elero 24 180.0101 User manual

DoorControl Nr. 24 180.0101 / 24 180.0301

Rolling door control for alternating current drives

GRUPPE

GÜN

T

HER

GB

It is important to observe these instructions in order to guarantee safety for persons!

Do not discard these instructions!

Incorrect assembly can cause serious injury.

• Connections to the mains must be carried out by specialised personnel.

• The control must be disconnected from the mains during connestion work.

• The mains disconnection mechanism must be secured against unintentional and unauthorised

restarting and shoule always be accessible.

• Powered doors with pulsed or automatic operation must fulfil EN 12453.

• With external evaluation devices connect the 8.2 kOhm resistor in series with the switch contact.

• Caution: A moving door panel must not pose a risk of injury or damage.

• An 8.2 kOhm resistor can be connected in the CLOSED direction in the case of roller shutter drives.

• Caution: The roller shutters must not pose a risk of injury or damage.

180

130

60

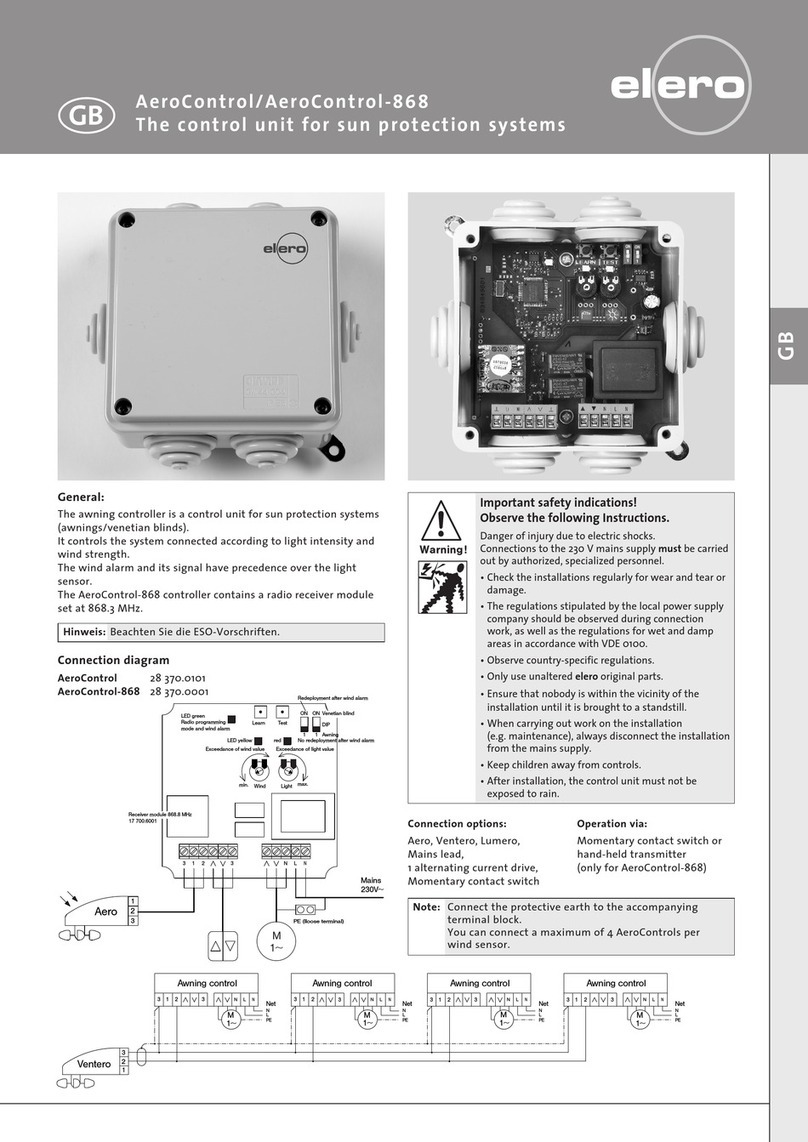

230 V Mains terminals Fuse

6,3 A tr.

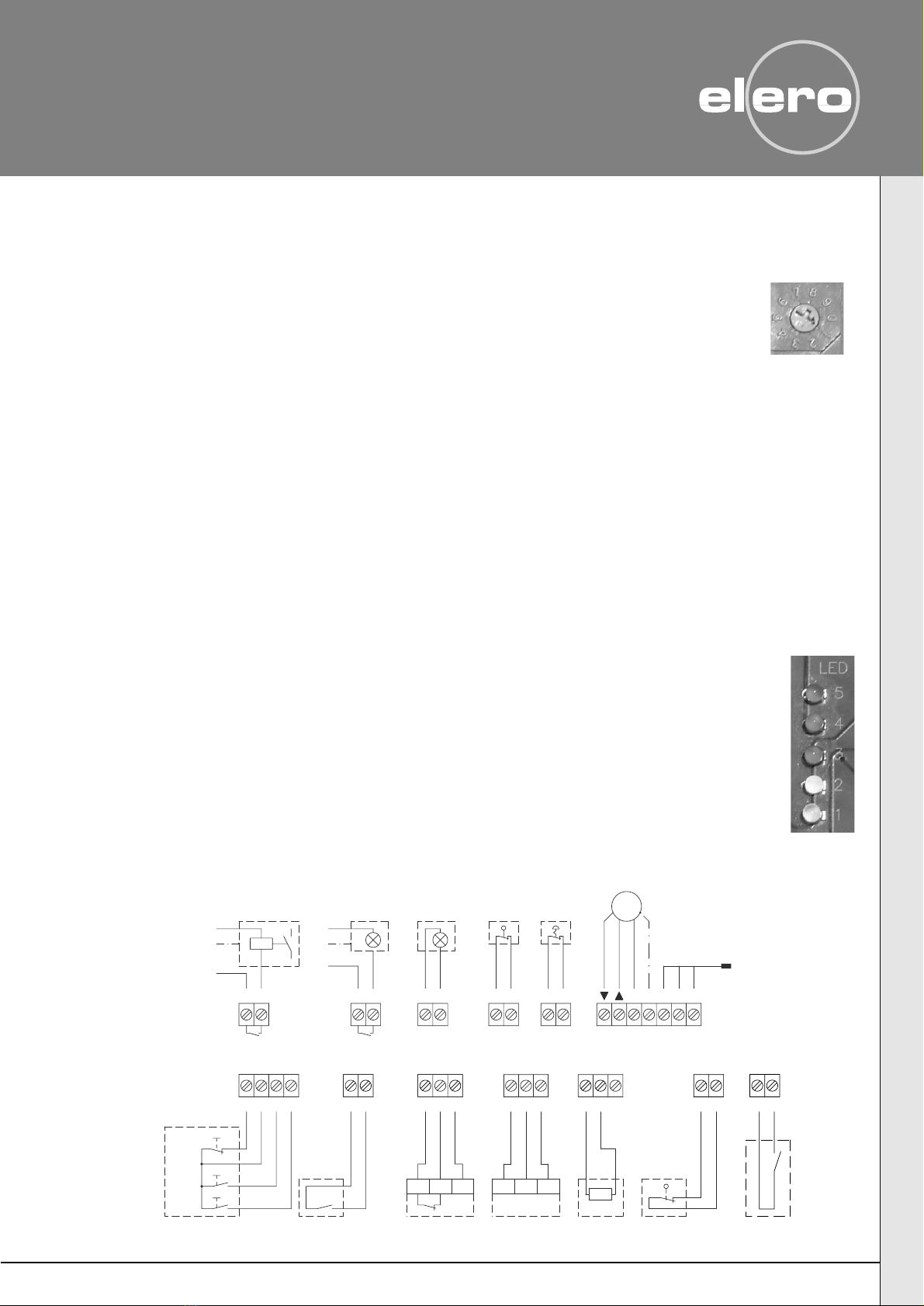

Selector

switch

S 1

LED

S 2

Hold-open time

Proigramming

button

S 3

Integrated radio

receiver or slot for

radio receiver 24 V terminals

Operating appliances

Warning!

Advice: Only tubular drives with mechanical limit switches can be connected.

DoorControl

2

Summarised description of DoorControl

•

Programmable motor run time monitoring (to be pro-

grammed with a self-retention operating mode [DIPI]

)

•

Diagnosis display using LED

•

Connection of a locking mechanism for the door edges

Opto-electronic switch actuator (OSE) by Fraba or an

8.2 kOhm resistance actuator

.

•

Testing of the signal path (in the event of a faulty locking

mechanism for the door edges in CLOSE dead man operation)

•

Possible connection for the CLOSE pre-limit switch

•

Possible connection for the CLOSE light barrier

•

Possible coding for dead man operation / self-retention (DIP1)

•

Possible coding for free movement / reversing up to the

open end position when the locking mechanism for the

door edges responds (DIP2)

•

Possible coding for lighting controller impulse /

120 seconds, failure notification or green traffic light

•

Radio receiver integrated or pluggable via the connector

•

Connectable external radio receiver

•

Possible connection for garage lighting / failure

notification or green traffic light

•

Possible connection for red traffic light, illuminates when

the door moves, flashes in the intermediate positions and

flashes with increased frequency during failure (run time,

locking mechanism for the door edges etc.)

Important assembly advice

1.

Assemble the control boxes near the door

(minimum height 1.5m)

2.

Assemble the activation buttons and / or key-operated

push buttons near the door with a complete overview of

the door movement area

.

3.

Open the control box and connect the motor cable to the

control.

4.

Motor feed cable: max. 15m long, min. 0.75mm

2

5.

Connect the touch keyboard in the correct position

(observe the coding)

6.

Connect the earthing contact connector, the green LED1

illuminates on the control board

.

7.

Direction of rotation control: press the OPEN key, the drive

rotates in the opening direction

.

Should this not be the case, disconnect the Schuko connector

from the mains and change the motor cables U + V.

8.

Reconnect the Schuko connector and check the direction

of rotation once again

.

9.

The limit switch position is stipulated in the drive instruc-

tion manual

.

10.

Only connect the operation devices when disconnected

from the mains

.

General information

DoorControl is designed for use with automatically operated

door installations with 230 V alternating current drives

.

The control is delivered with a 1.5m long connecting cable

with an earthing contact connector and a touch keyboard

(Open-Stop-Close) built into the casing cover

.

The automatic

closing mechanism, with or without radio receiver, is built

into the control

.

All signal inputs operate with 24 V voltage and are galvani-

cally separated by optocouplers

.

A 24 V DC, maximum 150 mA,

mains unit is integrated for supplying power to the light

barriers andcommands.

.

Tecnical features:

Power supply 230 V/AC 50/60 Hz

On site fuse max. 10 A

Power consumption max. 6 Watt

Switching power max. 6 A

Breaking capacity max. 1300 VA

Protection class IP 54

Internal fuse 6,3 A tr.

Dimensions 180 x 130 x 60 mm

Operating temperature – 10 to +50 °C

TÜ certified EN 12453

Modes of operation

Setting in the switching block

S 1 DIP switch position

Dead man Dead man in OPEN and CLOSE

Self-retention without programmed motor run time only in OPEN

Reversing up to the limit switch When the locking mechanism for the door edges

Free movement responds the opening direction switches on.

Relay K3 switches Lighting control via the stair light timer etc. with each

an impulse (approx. 1 sec.) opening command

Relay K3 switches Direct lighting control (light bulbs etc.)

approx. 120 secs. with each opening command

Relay K3 switches a persistant e. g. running time exceeded

command during failure

Relay K3 switches on when the For controlling the red-green-traffic light

end position is upward (green traffic light)

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

ON

1

DIP 1

DIP 1

DIP 2

DIP 2

DIP 3

DIP 4

DIP 3

DIP 4

DIP 3

DIP 4

DIP 3

DIP 4

DoorControl

3

Functions

➱

Motor run time monitoring

DoorControl includes programmable motor run time moni-

toring which automatically switches the drive off in the

event of excessive motor run time

.

In order to programme

the motor running time the drive should be taken to the

CLOSE door position

.

Set

DIPI

to the ON position

.

Briefly press programming

button S3, LED 2 illuminates, now move the drive in self-

retention until reaching the limit switch door OPEN

.

LED2

goes out, the motor run time is now programmed

..

If the programming button S3 is pressed for more than

5 secs. (LED2 goes out) the run time monitoring is reset

to the maximum value (0 secs.).

➱

Locking mechanism for the door edges (OSE or 8,2 kOhm)

Should the locking mechanism for the door edges be activa-

ted during a CLOSING movement, the control switches over

to the opening direction (reversing or free movement). If the

CLOSE pre-limit switch is pressed, the drive is stopped. If the

locking mechanism for the door edges is faulty, the drive can

be operated with the built-in touch keyboard and the exter-

nal triple switch in dead man operation.

➱

Light barrier

If the light barrier is activated during a CLOSING move-

ment, the control switches over to the opening direction

and the drive moves up to the OPEN end position

.

When

the automatic closing mechanism is switched on, the hold-

open time is reinitiated

.

Should the installation be in an

intermediate position and the light barrier is activated, the

opening direction is started

.

➱

Radio remote control Channel 1

The integrated or the internally pluggable radio receiver, as

well as the external input FS (terminal 13+14) change

function with each activation

.

(

Switching sequence UP-STOP-DOWN-UP

. . .)

When the automatic closing mechanism is switched on the

radio remote control always switches on the opening

direction

.

With each subsequent command, the hold-open

time is reinitiated

.

The programming must be based on the radio remote

control in use

.

➱

Radio remote control Channel 2

Relay K3 can be additionally controlled with the second

channel

.

➱

Automatic closing mechanism

The automatic closing mechanism can be swit-

ched on and off with the rotary switch S2.

When the automatic closing mechanism is

switched on, the preliminary warning time swit-

ches on for approximately 5 secs. at the end of

the hold-open time. The closing procedure is then started.

The door can be opened with the “On” timer contact (terminal 10

a

and closed again with “Off” by the adjusted automatic door-edge

security system.

If the locking mechanism for the door edges has been

activated 3 times before reaching the CLOSE limit switch

the automatic closing mechanism becomes inactive

.

Level 0

Active red traffic light and error message

Level 1

Active red traffic light, error message flashing

Level 2

Automatic closing function on, “hold open” time 10 se

Level 3

as above 20 seconds

Level 4

as above 30 seconds

Level 5 as above 40 seconds

Level 6 as above 50 seconds

Level 7 as above 60 seconds

Level 8 as above 60 seconds (after the light barrier

is CLOSED, the “hold open” time reduced

by approx. 4 secs)

Level 9 Automatic closing function on, “hold open” time 10 sec

LED diagnosis

LED 5 (red)

Stop button activated (terminals 9+10)

LED 4 (red)

Light barrier activated

LED 3 (red)

Illuminates when the locking

mechanism for the door edges is

faulty or activated

LED 2 (yellow)

Programme motor run time

/

radio reception

LED 1 (green) Power

(operating voltage)

Flashes during OPEN and CLOSE

movement

Flashes when the hold-open time runs out

LED 1 (green)

+ LED 3 (red) Flashes when the running time is exceeded

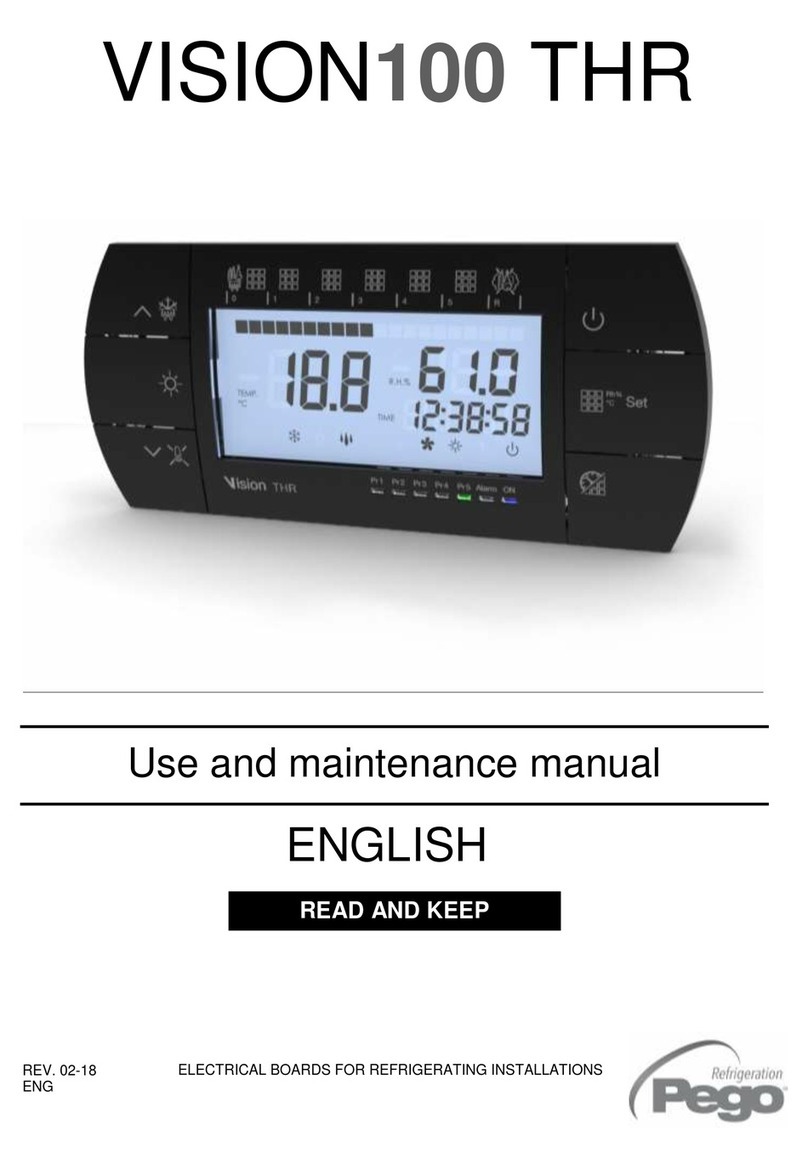

mains 230V/AC

M

1~

-+ OUT

Safety

switch

error message

Red traffic light or

Light or

green traffic light

Light or failure notification

with latching relay

Emergency

stop

Triple switch

Stop

Up

Down

pull switch

Radio remote

control,

Light barrier

closing direction

Terminals 15/17

max. 150 mA

Fraba OSE

GN BN WS

R 8,2 kOhm

Pre-limit switch CLOSE

or

locking mechanism for the door edges

max. 10A

Fuse on site

21 22

NPEPE N L12345678

1091211 1715 16

K3

L

N

PE

L

PE

N

87

K3

13 14 1918 20 2018 19

inputs/outputs

operating elements

Safety devices Neutralization

24V DC inputs/outputs

230V AC

Terminal diagram DoorControl

230 V/max. 60 W

10 11

Timer

max. 230 V/60 W

MANUFACTURERE'S DECLARATION

in compliance with the machinery directive 98/37/EU,

EMC directive 89/336/EEC;

low voltage directive 73/23/EEC

We hereby declare that the following product (s) is (are) in compliance

with the directives of the European Community.

Product designation:

DoorControl

The compliance of the described product (s) with the relevant

safety regulations as according to the directives is demonstrated by compliance

with the following standards:

xEN 12453 Safety of use of power-operated doors

xEN 50178

xEN 60204-1

xEN 50082-1+2

xEN 55014-1+2

xEN 60555 parts 1-3

The commissioning of this (these) product (s) is not permitted until ascertained that the

machine in which the abovementioned product (s) is (are) installed is in compliance with the

directives or the relevant national standards.

Beuren, 25. 06. 2002

elero GmbH

Antriebstechnik

Ulrich Seeker Linsenhofer Str. 59-63

EC Representative D-72660 Beuren

2020

13 305.6101

Technical parameters subject to change

04/07

elero UK Ltd.

Foundry Lane – Halebank

Widnes, Cheshire WA8 8TZ

Tel. (44) 870/24042 19

Fax (44) 870/240 4086

www.elero.com

elero GmbH

Antriebstechnik Linsenhofer Straße 59–63

D-72660 Beuren

Telefon (070 25) 13-01

Telefax (070 25) 13-212

Telefon (070 25) 13-01

Telefax (070 25) 13-212

www.elero.com

This manual suits for next models

1

Other elero Control Unit manuals