Wavetek 1370 Installation instructions

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Fluke / Wavetek 1370 at our website: Click HERE

PRELIMINARY OPERATOR'S AND

MAINTENANCE MANUAL

Model

1370

12

MHz

VXI

Sweep/Function Generator

Q

1991

Wavetek

This document contains information proprietary to

VJavetekand

is

providedsolelyfor instrumentoperation

andmaintenance.The informationinthisdocument may

not

be

duplicated in any manner without the prior ap-

proval

in

writing from Wavetek.

WAVETEK

SAN

DIEGO,1NC.

9345

Balboa

Ave..

San

Diego, CA 92123

P. 0.Box 85265.

San

Diego,

CA

92138

Tel

6191279-2200

FAX

67915659558

Manual Revialon:

A.

7/91

Manual

PanNumber: 1006-00-0648

Instrument

Pen

Number:

1000-00-0640

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

WARRANTY

Wavetek warrants that all products manufactured by Wavetek conform to published Wavetek

spectiica!ions andarefreefromdefectsinmaterialsandworkmanshipfor aperiodof one

(1)

year from

:he

date

ot deliverywhen used under normal conditionsandwithin the service conditions for which

:hey were furnished.

The obligation o: Wavetek arisingfrom aWarranty claimshall belimitedto repairing,or at itsoption,

replacingwithout charge, any productwhich inWavetek's sole opinion provesto bedefective within

the scope of the Warranty. In the event Wavetek is not able to modify, repair or replace non-

conforming defectivepartsor componentsto aconditionaswarrantiedwlthina reasonabletime after

receiptthereof, Buyers shall be creditedfor their value at the original purchase price.

Wavetek must benotifiedinwritingof thedefector nonconformltywlthintheWarranty period andthe

affectedproductreturnedtoWavetek'sfactory ortoanauthorizedservicecenterwithin

(30)

daysatter

discovery of suchdefect or nonconformity.

For ~roductwarranties requiring returnto Wavetek, products must be returnedto a service facllity

designated by Wavetek. Buyer shall prepay shipping charges, taxes, duties and insurance for

products returned to Wavetek for warranty service. Except for products returned to Buyer from

another country, Wavetek shall pay for return of productsto Buyer.

Wavetek shall have no responsibility hereunder for any defect or damage caused by improper

storage,improperinstallation,unauthorized

modification,

misuse,neglect,Inadequatemaintenance,

accidentor for any productwhich has beenrepairedor alteredbyanyoneother thanWavetek or its

authorized representative and not in accordancewith instructionsfurnished by Wavetek.

Exclusion

of Other Warrantles

The Warranty describedabove IsBuyer's aole andexclueive remedy and noother warranty,

whether written or oral, Isexpressed or implted. Wavetak epedflcally dlaclarma the lmplled

warrantiesof

merchantabllltyandfltnessfor

aparticularpurpose. Nostatement, representation,

agreement, or understanding, oral or written, made by an agent, distrlbutor, representative, or

employeeof Wavetek,which is notcontainedintheforegoingWarrantywlllbebindinguponWavetek,

unlessmadeinwritingandexecutedbyanauthorizedWavetek employee.Undernoclrcumstancea

shallWavetek beliableforanydlrect, indirect,special,

incidental,

or

consequential

damagea,

expenses, Lossesordelays

(Including

lossofprofits)baaedoncontract, tort, oranyotherlegal

theory.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

SAFETY FIRST

PFIOTECTYOURSELF. Follow these precautions:

Don'ttouchthe outputs ofthe instrumentor any exposedtest wiring carrying the

output signals. This instrumentcan generate hazardous voltages and currents.

Don'tbypasstheVXI chassis'powercord's ground leadwith two-wireextension

cords or plug adaptors.

Don'tdisconnectthegreenandyeilowsafety-earth-groundwlrethat connectsthe

ground lugof the VXI cha sis power receptacleto the chassis ground terminal

(markedwith

@

or

A

1.

Don'tholdyour eyesextremelyclosetoan

rf

outputfor a longtime. Thenormally

nonhazardous low-power

rf

energy generated by the instrument could possibly

cause eye injury.

Don't energize the VXI chassis untildirectedto by the installation instructions.

Don't repairthe instrument unlessyou are a qualifledelectronics technician and

know how to work with hazardousvoltages.

Pay attention to the WARNING statements. They point out situations that can

cause injury or death.

Pay attention to the CAUTION statements. They point out situations that can

cause equipment damage.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS

SECTION

1

GENERAL

.................................................................................

:

.

1

THE

MODEL 1370

1-1

.....................................................................................

:

.

2 SPEClFJCATlONS

1

.

1

.............................................................................................

'

.

2

7

Functions 1

.

1

............................................................................

.

:

2.2 Ooeraling Modes

1-1

................................................

.

........................

2.3 FrequencyRange

..

1

1

1

.

2.4

Outputs

............................................................................................

1-1

.................................

.........................................

.

1

2.5 FrequencySweep

..

1-2

......##....................

...............................................................

.

1

2.6

Inputs

..

1-2

..........................................................................................

1.2.7 Precision 1-2

................................................................................

1.2.8

Waveform Quality 1-3

1.3 GENERAL

..............................................................................................

1-3

.........................................................................

1

.

3.1 SCPl Pr0g;amming 1-3

1.3.2 VXIlnkrface

........................................................................................

1-3

.................................................................................

i

.

3.3 Environmental 1-3

1.3.4 Size

.................................................................................................

1-3

........................................................

..................................

1

.

3.5 Power

..

1-3

1

.

3.6 Reliability

.............................................................................................

1-3

........................................................................................

1

.

3.7 Normal Use 1-3

1.3.8 Safety

.........................

...

............................................................

1-3

..............................

............

1.3.9 EMC

..

.....................................

1-3

SECTION

2

PREPARATION

...........................

2.1 RECEIVING INSPECTiON

.....

,,,

.............

2-1

2.1.1 Unpacking Instructions

..........................................................

2-

1

.......................

.............

.........

2

.

7

.

2 Returning Equipment

......

,

.....

,,

2-1

........................

2.2 PREPARATIONFOR STORAGE OR SHIPMENT

.,

,,

...,.,...

2-1

............................

......

..

.

2.2.1 Packaging

,..

..,

,......

,

...

....

..

,

..

2-1

....................

....

...

....

2.2.2 Srorage

,

.,

,

...

..,......

2-1

...............

............

.............

2.3 PREPARATIONFOR

USE

....,

.............

..

..

2-1

.........

........................

..

2.3.1 LogicalAddress Selection

,..

..

......,

,

..

,

2-1

2.3.2 DataTransferBus Arbit:ation

..............................................................

2-2

2.4

INSTALLATION

........................................

,

.................................................

2-4

...........................

2.5 INITIALCHECKOUTAND OPERATION VERIFICATION

2-4

SECTION

3

OPERATlON

3.1 INTRODUCTION

............................................

..

..................

3-1

...................................................

3.2 CONNECTORS AND LED INDICATORS 3-1

..................................

................

3.3 MODEL 1370 PROGRAMMING

.....

3-1

.......................................................................

3.3.1 SCPl CommandTable 3-1

3.3.1.1 Long and Short Form Keywords

................................................

3-3

...............................

3.3.1.2 SCPl CommandTree

...................

.......................

3-3

..............................................................

3.3.2 Command MessageForma!

3-4

.....................................................................

3.3.2.1 Program MessageUn~t 3-4

.............................................................

.............

3.3.2.2 Program Message

..

3-4

..................................

3.3.2.3 ProgramMessage Delimiters

..

......

3-4

.................................................................................

3.3.2.4 Parameter Forms

3-4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

CONTENTS (Continued)

....

.............

Program MessageTerminators

...

..

..................

3-7

................................................................................................

Queries

3-7

Model

1370

SCPl Commands

.............................................................

3-7

................................

..................................

Frequency ~Vessages

..

3-7

Funct~or:Messages

.............................................................................

3-8

Voltage (Amplitude) Messages

...........................................................

3-8

Voltage (Offset)Messages

........................

..

.................................

3-8

...........

...................

FrequencySweep Messages

........

..

3-9

Burs1Count Value

........................................

3-10

..............................................................................

Mode Messages

3-10

Output StateCommand

....................

.,

...............

..

..............

3-10

TTL

Trigger Sync Output Messages

...................................................

3-17

Trigger Source Messages

...................................................................

3-11

Trigger Slope Messages

....................................................................

3-!I

System Error Queries

.......................

.....

.................................

3-12

Model

1370

Calibration Query

............................................................

3-12

....

'TST Self Test Query

....................

.......

.........

3-14

........................................................................

'TRG System Trigger

3-74

...............

..............................

IEEE

488.2

Common Commands

..........

3-14

........................................................................

3.4

MODEL 1370OPERATION

3-14

Output Terminations

..........................................................................

3-14

lnput/Output Protection

.......................................................................

3-15

Power On/Reset Defaults

...................................

......

.....................

3-15

Continuous Mode

.............................................................................

3-15

DC

Output

..........................

..

.........................................................

3-16

VCG Operation

....................................................................................

3-:7

Introduction

.........................

..

.........................................................

3-77

Frequency Modulation (FM)

................................................................

3-18

Exrernal FrequencySweep

...................

...

....

.............................

3-18

Triggered Operation

....................

....

.........................................

3-18

Introduction

......................................................................................

3-18

.................................

ExternalTrigger Input

.........................

...........,...

3-13

.....................................................................

BUSTrigger Commands

3-19

VXI Trigger Bus Input

..........................................................................

3-19

Gated Operation

.......................

..

.....................................................

3-20

Burs: Operation

...................................................................................

3-21

..................................................

ExternalWidth

.....................

.......

3-22

InternalFrequencySweep

............................

..

.................................

3-22

................................................................................

Status Command

3-22

SECTION

4

CIRCUIT DESCRIPTION

TO

BE

SUPPLIED AT A LATER GATE

SECTION

5

CALIBRATION

..................................................................................

5.1

FACTORY REPAIR

5-7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5.2

REQVIRED TEST EQUIPMENT

...........................................

...

.............

5-

1

5.3

CALIBRATION

.......................................................................................

5-

1

5.3

1

Semi-Automated Procedure

...............................................................

5-1

5.3.2

Preparation

..........................................................................................

5-2

5.3.3

Connec!or Term~nat~on

........................................................................

5-2

5.3.4

Caiibrat~onProcedure

...................

....

.........................................

5-2

SECTION

6

TROUBLESHOOTING

TO

i3E

SUPPLIEDAT A LATER DATE

SECTION

7

PARTS AND SCHEMATICS

7.1

DRAWINGS

..........................................................................................

7-1

..................................................................................................

7.2

EqRATA

7-1

7.3

ORDERING PARTS

....................................................................................

7-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TABLES

Table 1-1

Table 3-?

TaSle 3-2

able3-3

Table 3-4

Table 3-5

Table 3-6

Table 3-7

Table 3-8

Table

5-1

Figure

1-1

=~gure

2-1

F~gure

2-2

F~gure2-3

F~gure3-1

Figure3-2

F~gure3-3

Figure 3-4

Figure 3-5

F~gure3-6

F~gure3-7

F~gure3-8

F~gute3-9

F~gure3-10

'~gure 5-1

FrequencyRanges

........................

....

.................................

1-3

Model 1370 FroniPanel

..........................................................

3-3

Model 1370 CommandSummary

..........................

..

.........

3-5

CalibrationSteps

..................................................................

3-12

Error Messages

.......................................................................

3-13

Self Test Respcnse

...................................

.....

.........................

3-14

IEEE 488.2 Commcn Commands

.....................

...

............

3-14

Input and Output Impedances

...............................................

3-14

FrequencyRanges

..........................................................

3-18

List

o! Tesr Equipment

............................................................

5:

ILLUSTRATIONS

Model 1375 12

MHz

VXI Sweep/FunctionGenerator

.............

1-0

Se! the

Logical

Address

.........................

..

.....................

2-2

BusArbitration Level Jumpers

................................................

2-3

...........................................................................

Test Setup 2-4

..........................................................

Model 1370 Front Panel 3-2

...................

.....................

ivlodel 1370 Command Tree

..

3-6

.................................................................

OutputTermination 3-15

....................................

Model 1370 Basic OperationSetup 3-16

...................................

ContinuousWaveform Characteristics 3-16

....................................................................

VCG Nomograph 3-17

Triggered WaveformCharacteristics

...................

......

........

3-19

..............................................

Gate Waveform Characteristics 3-23

...........................................

BurstWaveform Characteristics 3-21

..............................

ExternaiWidthWaveform Characteristics 3-22

Test Points and Adjustments

..........................

...

..........

5-5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

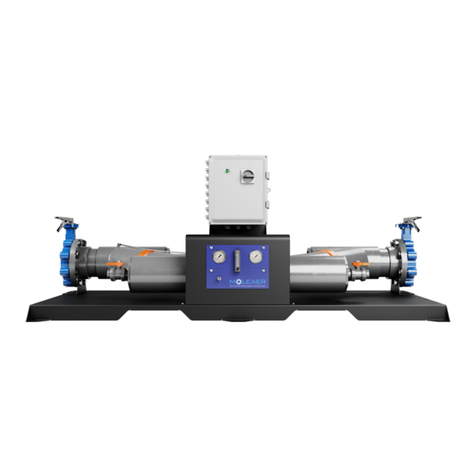

RUS

FAIL

MODID

Alll

A24

a

SYNC

OUT

SWEEP

OUT

model

1370

Figure

1-1,

Model

1375

I2

MHz

VXI

Sweep/Function Generator

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

GENERAL

1.1

THE MODEL 1370

The

MODEL

1370is a three function(sine, triangle,

somuare]

'C

size\/XIProgrammableSweepiFunction

Geqer80r.

I!

car. operate as a continuous, trig-

gered,

gated or burs: signal source at output

arnpiit~desup to 20 Vpp. Additionally, the Model

1370

can be programmed for dc and 'external

wid!h

(two level output determined by external

s~gna!andprogrammabletrigger referencelevel).

It

hasbi-directionalfrequencysweepcapabilirywithin

tie frequency range of .01 Hz and 12

MHz,

with

either linear

or

logar~thmicsweep characteristic.

i3eourDu; level is swecified from 10 mV to

10

Vpp

!nto

SOR

rerm~nation,and 20 mV to 20 Vpp inro an

oDen circclit with

3.5

digits of resolution. Offset can

beprogrammedtovary thewaveiorm'sbaseline

up

ro

2

1

OV,

or inthedcfunction,varythedc outpu!. The

kmc!ion output is protecred from external over-

voliagesupto

1

C3V peak.Activationof theprotection

circui!~sets error status bits monitored by the VXI

son?roller.

Conirolof the sweepifunction generator adheres to

:he

SCPl

(Standard Commands for Programmable

Insrrumenls)industrystandard languageforremote

in~lrurnentprogramming.

1.2 SPECIFICATIONS

1.2.1 Functions

Prqrammable sine, triangle, square, square com-

?;men!,external width, or dc.

1.2.2

Operating Modes

Continuous:

Oulput

continuous at programmed frequency. Fre-

quency can be modified via the VCG

IN.

Trlggered:

3u!pill quiescent until triggered by an exrernal

signal, a

TTLTRG

signal, or a VXI bus command,

lhen

generates one cycle of the programmed ire-

quency

Gated:

S~mlarto ti~ggeredmode except output continues

for

theGurat~on

of

gatesignal. The last cyclestarted

IS

czm~lered.

Burst:

Programmable numoer of waveform cycles

I.!

a

ourst. Burst length,initiated by the tr~ggers~gnal,is

programmable between2and2wcycles.ivlaxinum

burst rate is

12

MHz.

1.2.3 Frequency Range:

0.01

Hz

to 12

MHz.

1.2.4 Outputs

Functlon Output:

Waveforms from 0.01 to

10

Vpp into 508 ((3.02 :o

20

Vpp

into r50k8). DC or offset programmaole

from-5Vto +5V into50Q (-10Vto +10Vinror3CkR).

Programmable on or off (Zoff

>5C3

rc

8).Absolute

peak amplitude plusoffsetmay not exceed

5V

Inlo

50R (10V into 250 kQ).

Source Impedance:

50Q.

Protection:

Outputprotected

tot

1

OOi/

peaks.

Sync Output:

TTL

level square wave into 50Q at programmed

frequency. In addition, the Sync Output may be

programmedto driveany oftheeight

TTLTRG'

lmes

on the VXI backplane.

TTL

Compatible:

50.4

to 22.4 V into 50R,

r0.8to r4.8

V

into 253

kR.

Source impedance:

509

Timing;

Concurrent with fl;nc:ion

output in square; lags sme

and triangle by

93'

Prolection:

Output protected to

*?5

V

inputs.

Sweep Output:

Linear 0 V to +tO V (open circuit) ramp signai

occurring during

a

frequency sweep. Instanra-

neousvalue of rampvoltage indicates percent

ttmE

completionof frequency sweep.

Amplitude:

0

V

t

5CO mV at sta::

a'

sweep,inoeasrqgto

I

1OV

2

SCO

mV

at

sweeo stop.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Output protectedto

-.

15

V

Inputs.

I

.2.5

Frequency

Sweep

Tie

SVEEP

OClT

3NC

IS

actwe w~th

2

Sweep Mode

se1ec:e3,

aq.2

1nzs:lve

2t

other rimes.

Sweep

Modes:

Co?:~r;wus

Swee~and,9eser (CRESet):

Cont~nuouslysweeps from programmed

start frequency to programmed stop fre-

quency, resets to start frequency and be-

gins

a

newsweep. Repeatscontinuouslyat

:ne soec~fiedsweep tlme.

Soni:,wous SweepandReverse(CREVerse):

Con:lnaously sweeps from start frequency

ta

stop freauency and back to start fre-

aJency. Repeatsconr~nuouslyat thespeci-

fied sweep ilme.

Triggered Sweep andReset(TRESet):

Programmed srart frequency is generated

continuously untilthe Model 1370receives

a

trlgger,whichwill initiateonesweeptothe

programmedstop frequencythenareset to

:he slart frequency.

Tvggeren' Sweep andReverse(TREVerse):

Programmed start frequency is generated

canrlnuouslyuntllatrlgger signal

IS

received,

ivh~cP,

will

rnjliateone sweep from the start

ireauencylothe stop frequency. The gen-

eraror immed~atelysweepsbacktothestart

freouency and holds for another trigger.

TiiggeredSweep andHold(HRESet):

Programmed start frequency is generated

cmtlnuouslyuntilatrigger signalisreceived,

lsnich will initiafeone sweep from the start

frequency to the stop frequency. Tne gen-

erator holds al the stop frequency until re-

ceipt ol

2

second trigger which ramps it

bacK to the start frequency, where

it

holds

iv

another trigger cycle.

Tr!g_oered Sweep and Hold

with

Reverse

(H8EVerse):

Picgrarnmed siar! frequency is generated

cor;hiuously untilatriggersignalisrece~ved.

v~hlchwill initiateone sweep from the start

irequency

to

the slop frequency. The gen-

eralor ?~oldsat the stop frequency until re-

motof a second trigger which sweeps it

back to the start frequency, where

it

holds

fa:

another trigger cycle,

i&mual

Sweep (ivlANual):

Outpu: frequency is programmed behveen

start and slop frequencies

Witr

:he

ald

3'

the SWEEP

OUT

voltage,usedfor3res,se!y

setting up sweep cha:acteristics.

Direction:

Sweepdirect~onis programmableelther upor dowo

in all modes.

Lln/Log:

Frequencysweep characteristic programmaoie for

elther llnear or logarithmic.

Time:

The durationof one swept transition between start1

stopfrequencies, programmed from 10msto 1COs

FlybackTime:

c1 ms.

Resolution:

A maximumof 4096 points per second (244 ps per

point).

Accuracy:

+0.2% for sweep time, +(2% of setting

+

2%

of

range)for startistop frequencies (see range defini-

tions in Table

1-7).

Range:

Maximum

calibrated range

IS

1CO:l ratlo of

startlstop

frequencies.

Wider rangeacceptedon a

single range(see Table 1-1)with a device speclf~c

error generated. Ratio of startistop values I~rnlted

only by lowest

practically

achievable value; excep:

for upper values

r

10

MHz,

then lower value limlted

to 22

MHz.

The greater of rhestart or stop frequen-

cies determines the selected range.

Trlgger Source:

May be from the external input, internal trrgger

source,the llLTRG' lines, the 'TRG command, or

the Word Serial Trigger command.

Trlgger Width:

Minimum of 0.5 ms for a sweep time 51s. For

sweep time >Is, minimum width is (.OCOS'sweep

time).

1.2.6

Inputs

VCG

In:

z

12V Into10

kR,

for upto 1200:l frequency change.

i

1OV givesthe 100C:l rangemaximum;

+

12Vgives

20%overrange.TheModel 1370usesnineinternally

selected frequency ranges (FR),where:

FR

=

102.

101,

...

.or 106Hz,perTable

1-1:

An internalvoltage (FRQ)between

1

and

12

volts

IS

used as the multiplier of FR to set the output fre-

quency.

If

the VCG input is used,

it

issummedwith

FRQ and the output frequency IS:

Frequency

=

(FRQ

+

VCG)

*

FR

Hz

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table

1-1.

Frequency

Ranges

Range Programmed

CW

or

1200:1

(FR)

I

upper sweep value

t

VCG

range

10.0kHz to 12 MHz

1

.OO

kHz to 1.20 MHz

100Hz to 120kHz

10.0Hz lo 12.0 kHz

1.00Hz to 7.20 kHz

100mHz to 120 Hz

10.0mHz lo 12.0 Hz

1.03mHz to 1.20Hz

100 uHz to 120 rnHz

+

r.:

~l

'

:.00 MHz to 12.0 MHz

i

!C'

1

103kHzto999kHz

,

n4

Id

a

10.0kHz to 99.9 kHz

!Iq.!ne:e

FRQ

and

VCG

are In volts.

A

sum of9.99 V

yves mzx~mumrange, and 12V gives 20%

overrange.

Slew Rate:

1

.O

V/p

1

Y

i

02

VCG

IN accuracy:

24%

1

.OO

kHz to 3.93 kHz

100 Hz ro 999 Hz

10.0Hz to 99.9Hz

1.30Hz to 9.99 Hz

1C3 nHz

to

999 mHz

Trlg In:

F~xeo

TL

compat~ble!rigger levelat 1.2 V. Trigger

is

?rograrnmabletoeithernegativeorpositiveslopes.

Inadd~t~on,anyoneof the eightTTLTRG'linesonthe

\/XI

backplane can beselected asthe trigger input.

I

tO.OmHilo99.9mHz

;dax;mum

Rafe:

12 MHz(24MHzfor Exter-

nal Width).

M~nirnum

Wdtn:

20 ns (except triggered

sweep modes).

Input Protection:

Inputs protected against s50V

1.2.7

Precision

Frequency

Resolution:

3-1/2digits.

Accuracy:

22%.

9ep

eafaSitiry:

*

1

%

for 24 hours.

Amplitude

Rssolutiont

3-112digitsor 2.5mV when

absfpeakamplitude

+

off-

set] >0.5V; 3-1/2 digits or

0.25 mV when abs[peak

amplitude

+

offsel] s0.5V.

Normal

sweep range

1CO

kHz

to

10.0 MHz

2.00MHz to 12.0MHz

10.0kHz

to

999 kHz

1

.C3 kHz to 99.9 kHz

100 Hz to 9.99 kHz

10.0Hz to 999 Hz

1.03Hz

lo

99.9Hz

100 mHz.to 9.99 Hz

10.0 mHz to 999 mHz

7

.OO

mHz

to

99.9mHz

Lowest

practlcal value

iO.0kHz

2.C3 UHz

1

.C3 kHz

100 Hz

10.0Hz

1

.OO

Hz

100mHz

10.0mHz

1

.OO

mHz

100 pH2

Accuracy:

*(2%

+

5mV) for 0.1 tc

1

Vpp(abs(peakamplitude

+

offset] s0.5Vj;

~(2%

+

20 mV) for 1

.O1

to 10Vp?.

*

40 mV for all other.

Repeatability

(24

HrsJ:*

(

1

%

+

1

0 mV).

Flatness:

k0.1 dB to lOOkHz,

s

1.5dBio12 MHz for out-

putat 5Vp-p. Referenceis

1

kHz.

Offset

Resolution:

3-1/2 digitsor 2.5 mVwnen

abslpeak ampliruae

+

off-

set] >OW; 3 112 digits or

0.25mV

when

abslpeak

amplitude

+

offset] 50.3..

Accuracy:

*40 mV in dc function.

Repeatability

(24 Hrs):

s(?

YO

+

20 mV).

I

.2.8

Waveform Quality

Sine Distort~on:

(5Vpp)TotalHarmonicDis-

tortion (THD) less

tran

05%,10 mHzto 99.9 kHz.

NoharmonicsaSove:

-40dBc, 100 kHz

tc!

999 kHz,-30 ~Bc,

1

MHzio

12MHz.

Time Symmetry:

=(I%

+

8ns).

Square Transition:

<I5ns

fcr

sSVpp.

<I

7

ns

for

>

5Vpp.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1.3

GENERAL

1.3.1

SCPl

Programming

,-

,-,ontor--s

ro

SCPl Version

1.0

and IEEE-4ee.2stan-

GZ~C

manoatec

commclds

Rc31

[eve!commancis

~vude

D1AGnostic MODE OUTPut

SOURce STATUS SYSTem

TRlGger

I

.3.2

VXI

Interface

hiessaaebased,

256

byteinputbuffer. Supponsthe

f,-,

.,,i,~mg

+.

,

subsets/prolocols:

A1

6

0

16

Master, A1

6

Dl

6

Slave;

VXI bus Instrument Protocol

(I);

VXI bus IEEE-488.2InstrumentProtocol

(14);

Event Generator, ResponseGenerator;

DC (DynamicConfiguration)Device,

t

3.3 Environmental

Temperalure Range:

25°C

+

10°C

tor

specifled

operation.

3~erating:

0°C to 50°C within toler-

ances rwice normal specl-

fications.

Srorage:

-40°C lo +71°C

(RH

not

controlled).

M'arm-up T~me:

20mrnutesforspecifiedop-

eration.

Altitude:

O~erating: Sea levei

!o

f3,SCS

f:

Storage: Sea level to 43.3CS

f!.

Rela!ive Humidity (non-condensing):

0°C to ilOaC: no1controlled.

+ll°C

to 40°C:

95i5-36

RH max.

+3l

"C to +40eC: 75t5%

RH

max.

+41°C to +50aC: 4555%

RH

max

Dimensions:

Single slot,

'C

size VXI

module. (30

x

260

x

353

mm).

Weigh!:

€1.6kg(3.5 ID).

1.3.5 Power

Tofa/:

<

24 Wans

Voltage

Peak

Current Dynarnlc Current

+24 Vdc 400 mA 150 mA

+5 Vdc 909 mA 109 mA

-2Vdc 50 mA 5 mA

-5.2 Vdc

50

mA

5

mA

-24Vdc 350 mA 100 mA

1.3.6 Rellablllty

>20,050 hours

MTBF

at 25"C, ground benign.

MIL-HDBK-217calculationat50%componentsrress.

1.3.7 Normal

Ume

Within

a

VXI mainframe

with

cooling air. Maximum

airflowrequirementfor10°C riseis0.06mm(.C925 in)

H,O

at 0.8 llsec

(1

-7CFM).

1.3.8 Safety

MIL-T-28800D,UL-1244,and

the

VXI SystemSpecl-

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PREPARATION

2.1 RECEIVING INSPECTION

Check the shipment at the time of delivery and

inspect each box for damage. Describe any box

damage and list any shortages on lire delivery

involce.

2.1.1

Unpacking

lnstructlons

Unpack the boxes.

Unpack the boxes in a

cleanand dry environment. Save all the pack-

Ing material In case the instrument must be

returnedfor repair.

Inspect the shlpment for damage.

Inspect

the equipment carefully for any signs of me-

chanicaldamageregardlessof theconditionof

the shipping boxes.

If necessary, flle a clalm,

In the case of

mechanicaldamage,call the snipper immedi-

ately and start the claim process

Call Wavetek.

Call Wavetek'sCustomer Ser-

vice representative

(6I9

279-2200) to inform

them that the shipment arrived damaged.

Pleasebe preparedto provideadetailed dam-

age repon.

Follow these steps when you return equioment to

Wavetek:

1.

Save the packlng matertal.

Always return

equipment in its original packing material and

boxes. If you use in-adequate material, you'll

:lave to pay to repairany shipping damage as

carrierswon'tpayclaimsonincorrectlypacked

equipmeni.

2.

CallWavetek CustomerServlce and ask for

a return authorlzatlon.

The Wavetek Cus-

tner Service representative

(619

279-2200)

wll

zsk

for your name.telephonenumber,com-

pany name, equipment type, model number,

serial number, and a description of the prob-

lem.

3.

Pack

and

shlp the

equipment,

2.2 PREPARATION FOR STORAOE OR

SHIPMENT

2.2.1 Packaglng

If at all possible, always use the original shipping

container. However,when using packing materials

olherthan !he original, usethe following guidelines:

1.

Wrap the Model 1370in ESDsensitive packing

material.

2. Use a double-walled cardboard shipping con-

tainer.

Protectall sides, includingthe top and bottom,with

shock absorbing material (minimum of

2

inch thick

material) to prevent movement of the Model 1370

within the container. Seal the shipping container

with approvedseatingtape. Mark "FRAGILE"onall

sides, top, and bottom of the shipping container.

2.2.2 Storage

The Model 1370 should be stored in a clean, ary

environment. In high humidity environments, pro-

tecttheModel

f

370fromtemperaturevariationsthat

could cause internal condensation. The tollowing

environmental conditions apply to both shippng

and storage;

Temperature

-40°C to +7iaC

Relative Humidity

not controlled,

non-condensing

Altitude

~40300

f!

(1

2192 m)

Vibrat~uion

<

29

Shock

c 40g

2.3 PREPARATION FOR USE

Paragraph 2.3 covers the following topics:

LogicalAddress Selection

DataTransfer Bus

Arbitration

Installation

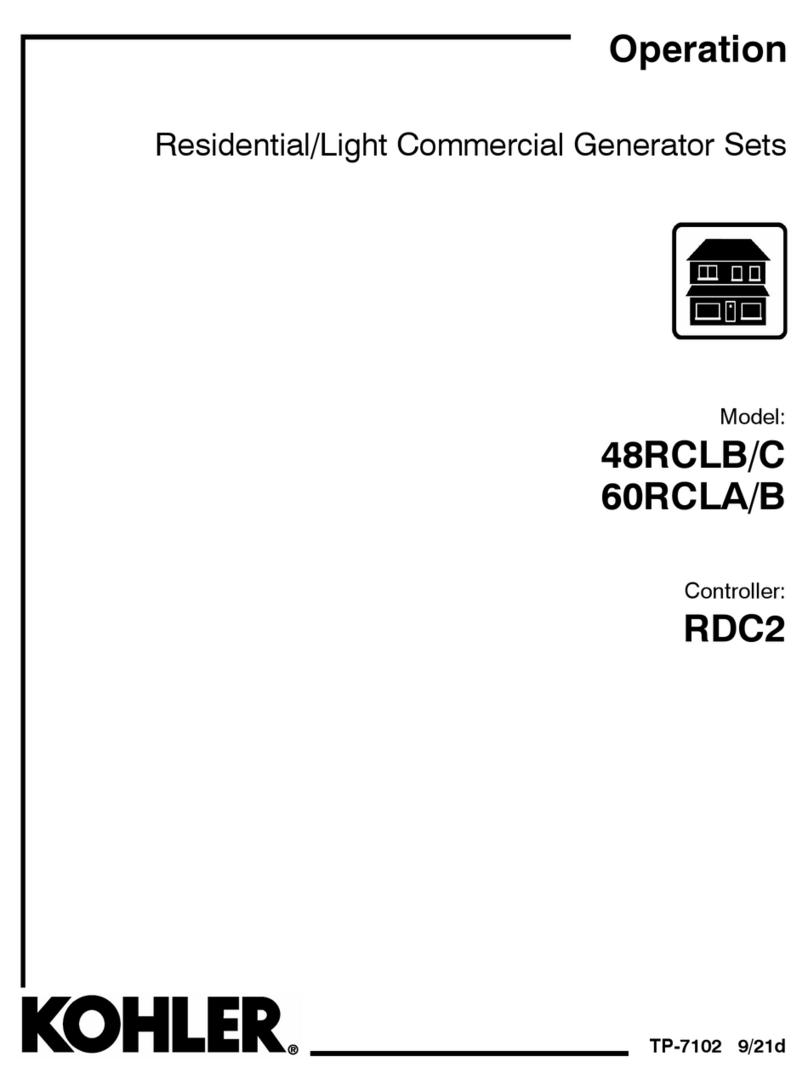

2.3.1 loglcalAddress Selection

The VXI chassis Resource Manager identifies units

inthe system by the unit's lcgicaladdress. The

VXI

logical address can range from 0 to

255

However,

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

aadresses 0 an0

255

are reserved for special func-

!ions. Address

0

identifies [heResourceManager.

Acaress

255

permits the Resocrrse Manager to

dynamically address the unit basedon the unitsVXI

chass~s

SIO:.

T3

change the Model 1370's logical address, use

!he

eight position DIPswltch (figure 2-1)accessible

fromthe side panel. The Model 1370 uses binary

values

(2'

to

Z7)

to

set the address usingtke actwe

low address switch. This means the OFF position

represents a log~cal1. Conversely,an ONposition

FeDresenrs

a

logical 0. Switch positionnumber one

IS

the least s~gnificantbit of the address, Insert

A

in

iiglrre

2-1

illustralesaswitch set loalogical address

of3

Vdavetek ships the Model 1370 with a logical ad-

dress of 255 for Dynamic Configuration, Refer to

msert

0

in figure

2-1.

2.3.2

Data Transfer Bur Arbltration

The Model 1370hasVMEbus Mastershipcapabil~ly

This means the SweepIFunction Generator, when

enabled,sendsResponsesandEventsas signalsro

i1sCommander. The Model 1370 cannot drive the

interrupt lines.

The Model 1370isconfiguredasa level

3

requestor

by the factory. The level 3 Bus Request and Bus

Grantlinesareused(BR3', BG31N', andBG30UTm).

The other Bus Grant lines are daisy-chained by

jumpers. TheVMEbusspecificationsdescribethree

priorityschemes:Prioritized,Round-robin,andSingle

level. The Prioritized arbitration assigns the bus

according to a fixed priority scheme where each of

four bus lines has a priority from highest (BR3') ro

lowest(BRO'). Round-robin arbitration assignsthe

bus ona rotatingbasis. Single levelarbitration only

accepts requests

on

BR3'.

ADDRESS

(

,

255

"----'

Flgure

2-1.

Set

the

LogicalAddre88

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

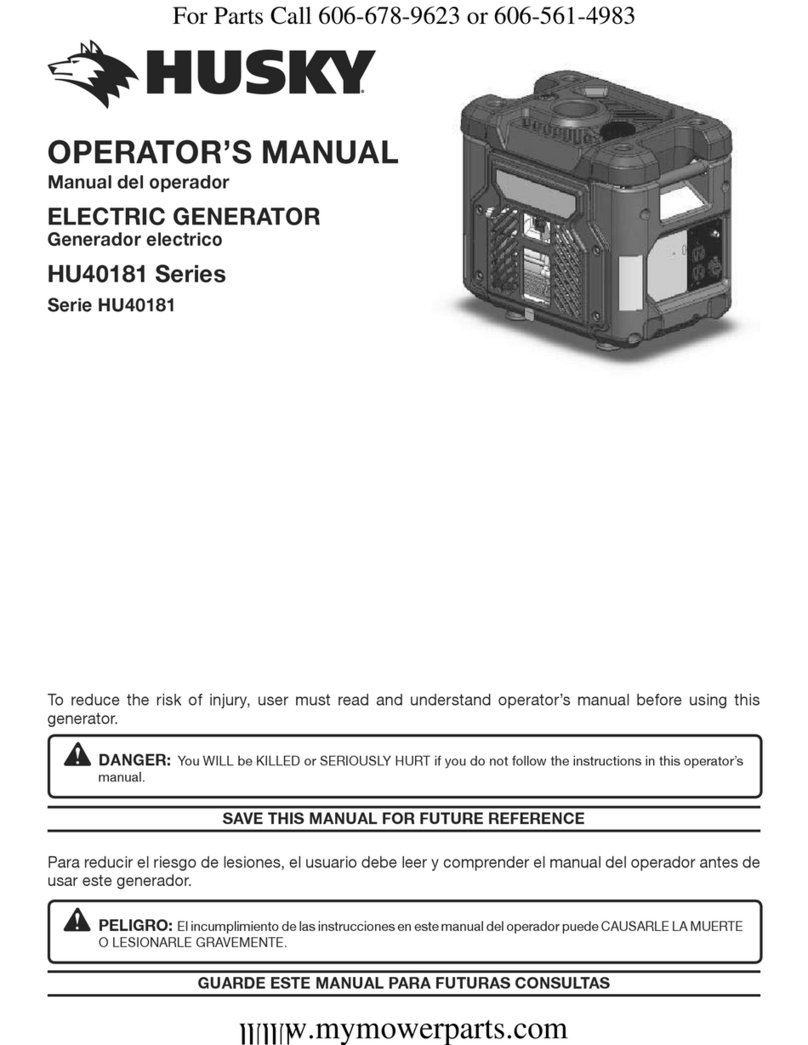

Flgure

2-2.

Bus

Arbitration

Level

Jumpers

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

I'

a

bltferenl

requeslor leveiis required,the jumpers

mus!

be

changed. The following instructions and

f,gure

2-2w1lla~d

ir,

recoifigurlngthe Model 1370to

a

new

ievel. Refer lo the VMEbus specification for

more

infornatiar on

'

daia

transfer

bus

arbitration'.

CAUTION

The Sweep/Functlon Generator

cont~ins

CMOS

devlceswhichare

sensltlve to statlc eiectrlclty,

Whenperforming thebusarbltra-

tlon level change,statlc electric-

ity dlscherge straps should be

worn.

Removethe four flat head screws onthe Model

1370 left s~depanel, remove the panel.

Remove the four pan head screws holdmg Ihe

VXI Interface card to the main Sweep/Function

Generator board

Slowly and gently

lilt

the VXI Interface card up

frorri

the FclnctionGenerator board. Cons~der-

aole force may 5e required as there are four

connecto:s between thetwo boards witn atotal

of

136 pins. Do not use a metallic prying tool.

Change the data transfer bus arbitration jump-

ers

lo

the desired level. Referto figure

2-2.

Carefully ~nstallthe VXI lnterfacecard onto the

Sv~eeplFunct~onGenerator board. Install the

four pan head screws, the slde panel and the

fo~:

flar leadscrews.

2.4

INSTALLATION

Tielnsrrumentwill beinstalled in

a

VXI mainframein

aty

slot except slot 0 (zero). When inserting the

~nstrunevmto the mainframe, it should be gently

rockedbackandforthtoseattheconnectors inlothe

backplanereceptacles. The ejectors will be

at

right

angles to the front panel when tne Instrument

IS

properly seatedintothe backplane. The two captlve

screws above and below the ejectors are used

ro

secure the instrument into the chassis.

2.5

INITIAL CHECKOUT AND

OPERATION VERIFICATION

This procedureprovidesthe operator,service teci-

nician,receivinginspector,etc,with aquickmethod

of verifying the functional operation of fhe Moae!

1370. This proceduredoesnot test theunit'sspecl-

fications. Connecttheequipmentas shownInf~gure

2-3 and perform the following procedure. This

procedure assumes the Model 1370 is properiy

installed ina

"C"

size VXI chassiswith aVXI control-

ler in slot 0.

PowerOn.

Withthe Model 1370installed inlne

chassisandthescopeconnected, poweronthe

VXI chassis:

Verify the

RUN

indicator is lit.

Verify the FAIL indicator is extinguished.

Verify the MODlD indicator flashes.

Default Settlnga.

Send the command:

OUT?:STAT

ON

Verify the scope displays a IkHz, 5Vpp sine

wave.

Frequency.

Change the frequency to

1CO

Hz

by sending the command:

FREQ

100

Verify the scope displays a 100 Hz. 5Vpo sine

wave. Change the frequency to

100

kHz

by

sending the command:

FREQ

1E5

Figure

2-3.

Teat Setup

MODEL

1370

OSCILLOSCOPE

-

-

0

TRIG

IN

a

'JCGlN

---8

swc

our

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Verliy the scope d~splays

a

1CO

kHz.5Vpp sine

wwe.

4,

Svfeep. Changeto tfiesweepmodebysending

the command:

zFLzz

:

!.tC:E

S:,,lz

Ver~fyrhe scope shows an outpur sine wave

startlng

at

999

Hz and linearly sweeping up to

9.99kHz In a 103ms tlme span. Verify SWEEP

OUT ~ydisplaying bothCHIandCH2. Change

the sweep tlme to 10 seccnds by sending the

command:

2:;:

:

::XE

10

Veriiy the scope shows an oulput sine wave

s:ar?lnga!

999

Hz

and linearly sweeping up to

9.99kHzina 10secondtime span. Changethe

st02 frequencyto 2kHz by sending:

25;

Ver~fythefrequency nowsweepsfrom 939 Hzto

2kHz

in

10 seconds. Change the start fre-

quency to 2CC Hz by sending the command:

FEZ2:STAR

20C

Verifythe frequency is now sweeping from 200

Hz to 2kHz in 10 seconds. Change the sweep

to dDwn by sending:

5:;~:

512

3~*,,y

Verify the frequency is sweeping from2kHz to

200 Hzin 10seconds. Change the sweep time

!o 1.0seconds by sending the command:

SYE:TIKZ

I

Verify the frequency

IS

sweeping from 2kHz to

203 Hz ~n

1

second. Change the spacmg from

linear t~ logarirhmicby sending:

Verifyan o~viouschange insweep characteris-

r~csmen switching to logarithmic sweep.

Change the mode back to cw by sending !he

cornmancl:

Verify

the output signal returns to 100 kHz. Se-

lect CHI scope display only.

5.

Functlon.

Change to the square waveform by

sending tne command:

Ver~fythe scope d~splaysa 100 kHz, 5Vpp

souare wave. Change to an inverted square

mveiorm5y sending the command:

Verify the scope displays a 100 kHz, 5Vpp

inverted square wave. Change to the triangle

waveform by sending:

Verify the scape displays a 103 kHz, SVpo

*

triangle wave.

6.

Amplitude. Change the amplitude to 2.5Vpp

by sending the command:

VOLT

2.5

Verify the scope displays a 100 kHz, 2.5 Vpp

triangle wave.

7.

Offset.

Off

setthewaveform

-

1.25Vdc bysend-

ingThe command:

Verify the scope displays a

100

kHz, 2.5

\/PO

triangle offset by

-1

-25Vdc.

8.

Trlgger.

Select the trigger mode by sending:

MODE

TRIG

Select rhe TRIG

IN

connector as the trigger

source by sending the command:

TRIG:SOUR EXT

Connect a

1

kHz,

lTL

trigger source

to

the

Model 1370 TRIG IN connector. Tie Model

1370'sdefault trigger setting is positive slope.

+

1,2Vlevel. Verify the scope displays asingle

cycleof a 100 kHz,2.5 Vpp trianglewaveotfse!

by -1.25 Vdc which repeats at 1ms intervals.

9,

Gate.

Select the gated mode by sending the

command:

KO9E

GAT

Verify the scopedisplays about50cycles of

1

C3

kHz,2.5 Vpp triangle waves offset by -1.25Vdc

which repeats at

1

ms intervals,

10. Burst. Select the burst mode by sending rne

command:

XODE

SURS

Change the burst count to 30 by sending the

command:

BURS

30

Verify the scope displays 30cycles ol

1

CO

kHz,

2.5 Vpp triangle waves offset by -1.25 \!dc

which repeats at

1

msintervals.

This completes the Model 1370's initral checkou?

and operation ver~ficationprocedure.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

OPERATION

3.1 INTRODUCTION

3.3.1

SCPI CommandTable

TnlssectionprovidestheOperator/Programmerwith

ine

information needed to operate the Model 1370

Sv:eep/Function GeneratorinaVXI system. The unit

resides ir: a \!XI chassis arld is subject to all of rhe

res:r~ciIonsand benefits o! that environment.

Pzragraph 3.2describes the Model 1370 connec-

;CKS

ardLED indicators. Paragraph3.3 defines the

Mcdel 1370 programming messages. Paragraph

3.4

demonstrates how to operate the Model 1370

,Jslng:he

defined

messages.

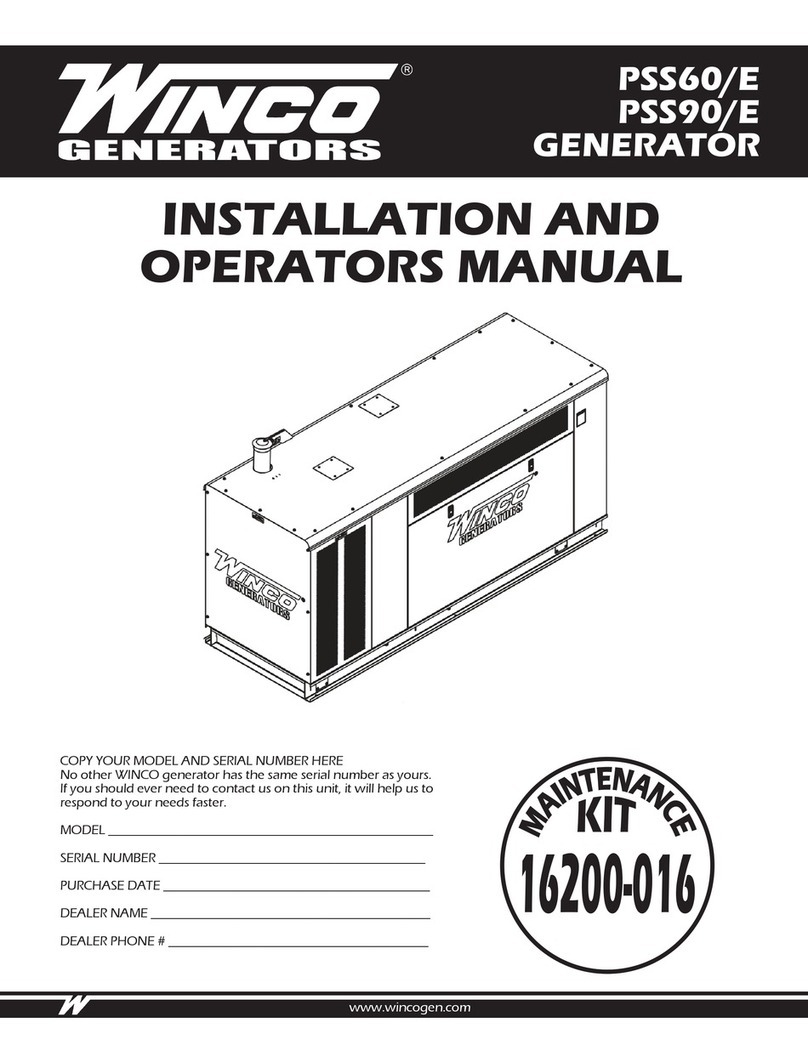

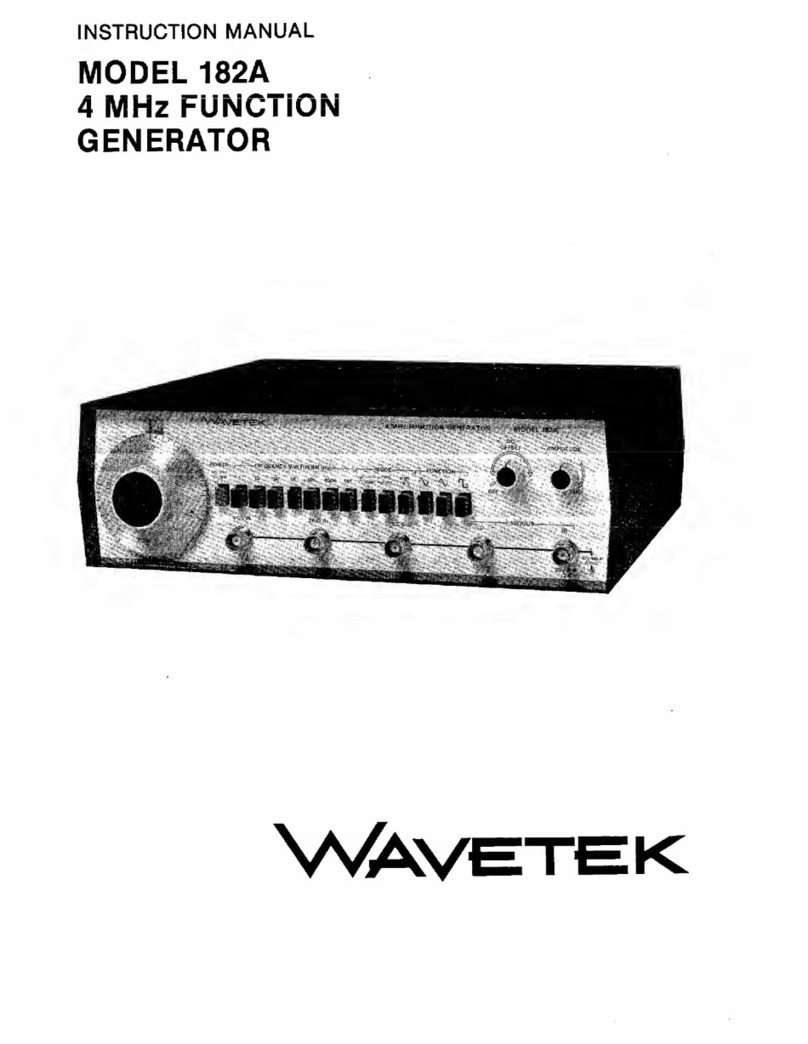

3.2 CONNECTORSAND LED INDICATORS

ih~sparagraph describes the Madel 1370 front

sanel connectors and LED ind~cators.Figure 3-1

!iius!ral?sthe front panel;nold numbers identifythe

1noicatc:s anc connectors. Table3-1describes the

'mctimoieach Item shown in figure 3-1.

3.3 MODEL

1370

PROGRAMMING

The Model 1370 ccmrnunicates within the SCPl

(STandard Commands for Programmable Instru-

ments) and IEEE 488.2 standards. Therefore,the

Lhdel 1370 must respond to two types of corn-

man&;

SCPl

commandsand IEEE 488.2Common

Commands. The IEEE 488.2 Common Commands

support

func:ions that are common to all instru-

rents

such

as reset, self tesr and status re?orting.

Common

Commands are non-heirarchical(can be

included

within

SCPI commands without disturbing

their

heirarchical selationships)andare easily icien-

ritied

Sy

their

leadingasterisk

(').

SCPl commands

Sl~Dpofifuncrionsthat arespecific to the instrument.

-

,

n:soarag:aph provibes the following information:

SCPl

Command Table

-

Paragraph3.3.1.

Comnand Message Format- Paragraph3.3.2.

;docel

i

370SCPlCommands

-

Paragraph3.3.3.

Se?'esl Q~eryResponse

-

Paragraph3.3.4.

Syslem

Trigger-Paragraph 3.3.5.

IEEE 488.2 Common Commands

-

Paragraph

2.2.e.

Table 3-2 lists the SCPl commands used in the

Model 1370andindicatestheir hierarchicalrelation-

ships. The IEEE 488.2 Common Commands are

listed in a separate table (Table 3-6). The SCPl

Command Table is organized as follows:

Keyword

:

SOURce

]

:FREQuency

[

:

CW]

:

XODE

START

STOP

Parameter Form

(numeric-value)

<lisr>

(numeric-value)

(numeric-value)

Notes

The indentationsof

keywords

indicates their hierar-

chicalrelationshipsaccordingto atreesystem. The

left-most edge is called the

roo! node.

Keywords

closer totherootnodeare higher inhierarchy:lower

nodes are to the right of their parent node. To

programor queryasettable parameter,the fullpatn

must be defined to reach the keyword appended

with the required parameter form.

A

SCPl program-

mlng string typically starts a[ the root node and

proceeds to the right through branch nodes fc the

leal

node.

This string of keywords separate0 by

colons and completely defining a single path is

defined as a Program Header, and is commonly

referredtoasa'command' (seeparagraph3.3.2)or

as a 'query' (see paragraph 3.3.2.6).

A

Pragram

Header followed by Program Data is defined as a

Program Message Unit (paragraph 3.3.2.1

).

In the example above the left-most keyword.

:SOiiRcej,

is directly off the root node. Nodes in

this posltion are called

Subsystems,

and all Key-

words indented under

;SOURce]

are part of the

Source Subsystem.

?REQuer,cy

IS one of themain

parametersundertheSourceSubsystem. Theth~ro

level keywords under FREQuencyset or query the

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

i-

Fundion

Generator

RUN

FAIL

7

TRIG

IN

VCG

IN

SYNC

OUT

SWEEP

OUT

FUNC

OUT

mode!

1370

Flgure

3-1.

Model

1370

Front

Panel

3-2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Table of contents

Other Wavetek Portable Generator manuals

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 1001A User manual

Wavetek

Wavetek 188 User manual

Wavetek

Wavetek 1001A User manual

Wavetek

Wavetek 188 User manual

Wavetek

Wavetek 150 User manual

Wavetek

Wavetek 132 User manual

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 148A User manual

Wavetek

Wavetek 180 User manual