4

switch does not turn it on and off properly.

User service. Some user-serviceable components

are described in the Troubleshooting section. We

cannot guarantee repairs made or attempted by

anyone other than authorized agencies.

Tool service must be performed only by

qualied repair personnel. Service or

maintenance performed by unqualied personnel

could result in risk of injury. For example, internal

wires may be misplaced or pinched, safety guard

Guard against electric shock. Prevent body

contact with grounded surfaces: pipes, radiators,

ranges, and refrigerator enclosures. Before

driving fasteners into walls, oors, or wherever

“live” electrical wires may be encountered, try to

ascertain whether there is a danger of shock.

Hearing protection. Wear ear protection when

using the tool for extended periods. Prolonged

exposure to high intensity noise can cause

hearing loss.

Safety glasses To prevent eye injuries, the tool

operator and all persons in the work area must

wear approved safety glasses conforming to ANSI

Z87.1 specications with permanently attached,

rigid side shields.

Use clean, dry, regulated, compressed air at 70

to 90 psi.

Do not connect tool to pressure which

potentially exceeds 200 psi.

Air hose. Only use hose that is rated for a

minimum working pressure of 150 psi or 150%

of the maximum system pressure, whichever is

greater.

Never use oxygen, carbon dioxide, combustible

gases or any other bottled gas as a power

source for this tool. Explosion and serious

personal injury could result.

Couplings. Connect tool to the air supply hose

with 1/4” NPT couplings that remove all pressure

from the tool when the coupling is disconnnected.

Be aware of air hoses and their connections.

Don’t trip over hoses. Make sure all connections

are tight.

Disconnect tool from air supply hose before

return springs may be improperly mounted.

When servicing tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorized parts or failure to follow

Maintenance instructions may create a risk of

injury. Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, etc. may damage

plastic parts.

SAFETY RULES FOR AIR NAILERS

doing any disassembly, maintenance, loading

fasteners, clearing a jammed fastener, leaving

the work area, moving the tool to another

location, or handing the tool to another person.

Never use a tool that is leaking air, has missing

or damaged parts, or requires repair. Before

each use, make sure all screws and caps are

securely tightened.

Check for damaged parts. Never use a tool if

safety, trigger, or spring are inoperable, missing or

damaged. Do not alter or remove safety, trigger,

or springs. Make daily inspections for the free

movement of trigger and safety mechanism.

Replacement parts. When servicing, use

only identical replacement parts and fasteners

recommended by us.

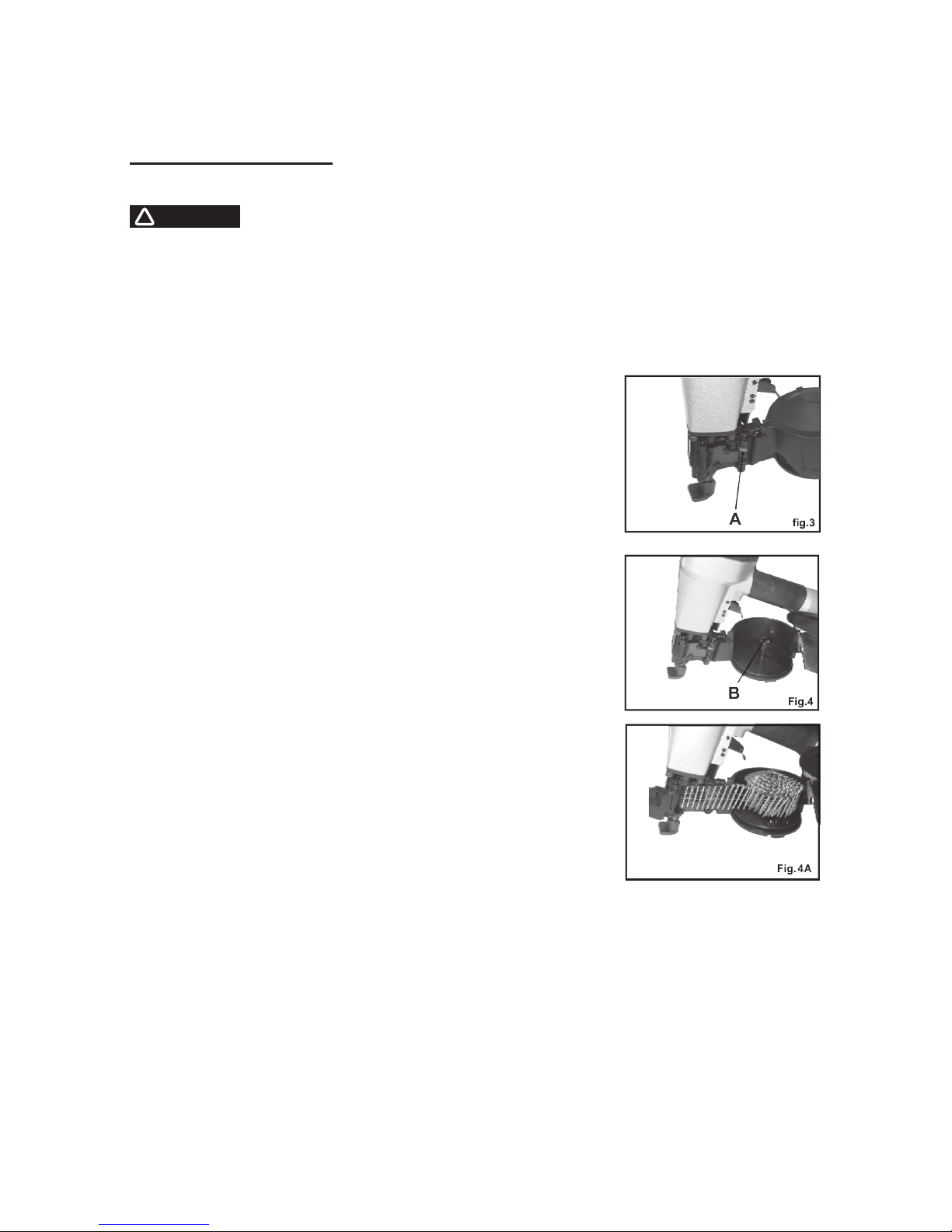

Be sure the tool is disconnected from the air

supply before loading the fasteners. Take

care on re-connection: fasteners may be red

accidentally during connection. The fastener

driving mechanism may cycle when the tool is

connected to the air supply.

Assume the tool contains fasteners at all times.

Always keep it pointed away from yourself and

others. No horseplay. Respect the tool as having

lethal potential.

Do not load fasteners with trigger or safety

depressed. The tool may unintentionally re a

fastener.

Do not depress the trigger unless the nosepiece

is directed at the worksurface or when not

driving fasteners. Never carry tool with nger on

or touching the trigger mechanism: tool may re

an unwanted fastener.