EN

6

SteamForce Pro

protective-earthed tools. Unmodied plugs and suitable sockets reduce

the risk of an electric shock.

e) Avoid physical contact with earthed surfaces such as pipes, heating

elements, stoves and refrigerators. The risk through electric shock

increases if your body is earthed.

f) Never use outside when raining.

g) This appliance can be used by persons aged from 14 years and above

and persons with reduced physical, sensory or mental capabilities or

lack of experience and knowledge if they have been given supervision

or instruction concerning use of the appliance in a safe way and

understand the hazards involved.

h) If the supply cord is damaged, it must be replaced by the manufacturer

or its service agents to avoid a safety hazard.

4. Safety Instructions for Steam Wallpaper Strippers

ATTENTION!When working with hot steam (min.100°C), there is a risk of serious scalding.

Hot steam and boiling water can emit when the safety valve is activated due

to overpressure in incorrect operation of the unit.

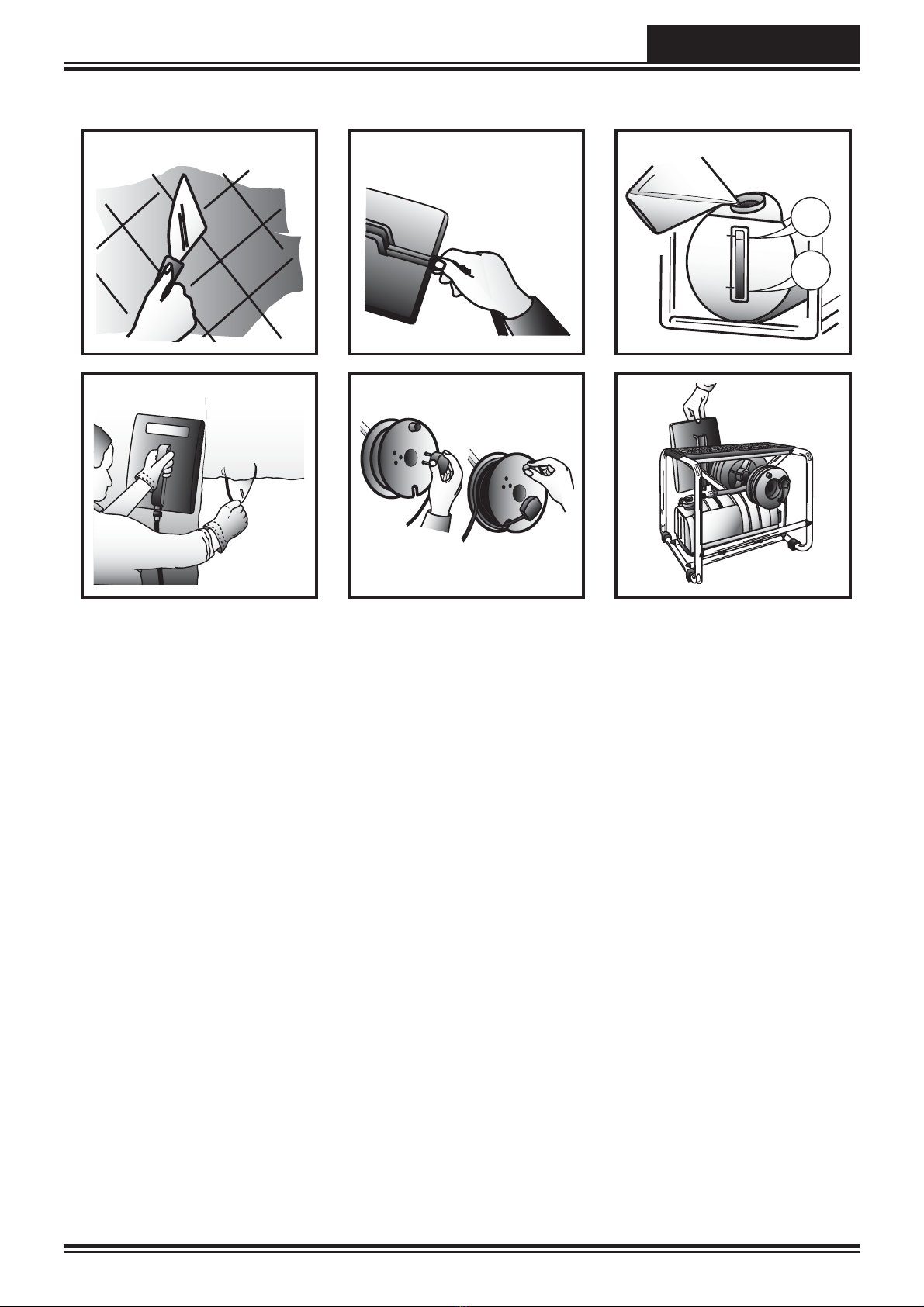

Only move with the carrying frame.The steam unit, hose and steamplate can

be very hot. Always wear suitable protective clothing / gloves.

Operate the unit only with pure water without agents or additives. Do not

switch the unit on when empty.

Never point the steamplate / bar at people, animals, at objects sensitive to temperature

or other electrical equipment. Always ensure that the unit is standing securely in a

horizontal position (on the oor).

Do not stand on or place objects on the steam hose. Never over-twist or make kinks in

the steam hose and never block the valve. Never pull on the steam hose or supply cord.

Every time the accessory is changed for lling / relling and emptying or when the steam

unit is not in use (including work pauses), pull the mains plug out of the socket-outlet.

Never overll the unit. Unplug the unit in the event of overlling or a fault. Use only

WAGNER original spare parts and accessories!

Caution! Danger of short-circuits! Cover socket-outlets and switches and do not subject

them to steam. Be careful of overhead dripping, when using on overhead areas tilt the

steamplate away from the face and body and regularly empty the steamplate of any

collected condensation. Do not allow water or steam to enter light switches or socket-

outlets. Always visually check that the hose and steamplate inlet are not blocked before

attempting to use. Do not strain, kink or trap the hose under heavy objects. Use only 4 psi