3

Safety instrucons

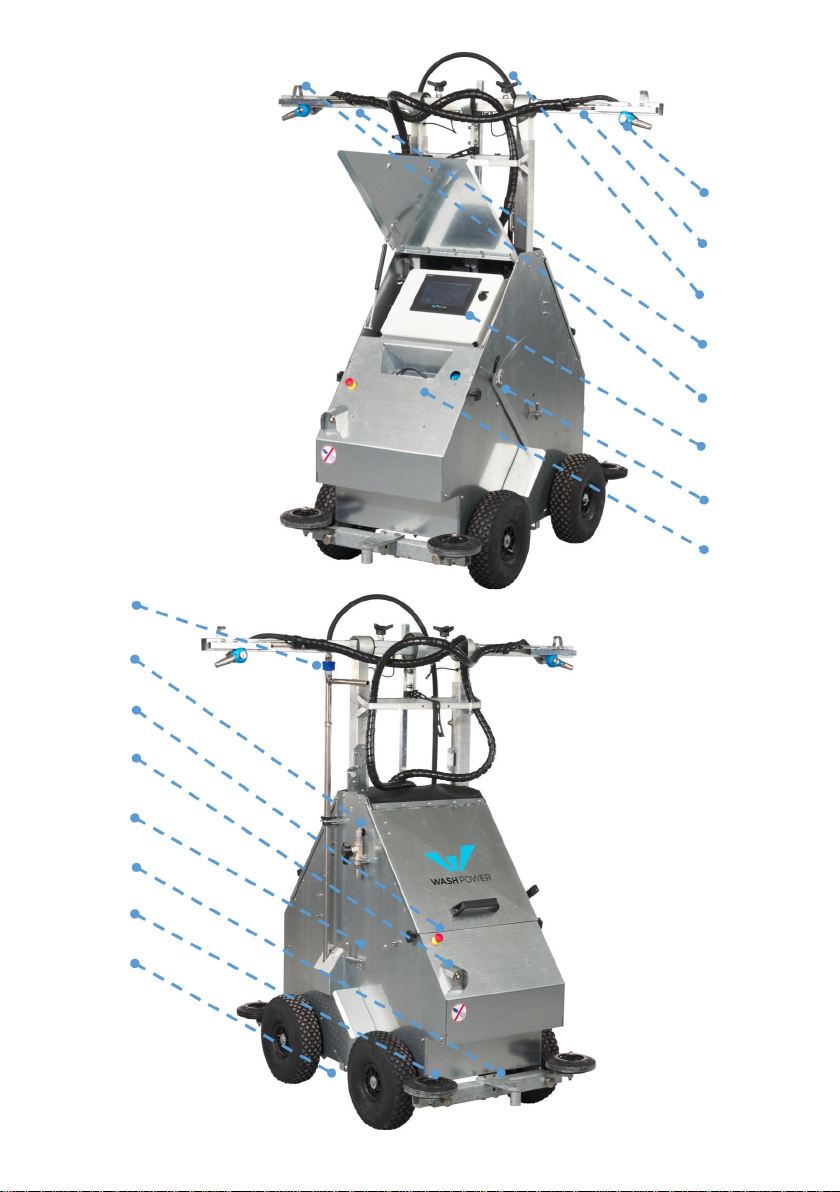

Explanaon of pictograms on the robot

Slippery oor aer washing

Breathing apparatus must be ed with a minimum of a P2 lter which

protects against both solid parcles and liquid aerosols.

Use protecve glasses in the pig house while it is being washed.

Water is highly electrically conducve.

Electricity must be connected away from the wash area.

General safety instrucons

Read the safety instrucons and direcons before use. Failure to comply with the safety

instrucons and direcons will result in the risk of serious injury.

Retain all safety instrucons and direcons for use later on.

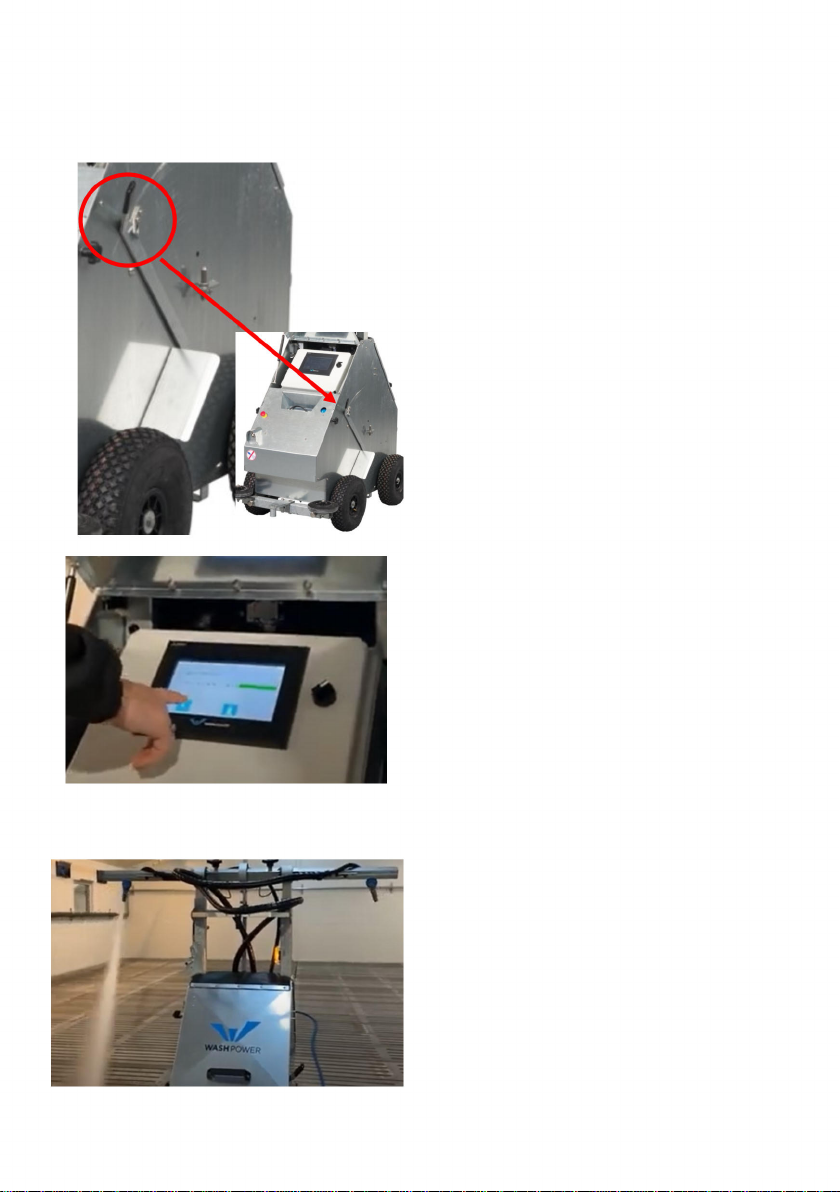

You must stay behind the robot according to its direcon of travel while it is in use.

When the robot is in operaon all persons must vacate the cleaning area.

• The work area must be dimensioned so that the robot can operate unhindered in

the enre area you wish to clean.

• In order to prevent the robot stopping unintenonally, the oor must be at and all

objects must be removed.

• When the robot is in use all persons must vacate the cleaning area.

• The charger wall plug must t the electrical socket.

• The charger wall plug must not be changed under any circumstances.

• Do not use adapter plugs together with grounded robots. Plugs that do not t the

wall socket pose a risk of electric shocks.