Wavetek 188 User manual

MODEL 188

4MHz SWEEP/

FUNCTION GENERATOR

INSTRUCTION MANUAL

MODEL 188

4MHz SWEEP/

FUNCTION GENERATOR

©- I960 -WAVETEK

THIS DOCUMENT CONTAINS INFORMATION PROPRIETARY TO

WAVETEK AND IS SOLELY FOR INSTRUMENT OPERATION AND

MAINTENANCE THE INFORMATION IN THIS DOCUMENT MAY

NOT BE DUPLICATED IN ANY MANNER WITHOUT THE PRIOR AP-

PROVAL IN WRITING OF WAVETEK

WAVETEK

SAN DIEGO

9045 Baeoa *• Sa"D*oc CA92123

“0 8o«6Si Si- D*gc Ca‘‘ 92U2

T* »«4>27*2200 TWX 910-33S-20C;

Manual Revision: 1/82

Instrument Release: D

WARRANTY

All Wavetek instrument* are warranted aga.nst defects mmateriel end workmanship for aperiod

of one year after date of manufacture Wavetek agrees to repair or replace any assembly or

component (except batteries) found to be defects, under normal use. during this period

Wavetek 's obligation under this warranty is limited sdefy to repaying any such instrument which ,n

Wavetek ssole opinion proves to be defective w.lh.n the scope of the warranty when returned

to the factory or to an authorized service center Transportation to the factory or service center

is to be prepaid by purchaser Shipment should not be made without prior authorization by

Wavetek.

This warranty does not apply to any products repa-red or altered by persons not authorized by

Wavetek, or not in accordance with instructions furnished by Wavetek If the instrument is

defective as aresult of misuse, improper repair, or abnormal conditions or operations, repairs will

be billed at cost

Wavetek assumes no responsibility for its product being used mahazardous or dangerous manner

either alone or in coniunction with other equipment High voltage used in some instruments may

bo dangerous If misused SpecaIdisclaimers apply to these instruments. Wavetek ossumes no

liability for secondary charges or consequential damages and. many event. Wavetek sliability for

brooch of warranty under any contract or otherwise, shall not exceed the purchase price of the

specific instrument shipped and agamst which aclaim is made

Any recommendations made by Wavetek for use of its products are based upon tests believed to be

reliable, but Wavetek makes no warranty of the results to be obtained This warranty is in lieu of

all other warranties, expressed or implied, and no representative or person is authorized to

represent or assume for Wavetek any liability mconnection with the sale of our products other

than set forth herein.

SAFETY

This instrument is wired for earth groundmg via me facility power wiring Do no bypass

earth grounding with two wire extension cords, plug adapters, etc

BEFORE PLUGGING IN the instrument, comply w.th installation instructions

MAINTENANCE may recuire power on witn the instrument covers removed This

should be done only by qualified personnel aware ot me electrical hazards

The instrument power receptical «connected to the instrument safety earth terminal

with agreen/yellow w.re Do not alter this connection (Reference 0or& stamped

inside tho rear panel near me safety earth terminal

)

WARNING notes call attention to possOlo mMiy or death hazards in subsequent

operations

CAUTION notes can attention to pos&We equipment damage msubsequent operations

CONTENTS

SECTION 1

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

GENERAL DESCRIPTION

1.1 THE MODEL 188 .1-1

1.2 SPECIFICATIONS M

1.2.1 Versatility 1-1

1.2.2 Frequency Precision 1-2

1.2.3 Amplitude Precision t-2

1.2.4 Waveform Characteristics 1-2

1.2.5 General 1-2

INSTALLATION

2.1 MECHANICAL INSTALLATION 2-1

22ELECTRICAL INSTALLATION 2-1

2.2.1 Power Connection 2-1

2.2.2 Signal Connections 2-1

2.3 ELECTRICAL ACCEPTANCE CHECK 2-1

24CHANGING THE OUTPUT IMPEDANCE 2-1

OPERATION

3.1 CONTROLS AND CONNECTIONS 3-1

3.2 OPERATION 3-2

3.2.1 Signal Termination 3-2

3.2.2 Manual Function Generator Operation 3-3

3.2.3 Voltage Controlled Function Generator Operation . . 3-3

3.2.4 Sweep Generator Operation 3-4

3.2.5 Waveforms 3-5

CIRCUIT DESCRIPTION

ALIGNMENT

5.1 FACTORY REPAIR 5-1

5.2 REQUIRED TEST EQUIPMENT 5-1

5.3 REMOVING GENERATOR COVERS 5-1

5.4 ALIGNMENT 5-1

TROUBLESHOOTING

6.1 FACTORY REPAIR 6-1

6.2 TROUBLESHOOTING TABLES 6-1

6.3 TROUBLESHOOTING INDIVIDUAL COMPONENTS 6-1

6.4 GENERAL INSTRUCTIONS 6-2

PARTS AND SCHEMATICS

7.1 DRAWINGS 7-1

7.2 ORDERING PARTS 7-1

7.3 ADDENDA 7-1

SECTION I

GENERAL DESCRIPTION

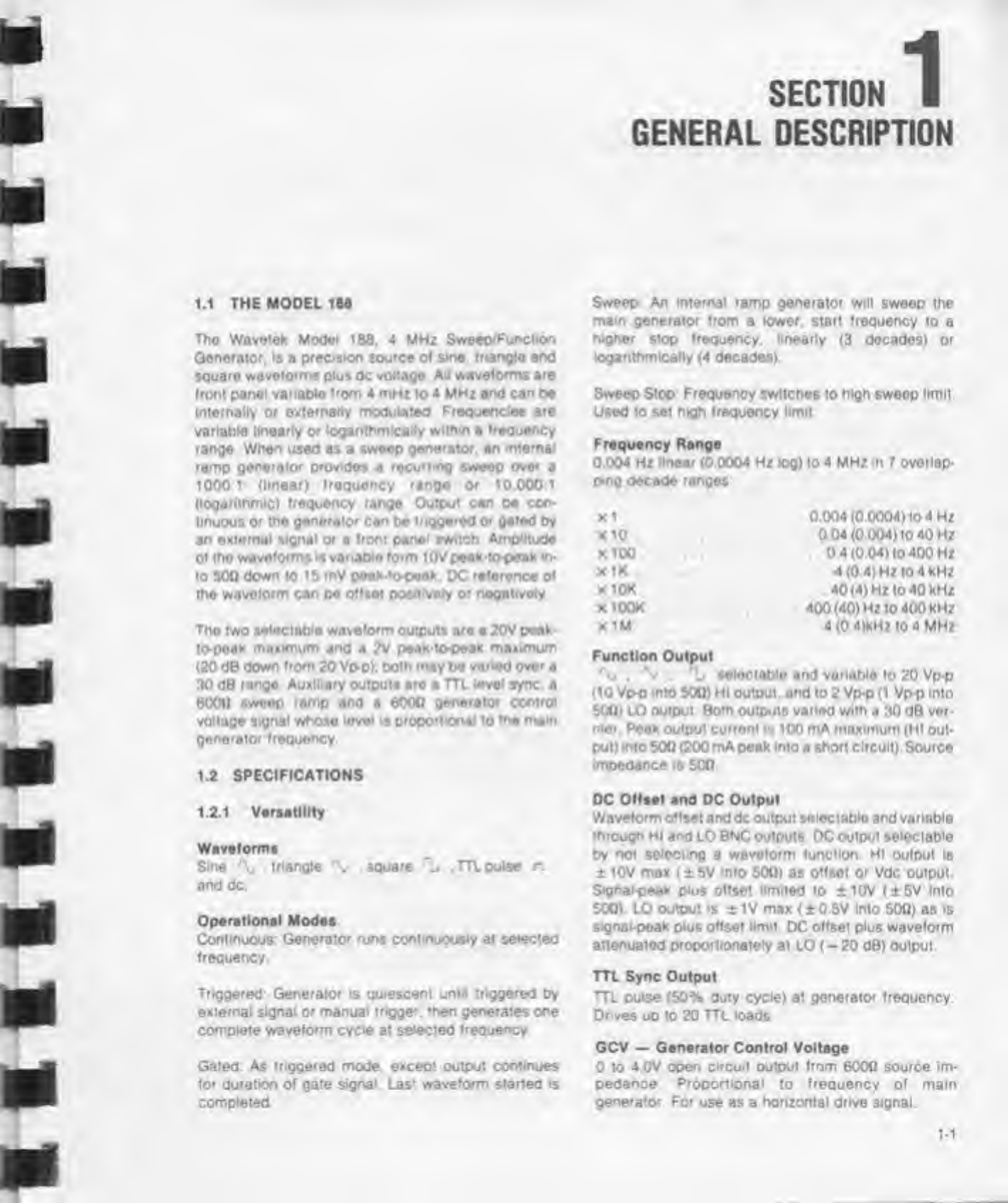

1.1 THE MODEL 188

The Waveiek Model 188. 4MHz SweetVFunction

Generator, is aprecision source of sine, triangle and

square waveforms plus dc voltage Ail waveforms are

front panel variable from 4mHz to 4MHz and can be

internally or externally modulated Frequencies are

variable linearly or logarithmically within afrequency

range When used as a sweep generator, an internal

ramp generator provides arecurring sweep over a

1000:1 (linear) frequency range or 10.000:1

(logarithmic) frequency range Output can be con-

tinuous O' the generator can be triggered or gated by

an external signal or afront panel switch Amplitude

of the waveforms is variable form 10V peak-to-peak in-

to 500 down to 15 mV peak-to^eak. DC reference of

the waveform can be offset positively or negatively

The two selectable waveform outputs are a20V peak-

to-peak maximum and a2V peak-to-oeak maximum

(20 dB down from 20 Vp-p). both may be varied over a

30 dB range Auxiliary outputs are aTTL level sync, a

6000 sweep ramp and a6000 generator control

voltage signal whose level is proportional to the main

generator frequency

1.2 SPECIFICATIONS

1.2.1 Versatility

Waveforms

Sine %.triangle \.square 'L .TTl pulse n

and dc.

Operational Modes

Continuous: Generator runs continuously at selected

frequency

Triggered: Generator is quiescent until triggered by

external signal or manual trigger, then generates one

complete waveform cycle at selected frequency.

Gated As triggered mode, except output continues

for duration of gate signal Las: waveform started is

completed

Sweep An Internal ramp generator will sweep the

main generator from alower, start frequency to a

higher stop frequency, linearly (3 decades) or

logarithmically (4 decades)

Sweep Stop Frequency switches to high swoop limit.

Used to set high frequency limit.

Frequency Range

0004 Hz linear (0 0004 Hz k>g) to 4MHz In 7overlap-

ping decade ranges

xl

x10

x100

xIK

X10K

X100K

X1

M

Function Output

'K* .\selectable and variabio to 20 Vp-p

(10 Vp-p into 50Q) HI output, and to 2Vp-p (1 Vp-p into

50Q) LO output Both outputs varied with a30 dB ver-

nier. Poak output current is 100 mA maximum (HI out-

put) into 500 (200 mApeak into ashort circuit) Source

impedance is 50Q.

DC Offset and DC Output

Waveform offset and dc output selectable and variable

through HI and LO BNC outputs DC output selectable

by not selecimg awaveform function. HI output is

410V max (± 5V into 500) as offsot or Vdc output.

Signal-peak plus offset limited to ±10V (±5V into

500). LO output is 4IV max (±0.5V into 500) as is

signal-peak plus offset limit. DC offset plus waveform

attenuated proportionately at LO (-20 dB) output.

TTL Sync Output

TTL pulse (50% duty cycle) at generator frequency.

Drives up to 20 TTL loads.

GCV —Generator Control Voltage

0to 4.0V open circuit output from 6000 source im-

pedance Proportional to frequency of main

generator. For use as ahorizontal drive signal.

0004 (0 0004) to 4Hz

0 04 (0.004) to 40 Hz

04 (0 04) to 400 Hz

4(0.4) HZ to 4kHz

40 (4) HZ to 40 kHz

400 (40) Hz to 400 kHz

4(0 4)kHz 10 4MHZ

1-1

VCG —Voltage Controlled Generator

Up to 1000:1 frequency change (linear mode) o< up to

10.000:1 change (logarithmic mode) with external 0to

± 4V signal. Upper and lower frequencies limited to

maximum and minimum of selected range.

Slew Rate: 2% ot range per *s (linear); 0to 100% of

range In 20 ms (logarithmic).

Linearity. ±0.5% through x100K range; ±2% on

x1Mrange.

Input Impedance: 2kO.

Sweep

Main generator is frequency modulated by Internal

sweep generator Main generator Irequency

ropoatodiy rises from frequency set by dial and range

button to frequency set by sweep stop knob

Sweep Mode: Linear (3 decades max) or logarithmic

(4 decades max)

Sweop Rate 30 ms to 1min (nominal) continuously

adjustable

Swoep Width: Up to 1:1000 (linear) or 1:10.000

(logarithmic) continuously adjustable

Sweep Output

Ramp waveform output with 4V peak into open circuit

Source Impedance 600Q. For use as a horizontal drive

signal

Trigger and Gate

Input: TTL compatible levels.

Pulso Width: 50 ns minimum.

Repetition Rato: 4MHz maximum.

1.2.2

Frequency Precision

Dial Accuracy

±5% of full scale

Time Symmetry

Square wave variation from 0.2 to 4.0ondial less than:

±1% to 100 kHz; ±5% to 4MHz.

1.2.3 Amplitude Precision

Sine variation with frequency less than: ±0.2 dB on

all ranges through xiOOK; ±1.0 dB to 4MHz.

1.2.4 Waveform Characteristics

Sine Distortion

Less than: 0.5% on xIK and x10K ranges; 1% on

xi. x 10. x100 and x100K ranges All harmonics

25 dB below fundamental on x 1Mrange

Triangle Linearity

Greater than 99% to 200 kHz

Square Wave Rise and Fall Time

At HI output, less than 50 ns for 10 Vp^> output Into

500 termination.

1.2.5 General

Environmental

Specifications apply at 25*C ±5*C. Instrument will

operate from 0*C to 50*C ambient temporatures

Dimensions

28 6cm (11 Vi m)wide: 8 9 cm (3Vfc in )high 26.7

(10W In) deep

Weight

2.7 kg (6 lb) net. 45kg (10 lb) shipping

Power

90 to 128V or 198 to 264V (specify); 48 to 66 Hz. loss

than 15 watts

NOTE

All specifications apply lor dial between 0

2

and 4.0; amplitude at 10 Vp-p from HI out-

put into 500 termination.

1-2

2.1 MECHANICAL INSTALLATION

After unpacking the instrument visually inspect ail

external parts for possiBie damage to connectors, sur-

face areas, etc If damage is discovered. Me aclaim

with the carrier who transported the unit. The shipping

container and packing material should be saved m

case reshipment is required

2.2 ELECTRICAL INSTALLATION

2.2.1 Power Connection

WARNING

To preclude Injury or deeth due lo shock,

the third wire earth ground must be con-

tinuous to the facility power outlet.

Before connecting to the facility power

outlet, examine extension cords, auto-

transformers, etc., between the Instru-

ment and the facility power outlet for a

continuous earth ground path. The earth

ground path can be Identified at the

plug on the Instrument power cord; ol

the three terminals, the earth ground

terminal Is the nonmalching shape,

usually cylindrical.

CAUTION

To prevent damage to the instrument,

check for proper match of line and instru-

ment voltage and proper fuse type and

rating

NOTE

Unless otherwise specified at the time ot

purchase, this instrument was shipped

from the factory for operation on a 90 to

128 Vac line supply and with a1/4 amp slow

blow fuse. Instruments configured tor 180

to 256 Vac have a1/8 amp slow plow fuse.

2

SECTION

INSTALLATION

Select the appropriate fuse and 115 or 230

switch position at the rear panel when

changing power sources

2.2.2

Signal Connections

Use 3toot RG58U 500 shielded cables eouipped with

BNC connectors to distribute all input and output

signals

2.3 ELECTRICAL ACCEPTANCE CHECK

This chockout procedure is ageneral verification of

generator operation. Should amalfunction be found,

refer to the warranty in the front of this manual

Atwo channol oscilloscope, four 3foot 500 coax

cabios with BNC connectors, acoax teo connector

and an additional function generator are required for

this procedure.

Preset the generator front panel controls as follows:

Control Position

Dial

MODE

FUNCTION

DCOFFSET

AMPLITUDE

FREQUENCY MULTIPLIER

SWEEP

2.0

CONT(released)

^

OFF (ccw)

MAX (cw)

x1

K

CONT(released)

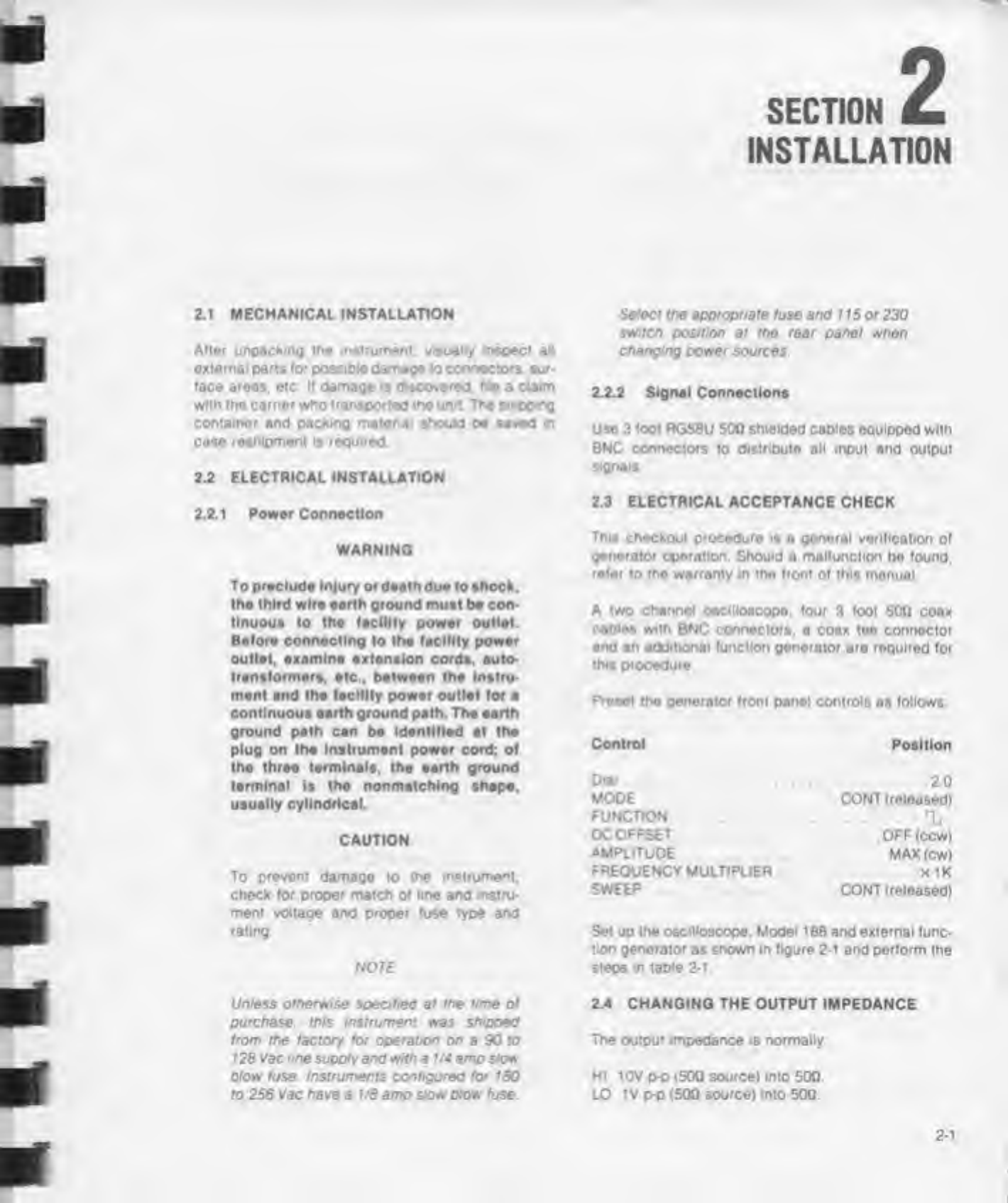

Set up the oscilloscope. Model 188 and external func-

tion generator as shown In figure 2-1 and perform the

steps in table 2-1.

2.4 CHANGING THE OUTPUT IMPEDANCE

The output impedance is normally.

HI 10V p-p (50Q source) into 500.

LO IV pp (500 source) Into 500

2-1

fl simultaneous 6000 ana 500 output impedances are

des»rea

*dc FUNCTION GENERATOR

OR VOLTAGE SOURCE

(INITIALLY OFF)

Figure 2*1. First Setup

Amplitude is normally variable over 30 dB for each

oulpul with a50 dB amplitude range available by

utilizing both outputs

1Change value ol Ri 48 Irom 4990 to 6040

2Remove Ri 49

The result is:

HI 10V p-o (500 source) into 500

LO 10V D-0 (6000 source) into 6000

Amplitude is variable over 30 dB Square wave rise

and tall time is less man 150 ns Any value greater

than 6000 may also be substituted lor the value of

R148 for other output impedances

To increase the range ot the variable amplitude con-

tro* In amodified unit beyond 30 dB. docroase the

value ot R124 as necessary Wavetorm quality

relative to the standard unit is not guaranteed below

-30 dB and above 20 kHz.

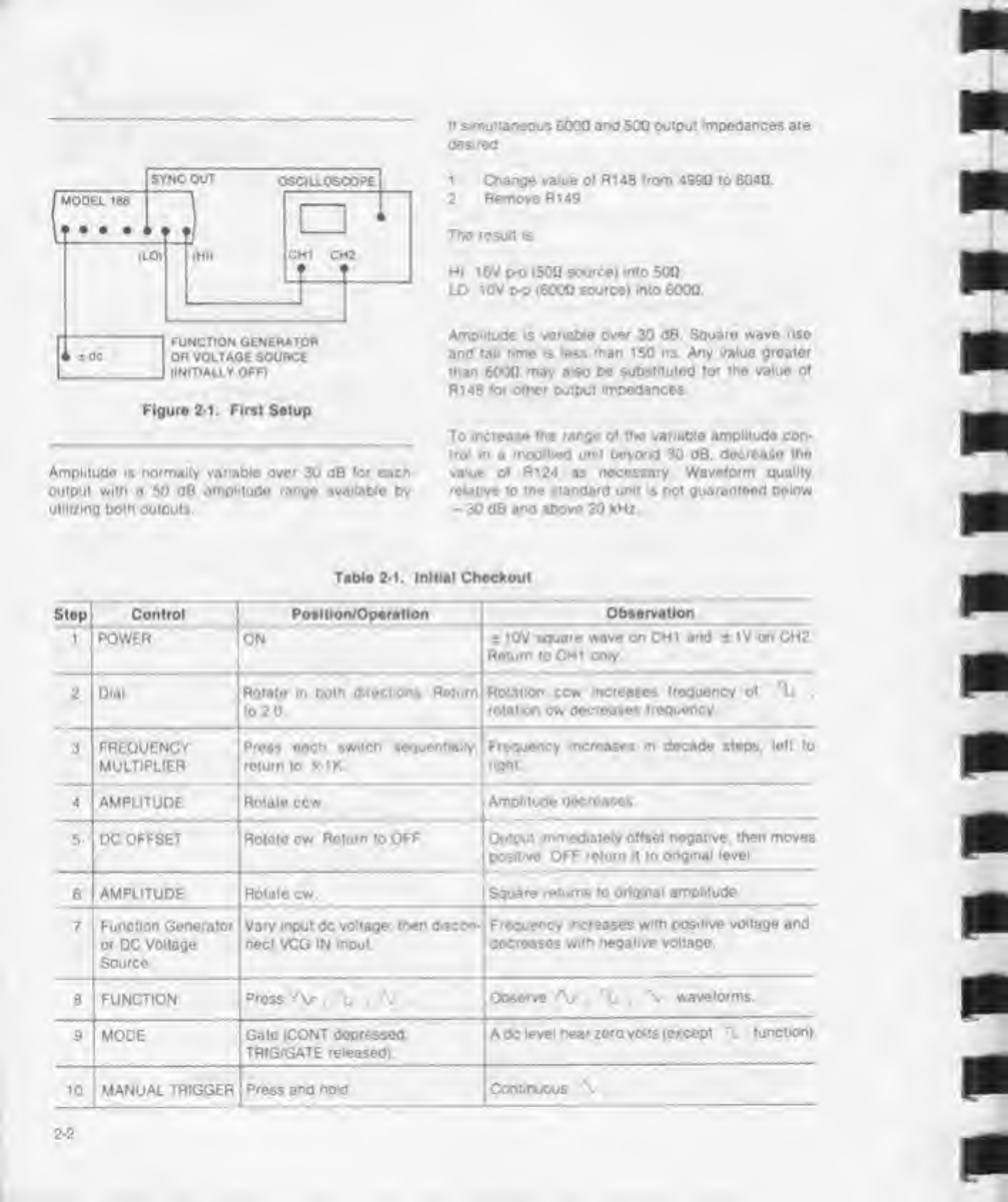

Table 2-1. Initial Checkout

Step

t

Control

POWER

Position/Operation

ON

Observation

110V square wave on CHI and *IV on CH2

Return to CHI only

2Dial Rotate mboth directions Return

to 20.

Rotation ccw increases frequency of 'L ;

rotation cw decreases frequency

3FREQUENCY

MULTIPLIER

Press each switch sequentially,

return to X1K.

i . -—

Froquoncy increases mdecade steps, left to

right

4AMPLITUDE Rotate ccw Amplitude decreases

5DC OFFSET Rotato cw Return to OFF Output immediately offset negative, then moves

positive OFF return it to o'rgmai level

6AMPLITUDE Rotate cw Square returns to original amplitude

7Function Generator

or DC Voltage

Source

Vary input dc voltage: then discon-

nect VCG IN input

Frequency increases with positive voltage and

decreases with negative voltage

8FUNCTION Press A/- .Tj .“V Observe -V .'L .\waveforms

9MODE Gate (CONT depressed

TRIG/GATE released) Adc level near zero volts (except rLfunction)

10 MANUAL TRIGGER Press and hold Continuous \.

2-2

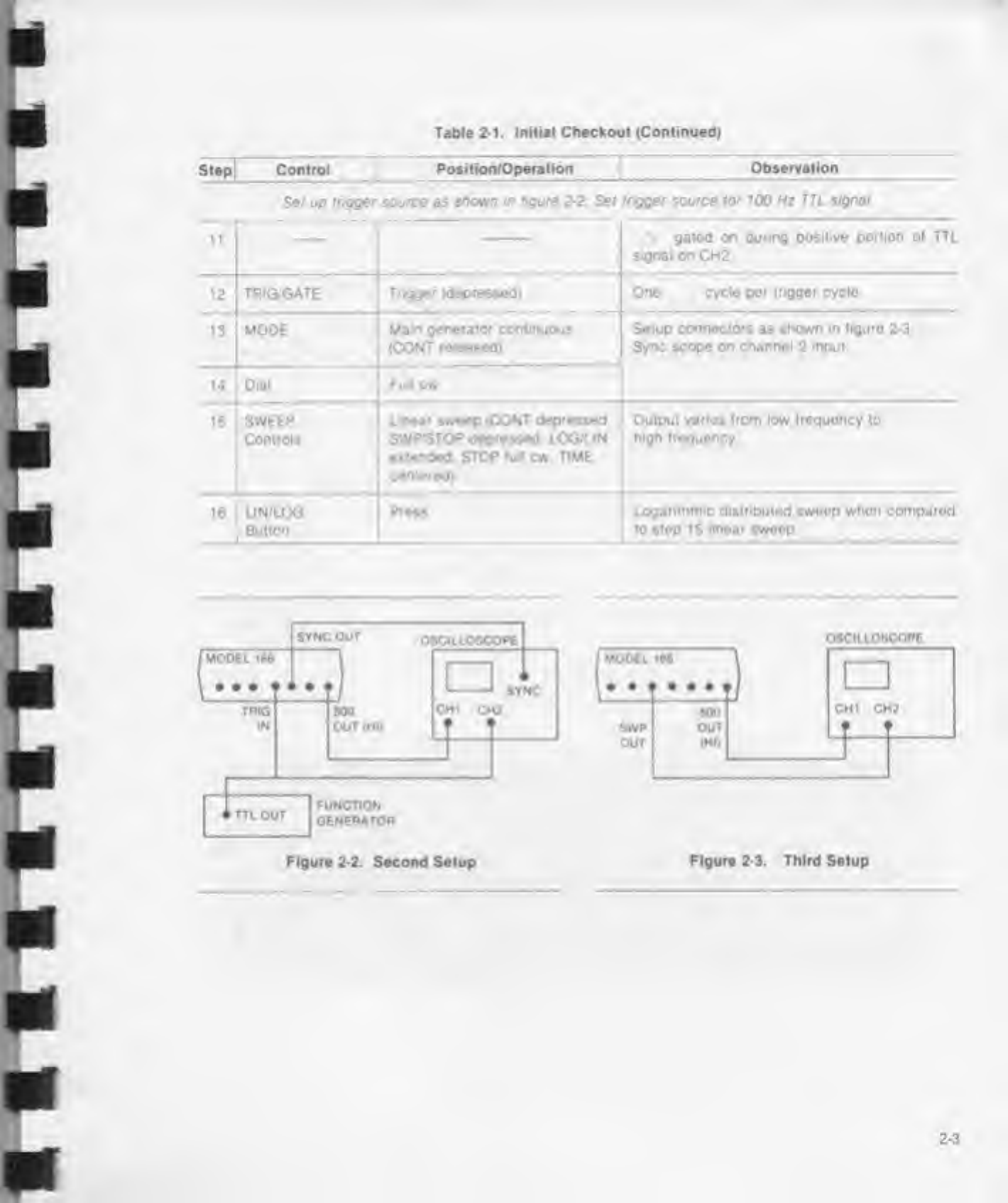

Table 2-1. Initial Checkout (Continued)

Step|Control |PoaHkxWOpiatton |Observation

Set up trigger source as shown in figure 22Set trigger source for 100 Hz TTL signal.

tt

i—\gated on during positive portion ot TTL

signal on CH2

12 TRIG/GATE Trigger (depressed) One cycle per trigger cycle.

13 MODE Main generator continuous

(CONT released)

Setup connectors as shown in figure 2-3

Sync scope on channel 2input

14 Dial Full cw

15 SWEEP

Controls

Linear sweep (CONT depressed.

SWP/STOP depressed LOG/lIN

extended. STOP full cw. TIME

centered)

Output varios from low troquoncy to

high IreQuoncy

16 UN/LOG

Button

Press Logarithmic distributed sweep whon comparod

to stop 15 linear swoop

1TTl OUT FUNCTION

GENEBATOB

Figure 2-2. Second Setup

OSCILLOSCOPE

Figure 2-3. Third Setup

2-3

SECTION

OPERATION

3.1 CONTROLS AND CONNECTIONS

The generator front panel controls and connectors are

shown in figure 3-1 and keyed to the following descrip-

tions

1Frequency Dial —Settings unde* the d«ai index

mark summed with 21 and multiplied by 4

determine the output signal frequency and the

sweep start frequency wsweep mode The dial

Is engraved with both linear and logarithms

scales outer scale imear and inner scale

logarithmic

2POWER Button —Tumsgonerator ON andOFF

3STOP Knob —Sets the upper frequency limit

when CONT 5Is depressed and SWP/STOP 6it

extended

4FREQUENCY MULTIPLIERControls -Selects

one of seven frequency multipliers for dial 1 set-

ting.

5CONT Button —Selects swoop submode to

mam generator scontinuous mode. Extended is

continuous (nonsweep) mode while depressed is

swoop mode Sweep is from alow frequency set

by 1to ahigh frequency set by 3Mam generator

mode control 8must be in continuous mode (ex-

tended)

6SWP/STOP Button -When button is depress-

ed (and 5depressed and 8extended) selects

repetitive sweop of the main generator frequen-

cy When pulton is extended, the frequency is

stopped at the upper sweep limit with uppor fro-

Quoncy being set by STOP control 3

7LIN/LOG Button —Selects linear or

logarithmic frequency distribution of sweep.

Figure 3-1. Controls and Connectors

3-1

VCG and main dial within afrequency range.

Linear operation is selected when the button is

extended. Logarithmic operation is selected

when the button Is depressed.

8, SGenerator MODE Controls -Selects one of

the following three modes

CONT —8 released Continuous output at

501) OUT 15 and 16 and SYNC OUT (TTL)

17 connectors.

TRIG —8and 9pressed DC level output

until generator triggered by the MAN TRIG 11

or with asignal at the TRIG IN connector 18

When triggered, the generator output is one cycle

of waveform followed by adc level

GATE —8pressed and 9 released As for

TRIG except the output is continuous for the

duration of the manual or external trigger signal

The last cycle started is always completed

10 TIME Knob -Sots the swoop time by control-

ling tho period of the sweep ramo generator

11Manual Trigger Button —Triggers or gates the

output signals whon generator mode is TRIG or

GATE (8 pressed) In trigger mode, one

waveform cycle is output when the button is

pushed In gate mode, wavotorm cycles aro con-

tinuously output as long as the button is held m

12 FUNCTION Selector —Selects one of throe

wavoforms or when all three buttons are released,

adc lovol

13 DC OFFSET Control -Offsets the 500 OUT

waveforms or gives dc levels from -10V to

+lOV(-5Vto +5VInto 500) at 15 and from

-IV to +IV (-0.5V to + 0 5V into 500) at 16

An OFF position ensures no offset.

14 AMPLITUDE Control -Ccw rotation reduces

waveform amplitudes at 15 and 16 by

30 dB DC and offset voltages are not affected

by this control.

15 500 OUT HI Connector —The main output of

tho generator at the function selected Maximum

20 Vp-p (lOVpp into 500) with 30 dB continuous

amplitude control. 500 source impedance

16 500 OUT LO Connector —Same as 15 ex-

cept 20 dB (1/10) lower in amplitude.

17 TTL OUT Connector —ATTL square for each

cycle of the generator To be used for syn-

chronization or as aTTL signal capable of driv-

ing 20 TTL loads

18 TRIG IN Connector —Accepts aTTL signal to

trigger or gate the generator. Triggers on the ris-

ing (low to high) transition and gates during the

positive (high) portion of the triggering signal.

19 SWP OUT Connector —Supplies a ramp

waveform with an approximate 4V peak into an

open circuit. For use as ahorizontal drive signal

Source impedance is 6000

20 GCV OUT Connector -Provides a 0 to 4V

open circuit output proportional to the frequency

Of the main generator. For use as ahorizontal

drive signal Source impedance is 6000

21 VCG IN Connector —Accepts ac or dcvoitagos

to proportionately control frequency within the

range dotormined by the FREQUENCY

MULTIPLIER 4.Positive voltage increases the

frequency set by the d-ai 1 ;negative voltage

decreases the frequency The VCG IN will not

drive the generator frequency beyond the nor-

mal dial limits Of arango Input impedance is

2kO

3.2 OPERATION

Perform the initial checkout in Section 2tor the tool of

the instrument. Any questions concerning Individual

controls and connectors may be answered In

paragraph 31

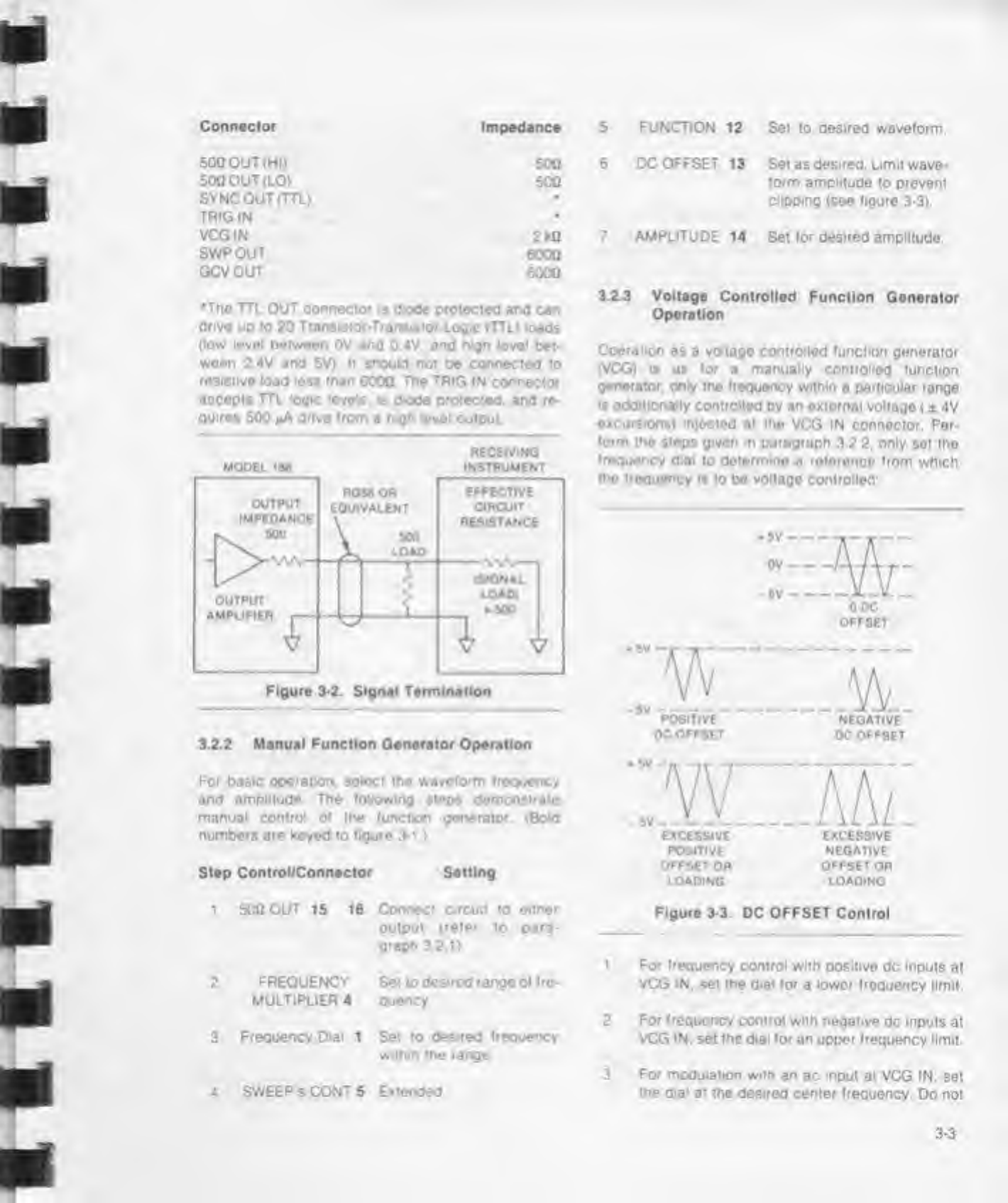

3.2.1 Signal Termination

Proper signal termination, or loading, of the generator

connectors >s necessary for its specified operation.

For example, the proper termination of either of the

500 OUT connectors is shown in figure 3-2 Placing

the 500 terminator, or 50Q resistance, in parallel with

ahigher impedance, matches the receiving instru-

ment input impedance to the coax characteristic and

generator output impedance, thereby minimizing

signal reflection or power loss on the line due to im-

pedance mismatch.

The input and output impedances of the generator

connectors are listed below

3-2

Connector Impedance 5FUNCTION 12 Set to desired waveform.

500 OUT(HI) 500 6DC OFFSET 13 Set as desired. Limit wave-

500 OUT(LO) 500 form amplitude to prevent

SYNC OUT (TTL) •clipping (see figure 3-3).

TRIGIN •

VCG IN 2kO 7AMPLITUDE 14 Set for desired amplitude

SWPOUT 6000

GCVOUT 6000

•The TTl OUT connector is dode protected ano can

drive up to 20 Transistor-Transistor-Logic (TTL) loads

(low level between OV and 04V. and high level bet-

ween 2.4Vand 5V) It shooId not be connected to

resistive load less than 600Q The TRIG IN connector

accepts TTL logic levels, is diode protected, and re-

quires 500 j*A dnve from an.gh level output

RECEIVING

MOOEl IBS INSTRUMENT

OUTPUT

IMPEDANCE

ROM OR

EQUIVALENT

\“

LOAD_

EFFECTIVE

CIRCUIT

RESISTANCE

OUTPUT

AMPl IPIFR ,

r

<(SIGNAL

LOAD!

P50U

muruiritn f

V1,

Figure 3-2. Signal Termination

3.2.2 Manual Function Generator Operation

For basic operation, select the waveform frequency

and amplitude The following steps demonstrate

manual control o» the (unction generator (Bold

numbers are keyed to figure 3-1.)

Step Control/Connector Setting

3.2.3 Voltage Controlled Function Generator

Operation

Operation as a voltage controlled (unction generator

(VCG) is as (or amanually controlled (unction

generator, only the frequency within aparticular range

»s add'tionaily controlled by an external voltago (± 4V

excursions) mjocted at the VCG IN connector. Per-

form the steps given in paragraph 3.2 2. only set tho

frequency dial to determine areference from which

the frequency is to be voltage controlled

HE

0DC

OFFSET

POSITIVE NEGATIVE

OC OFFSET DC OFFSET

:.W"TAT

EXCESSIVE EXCESSIVE

POSITIVE NEGATIVE

OFFSET OR OFFSET OR

LOADING LOAOING

1500 OUT 15 16

2FREQUENCY

MULTIPLIER 4

3Frequency Dial 1

4SWEEP SCONT 5

Connect circuit to either

output (refer to para-

graph 321)

Set to desired range of fre-

quency

Set to desired frequency

within the range

Extended

Figure 3-3. DC OFFSET Control

1For frequency control with positive dc inputs at

VCG IN. set the dial for alower frequency limit

2 For frequency control with negative dc inputs at

VCG IN. set the dial for an upper frequency limit.

3 For modulation with an ac input at VCG IN. set

the dial at the desired center frequency. Do not

exceed the limits of the selected frequency

range

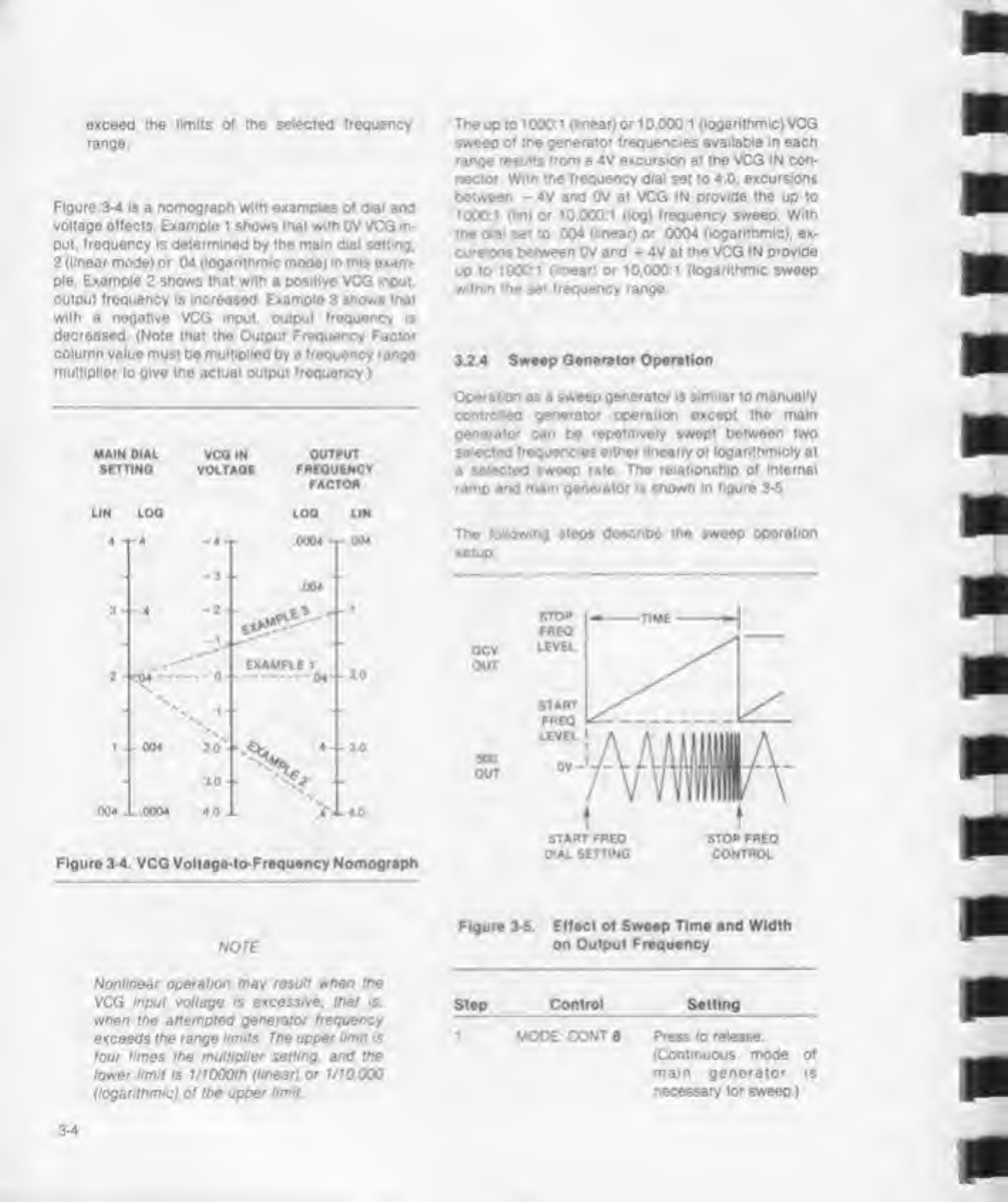

Figure 3-4 is anomograph with examples of dial and

voltage effects. Example 1shows that with OV VCG in-

put. frequency is determined by the main dial setting.

2(linear mode) or 04 (logarithmic mode) In this exam-

ple. Example 2shows that with a positive VCG input,

output frequency is increased Example 3snows that

with anegative VCG input, output frequency is

decreased (Note that the Output Frequency Factor

column value must be multiplied by afrequency range

multiplier to give the actual output frequency

)

MAIN DIAL VCO IN OUTPUT

SETTING VOLTAGE FREOUENCV

FACTOR

Figure 3-4. VCG Voltage-to-Frequency Nomograph

The up to 1000:1 (linear) or 10.000:1 (logarithmic) VCG

sweep of the generator frequencies available in each

range results from a4V excursion at the VCG IN con-

nector With the frequency dial set to 4.0. excursions

between -4V and 0V at VCG IN provide the up to

1000.1 (lm) or 10.000:1 (log) frequency sweep. With

the d>ai set to .004 (linear) or 0004 (logarithmic), ex-

curs ons between 0V and +4V at the VCG IN provide

up to 1000:1 (linear) or 10.000:1 (logarithmic sweep

within me set frequency range

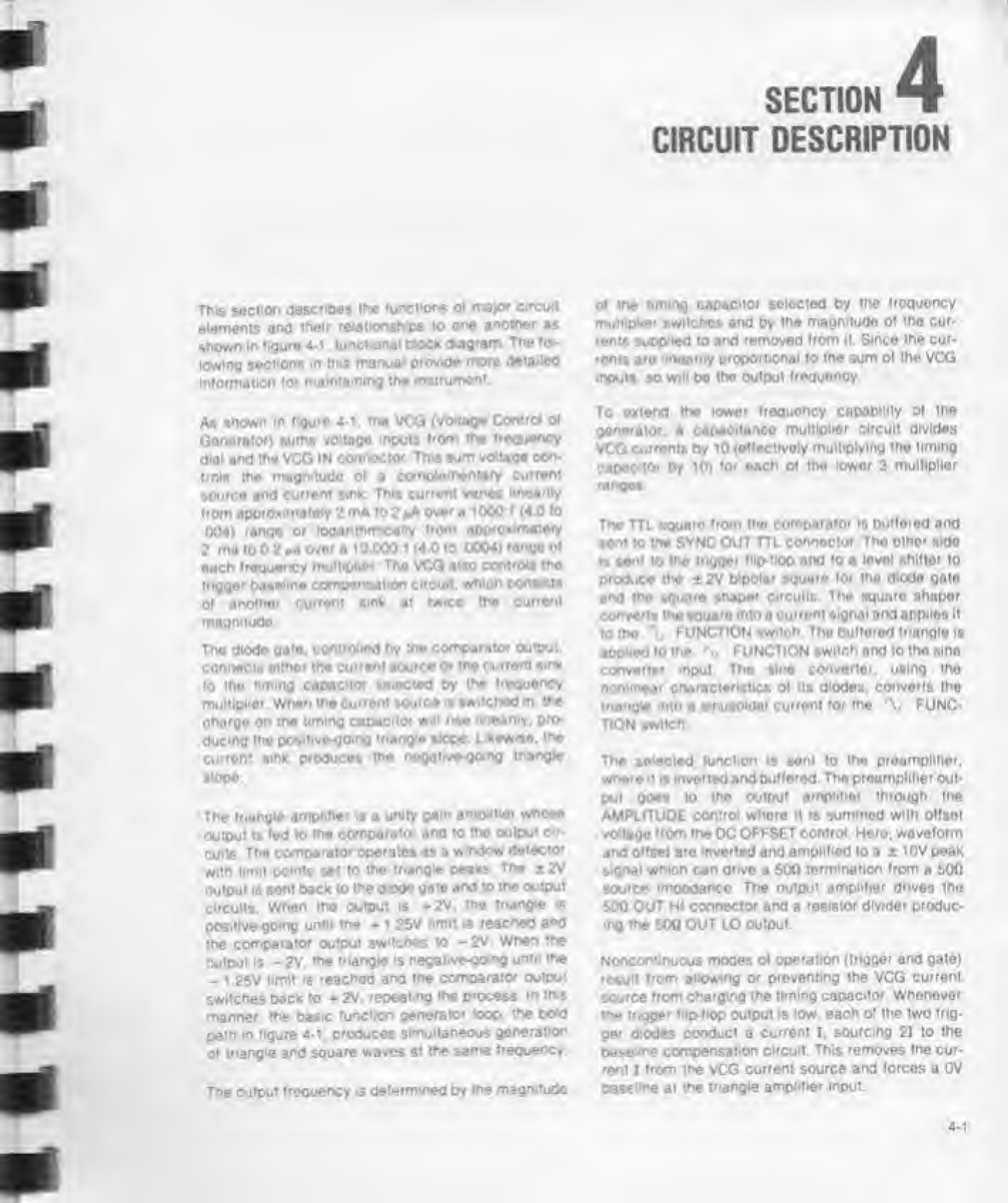

3.2.4 Sweep Generator Operation

Operation as asweep generator is similar to manually

controlled generator operation except the main

generator can be repetitively swept between two

selected frequencies either linearly or logarithmicly at

aselected sweep rate The relationship of internal

ramp and mam generator is shown in figure 3*5.

The io*Ow»ng steps describe the sweep operation

setup

GCV

OUT

soo

OUT

8TOP

FREO

LEVEL

START

FREO

LEVEL

STOP FREQ

CONTROL

NOTE

Nonlinear operation may result when the

VCG input voltage is excessive, that is.

when the attempted generator frequency

exceeds the range limits. The upper limit is

four times the multiplier setting, and the

lower limit is 1/IOOOth (linear) or UtO.OOO

(logarithmic) of the upper limit

Figure 3-5. Effect of Sweep Time and Width

on Output Frequency

Step Control Setting

1MOOE: CONT 8Press to release

(Continuous mode of

main generator is

necessary for sweep

)

Step Control Setting

2Frequency dial 1Select sweep start

freaiency

3SWEEP SCONT 5Depressed. (Selects

sweep submode ol main

generator’s continuous

operation)

4SWP/STOP 6Press to release. (Ex-

tended allows setting of

stop frequency

)

5STOP 3Select the stop frequen-

cy (The stop frequency

will always be higher

than the start frequen-

cy)

6Time 10 Sets the internal sweep

rate

3.2.5 Waveforms

Waveform liming lor each mode ol operation is shown

In figure 3-5.

m

OFFSET PERIOD

IAMPLITUDE

ovac 1J L- 1

CONTINUOUS

MODE

SINE ^vwwyv

T«'ANGLEVVVVVVVV

souAREirumrijijw

sync \JTj^j-i_rLn_n_n_r

TRIGGERED

MODE

TRIG INZL

SINE—

TRIANGLE

lSQUARE—1J-

GATID

MODE

iS0UABi uiru in

Figure 3-5. Waveform Characteristics

4-0

SECTION T

CIRCUIT DESCRIPTION

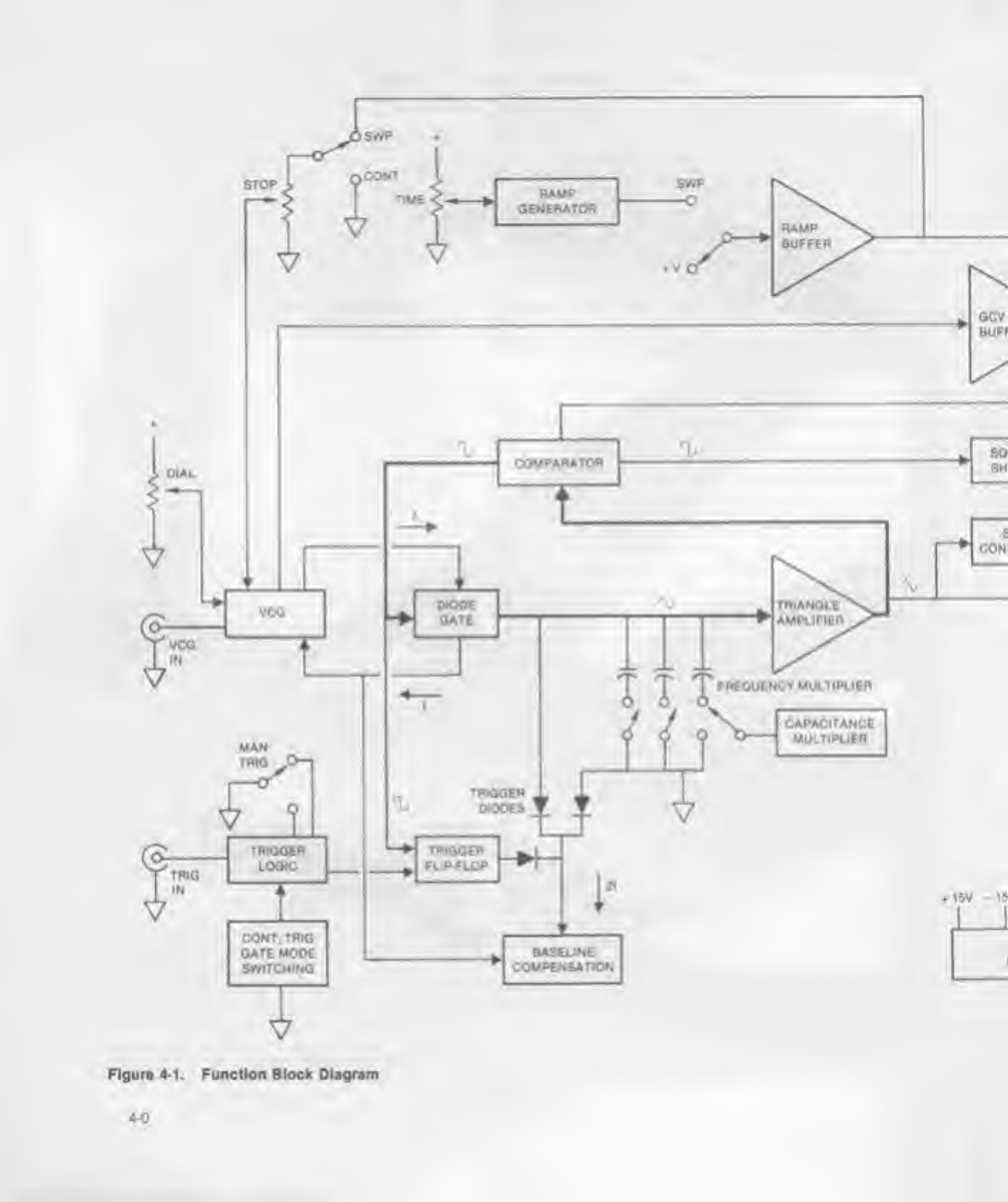

This section describes the functions ot majw circuit

elements and their relationships to one another as

shown in figure 4-1. functional Block digram The fol-

lowing sections in this manual provide more detailed

information for maintaining the instrument

As shown in figure 4-1. the VCG (Voltage Control of

Generator) sums voltage inputs from the frequency

dial and the VCG IN connoctor This sum voltage con-

trots the magmtudo of acomplementary current

source and current sink This current vanes linearity

from approximately 2mA to 2|iA over a1000 1(4 0to

004) range or logarithmically from approximately

2ma to 0 2 »a over a 10,000 1(4 0to 0004) range of

each frequency multiplier Tho VCG also controls the

trigger Baseline compensation circuit, which consists

of another current sink at twice the current

magnitude.

Tho diode gate, controlled By the comparator output,

connects either the current source or the current sink

to Ihe timing capacitor selected By the frequency

multiplier When the current source is switched in. the

charge on tho timing capacitor will nse imeaniy. pro-

ducing the positive-going triangle slope. l*ew.se. the

current sink produces the negative-go^ triangle

slope.

The triangle amplifier is aunity gam amplifier whose

output is fed to the comparator and to the output cir-

cuits The comparator operates as awindow detector

with limit points set to the triangle peaks The tZV

output is sent Back to the diode gate and to the output

circuits. When the output is +2V. the triangle is

positive-gong until the +125V limit is reached and

the comparator output switches to -2V When the

output is -2V. the triangle is negatrve-gomg until the

-1.25V limit is reached and the comparator output

switches back to *2V. repeating the process in th«s

manner, the basic function generator loop, the Bold

path in figure 4-1. produces simultaneous generation

of triangle and square waves at the same frequency

The output frequency is determined By the magnitude

of the timing capacitor selected By tho frequency

multiplier switches and By the magnitude of the cur-

rents supplied to and removed from it. Since the cur-

rents are imeanly proportional to the sum ot the VCG

inputs, so will Be the output frequency.

To extend the lower frequency capability of the

generator, acapacitanco multiplier circuit divides

VCG currents By 10 (effectively multiplying the timing

capacitor By 10) tor each of the lower 3multiplier

ranges

The TTL squaro from the comparator is Buftorod and

sent to the SYNC OUT TTL connector The other side

is sent to the tnggor flip-flop and to alevel shifter to

produce the *2V bipolar square for the diodo gale

and the square shaper circuits Tho squaro shapor

converts the souare into acurrent signal and applios It

to the Tj FUNCTION switch The Buffered triangle is

applied to the \FUNCTION switch and to the sino

converter input The sine convertor, using the

nonlinear characteristics of its diodes, convorts tho

triangle into asinusoidal current for fhe %FUNC-

TION switch

The selected function is sent to the preamplifier,

where it is inverted and Buffered. The preamplifier out-

put goes to the output amplifier through the

AMPLITUDE control where it is summed wilh offset

voltage from the DCOFFSET control Here, waveform

and offset are inverted and amplified to a±10V peak

Signal which can drive a500 termination from a500

source 'mpedance The output amplifier drives the

500 OUT HI connector and aresistor divider produc-

ing the 500 OUT LO output.

Noncontmuous modes of operation (trigger and gate)

result from allowing or preventing the VCG current

source from charging the timing capacitor. Whenever

the trigger tiip-flop output is low. each of the two trig-

ger diodes conduct acurrent I, sourcing 21 to the

baseline compensation circuit This removes the cur-

rent Ifrom the VCG current source and forces aOV

Baseline at the triangle amplifier input.

4-1

When the CONT switch is releasee. trigger logic is in-

hibited from passing any trigger signals and the tug-

ger (lip-flop output is held high This prevents me trig-

ger diodes from conducting and the generator loop

operates continuously.

When the CONT switch is pressed, the generator looo

is held at the OV baseline. Pressing the TfliG/GATE

switch puts the instrument in triggered mode and any

external or manual trigger signals al the trigger logic

input will be transformed into anarrow pulse cor-

responding to the low-to-high transition oIthe trigger

input. This pulse sots the trigger flip-flop high and

allows Ihe generator loop to run When the tr.angle

negative peak is reached, the comparator low-to-high

transition clocks the trigger Hip-Hop low and. when the

OV baseline level is reached, the generator loop again

stops The result is asingle cycle generated after

the triggering signal corresponding to 0to 360* of

phase Successive triggered waveforms always start

at Ihe samo 0*point.

Roloasmg the TRIG/GATE switch puts the instrument

In the gated modo This is identical to tho triggered

mode, except tho trigger flip-flop is held high for the

full duration of the triggering signal Tho generator

produces continuous waveforms during the time the

external signal Is high or the manual lugger swilch is

held tn The last triggered cycle started is always com-

pleted and successive gated bursts always start at the

0#point

When sweep mode is selected by acombination of

the mam generator in continuous mode and the ramp

generator switches set to SWP. the ramp generator is

enabled and aramp voltage becomes part of the con-

trol voltage mme VCG circuit to control me main

generator frequency. Ramp period, variable from

30 ms to 1mmute. is set by me TIME Control. Ramp

generator output is buffered to drive the sweep output

and VCG circuit. The ramp magnitude suppling the

VCG input is controlled by the STOP potentiometer.

Selecting the stop switch position biases the buffer

amplifier to alevel equal to the positive peak of the

ramp (+V) In this static mode the upper sweep limit

can be set by me STOP Control

When the CONT position of the SWEEP switch is

selected the ramp generator is disabled and the buf-

fered ramp is disconnected from ihe VCG input

The GCV (Generator Control Voitago) from the VCG

ci'Cu't IS aresultant voltage from me throe VCG in-

puts: dai. VCG IN and sweep ramp This voltage is

buffered and made available at the GCV BNC

4-2

SECTION W

ALIGNMENT

5.1

FACTORY REPAIR 5.4 ALIGNMENT

Wavetok maintains afactory repair department tor

those customers not possessing the necessary per-

sonnel or test equipment to maintain the instrument If

an instrument is returned to the factory for alignment

or repair, adetailed description ot the specific

problem should be attacned to minimize turnaround

time,

5.2

REQUIRED TEST EQUIPMENT

Voltmeter Millivolt dc measurement (1 %accuracy)

Osoiloscopo *60 MHz bandwidth

Counter 4MHz (0 1% accuracy)

500 Feedthru si%accuracy. 2W

Distortion Anaiyzor To 400 kHz

RG58UCoax Cable 3ft length BNC male contacts

After referring to the following preliminary data, per-

form alignment, as necessary, per table 5-1 If per-

forming partial alignment, check previous settings

and adjustments for applicability Soo figures 5-1 and

5-2 for alignment control location

1Ail measurements made at the FUNCTION OUT

connector must be terminated Into a500 (±i%)

load

2Start the alignment by connecting the unit to an

appropriate ac power source and setting the

front panel switchos as follows

5.3

REMOVING GENERATOR COVERS

1. invert the instrument and remove the lou-

serews in the bottom cover.

2. Turn the Instrument upright: remove the too

cover for access to generator alignment con-

trols

3

When alignment is complete, secure the bottom

cove' with four screws

NOTE

Remove me cover only when it is neces-

sary to make adiostments or measure-

ments

POWER

Frequency Dial

FREO MULT(Hz)

MODECONT

FUNCTION

DC OFFSET

AMPLITUDE

LIN/LOG

SWEEP SCONT

SWP/STOP

ON

40

X1K

CONT (released)

a.

OFF

MAX

LIN (released)

CONT (released)

STOP (released)

3Allow the unit to warm up at least 30 minutes tor

final alignment Keep the instrument cover on to

maintain heat Remove cover only to make ad-

justments or measurements.

Other manuals for 188

1

Table of contents

Other Wavetek Portable Generator manuals

Wavetek

Wavetek 1370 Installation instructions

Wavetek

Wavetek 3000 User manual

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 150 User manual

Wavetek

Wavetek 188 User manual

Wavetek

Wavetek 144 User manual

Wavetek

Wavetek 132 User manual

Wavetek

Wavetek FG3B User manual

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 1001A User manual

Popular Portable Generator manuals by other brands

Master

Master MGY5000C OWNER'S OPERATION AND INSTALLATION MANUAL

Power Craft Garden

Power Craft Garden 67995 instruction manual

Teledyne

Teledyne SFG-20 Series user manual

Generac Power Systems

Generac Power Systems GP3000i owner's manual

Subaru

Subaru SGX3500 Service manual

Impax

Impax IM1500I instruction manual