WaterLogic WL350 Operating instructions

Other manuals for WL350

5

Other WaterLogic Water Dispenser manuals

WaterLogic

WaterLogic WL350 Reference guide

WaterLogic

WaterLogic ARAMARK User manual

WaterLogic

WaterLogic WL900 User manual

WaterLogic

WaterLogic WL900 User manual

WaterLogic

WaterLogic WL900 User manual

WaterLogic

WaterLogic WL Cube Manual

WaterLogic

WaterLogic WL100 User manual

WaterLogic

WaterLogic WL2 Firewall User manual

WaterLogic

WaterLogic WL200 Reference guide

WaterLogic

WaterLogic WL 1000 GF User manual

WaterLogic

WaterLogic WL400 Series Operating instructions

WaterLogic

WaterLogic WL7 User manual

WaterLogic

WaterLogic WL2FW FIREWALL Series User manual

WaterLogic

WaterLogic WL290 User manual

WaterLogic

WaterLogic WL800 - MAX II Manual

WaterLogic

WaterLogic WLH2 Classe User manual

WaterLogic

WaterLogic WL250 Operating instructions

WaterLogic

WaterLogic WL250 Manual

WaterLogic

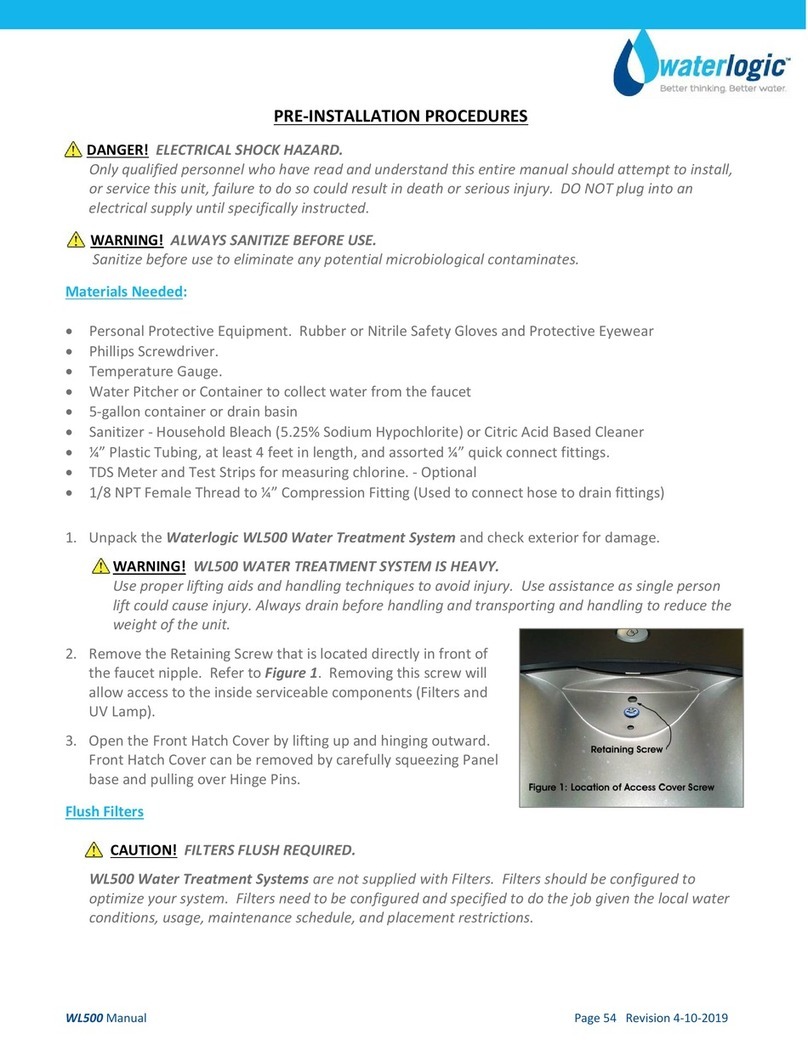

WaterLogic WL500 - Sparkling Reference guide

WaterLogic

WaterLogic WL290 Operating instructions

Popular Water Dispenser manuals by other brands

Culligan

Culligan GOLD SERIES Brochure & specs

Aqua Cooler

Aqua Cooler AC-CURVE-CT-HC Usage and Care Manual

ScaleBlaster

ScaleBlaster SB-75 Installation & operation manual

Aqua Computer

Aqua Computer mps flow 100 User and installation manual

Elkay

Elkay DSWH160UVPC Installation and maintenance manual

vitapur

vitapur VWD1185BLS Use & care guide

Elkay

Elkay EFA Series Installation, care & use manual

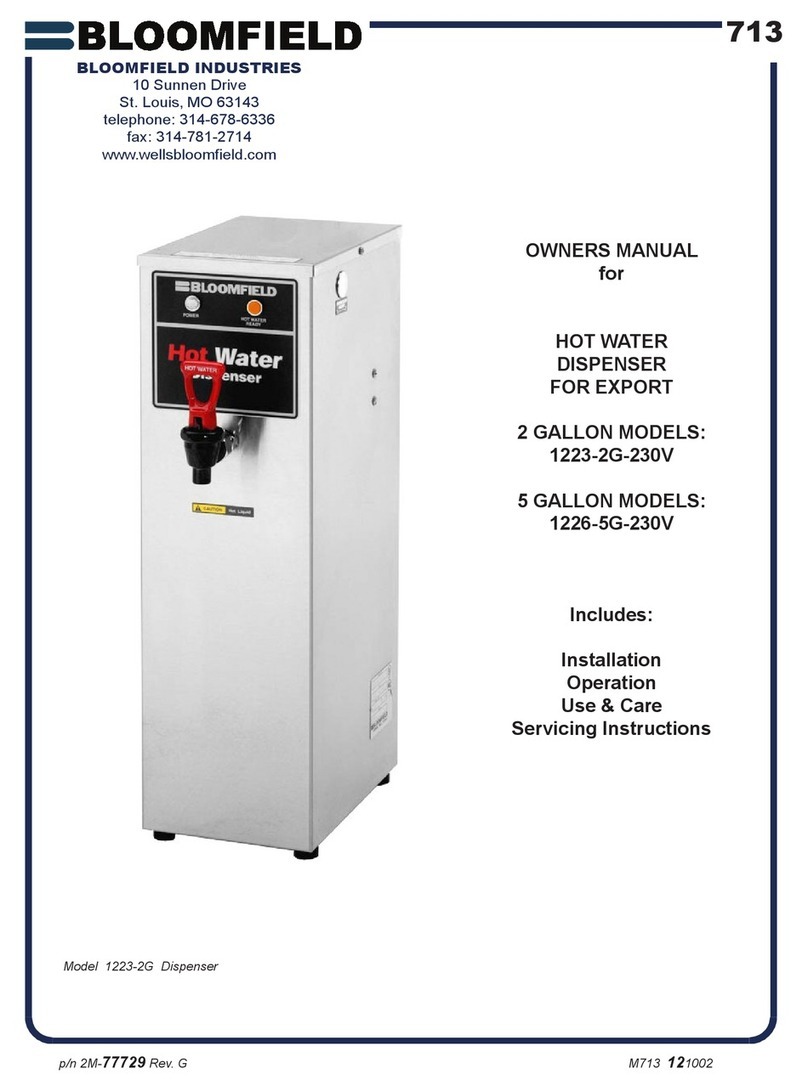

Bloomfield

Bloomfield 1223-2G-230V owner's manual

DRAGONN

DRAGONN DN-KW-WP01 instruction manual

Hague Quality Water

Hague Quality Water WaterMax 61AAN Owner's manual and installation guide

Elkay

Elkay LVRCGRNTLD B Series Installation, care & use manual

GE

GE Profile FQROPF use and care manual