Warn A2000 User manual

Other Warn Winch manuals

Warn

Warn 39116 User manual

Warn

Warn Endurance 12.0 User manual

Warn

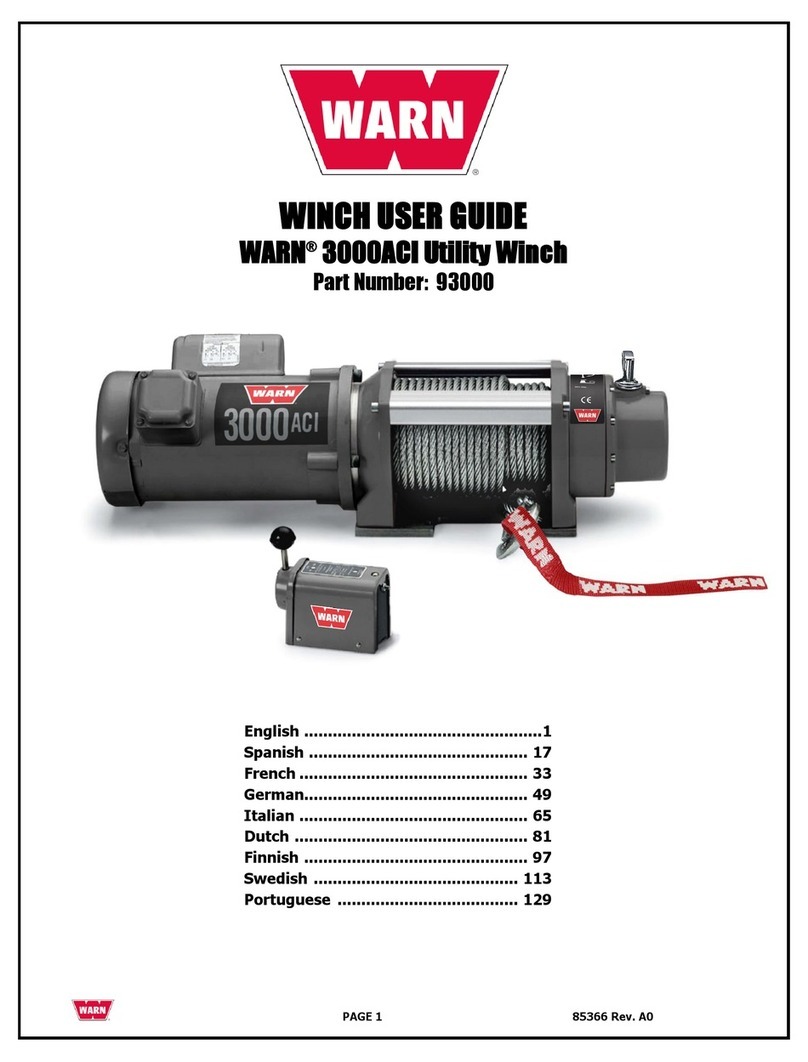

Warn 103420 User manual

Warn

Warn 72008 User manual

Warn

Warn 84704 User manual

Warn

Warn PROVANTAGE 4500-S Operating instructions

Warn

Warn M15000 User manual

Warn

Warn 72492 User manual

Warn

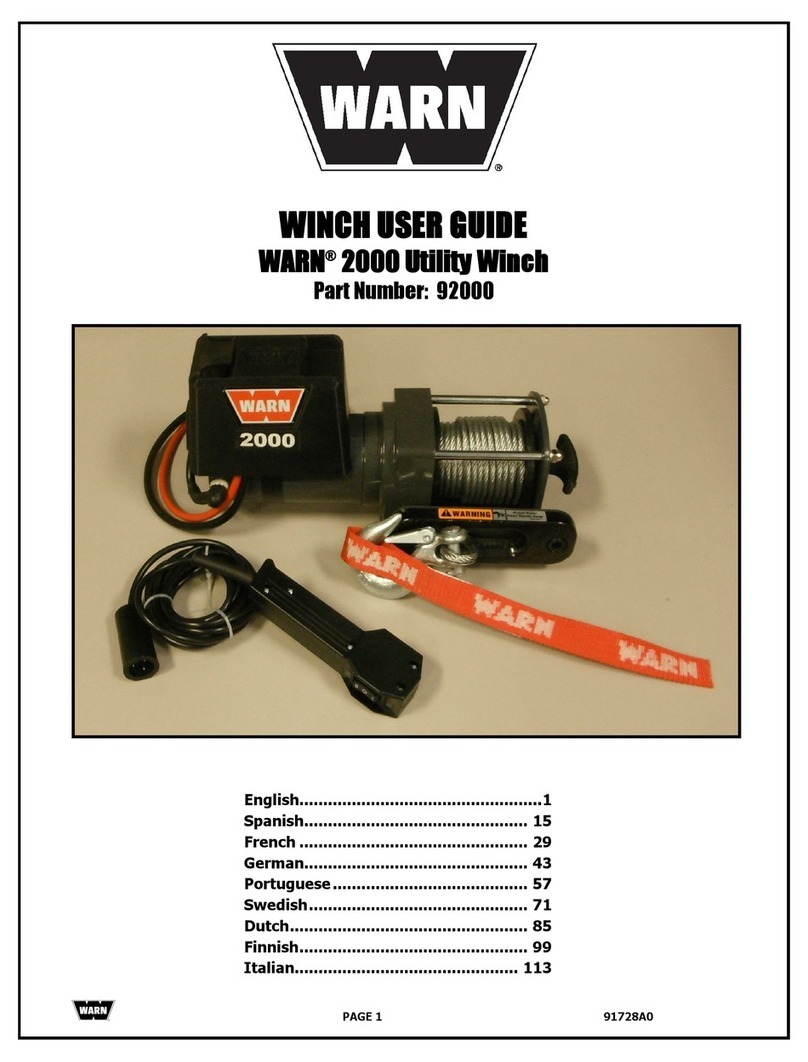

Warn 2000 User manual

Warn

Warn 12-A-1D Series User manual

Popular Winch manuals by other brands

Topex

Topex 97X080 Instructions for use

Eastbound

Eastbound MotoWinch 1707001 operating instructions

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual

Granit

Granit 11157675 operating instructions

TREX

TREX TB75 user manual