glasses have only impact

resistant lenses. They are not safety

glasses.

WARNING! Wearing glasses or goggles

not in compliance with ANSI Z87.1 when

operating this tool could cause serious

injury.

Hand-held air tools may produce

vibration and should not be used for

long periods without a break. Vibration

can cause disease. Gloves may help to

maintain good blood circulation in the

fingers.

Prevent unintentional starting. Ensure

the switch is in the off position before

connecting to the power source and/or

battery pack, picking up or carrying the

tools. Carrying tools with your finger on

the switch, or energising tools that are

switched on, invites accidents.

Remove any adjusting key or wrench

before turning the tool on. A wrench or

key left attached to a rotating part of the

tool may result in personal injury.

Dress appropriately. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts to prevent them from becoming

caught in the tool.

IMPORTANT SAFETY INFORMATION

FOR USE.

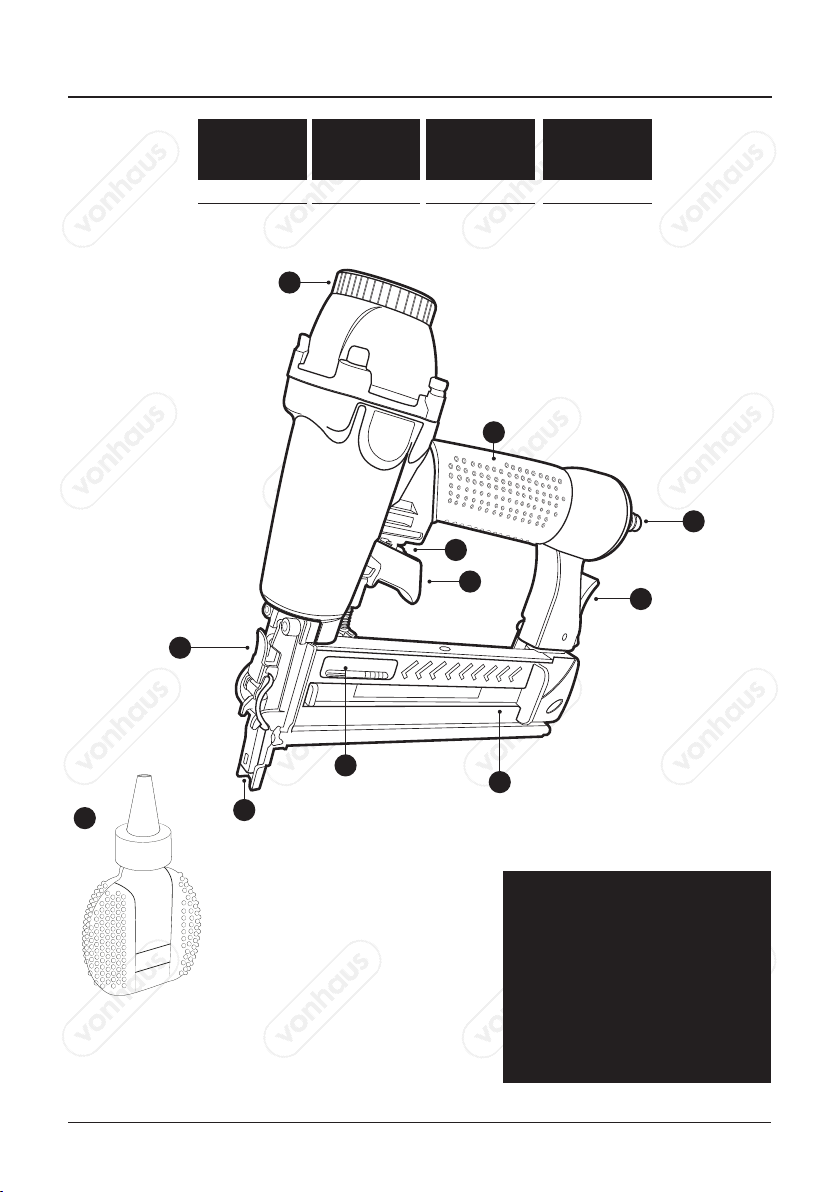

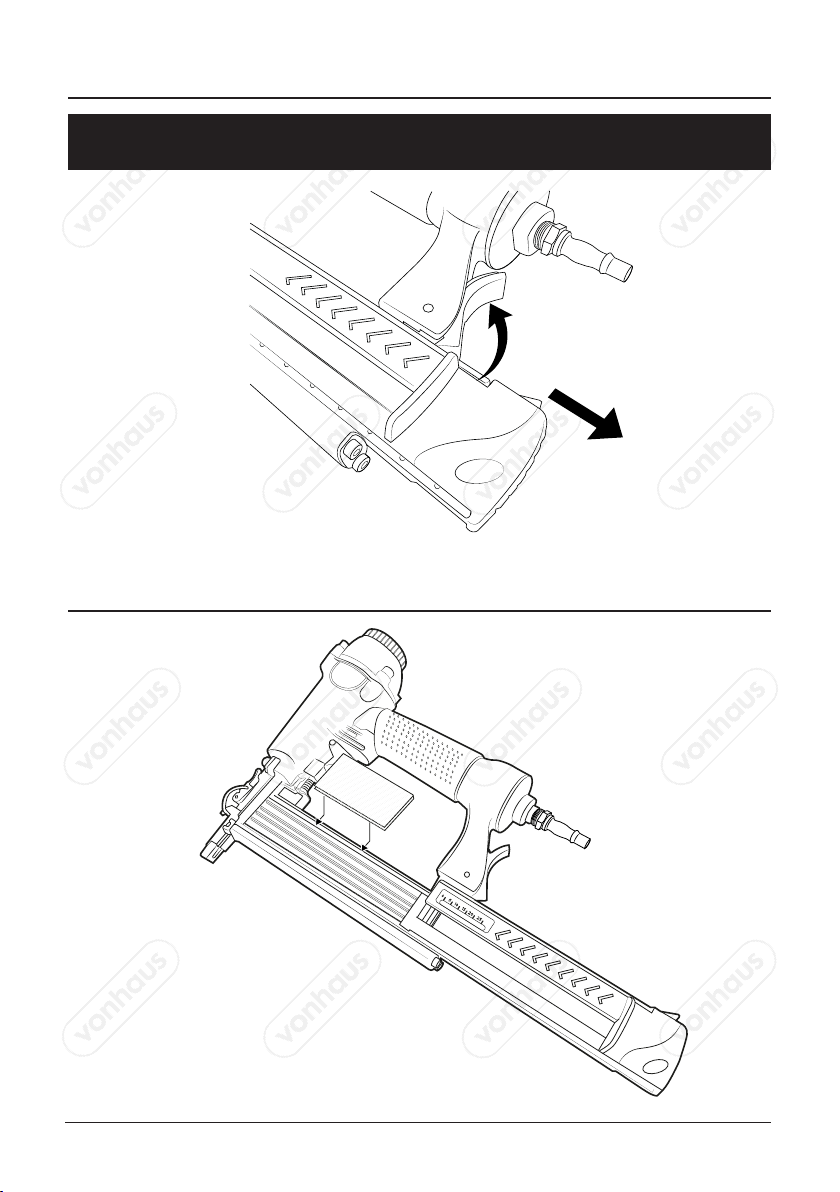

WARNING! Know your Tool. Do not

connect the tool to the compressor

1