WaterLogic WL250 Operating instructions

Other manuals for WL250

6

Other WaterLogic Water Dispenser manuals

WaterLogic

WaterLogic WL100 User manual

WaterLogic

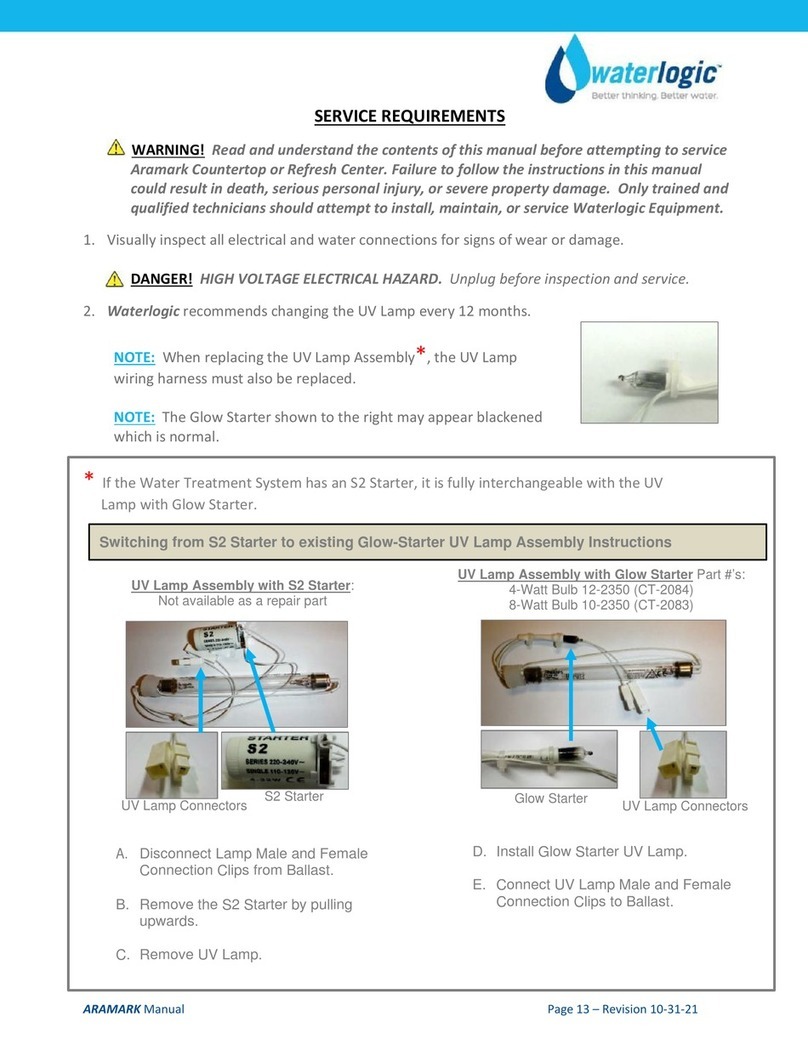

WaterLogic ARAMARK User manual

WaterLogic

WaterLogic WL800 User manual

WaterLogic

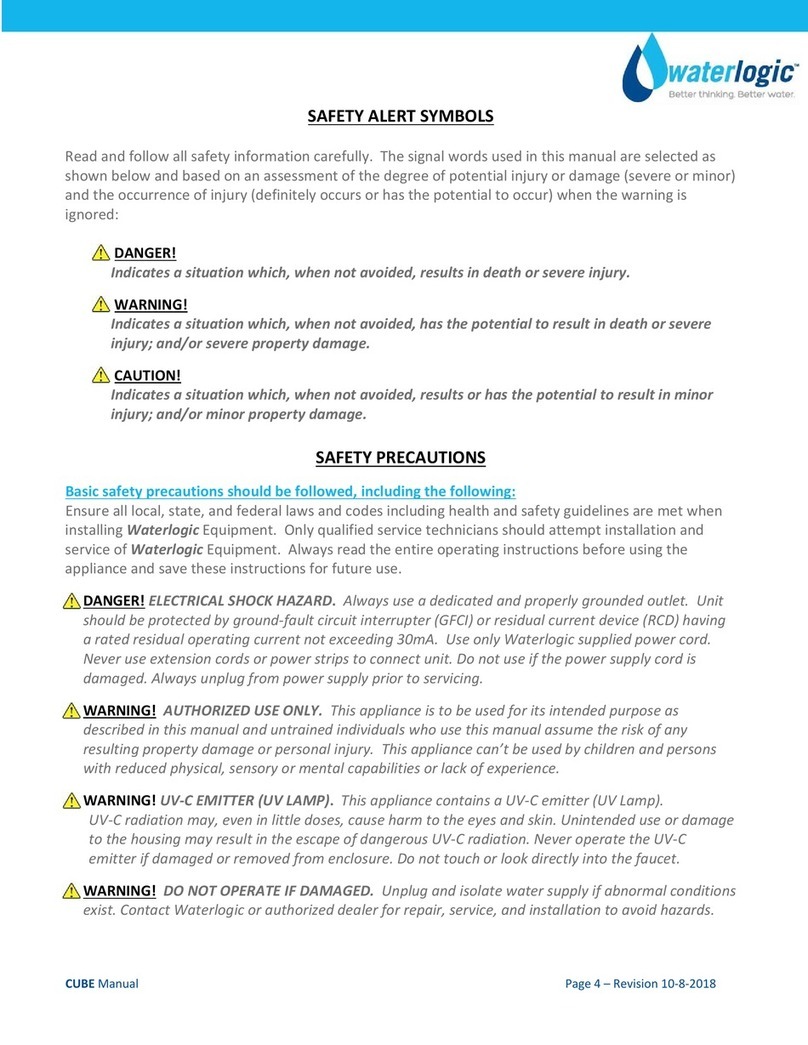

WaterLogic CUBE Reference guide

WaterLogic

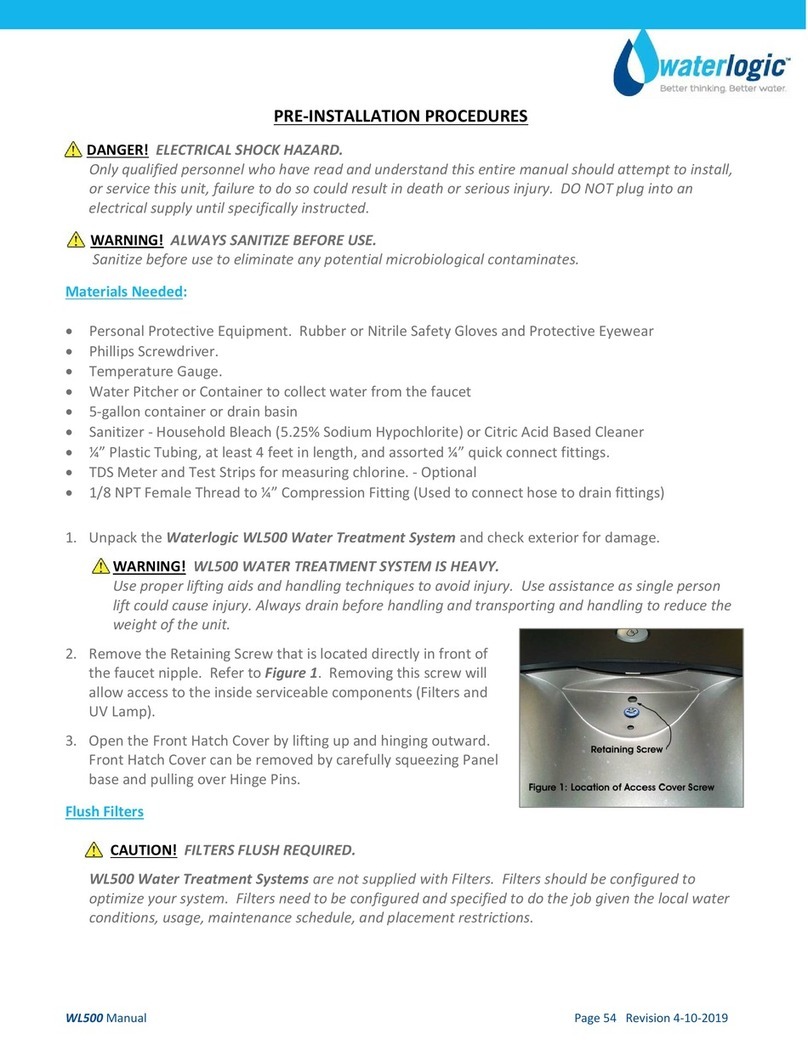

WaterLogic WL500 - Sparkling Reference guide

WaterLogic

WaterLogic WL500 - Sparkling Operating instructions

WaterLogic

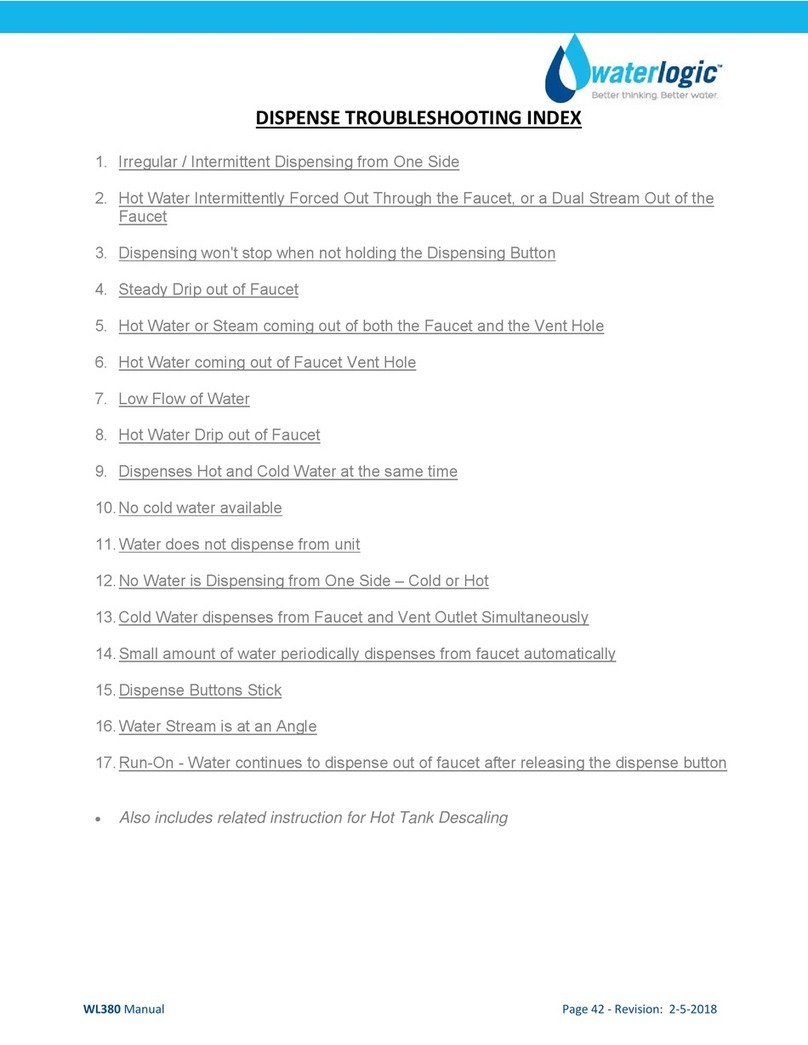

WaterLogic WL380 Operating instructions

WaterLogic

WaterLogic WL200 Operating instructions

WaterLogic

WaterLogic WL800 - MAX II Manual

WaterLogic

WaterLogic WL2 Firewall User manual

WaterLogic

WaterLogic WL900 User manual

WaterLogic

WaterLogic WL900 Operating instructions

WaterLogic

WaterLogic WL200 Reference guide

WaterLogic

WaterLogic WL1000GF MAX User manual

WaterLogic

WaterLogic CUBE Operating instructions

WaterLogic

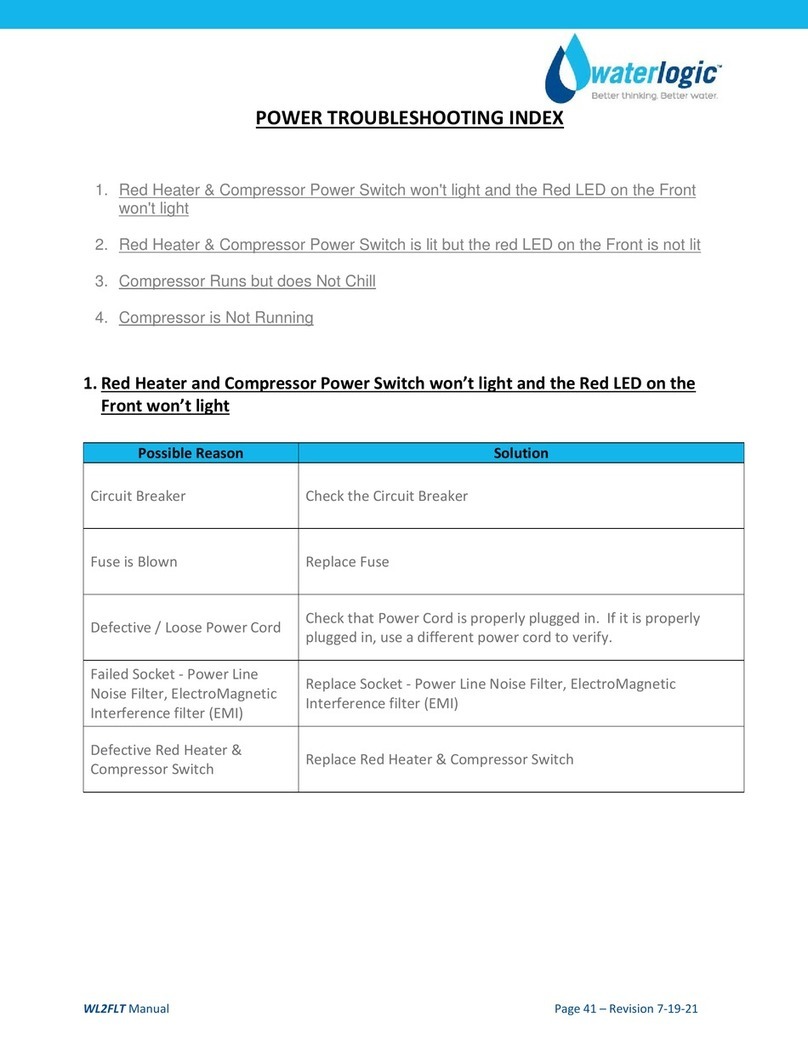

WaterLogic WL2FLT Operating instructions

WaterLogic

WaterLogic WL290 User manual

WaterLogic

WaterLogic WL250 Operating instructions

WaterLogic

WaterLogic ICE 900 User manual

WaterLogic

WaterLogic WL500 - Sparkling Manual

Popular Water Dispenser manuals by other brands

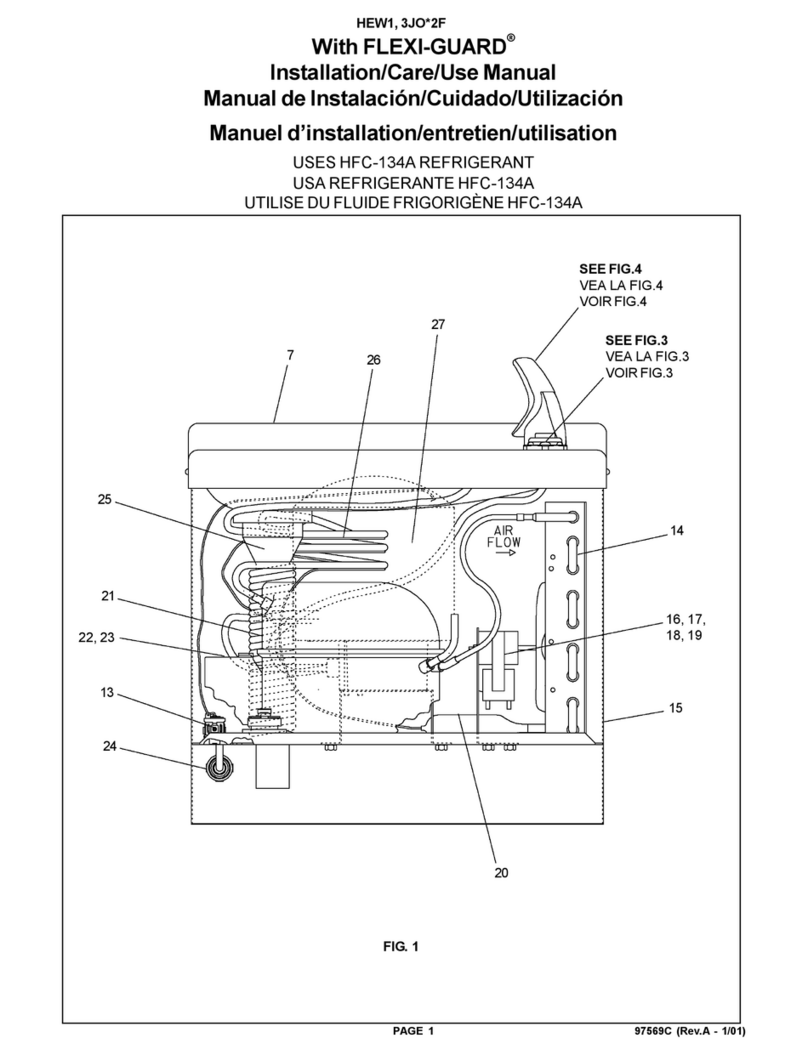

Elkay

Elkay HEW1JO 2F Series Installation, care & use manual

Follett

Follett Symphony Plus 25 series Operation and service manual

Frigidaire

Frigidaire EFWC498-BLACK instruction manual

EcoWater

EcoWater Timetronic 314 User/installer handbook

Elkay

Elkay EZS8WS 1G Series Installation & use manual

Canature WaterGroup

Canature WaterGroup 185HTO owner's manual