Wavetek 132 User manual

MODEL 132

VCG/NOISE

GENERATOR

-

1981

-

Wavetek

THIS DOCUMENT CONTAINS INFORMATION PROPRIETARY TO

WAVETEK AND IS SOLELY FOR INSTRUMENT OPERATION AND

MAINTENANCE. THE INFORMATION IN THIS DOCUMENT MAY

NOT BE DUPLICATED IN ANY MANNER WITHOUT THE PRIOR

APPROVAL IN WRITING OF WAVETEK.

SAN DIEGO

9045 Balboa Ave., San Diego, CA 92123

P. 0 Box 651,

San

Diego, Calif. 92112

Tel 7141279-2200 TWX 91 O-335-2007

Manual Revision: 10181

Instrument Release: U-l 0180

Section One

CONTENTS

SPECIFICATIONS

Section Two OPERATION

Section Three CIRCUIT DESCRIPTION

General Description

11

Section Four MAINTENANCE

Section Five DATA PACKAGE

Physical and Electrical Specifications

..............

1

Inspection

......................

Operating Controls

....................

Operation

......................

Introduction

......................

13

Recommended Test Equipment

...............

13

Checkout and Calibration

.................

13

Troubleshooting

....................

16

SCOPE OF MANUAL SCOPE OF EQUIPMENT

Introduction

.....................

21

Recommended Spare Parts List

...............

21

This manual contains instructions for operating, test- The Model 132 is a source of analog and digital

noise,

ing, and maintaining the Wavetek Model 132

VCG/

as well as a precision source of sine, triangle and

square

Noise Generator. The Wavetek product-improvement waveforms. Noise outputs, or waveforms can

be used

program ensures that the latest electronic developments individually, or combined to provide selectable, cali-

are incorporated into the Wavetek instruments by the brated signal-to-noise and noise-to-signal ratios to

addition of circuit and component changes as rapidly

+60

dB. Waveforms can be varied over a frequency

as development and testing permit. Due to the time re- range of 0.2 Hz to 2 MHz. Length of the digital se-

quired to document and print this manual, it is not quence is selectable to a maximum of

-

1 bits.

always possible to incorporate these changes into the Clock rates, variable from 160 Hz through 1.6 MHz,

manual. In this case, data will be found on engineering give added versatility to the noise generator. These

change sheets at the back of the manual. If there are no clock rates allow selectable noise bandwidths variable

change sheets, the manual is correct as printed. from 10 Hz to 100

3

4

7

SAFETY

Thi s

instrument i s

wire dfor earth g rounding via the ty powe r

wiring.

ss earth grou n

ding w

ith two wir eextension cords,

plug adapter setc.

BEFORE PLUGGING IN the instrument, comply with installation instructions.

MAINT ENANCE

may requir epower on w ith th e

instrumen t

cover sremoved.

shoul d

be don e

only by qualif

ied

personne lawar e of the elect ha

zards.

WARNING

operations.

Do not

notes call attention t o

possible injury or death hazards i n

subsequent

CAUTION notes call attention to possible equipment damage in subsequent operations.

VERSATILITY HORIZONTAL PRECISION

Waveforms

Sine

,

square

,

triangle waveforms

and analog noise

,

or

digital noise l-u--L

Frequency Range of Signal

0.2 Hz to 2 MHz in 6 decade ranges

Ranges

x10

Xl00

X1K

X10K

XIOOK

X1M

0.2 Hz to 20 Hz

2 Hz to 200 Hz

20 Hz to 2 kHz

200 Hz to 20 kHz

2 kHz to 200 kHz

20 kHz to 2 MHz

Function Outputs

Sine

,

square

,

and triangle selectable,

with 60

dB

step attenuator in 10

dB

steps and over-

lapping calibrated vernier;

5Oa

output impedance,

20 V p-p into open circuit and 10 V p-p into

load from source impedance.

Sync Output

Greater than 1 V p-p square wave into open circuit at

output impedance.

DC Offset

V offset V offset into load) controlled

from rear panel; peak amplitude limited by the dynam-

ic range of the amplifier output.

VCG

-

Voltage Controlled Generator

Frequency of the generator may be dc-programmed,

or ac-modulated by external 0 to V signal. Voltage

control circuitry is capable of 1000: 1 deviation. The

VCG amplifier has a 100 k H z bandwidth and a slew

rate of 0.1 The instantaneous frequency is the

result of the sum of the dial setting and the externally

applied voltage.

Stability

Short term for 10 minutes

Long term for 24 hours

Percentages apply to amplitude, frequency, and dc

offset.

SECTIO N

1

SPECIFICATIONS

Dial Accuracy

of full scale, 1 Hz to 2 MHz

Frequency Vernier

One

turn equals 1% of full scale.

Time Symmetry

% through XIOOK range

VERTICAL PRECISION

Sine Wave Frequency Response

Amplitude change with frequency less than:

0.1

dB

from 0.2 Hz to 200 k H z

0.5

dB

from 0.2 Hz to 2 MHz

PURITY

Sine Wave Distortion

Less than:

0.5% on X10, X100,

X1K,

X10K

ranges

1.0% on XIOOK range

All harmonics 30

dB

down on Xl MHz range

Square Wave Rise and Fall Time

Less than 50 ns terminated into

NOISE

outputs

Pseudo-random analog or digital noise with a maximum

of 20 V p-p excursion (open circuit) with 60

dB

step

attenuator in 10

dB steps and overlapping calibrated

vernier.

Sequence Lengths

Push buttons on the front panel provide a sequence

length of

-

1,

-

1, or

-

1.

1

ENVIRONMENTAL

Noise C

lock

Frequency

Switch selectable noise frequencies are listed

Clock Frequency

160 Hz

1.6 kHz

16 kHz

160 kHz

1.6 MHz

Analog Noise

Bandwidth

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

OPERATIONAL MODES

FUNC Function Mode

-

Provides the selected

form at the main output.

S/N Signal-to-Noise operation adds noise to a selected

signal of constant amplitude. The signal-to-noise ratio

is variable from 0 to

+60

dB.

N/S Noise-to-Signal operation adds a selected signal

to a constant amplitude noise. The noise-to-signal ratio

is variable from 0to

+60

dB.

FM Frequency Modulation

-

Provides random modu-

lation of the frequency of the generator. The S/N

-

N/S

(dB)

ratio control also controls the amount of fre-

quency deviation.

NOTE

When noise is added to the signal output,

specifications apply up to 200

kHz

and

the square wave rise time is dera ted by

a factor of 10. In the clock range of

1.6 MHz, the maximum calibrated

signal-

to-noise ratio is 30

dB

Temperature

All specifications listed, except stability, are for

For operation from

O°C

to derate all

specifications by factor of 2.

MECHANICAL

Dimensions

inches wide, inches high, inches deep

Weight

8 Ibs net, 12 Ibs shipping

Power

105 V to 125 V

or

200 V

to

250

V,

50 Hz

to

400 Hz.

Less than 15 watts.

NOTE

All

specifications apply for frequencies

obtained when dial is between 0.

1

and

2.0 and at V p-p in to a 50 ohm load.

It is possible to stop the generator from

oscillating by applying a negative VCG

voltage when the dial is already set at

minimum frequency. VCG inputs up to

30 V will not permanently damage the

ins trumen t.

SECTION

OPERATION

INSPECTION

The following procedures should be performed to as-

sure the user that the instrument has arrived at its

destination in satisfactory operating condition. Com-

plete calibration and checkout instructions are pro-

vided in Section 4 to determine compliance with elec-

trical specifications.

Checking Visually

7.

After carefully unpacking the instrument, visually in-

spect the external parts for damage to knobs, dials,

indicators, surface areas, etc. If damage is discovered,

file a claim with the carrier who transported the in-

strument. Retain the shipping container and packing

material for use in case reshipment is required.

Checking Electrically

NOTE

lnstrumen ts are normally shipped con-

nected for 115 V power unless 230 V

power is ordered. Refer to the end of

this section for conversion instructions.

The steps in this paragraph provide a quick checkout

of the instrument operation. If electrical deficiencies

exist, refer to the WARRANTY in the front of this

manual. The following test equipment is recommended

for performing this electrical inspection:

Name Required

Characteristics

Oscilloscope

Plug-l n

Plug-l

n

Counter-Timer

To 30 MHz

Dual channel

Peak mV measuring

capability

To 2 MHz with 5-digit

resolution

1.

Turn

FREQ

HZ selector to the Xl K position.

(This connects ac power to the unit and estab-

lishes the frequency multiplier.)

2.

3.

4.

5.

6.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Depress MODE

-

FUNC push button.

Connect oscilloscope to the OUT connec-

tor with a terminator.

Set frequency dial to the 1.0 mark and

FREQ

VERNIER to CAL position.

Set function selector to the position.

Set OUTPUT

ATTEN

(dB) and OUTPUT VER-

NIER

(dB)

to maximum clockwise

(cw)

posi-

tion (no attenuation).

Check for 1 kHz sine wave with at least 10 V

p-p amplitude on oscilloscope.

Select and with function selector

and check for 10 V p-p amplitude on oscil-

loscope.

Turn frequency dial from maximum counter-

clockwise (ccw) to maximum cw position and

check for frequency change.

Step OUTPUT

ATTEN

(dB)

selector through

its range and verify attenuation at each step.

Rotate OUTPUT VERNIER

(dB)

control from

maximum cw to maximum ccw position and

check for decreasing amplitude.

Rotate

FREQ

VERNIER control and check for

frequency change.

Set FREQ VERNIER control at maximum cw

and frequency dial at 0.02. Set frequency to

20 Hz with counter. Connect a 0 to +5 Vdc

input to the VCG IN connector. Slowly increase

voltage input from 0 to +5 V and check that

frequency of output waveform increases from

approximately 20 Hz to 2 kHz.

Depress SEQUENCE LENGTH

-

1

push

button.

Set NOISE FREQ HZ selector to the

16K/160K

position and vernier control fully cw.

Connect a BNC cable from the NOISE SYNC

connector (rear panel) to the external trigger

input of the oscilloscope.

Rotate the function selector to and check

to assure oscilloscope displays digital noise.

Check to assure SEQUENCE LENGTH push

buttons vary the bits in the sequence length.

Step NOISE FREQ HZ selector through its

range and check to assure clock frequency

changes. (Use NOISE CLOCK connector on rear

panel.)

3

20.

21.

22.

23.

24.

25.

26.

27.

28.

Verify that NOISE FREQ HZ vernier control

provides approximately IO: 1 variation in clock

frequency at the NOISE CLOCK connector

(rear panel).

Rotate function selector to position and

check to assure oscilloscope displays analog

noise.

Check to assure SEQUENCE LENGTH push

buttons vary the length of the sequence of

analog noise. (Use NOISE SYNC connector on

rear panel.)

Connect oscilloscope external trigger cable to

FUNCTION SYNC connector (rear panel) and

set function selector to position.

Set S/N

-

N/S

(dB)

selector to -10 position

and vernier control fully ccw.

Depress MODE

-

FM push button and check

to assure square waveforms are frequency modu-

lated by analog noise.

Release MODE

-

FM push button and depress

MODE

-

S/N push button. Check to assure

square wave and analog noise are mixed.

Depress MODE

-

N/S push button and rotate

S/N

-

N/S

(dB)

selector ccw through each

position, checking for reduction in signal level.

Verify that the S/N

-

N/S

(dB)

vernier attenu-

ates the signal approximately 10

dB

between

each step of the S/N

-

N/S (dB) selector.

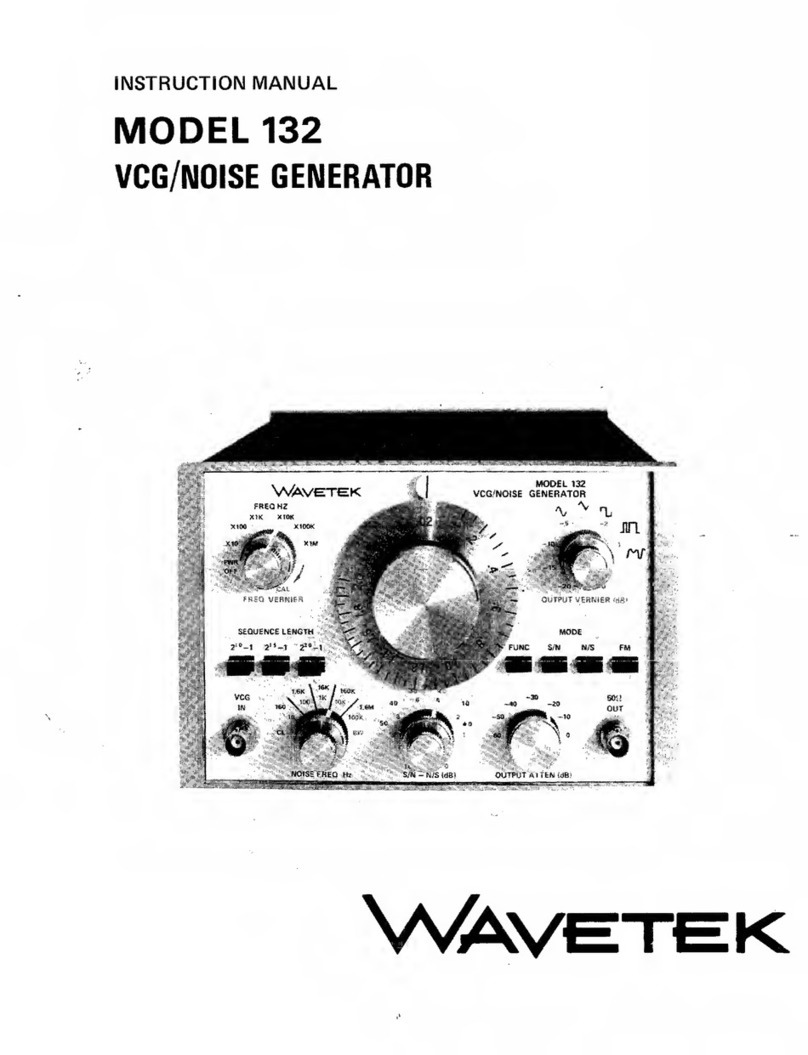

OPERATING CONTROLS

The operating controls and electrical connections for

the Model 132 are shown in Figures

2-I

and 2-2. Each

of the following paragraph numbers corresponds to a

number appearing in Figure 2-1, front panel, or

Figure 2-2, rear panel. The listing below discusses each

control and its function.

FRONT PANEL

1.

FREQ HZ/PWR OFF

-

Selects one of six dec-

ade ranges from X 10 to

X1M

for generator

frequency. This value multiplied by the fre-

quency dial setting (3) gives the output frequen-

cy of the generator. Extreme ccw rotation will

place the switch in the PWR OFF position, turn-

ing off all power to the function and noise

generators. This control has no affect on the

noise frequency.

2.

FREQ VERNIER

-

Allows precision electronic

control of the signal output frequency. A full

turn of the control is approximately equal to 1%

4

MODE

of full scale. When turned to the full cw position

(CAL), settings on the main dial will be cali-

brated.

Frequency Dial

-

Allows coarse control of the

signal output frequency.

Frequency Index

-

Indicates the frequency dial

setting (3) by reading the dial position opposite

the scribe line on the frequency index. The in-

dex is illuminated when power to the unit is on.

Function Selector

-

Selects the desired function

or noise output. To select

,

,

or

waveforms, or or noise, the FUNC

push button (7) must be depressed.

OUTPUT VERNIER (dB)

-

Provides vernier

control of 0 through -20

dB

from the OUTPUT

ATTEN

(dB)

setting (12). This is the fine ad-

justment for the output signal and will attenuate

signal and noise.

FUNC

-

When depressed, this control allows

the selected waveform or noise, as determined

by the position of the function selector (5), to

be present at the OUT connector (11).

This push button must also be in the depressed

position for the frequency modulation mode

(10).

S/N

-

Depressing this push button allows a

calibrated amount of analog noise to be added

to the selected signal, either

,

,

or

wave. The signal-to-noise ratio (S/N) is

determined by the S/N

-

N/S (dB) attenuator

control (13). When in this mode, the peak to

peak signal amplitude is reduced internally, since

adding noise to the signal would overdrive the

output amplifier.

N/S

-

Depressing this push button allows a

calibrated amount of the selected signal, either

i

,

or

wave, to be added to the

analog noise. The noise-to-signal ratio (N/S) is

determined by the S/N

-

N/S attenuator

control (13). When in this mode, the peak to

peak signal amplitude is reduced internally, since

adding the signal to the noise would overdrive

the output amplifier.

132

GENERATOR

Figure 2-l. Operating Controls, Front Panel

10.

11.

12.

FM

-

Depressing this push button along with

the FUNC push button (7) allows the selected

signal, either A

, ,

or wave, to be

pseudo-randomly frequency modulated, or jit-

tered. The modulating signal is provided by

pseudo-random analog noise, and the S/N

-

N/S

(dB)

controls frequency deviation. The

bandwidth of the modulating signal is controlled

by the NOISE

FREQ

HZ selector (15) and

vernier (16).

OUT

-

Provides the selected generator out-

put function. The generator may operate into an

open circuit providing 20 V peak to peak maxi-

mum, or into a load providing a

10

V peak

to peak output.

OUTPUT

ATTEN

(dB)

-

Attenuates the output

(both signal and noise) from 0

dB

to -60

dB

in

six calibrated 10

dB

steps according to the fol-

lowing table:

Step

Attenuator

Position

Output peak to peak into Load

Maximum Minimum

Vernier Vernier*

fully cw

0

dB

10V

IV

-10

dB

3V 0.3 v

-20

dB

I V 0.1 v

-30

dB

0.3 v 0.03 v

-40

dB

0.1 v 0.01 v

-50

dB

0.03 v 0.003 v

-60

dB

0.01 v 0.001 v

* The values in this table are approximate. The OUT-

PUT VERNIER

(dB)

(6) will reduce the output

approximately 20

dB

in all cases, as shown.

13.

S/N

-

N/S (dB)

-

I n

the S/N

mode, this control

attenuatesthe analog noise from

0 to

-50

dB

in

five calibrated 10

dB

steps. The selectable signal

5

14.

15.

16.

17.

amplitude remains constant, thus giving cali-

brated 0 to -50

dB

signal-to-noise ratios. In the

N/S

mode, the signal is attenuated with the

noise remaining unchanged, thus giving

noise-

to-signal ratios from 0 to -50

dB.

The steps for

this control are indicated in black numerals

on

the front panel.

S/N

-

N/S (dB) Vernier

-

Allows a calibrated

fine adjustment of the S/N

-

N/S

(dB)

step at-

tenuator (13). This control is continuously vari-

able over at least a 10

dB

range. When added to

the coarse control

(13),

this amount equals the

total S/N or N/S ratio. Approximate values of

attenuation are indicated in red numerals on the

front panel.

NOISE FREQ HZ

-

This range control selects

the clock frequency, or bandwidth for the digi-

tal, or analog noise, respectively. When using the

digital noise function, clock frequencies from

160 Hz through 1.6 MHz (indicated in black

numerals and letters on the front panel) are

available. When using analog noise or the S/N,

N/S modes, the bandwidth of the analog noise

may be selected from 10 Hz to 100 kHz (in-

dicated in red numerals and letters on the front

panel). In the FM mode, this control establishes

the bandwidth of the analog noise used for fre-

quency modulation. There are four detent posi-

tions with an overlapping vernier control (16).

With the vernier in the full cw position, the

clock frequency, or bandwidth, is equal to the

value printed to the right of the detent mark.

NOISE FREQ HZ Vernier

-

As mentioned in

number 15, this control provides a continuous,

fine control between the detent positions of

thecoarse control. When in the full cw position,

the clock frequency, or bandwidth, is equal to

the value appearing at the right of the detent

mark. As the knob is rotated ccw, the clock

frequency, or bandwidth, is decreased. In the

full ccw position, the actual value will be at

least 10: 1 (and as much as 100:

1)

lower than

the value to the right of the detent mark.

VCG IN

-

This connector

allows

external volt-

age control of function generator frequency. Up

to

1000:1

frequency change may be obtained.

A positive voltage increases frequency and a

negative voltage decreases frequency. Refer to

“Operation as a Voltage Controlled Generator.”

18.

19.

20.

SEQUENCE LENGTH

-

1

-

Depressing this push button will

provide 1,023 counts of the selected clock fre-

quency, or bandwidth, determined by the

NOISE

FREQ

HZ controls (15 and

16),

for

generation of a digital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

-

1

-

Depressing this push button will

provide 32,767 counts of the selected clock

frequency, or bandwidth, determined by the

NOISE

FREQ

HZ controls (15 and 16), for

generation of a digital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

-

1

-

Depressing this push button will

provide

1,048,575

counts of the selected clock

frequency, or bandwidth, determined by the

NOISE FREQ HZ controls (15 and

16),

for

generation of a digital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

REAR PANEL

21.

22.

23.

24.

DC OFFSET

-

This control adjusts the V

base line above or below ground V offset

into load). The OFF position gives normal

vertical symmetry. Peak amplitude is limited by

the dynamic range of the amplifier output.

FUNCTION SYNC

-

This connector provides a

synchronizing signal output at the same fre-

quency of the main generator; that is, at the

same frequency as the sine, triangle or square

wave. The amplitude is greater than 1 V peak to

peak square wave into open circuit at

output impedance.

NOISE SYNC

-

This connector provides a syn-

chronizing output signal for monitoring the dig-

ital or analog noise. A sync signal is generated at

the beginning of each repetitive cycle for the

selected sequence length of digital or analog

noise.

_

NOISE CLOCK This connector provides an

external output of the basic clock frequency

used to generate the digital sequence and analog

noise.

SAN

PAT. NO X268.738

OTHER

PAT AMP

Figure 2-2. Operating Controls, Rear Panel

OPERATION Operation as a Voltage Controiled Generator

No preparation for operation is required beyond com-

pletion of the initial installation previously stated in

this section. It is recommended that a one-half hour

warm-up period be allowed for the associated equip-

ment to reach a stabilized operating temperature and

for the Model 132 to attain stated accuracies.

The VCG input connector can be used to externally

control the frequency of the generator. If a positive

voltage is applied to the VCG input terminal, the

frequency will increase from the dial setting, A nega-

tive voltage will cause the frequency to decrease from

the dial setting. The VCG range of the Model 132 is

1000:1.

Operation as a Function Generator

1.

2.

Terminate OUT connector with

2 watt termination.

Select the desired waveform by setting function

1.

2.

3.

4.

5.

Terminate OUT connector with 50 ohm

2 watt termination.

Select the desired waveform by setting function

selector to

, ,

or

.

Set FREQ HZ selector to desired multiplier.

Connect external voltage source (dc program-

ming or wideband ac signal) to VCG IN con-

nector.

selector to

, ,

or

,

Set frequency dial and FREQ HZ range multi-

plier for desired output frequency.

Depress MODE

-

FUNC push button.

Select output signal amplitude by setting OUT-

PUT

ATTEN

(dB)

control to appropriate attenu-

ation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER

(dB)

control.

A positive or negative dc offset may be applied

to the waveform by setting the DC OFFSET

(Rear Panel) to the desired level. The peak

signal value plus the offset cannot exceed V

into 50 ohms.

NOTE

VCG input requires 0 to volts for

operation over full-scale range, but can

withstand many times maximum input.

Set frequency dial as follows:

a.

For frequency modulation with ac input, set

dial for center frequency.

7

6.

b. For increasing frequency sweep with positive

dc input, set dial to lower frequency limit.

c. For decreasing frequency sweep with nega-

tive dc input, set dial to upper frequency

limit.

To sweep the audio range from 20 Hz to 20 kHz,

set the controls to 20 Hz as follows:

a. Set the main dial to 0.02.

b. Set the frequency vernier to the full ccw

position.

c. Introduce a 0 to +5 V ramp into the VCG

inputconnector.

The maximum frequency which may be obtained, when

using the VCG input, is the range multiplier times the

value at the top of the dial (2.0). The minimum fre-

quency is the range multiplier times the value at the

bottom of the dial (0.002

-

frequency vernier must

be in ccw position). Verify this using the nomograph

in Figure 2-3.

MAIN DIAL VCG IN OUT

SETTING VOLTAGE FREQUENCY

.02

.2

.4

.6

.8

1.6

1.8

2.0

A

B

C

Figure 2-3

-

VCG Voltage-to-Frequency Nomograph

In example 1, the dial is set at 1.0 and 0 voltage is

applied to the VCG input. Extend a straight line from

1.0 (dial setting) through 0 voltage (VCG voltage) and

obtain a dial frequency of 1.0. For the total output

frequency, multiply the range by 1 with the same dial

setting. Example 2 shows the results of using a ramp

from -1 volt to

+2.5

volts for the VCG voltage. This

results in a swept output from 0.6 to 2.0 on the dial.

Remember to multiply the dial times the range.

Operation as a Calibrated Signal-to-Noise Source

1.

Select the desired signal waveform by setting

function selector to

,

,

or

.

2.

Set frequency dial and FREQ HZ range multi-

plier for desired signal output frequency.

3.

Depress MODE

-

S/N push button.

4.

Select noise bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

bandwidth by turning the noise frequency Hz

vernier control.

5.

Select desired SEQUENCE LENGTH by de-

pressing appropriate push button.

6.

Select signal-to-noise ratio by setting S/N

-

N/S

(dB) control to appropriate attenuation position

and fine adjusting attenuation to desired value

with S/N

-

N/S vernier control.

7.

Select total output amplitude by setting OUT-

PUT

ATTEN

(dB)

control to appropriate atten-

uation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER (dB)

control.

Operation as a Calibrated Noise-to-Signal Source

1.

2.

3.

4.

5.

6.

7.

Select the desired signal waveform by setting

function selector to

,

,

or

,

Set frequency dial and FREQ HZ range multi-

plier for desired signal output frequency.

Depress MODE

-

N/S push button.

Select noise bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

bandwidth by turning the noise frequency Hz

vernier control.

Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

Select noise-to-signal ratio by setting S/N

-

N/S

(dB) control to appropriate attenuation position

and fine adjusting attenuation to desired value

with S/N

-

N/S vernier control.

Select total output amplitude by setting OUT-

PUT

ATTEN

(dB) control to appropriate atten-

uation position and fine adjusting signal to

de-

sired amplitude with OUTPUT VERNIER (dB)

control.

Operation as a Random FM Source

Before using the generator as a random FM source,

please note the following.

The frequency of the generator is being varied or

modulated by a changing voltage in the same way as

described in “Operation as a Voltage Controlled Gen-

erator.” However, instead of using a dc ramp, or ac

signal, a random analog voltage is used. When the FM

push button is depressed, the analog noise is injected

internally into the VCG circuit; therefore, the modu-

lation is created by random noise. The S/N

-

N/S

(dB)

knob controls the maximum amount of frequency

deviation, since it controls the amplitude of the noise.

Bandwidth of the FM signal is controlled by the

NOISE FREQ HZ control. Using the generator in the

FM mode may be accomplished as follows:

1.

2.

3.

4.

5.

6.

7.

Select the desired signal waveform by setting

function selector to

, ,

or

.

Set frequency dial and FREQ HZ range multi-

plier for desired center output frequency.

Depress MODE

-

FUNC and FM push buttons.

Select the bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

frequency by turning the noise frequency Hz

vernier control.

Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

Select signal frequency deviation by setting

S/N

-

N/S

(dB)

control to appropriate attenua-

tion position and fine adjusting attenuation to

desired deviation with S/N

-

N/S vernier control.

Select output signal amplitude by setting OUT-

PUT

ATTEN

(dB) control to appropriate atten-

uation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER

(dB)

control.

Operation as a Digital or Analog Noise Source Figure 2-2. Common Ground Connection Diagram

1.

2.

3.

Set function selector to digital or analog noise

position.

Depress MODE

-

FUNC push button.

Select clock frequency for digital or bandwidth

for analog noise by setting NOISE FREQ HZ

control to desired range and fine adjusting fre-

quency by turning the noise frequency Hz ver-

nier control.

4.

5.

Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

Select noise amplitude by setting OUTPUT

ATTEN

(dB) control to appropriate attenuation

position and fine adjusting noise to desired

amplitude with OUTPUT VERNIER (dB) con-

trol.

Connect Signal and Chassis Grounds

The instrument is shipped from the factory with the

signal ground floating above chassis ground, unless

otherwise specified. A common signal/chassis ground

can be obtained as follows:

1.

2.

3.

Remove power cord.

Loosen two captive thumb screws on rear panel

and remove panel.

Solder a jumper wire between the ground lugs

(green wires) of the SYNC OUT connector and

the power connector (Figure 2-4).

ADD

JUMPER

POWER

CONNECTOR

J1

BRACKET

POWER SYNC

DC

OFFSET

TRANSFORMER OUT

R

172/SW4

T1

CONNECTOR J3

Converting Output Impedance to 600 Ohms

Unlessotherwise specified, this instrument was shipped

with 50 ohm output impedance, but can be converted

to 600 ohm output if needed. Place a resistor

in series with the wire leading from the center tap of

the OUT BNC and the attenuator control.

9

Converting to Line Power

instruments are shipped from the factory with the

power transformer connected for

1

15-volt

line power,

unless ordered for 230-volt use. Converting a 115-volt

unit for 230-volt operation is a simple matter.

2.

Loosen two captive thumb screws on rear panel

and remove panel.

1.

Remove power cord.

3.

4.

The conversion switch is located on the chassis.

Use a thin-bladed screwdriver to move the 115-

230 switch to the 230 position.

Replace

1/4-ampere

fuse with a

1/8-ampere

fuse

of the same type.

SECTION

3

CIRCUIT DESCRIPTION

GENERAL DESCRIPTION

Refer to the block diagram of the Model 132

VCG/

Noise Generator, Figure 3-l.

Basically, a square wave is applied to the input of an

integrator composed of a wide-band differential dc

amplifier, integrating resistor and capacitor. Output

of the integrator is fed into the hysteresis switch.

The hysteresis and output switches function like a

Schmitt trigger with the limit points set at the

wave-

form extremes, firing when the triangle wave reaches

+1.25

volts and -1.25 volts. When firing occurs, the

hysteresis and output switches are set, reversing the

square wave fed into the integrator. Reversal of the

square wave causes the triangle wave to reverse direc-

VCG

VCG

Cl RCUIT

+5

v

POWER

SUPPLIES

+15 v

-15 v

HYSTERESIS

OUTPUT

SWITCH

ATTENUATOR

I

MODE

SINE

CONVERTER SWITCHING

CIRCUIT

FUNC

SYNC

OUT

DIGITAL

I

I

FILTER

I

I

I

23

NOISE

SYNC

NOISE

CLOCK

Figure 3-l. Functional Block Diagram

11

tion. The result is simultaneous generation of a square

wave and triangle wave of the same frequency with

the positive half cycle of the square wave coincident

with the negative slope of the triangle wave.

The magnitude of the capacitor across the integrator

and amplitude of the current into the integrator deter-

mine the frequency of oscillation. Capacitance across

the integrator is changed by rotating the frequency Hz

selector. Amplitude of the current into the integrator

is determined by four parameters which are summed

in the VCG circuit:

(1)

hysteresis switch output, (2)

the frequency

dial

voltage, (3) the frequency vernier

voltage, (4) the VCG analog voltage input and (5) the

analog noise when in the FM mode.

The sine wave is produced by feeding the triangle

wave into a shaping network composed of resistors

and diodes. As the triangle wave voltage passes through

zero, loading of the triangle wave is minimal and thus

the slope is maximum. As the triangle voltage in-

creases, diodes with current limiting resistors conduct

and successively cause the slope of the output to be

reduced.

Since the diode break points are mathematically com-

puted and fitted to the true sine shape, the resultant

waveform resembles a pure sine wave. Using a com-

plementary pair of diodes on each break point, the

circuitry is completely symmetrical about ground. The

sine wave, produced by shaping, is considerably less

in amplitude than the triangle wave input and is thus

amplified to be equal to the triangle wave.

Either square, triangle, or sine waveforms can be se-

lected as a signal

source.

The noise source is derived

from a digital filter. A clock oscillator of 160 Hz to

1.6 MHz range functions as a trigger source for the

digital pseudo-random sequence generator (P RSG).

Output of the PRSG is a random binary signal that

can function as digital noise. The number of bits in

each sequence can be selected by the SEQUENCE

LENGTH controls. Parallel data is fed from the PRSG

to the digital-to-analog converter where the informa-

tion is summed and filtered to provide a random

analog noise signal.

The selected sine, triangle, square, analog noise,

or

digital noise signal is routed to the mode control

circuitry where one of the following modes of opera-

tion is selected: Function

(FUNC);

frequency modula

tion (FM); signal-to-noise (S/N)

;

or noise-to-signal

(N/S). I n the signal-to-noise and noise-to-signal modes,

one signal is fed to the S/N attenuator and then mixed

with the other signal in the S/N summing amplifier in

a known

dB

ratio selected by the S/N attenuator. Out-

put of the mode switching circuit is coupled to the

output amplifier. From the output amplifier the signal

is fed to the precision output attenuator and finally to

aoutput connector.

All circuits, except for the hysteresis switch, output

amplifier, and PRSG, operate from volt supplies.

The hysteresis switch and power amplifier require

volts and volts, respectively. Operation of the

PRSG requires a

+5

V supply.

12

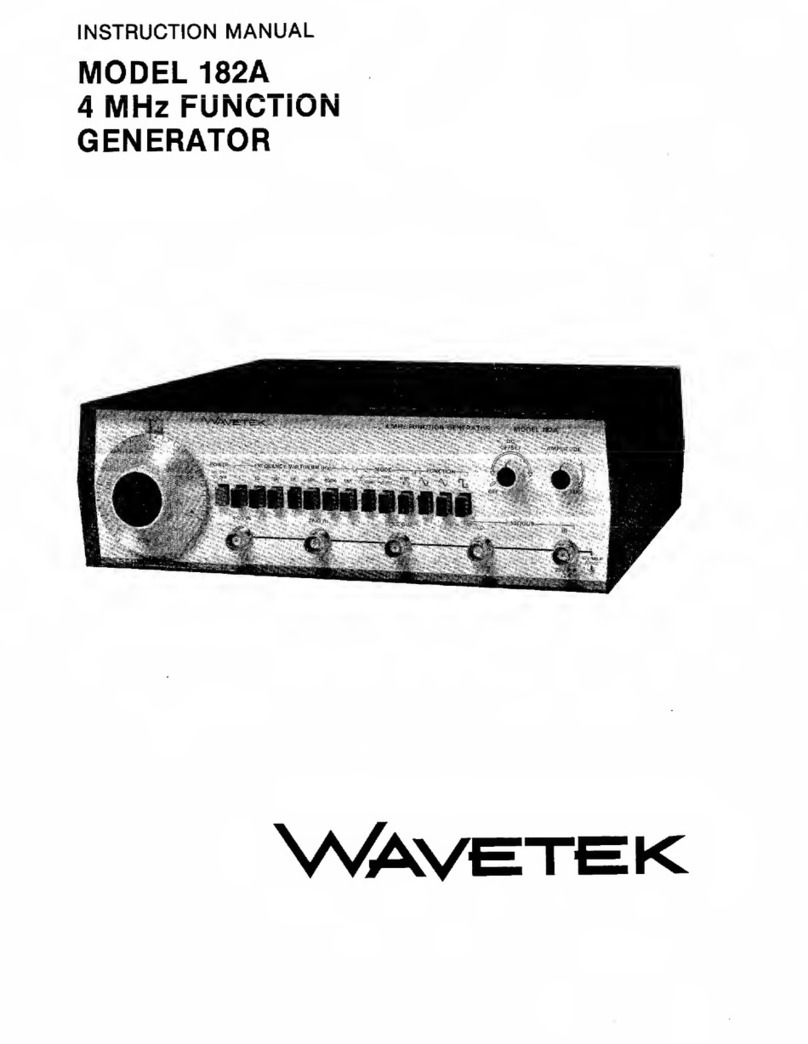

Other manuals for 132

2

Other Wavetek Portable Generator manuals

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 132 User manual

Wavetek

Wavetek 148A User manual

Wavetek

Wavetek 3000 User manual

Wavetek

Wavetek 1001A User manual

Wavetek

Wavetek 1001A User manual

Wavetek

Wavetek 1370 Installation instructions

Wavetek

Wavetek 144 User manual

Wavetek

Wavetek 150 User manual

Wavetek

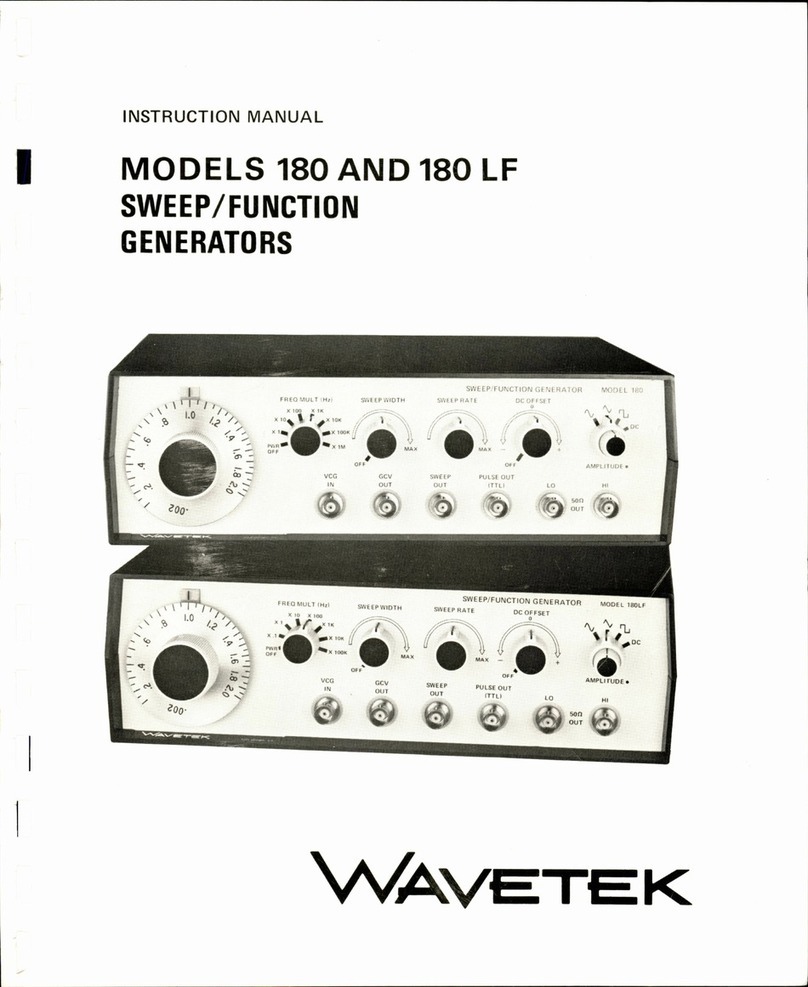

Wavetek 180 User manual