1. Important safety notes

1.4 Safety regulations for proper use

Only spcedially trained persons may operate the machine. The guarantee and

warranty are voided if damages are caused by improper operation.

1. We remind you that no liability will be accepted for damages caused by not observing these

operating instructions.

2. The operator of the machine is to ensure that at least one copy of the operating

instructions is stored in the immediate vicinity of the machine and available to the people

who work with the machine.

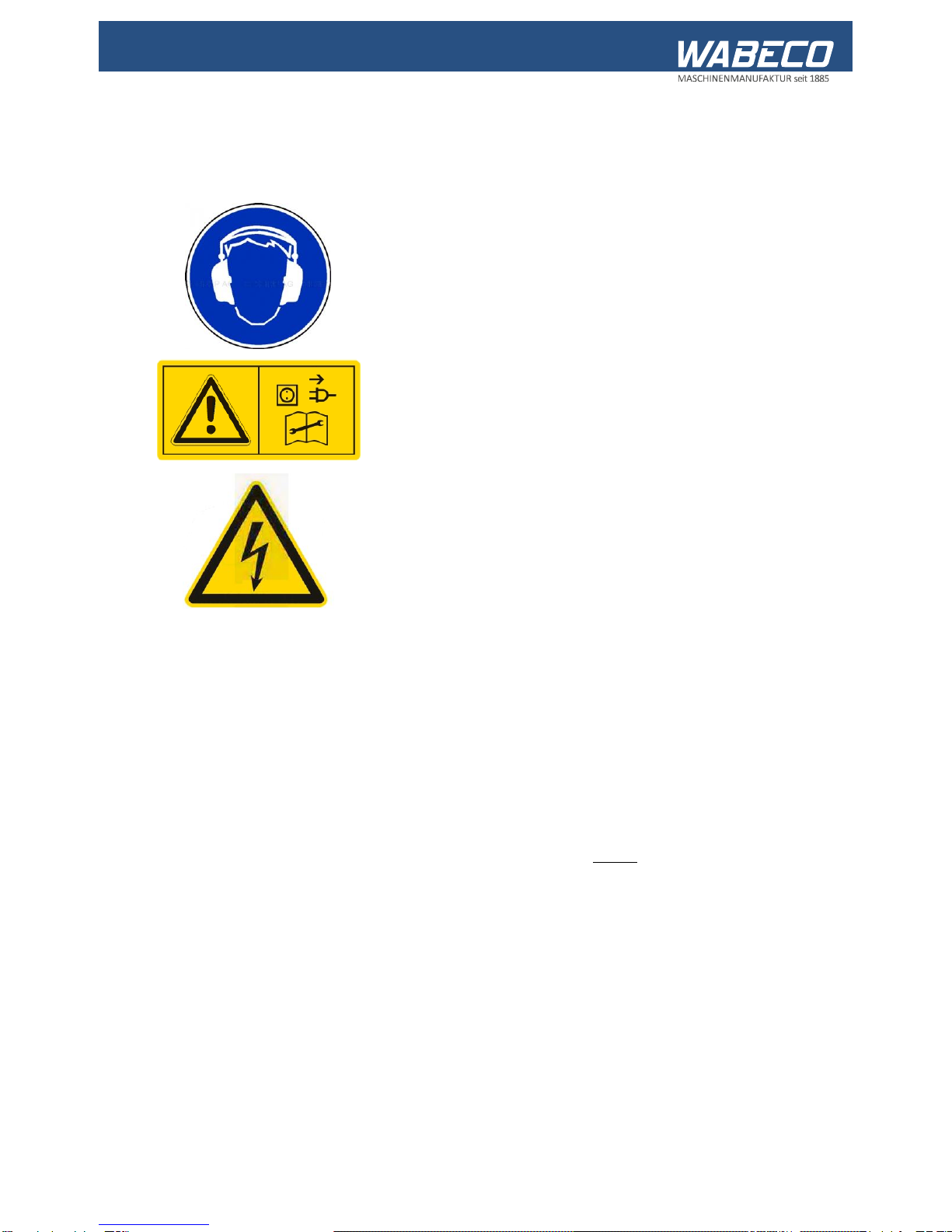

3. The operator is to ensure that the safety and danger notifications on the machine are

observed and that the signs are kept in a legible state.

4. Do not work without goggles.

5. Wear close fitting clothing and, if you have long hair, wear a hair net. Do not wear loose

fitting or loose items (ties, shirt sleeves, jewellery etc.).

6. Gloves may not be worn.

7. In the event of an emission noise level as of 80 dB (A) at the workplace, ear defenders must

be worn.

8. The machine may not operate without supervision.

9. Secure your machine in such a way that it cannot be switched on by children. Persons who

have not been trained may not operate the machine.

10. Before using the machine, make sure it is in good working condition. Pay special attention

to any damage to the grounded plug or the electrical connections. Never operate the

machine with a defective, crushed or exposed cable.

11. Plug the grounded plug into a suitable socket for the machine. The cable for the machine

may only be connected to a safety socket or a connection box. Have the safety socket or

connection box checked by an electrical specialist before hand.

12. The safety socket or connection box must be close enough to the machine that the power

cable is not under strain.

13. When carrying out maintenance and cleaning work, the machine must be switched off and

the grounded plug pulled out.

14. Set-up work is only to be carried out with the machine switched off.

15. Do not reach into the operating machine.

16. Always switch the machine off when you are not using it.

17. Remain with the machine until it has come to a standstill.