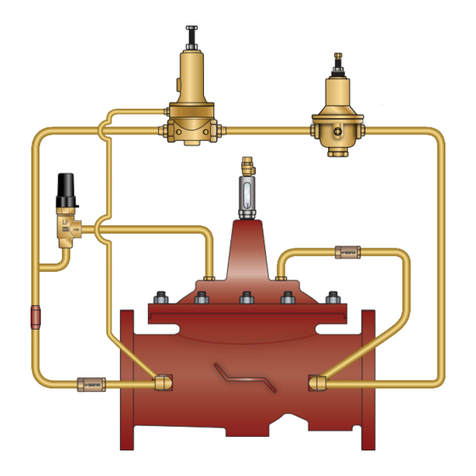

To ensure peak performance and longevity of your automatic

control valve, Watts/Ames recommends following the below

standard maintenance schedule.

• Monthly Maintenance

– Visual inspection of valve(s) for leaks

– Inspect for proper operation(s); exercise valve.

• Quarterly Maintenance

– Conduct monthly inspection.

– Validate/Re-establish necessary setpoints of controls/pilots.

• Annual Maintenance

– Conduct monthly & quarterly inspections.

– Inspect & clean all strainers.

– Inspect valve coating, touch up as required.

• 3-5 Year Maintenance

– Conduct monthly, quarterly, & annual maintenance.

– Inspect & replace valve elastomers (diaphragm, O-rings,

valve/pilot seats)

– Re-establish necessary set points of controls/pilots.

Automatic Control Valve Maintenance Schedule

Troubleshooting Guide

Warning: The valve cannot be serviced under pressure.

Upstream and downstream Isolation Valves must be installed

to protect system piping. Accurate diagnosis and trouble-

shooting requires the valve to open fully, and may subject

downstream piping and equipment to high pressure and/or

flow rates. The downstream Isolation Valve should be kept

closed while diagnosing the valve.

Extreme caution should be used while performing the

troubleshooting techniques listed below.

WARNING

!

Recommended tools for diagnosis: (3) PRESSURE GAUGES,

installed to monitor the inlet pressure, outlet pressure, and cover

chamber pressure. If included, a POSITION INDICATOR should

be installed to visually assess the position of the disc &

diaphragm assembly.

Test 1: Diaphragm Seal Test

1. Close upstream & downstream isolation valves. Close pilot

isolation valves or remove pilot control tubing to isolate valve

cover from incoming fluid & pressure. Remove uppermost

cover plug, test cock, or limit switch.

2. With the valve cover chamber vented to atmosphere,

partially open the upstream isolation valve, allowing incoming

pressure to lift the disc & diaphragm assembly. A volume of

water will be displaced from the cover chamber as the valve

opens; consult valve specification sheets for approximate

cover capacity. A continuous flow of water from the open port

indicates a damaged diaphragm or loose disc & diaphragm

assembly. Disassemble valve and replace diaphragm or tighten

disc & diaphragm assembly.

Test 2: Seat Seal Test

1. Close downstream isolation valve and install pressure gauges

on an open inlet and outlet port of main valve.

2. Open upstream isolation valve to allow pressure on to the

valve cover. Allow valve to fully close.

3. Monitor downstream pressure gauge; reading should hold

steady below incoming pressure. If pressure on downstream

side rises to match upstream pressure, leakage is occurring

through the seat of the main valve. Disassemble valve, inspect

and repair/replace any required parts.

a. If gauge pressure rises to match outlet pressure (down-

stream of closed isolation valve) yet remains below inlet

pressure, the isolation valve may be leaking as opposed to

main valve seat.

Test 3: Freedom of Movement/Valve

Travel Test

1. Close upstream and downstream isolation valves. Install valve

position indicator.

2. Partially open upstream isolation valve and allow cover to fill

with fluid & pressure, closing the valve fully. Mark the position

indicator’s full closed position.

3. Isolate cover chamber from receiving fluid and pressure by

closing isolation valves or removing control tubing.

4. Carefully vent cover chamber to atmosphere by opening test

cock or removing a cover plug. Observe the valve position

indicator as the valve travels to the full-open position. The disc

& diaphragm assembly should move freely from fully closed to

fully open position without binding or “grabbing” at any point

during its movement.

a. The disc & diaphragm assembly may momentarily “hesi-

tate” while travelling from fully closed to fully open position

– this is a normal characteristic of diaphragm operated

control valves, and does not indicate mechanical binding

or improper valve operation.

b. A continuous discharge of water from the cover chamber

after venting to atmosphere indicates leakage past the

diaphragm.

5. If necessary, disassemble valve and inspect/repair disc &

diaphragm assembly.

4 IOM-A-ACV-985-20_685-20 2115 EDP# 1917104 © 2021 Watts IOM-A-ACV-985-20_685-20 2115 EDP# 1917104 © 2021 Watts 5