Display shows “ER”: The Rapid RH®4.0 Easy Reader may not be properly communicating

with the Smart Sensor for the following reasons: (1) The Easy Reader was not in contact

with the Smart Sensor long enough. Hold the Easy Reader in the Smart Sensor until the

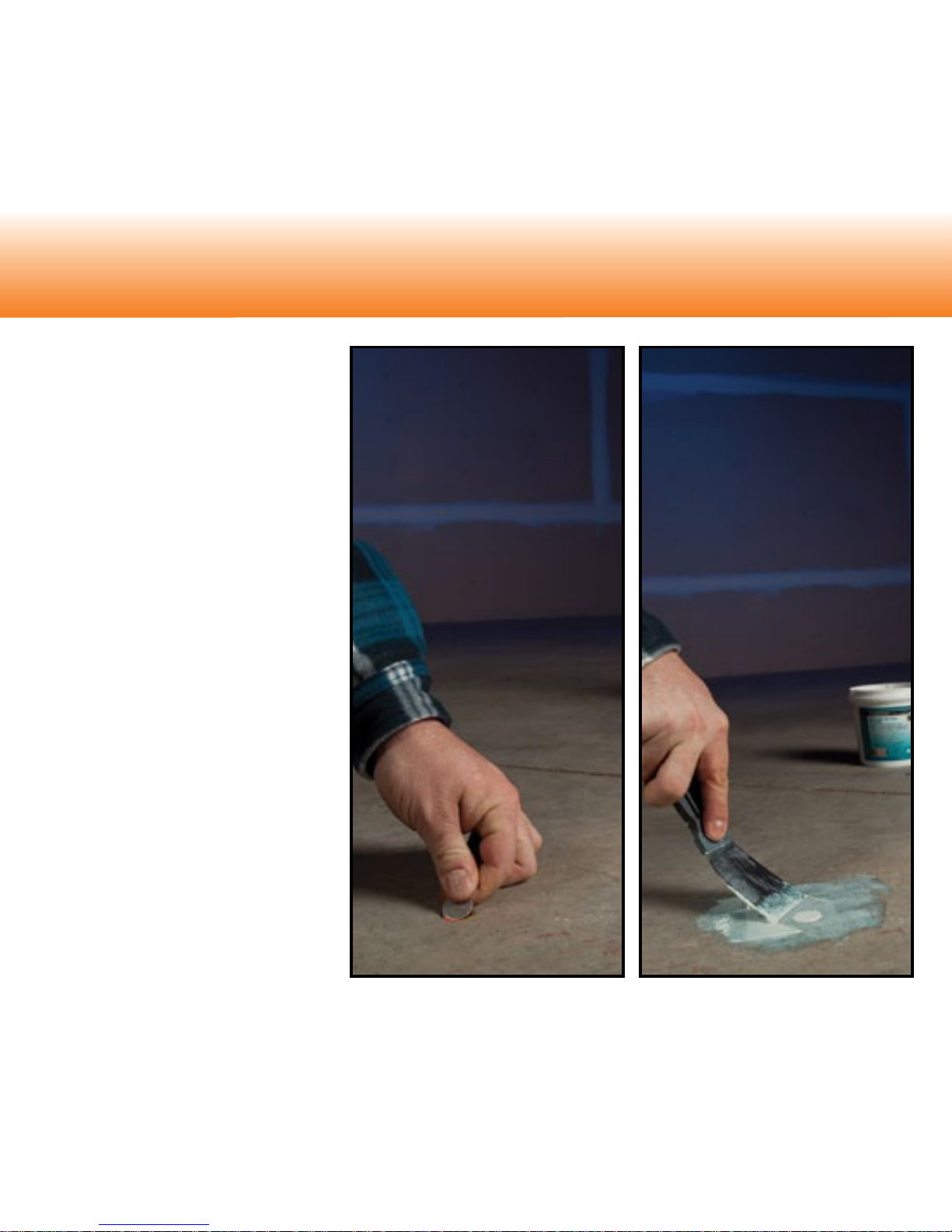

rst relative humidity reading appears on the screen, then remove. (2) Debris is blocking

proper contact. Check the Smart Sensor housing for any debris. Try gently twisting the

Rapid RH®4.0 Easy Reader back and forth a few times to “sweep” away any particles that

may have blocked complete contact. If this does not work, vacuum out the housing.

Replace the batteries: The Easy Reader comes with two AAAA alkaline batteries. If

batteries are low, the display will read “LO.” Replace batteries immediately. To replace

the batteries, open up the battery cover by removing the one battery cover screw with

a jeweler’s Phillips screwdriver. DO NOT OPEN UP THE FULL BODY OF THE EASY

READER AT ANY TIME.

Trouble Shooting

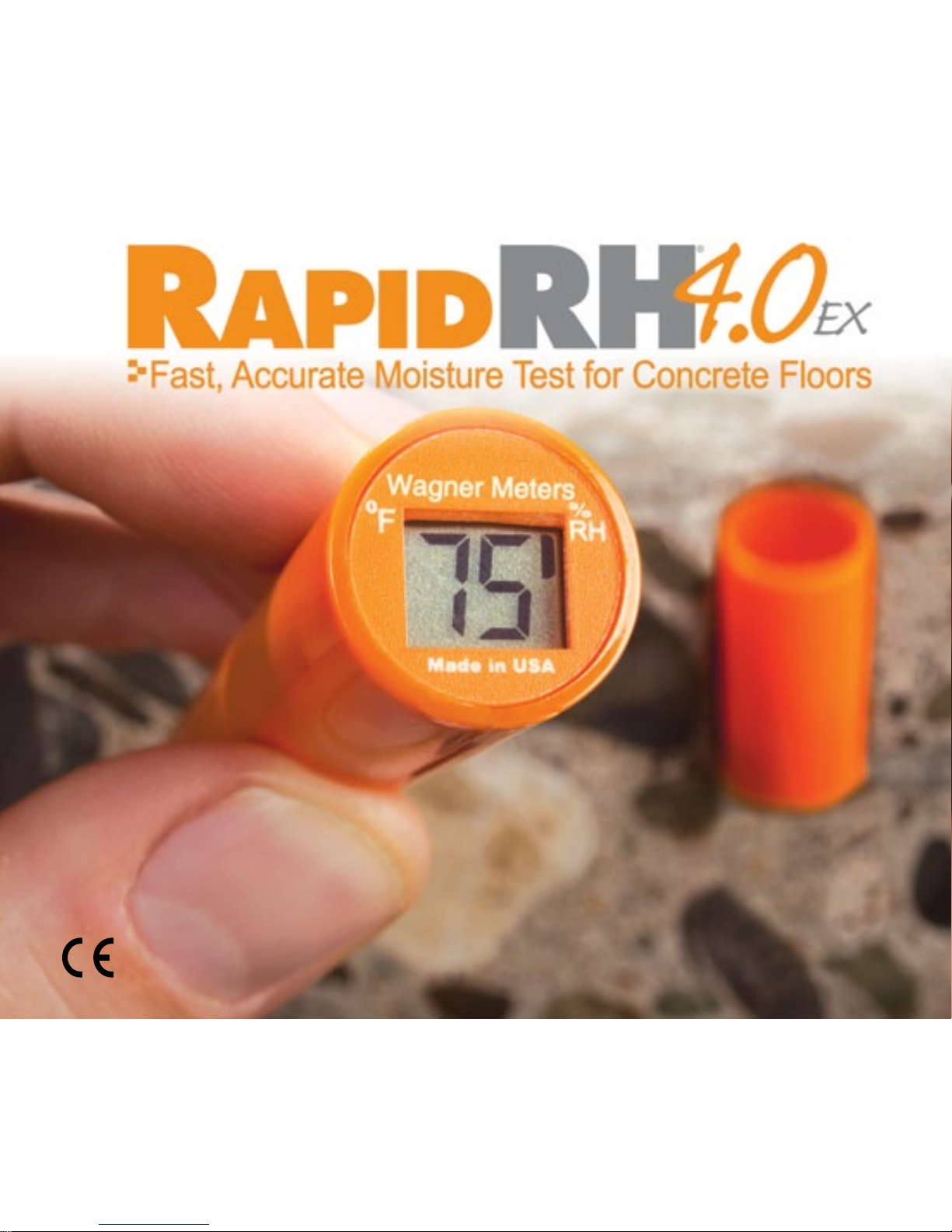

The Rapid RH®4.0 EX is intended for interior use only. It is imperative that the interior application

area be protected from weather elements such as rain and snow to prevent water intrusion. The Rapid

RH®4.0 EX is not to be used in concrete less than 28 days old. Follow ASTM F2170, Standard Test

Method for Determining Relative Humidity in Concrete Floor Slabs using in situ Probes1.

NIST2traceable accuracy:

Readings at +/- 2% RH from 50% to 90%

Readings at +/- 3% RH from 90% to 95%

Avoid severe cold or hot storage environments (i.e. vehicles)

1Available from ASTM International, P.O. Box C700, West Conshohocken, PA 19428-2959, www.astm.org

2National Institute of Standards and Technology

Use Conditions