TROUBLESHOOTING

LEDs on a switch or sensor

don’t light

1. Check to see that the the device is connected to the DLM Local Network.

2. Check for 24VDC input to the device: Plug in a different DLM device at the device location. If the

device does not power up, 24VDC is not present.

• Check the high voltage connections to the room controller and/or plug load controller(s).

• If high voltage connections are good and high voltage is present, recheck DLM Local Network

connections between the device and the room controller(s).

The wrong lights and plug

loads are controlled

Configure the switch buttons and sensors to control the desired loads using the Push n’ Learn

adjustment procedure.

LEDs turn ON and OFF but

load doesn’t switch

1. Make sure the DLM local network is not in PnL.

2. Check load connections to room controllers and/or plug load controllers.

Lamps do not dim, or lamps

drop out at low dim levels

1. Make sure a 0-10V dimming ballast and rapid start sockets are installed per the ballast

manufacturer’s recommendation. Shunted sockets are typically not acceptable.

2. Check wiring per ballast manufacturer’s instructions.

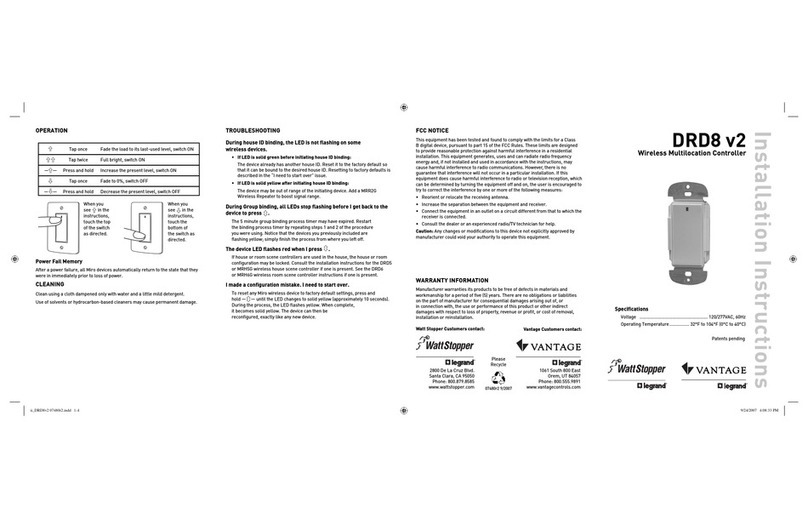

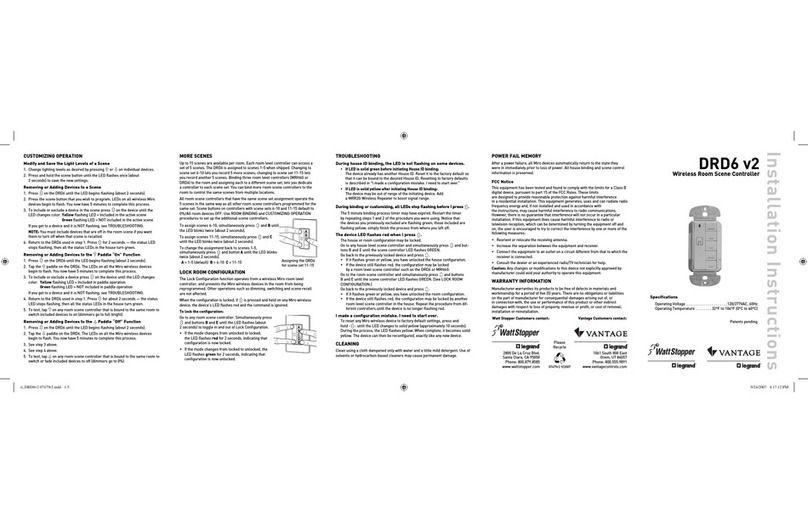

UNIT ADJUSTMENT PUSH N’ LEARN PNL

Load Selection Procedure

A configuration button (Config) allows access to Wattstopper’s

patented Push n’ Learn™ technology to change binding

relationships between sensors, switches and loads.

Step 1 Enter Push n’ Learn

Press and hold the Config button (on any DLM device) for 3

seconds.

The red LED on the LMRC-111/112 begins to blink. When you

release the button, the red LEDs on other

communicating devices connected to the DLM

Local Network begin to blink. They continue to

blink until you exit PnL mode.

All loads in the room turn OFF immediately after

entering PnL, then one load will turn ON. This

is Load #1, which is bound to switch button #1

and occupancy sensors as part of the Plug n’

Go factory default setting. All switch buttons and

sensors that are bound to this load have their blue

LED solid ON.

Config button &

red LED

Step 2 Load selection

Press and release the Config button to step through the loads

connected to the DLM Local Network. As each load turns ON

note the devices (switch buttons and sensors) that are showing

a bright solid blue LED. These devices are currently bound to

the load that is ON. The blue LED on the room controller or plug

load controller connected to the load is also lit.

• To unbind a switch or dimmer button from a load, press the

switch button while its blue LED is ON bright. The blue LED

goes dim to indicate the button no longer controls the load

that is currently ON.

• To unbind an occupancy sensor, press the up () or down

() adjustment button while its blue LED is ON. The blue

LED turns OFF to indicate the sensor no longer controls the

load that is currently ON.

Pressing the switch button or sensor up () or down () again

while the load is ON rebinds the load to the button or sensor and

the blue LED illuminates brightly.

Step 3 Exit Push n’ Learn

Press and hold the Config button until the red LED turns OFF,

approximately 3 seconds.